A novel method for production of iron ore concentrates suitable for iron and steel making processes

A technology for iron ore and concentrate, applied in the new field of producing iron ore concentrate suitable for iron and steel manufacturing process, can solve the problems of loss, complicated process, unsuitable iron value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Weathered Magnetite (Iron Distribution - 50% Magnetite, 30% Hematite and 20% Goethite)

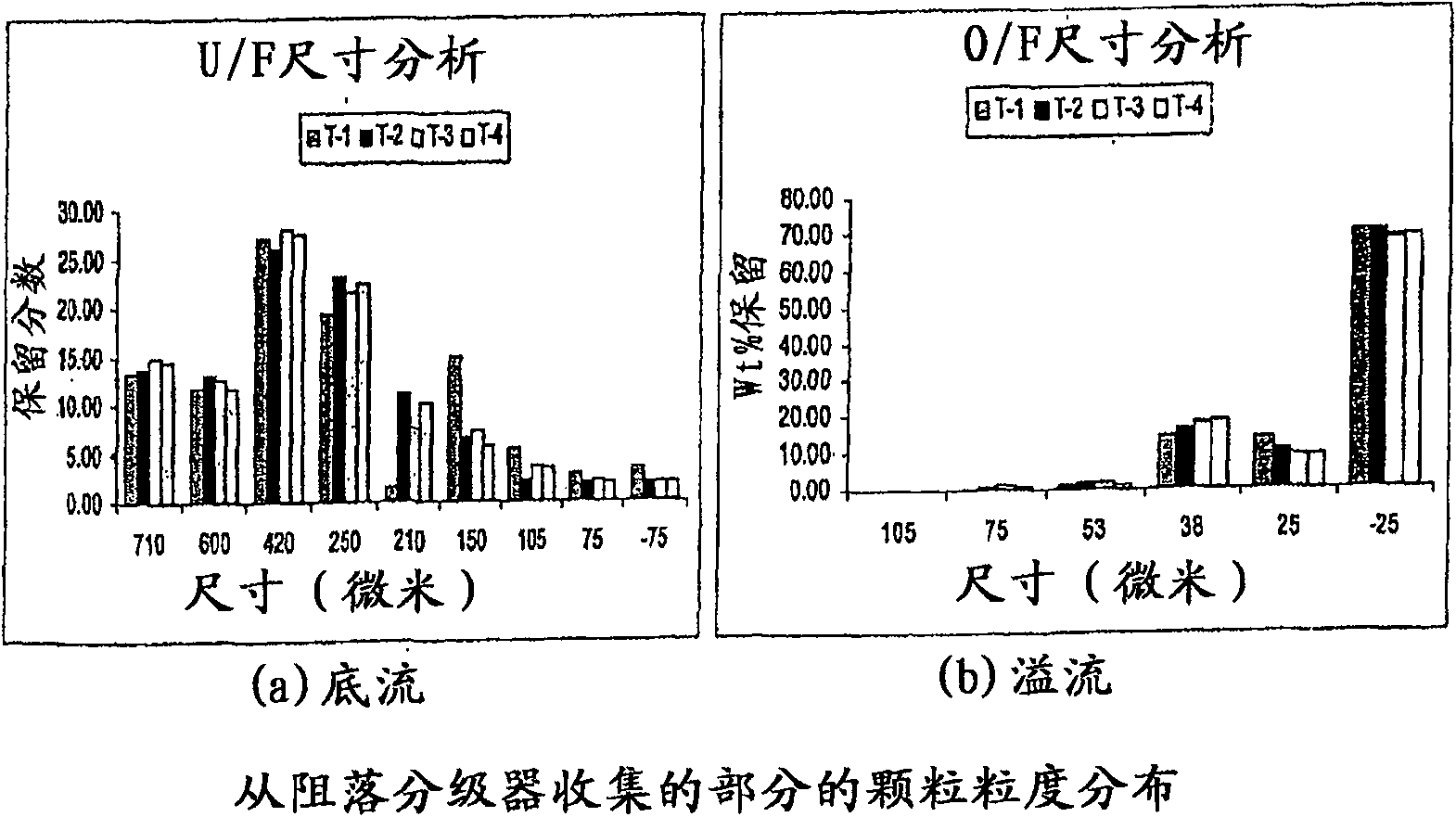

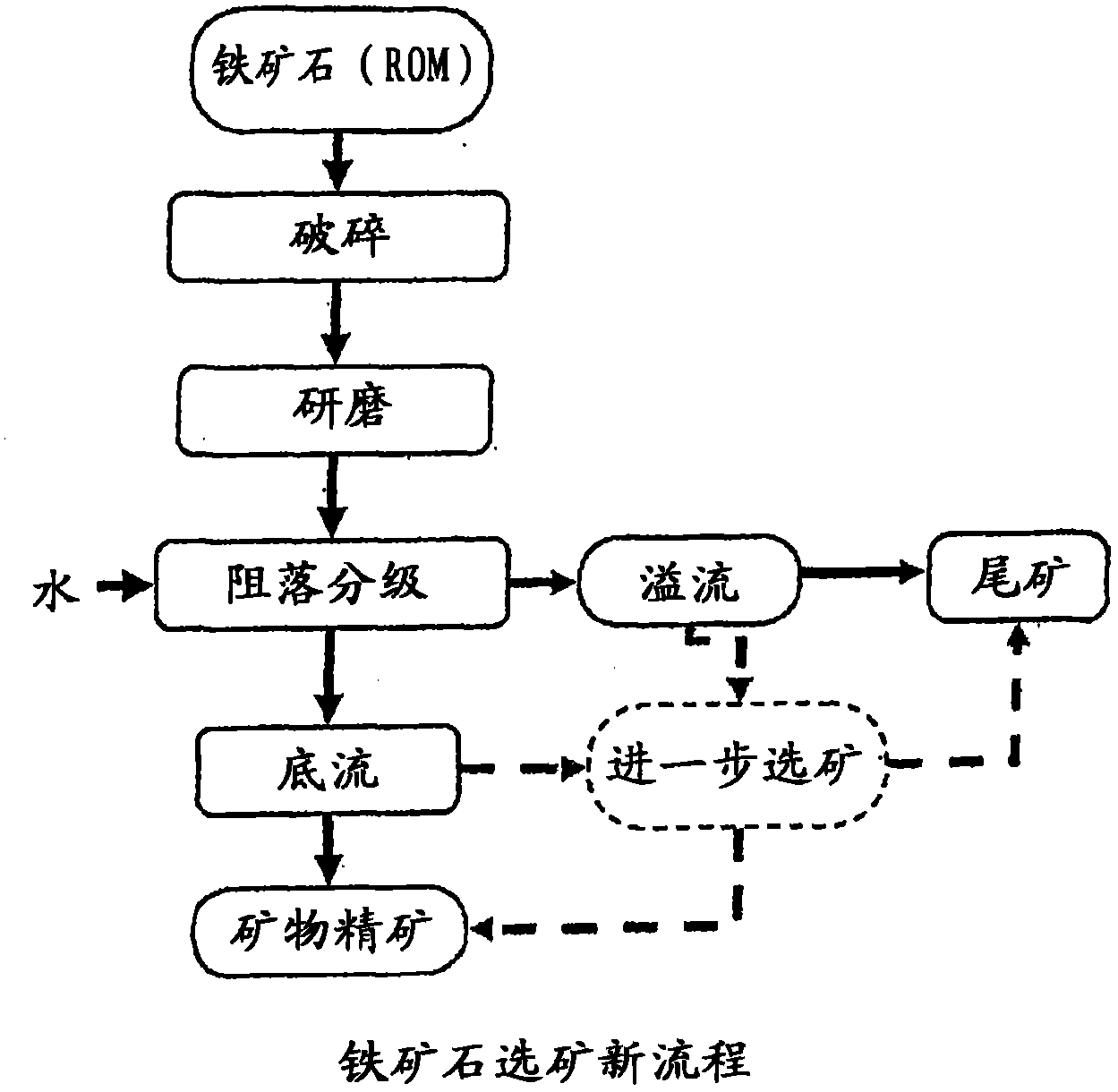

[0025] Experiments were carried out with the new method using magnetite containing 55-65% iron. In one trial, 1 ton of ROM was crushed and ground to a size of less than 1 mm and then processed with a drag-fall classifier. The experimental conditions are as follows: feed pulp density 20-30% by weight, feed rate 0.1-0.5t / hr, agitated bed pressure 0.04-0.09 bar, and agitated water flow rate 3-12LPM. Through this process, a concentrate with 64-67.5% Fe is obtained. Experimental results (falling classifier) such as image 3 depicted in . The overflow fraction is processed in LIMS and / or HIMS and about 60% of the ore minerals are separated as magnetic fraction. The 64%-66% Fe underflow concentrate is also processed in the LIMS and / or HIMS to produce a +67% Fe grade concentrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com