Separation-smelting combined method for producing iron ore concentrate from oolitic lean hematite

A combination of beneficiation and smelting, hematite technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as difficult to obtain results, difficult to meet the requirements of flotation iron concentrate grade, and inability to obtain iron concentrate , to achieve the effects of low sulfur content, good technical and economic indicators, and high iron grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Oolitic lean hematite (raw ore sample): TFe: 31.40%, P: 0.12%, S: 0.05%, SiO 2 : 23.91%, CaO: 5.23%, MgO: 1.86%. (mass percentage, the same below)

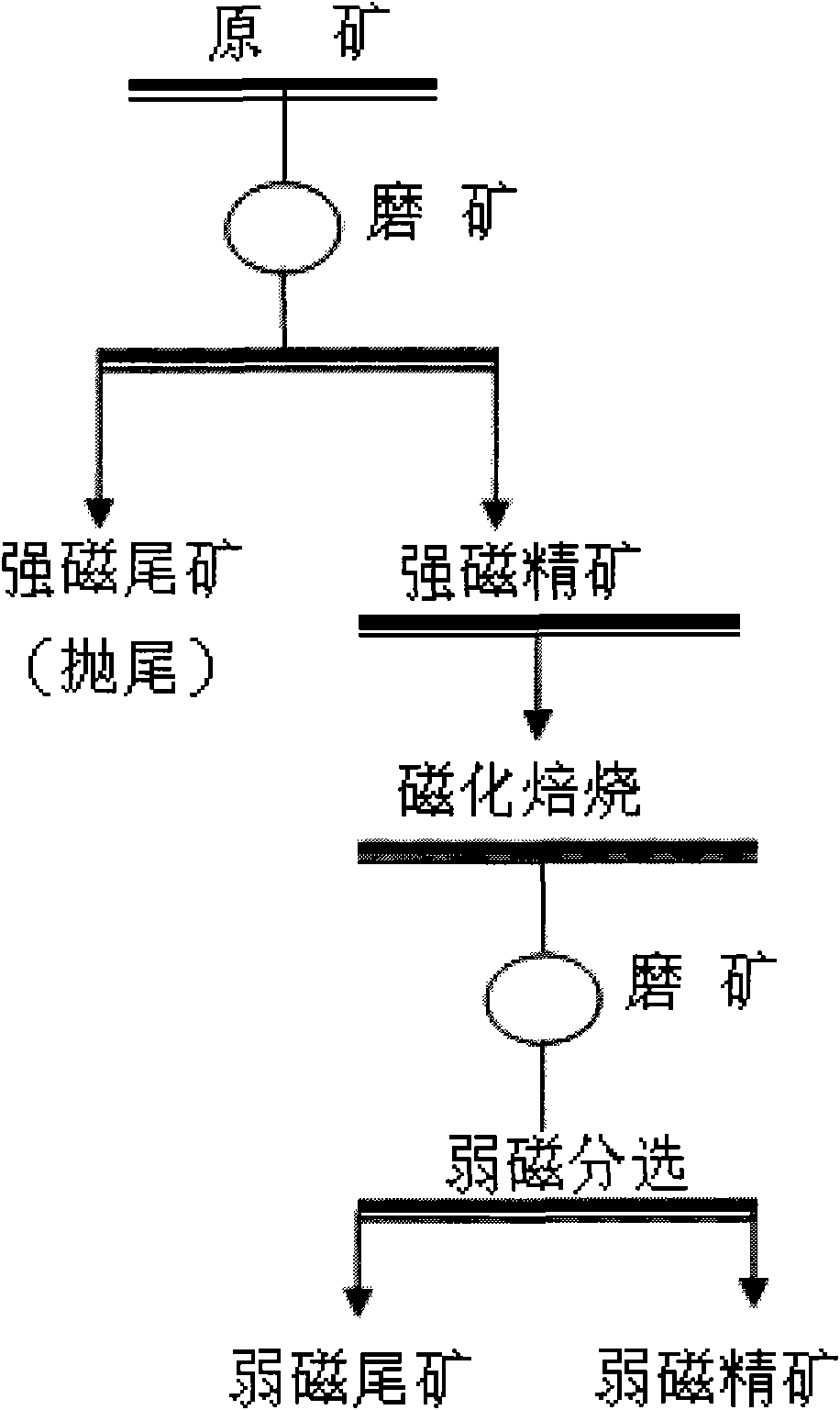

[0015] Firstly, the ore is crushed and ground, wet ground to -200 mesh content of 79.6%, the ore pulp after grinding enters the strong magnetic separator for pre-selection under the magnetic field strength of 780kA / m, the magnetic minerals enter the strong magnetic concentrate, and the non-magnetic minerals enter the tailings Mine, the tailings are removed in advance; the strong magnetic separation concentrate is mixed with coal powder, the weight of coal powder accounts for 15% of the concentrate weight, heated to 950°C in a muffle furnace, and kept for 1.5h for magnetization roasting; magnetization roasting ore After the sample is cooled, it is re-grinded. Wet grinding to -200 mesh accounts for 82.5%. ore, and become the final high-quality iron ore concentrate product.

[0016] The results of this embodiment are: the c...

Embodiment 2

[0018] Oolitic lean hematite (raw ore sample): Tfe: 30.80%, P: 0.14%, S: 0.08%, SiO 2 : 22.45%, CaO: 5.96%, MgO: 1.93%.

[0019] Firstly carry out crushing and grinding, wet grinding to -200 mesh content 81.50%, the ore pulp after grinding enters the strong magnetic separator for pre-selection under the magnetic field strength of 820kA / m, the magnetic minerals enter the strong magnetic concentrate, and the non-magnetic minerals enter the tailings Mine, remove tailings in advance; strong magnetic separation concentrate is mixed with coal powder, the weight of coal powder accounts for 20% of the concentrate weight, heated to 1000 ° C in a muffle furnace, and kept for 2 hours for magnetization roasting; magnetization roasting ore sample Regrind after cooling, wet grinding to -200 mesh accounts for 84%, and feed it to the weak magnetic separator after pulp adjustment, and carry out weak magnetic separation under the field strength of 230kA / m, and the magnetic minerals enter the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com