Energy-saving, high-gradient and high-intensity magnetic separator

A high-gradient, strong magnetic separation technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high energy consumption of equipment, high manufacturing cost, high energy consumption, etc., to reduce the cost of mineral processing, mechanical Easy to equip and increase throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

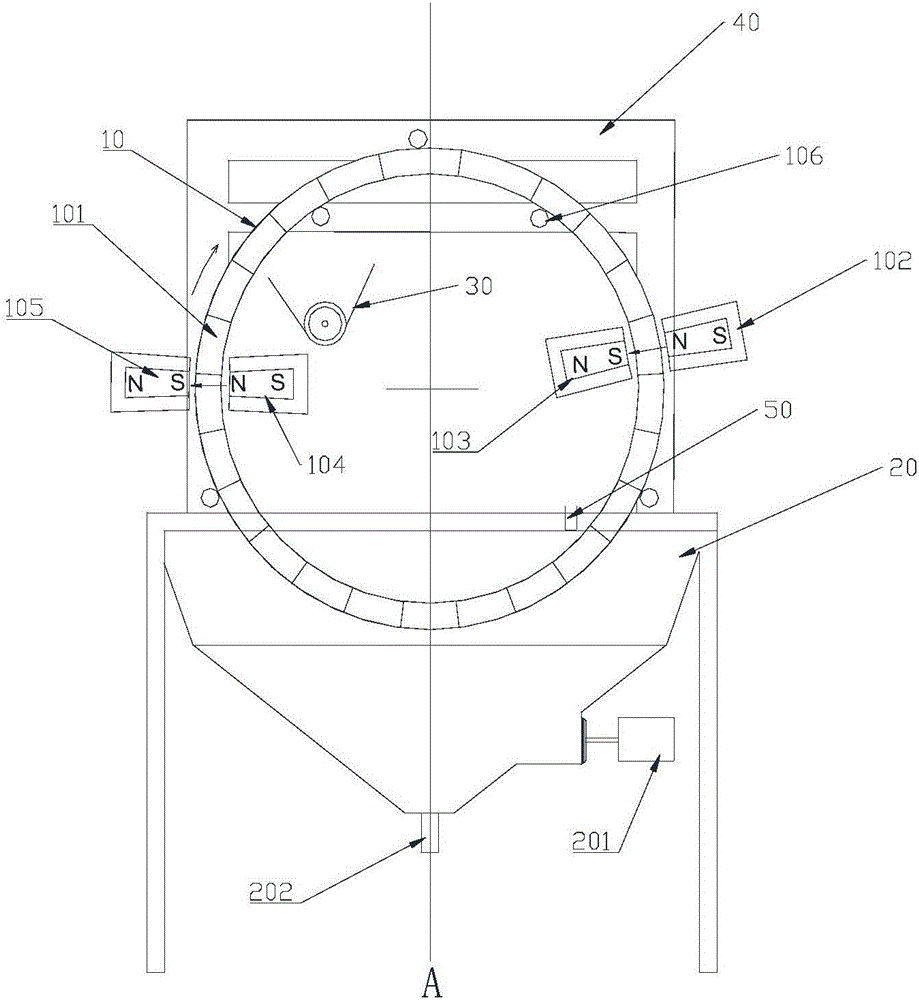

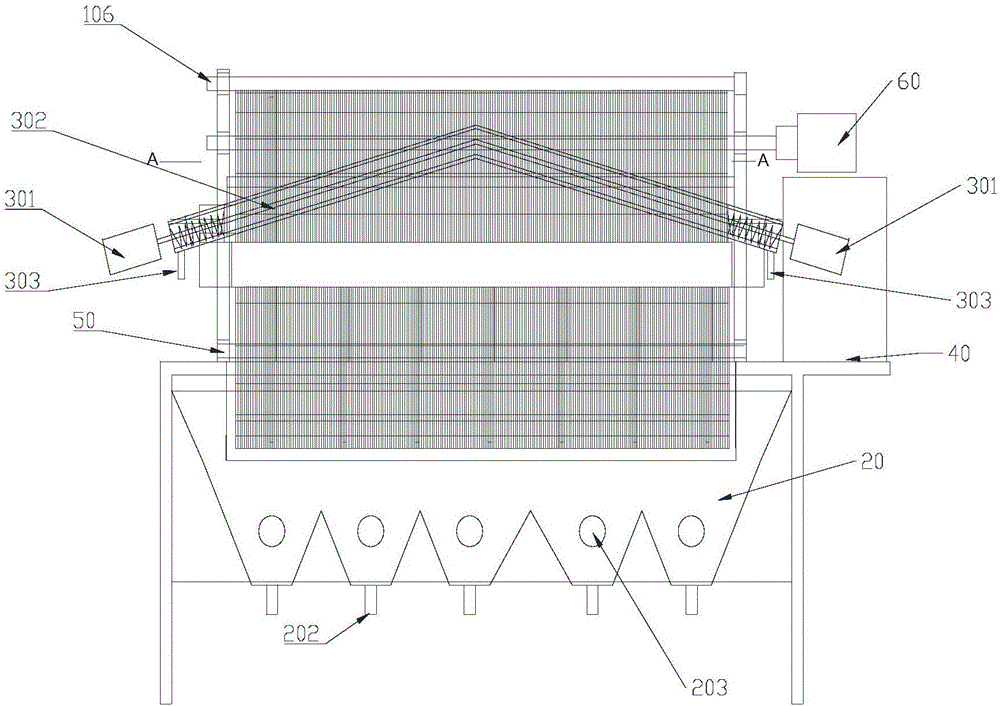

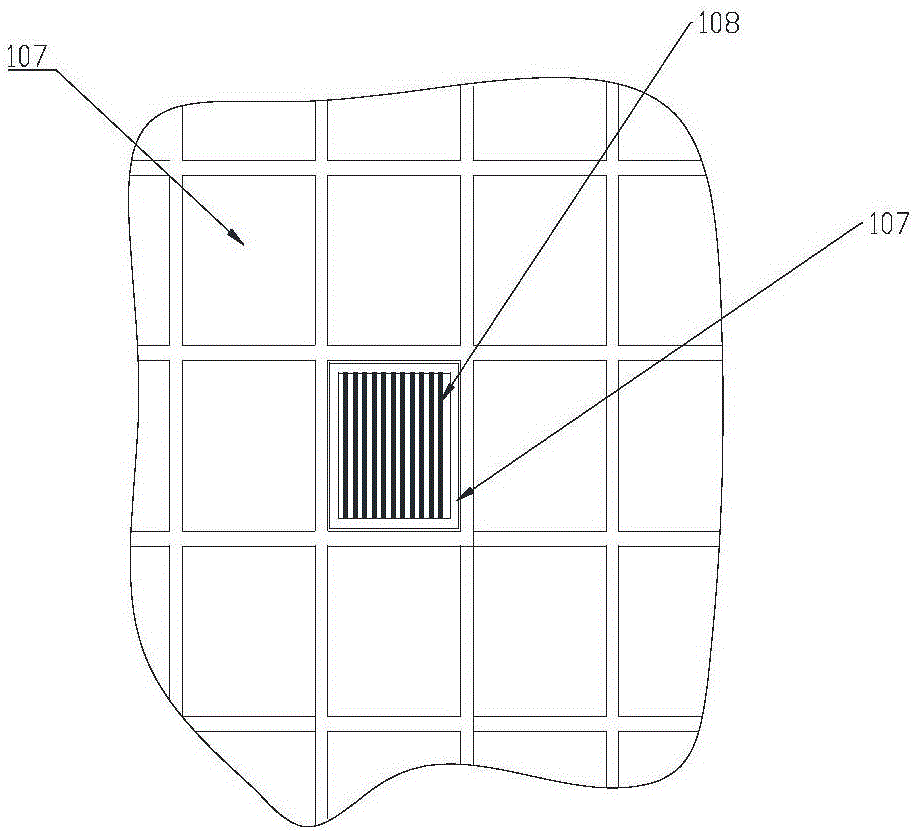

[0033] Such as Figure 1 to Figure 3 As shown, the energy-saving high-gradient strong magnetic separator of the present invention comprises a magnetic separation device 10, a feeding device 30, a feeding device 50 and a sorting box 20, wherein the magnetic separation device 10 comprises a magnetic separation drum 101, a magnetization The driving device 60 of the magnetic system, the demagnetization magnetic system and the magnetic separation drum, the magnetic separation drum 101 is provided with a medium rod 108 along the circumferential direction of the magnetic separation drum 101; the feeding device 50 is located on the magnetic separation drum The lower end of the inner space of 101 is conducive to the position where the medium rod on the magnetic separation drum fully absorbs the weakly magnetic mineral particles, and facilitates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com