Method for sintering vanadium/titanium magnetite concentrate and siderite

A vanadium-titanium-magnetite concentrate and sintering method technology, applied in the metallurgical field, can solve problems such as rising sintered solid fuel consumption, and achieve the effects of reducing raw material costs, alleviating resource shortages, and maintaining product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

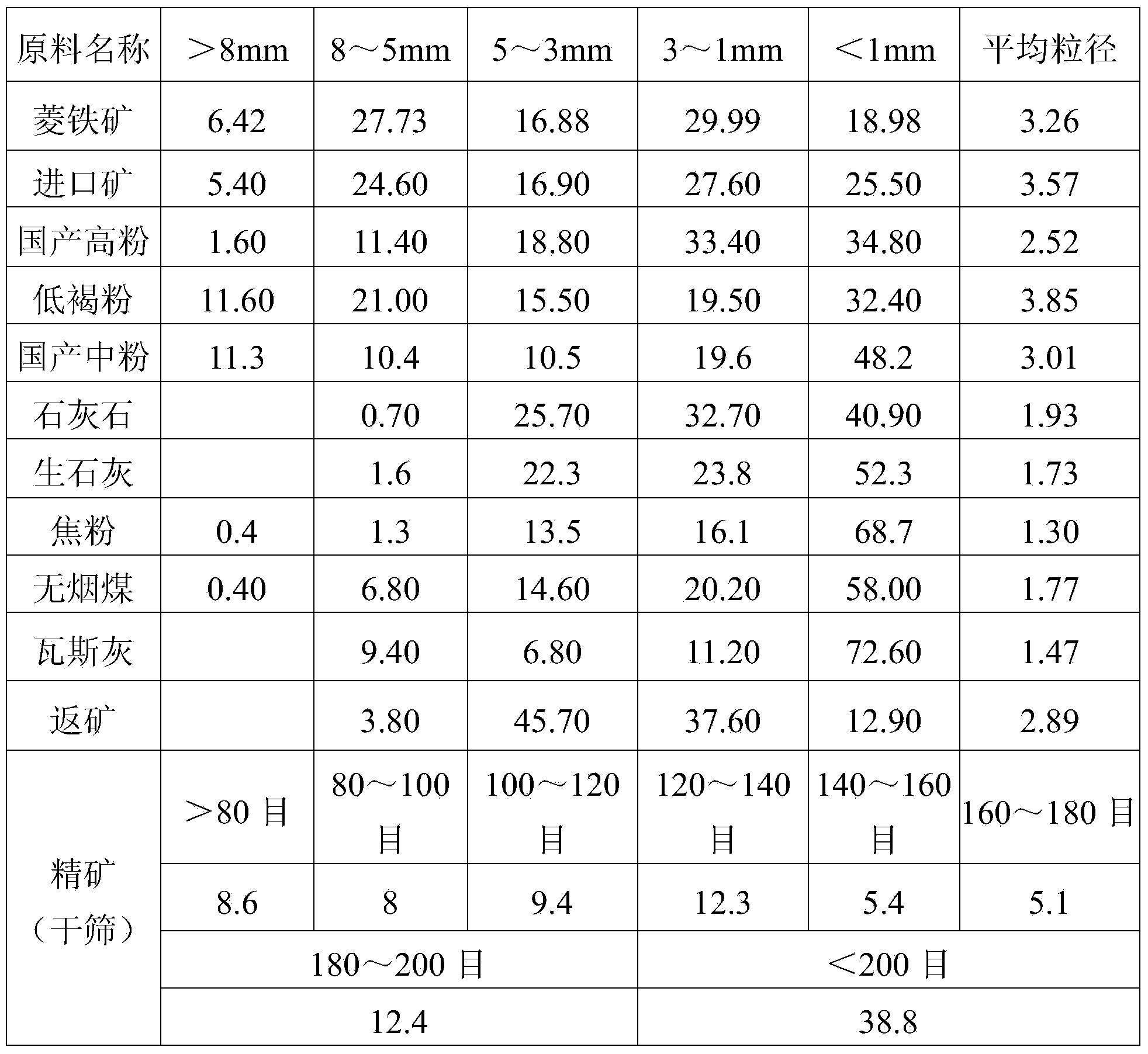

[0039] Use the following method to sinter vanadium-titanium magnetite concentrate with siderite. First, prepare the siderite ore: use a small vibrating screen to screen the purchased siderite raw ore in the raw material storage yard, so as to screen out the part with a particle size greater than 8mm, and then use the jaw crusher to crush the oversized material. The gap of the crusher is 6mm, and then the siderite obtained after crushing is mixed with the undersieve, so that the content of the siderite with a particle size>8mm accounts for 5wt% of the total siderite content, and the particle size< The content of 1mm siderite accounts for 10wt% of the total siderite content. Then, raw materials were prepared in accordance with the component ratios shown in Table 1 and the particle size compositions shown in Table 2 below.

[0040] Table 1 The main components of the raw fuel of Example 1 (wt%)

[0041] raw material name

TF

SiO 2

CaO

h 2 o

burn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com