Method for increasing recovery rate of complex refractory iron oxide ores

A technology of iron oxide and recovery rate, which is applied in chemical instruments and methods, wet separation, solid separation, etc., to achieve the effects of reducing inclusions, strengthening recovery effect, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

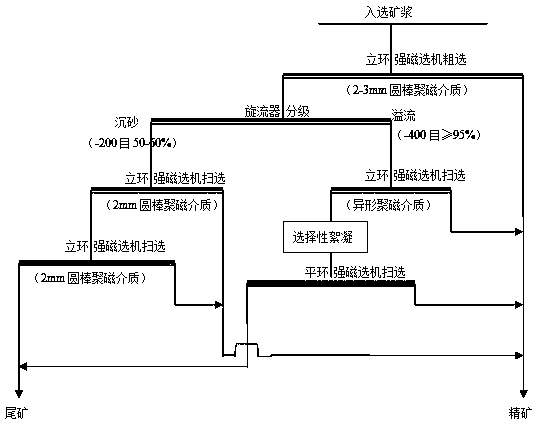

Image

Examples

Embodiment 1

[0021] Step 1. Preparation of complex and refractory iron oxide ores before sorting: For weak iron ore with an iron grade below 40%, mineral embedded particle size below 74 microns, and iron minerals and gangue minerals composed of 3 or more types The magnetic iron oxide ore is crushed in the stope, and when the particle size reaches 20mm or less, it is transported to the concentrator, and then undergoes two stages of continuous wet grinding and classification operations to ensure that 80% of the materials entering the beneficiation are -200 mesh.

[0022] Step 2, strong magnetic roughing: prepare the selected slurry with a mass concentration of 40% of the material prepared in step 1, and feed the selected slurry into a vertical ring pulsating strong magnetic separator with a diameter of 2mm as the magnetic gathering medium to complete the roughing operation , roughing operation to obtain concentrate pulp and tailings pulp, and the concentrate pulp is pumped into the concentrat...

Embodiment 2

[0026] Step 1. Preparation of complex and refractory iron oxide ores before sorting: For weak iron ore with an iron grade below 40%, mineral embedded particle size below 74 microns, and iron minerals and gangue minerals composed of 3 or more types The magnetic iron oxide ore is crushed in the stope, and when the particle size reaches 20mm or less, it is transported to the dressing plant, and then undergoes two stages of continuous wet grinding and classification operations to ensure that 90% of the materials entering the separation with a particle size of -200 mesh.

[0027] Step 2, strong magnetic roughing: the material prepared in step 1 is prepared into a selected slurry with a mass concentration of 50%, and the selected slurry is fed into a vertical ring pulsating strong magnetic separator with a diameter of 3mm as the magnetic gathering medium to complete the roughing operation , roughing operation to obtain concentrate pulp and tailings pulp, and the concentrate pulp is p...

Embodiment 3

[0031]Step 1. Preparation of complex and refractory iron oxide ores before sorting: For weak iron ore with an iron grade below 40%, mineral embedded particle size below 74 microns, and iron minerals and gangue minerals composed of 3 or more types The magnetic iron oxide ore is crushed in the stope, and when the particle size reaches 20mm or less, it is transported to the concentrator, and then undergoes two stages of continuous wet grinding and classification operations to ensure that 85% of the materials entering the beneficiation are -200 mesh.

[0032] Step 2, strong magnetic roughing: the material prepared in step 1 is prepared into a selected slurry with a mass concentration of 45%, and the selected slurry is fed into a vertical ring pulsating strong magnetic separator with a diameter of 2 mm as the magnetic gathering medium to complete the roughing operation , roughing operation to obtain concentrate pulp and tailings pulp, and the concentrate pulp is pumped into the conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com