Process for extracting iron from comprehensive tailings of refractory iron ores

A technology for iron ore and tailings, which is applied in the field of iron extraction technology from comprehensive tailings of refractory iron ore, and can solve problems such as difficult iron extraction technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

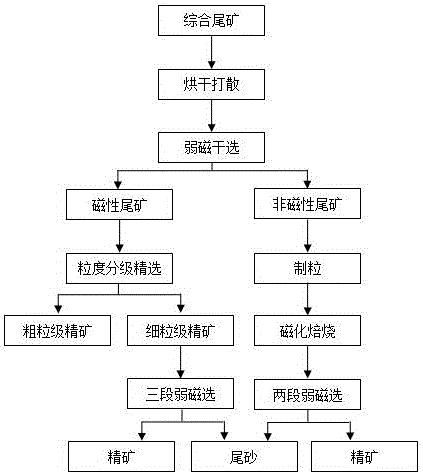

Method used

Image

Examples

Embodiment 1

[0020] Take the comprehensive tailings of JISCO tailings dam east area. The comprehensive tailings are mixed tailings of refractory iron ore strong magnetic separation tailings, weak magnetic separation tailings and reverse flotation tailings in a mass ratio of 1:1:1. Comprehensive tailings iron grade 20.38%, FeO mass percentage 6.71%, SiO 2 Mass percentage composition 40.43%, carry out following treatment:

[0021] A. Carry out drying treatment to the comprehensive tailings, and use a spiral mixer to break up and mix the agglomerated comprehensive tailings, and the drying temperature is 200°C;

[0022] B. The above-mentioned integrated tailings after being broken up are magnetically separated with a dry-type weak magnetic separator to obtain magnetic tailings and non-magnetic tailings, and the magnetic field strength of magnetic separation is 1800 Oe;

[0023] C. The above-mentioned magnetic tailings are desiliconized and concentrated by particle size classification-weak mag...

Embodiment 2

[0026] Take the comprehensive tailings in the southern area of the tailings dam of JISCO. The comprehensive tailings are mixed tailings of refractory iron ore strong magnetic separation tailings, weak magnetic separation tailings and reverse flotation tailings in a mass ratio of 1:1:1. The iron grade of the comprehensive tailings is 21.32%, the mass percentage of FeO is 6.84%, and the content of SiO 2 Mass percentage composition 39.45%, carry out following treatment:

[0027] A. Carry out drying treatment to the comprehensive tailings, and use the stirring blade of the spiral mixer to break up the agglomerated comprehensive tailings and mix them evenly, and the drying temperature is 200°C;

[0028] B. The above-mentioned integrated tailings after being dispersed are magnetically separated with a dry-type weak magnetic separator to obtain magnetic tailings and non-magnetic tailings, and the magnetic field strength of magnetic separation is 1900 Oe;

[0029] C. The above-ment...

Embodiment 3

[0032] Take the comprehensive tailings in the west area of the tailings dam of JISCO. The comprehensive tailings are mixed tailings of refractory iron ore strong magnetic separation tailings, weak magnetic separation tailings and reverse flotation tailings in a mass ratio of 1:1:1. Comprehensive tailings iron grade 20.77%, FeO mass percentage 7.03%, SiO 2 Mass percentage composition 40.52%, carry out following treatment:

[0033] A. Carry out drying treatment to the comprehensive tailings, and use the stirring blade of the spiral mixer to break up the agglomerated comprehensive tailings and mix them evenly, and the drying temperature is 200°C;

[0034] B. The above-mentioned integrated tailings after being dispersed are magnetically separated with a dry-type weak magnetic separator to obtain magnetic tailings and non-magnetic tailings, and the magnetic field strength of magnetic separation is 2000 Oe;

[0035] C. The above-mentioned magnetic tailings are desiliconized and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com