Method for raising grade of hematite by biologically reducing and magnetizing and dressing

A technology for improving grades and hematite, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as environmental pollution, low indicators, high energy consumption, etc., and achieve short process, low cost, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

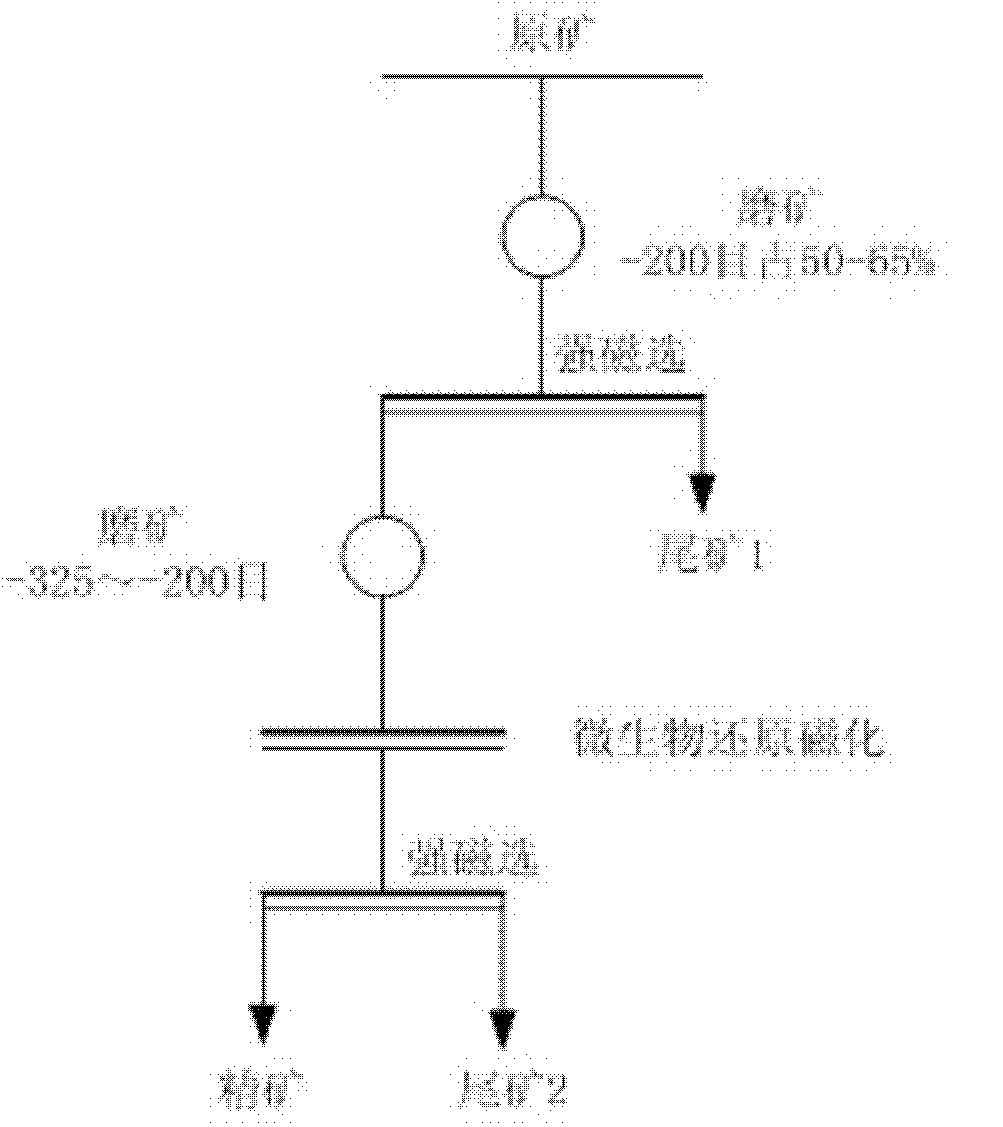

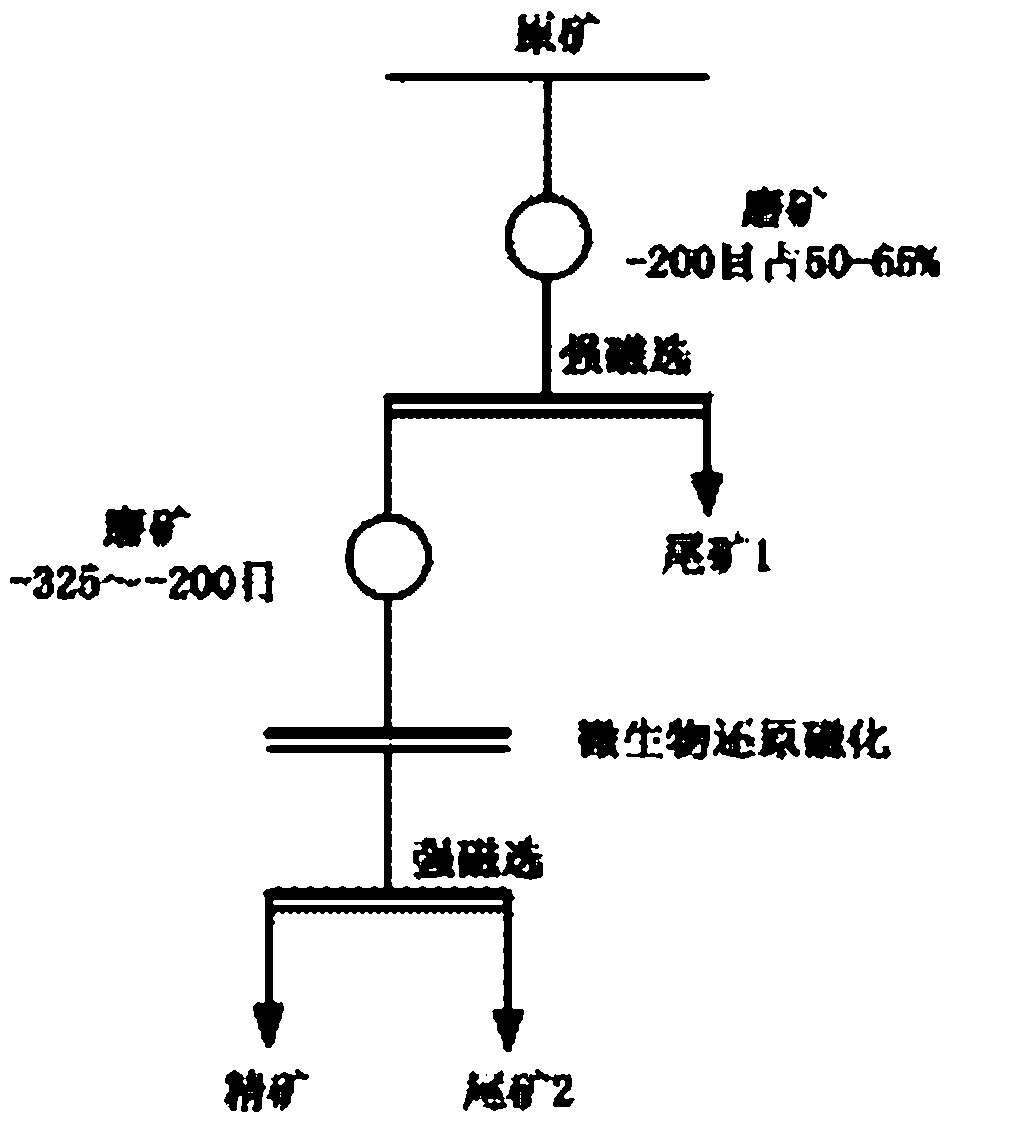

Method used

Image

Examples

Embodiment 1

[0025] Example 1: The main chemical composition of a certain hematite is: TFe 28.82, P 0.35, S 0.028, C 0.96, SiO 2 48.64, Al 2 o 3 6.08, CaO 3.64, MgO 0.84, Na 2 O 0.24, K 2 O,0.27. Mineral composition: Metal minerals are mainly hematite, followed by limonite and siderite, and the content of other metal minerals is extremely low; gangue minerals are mainly quartz, clay minerals, muscovite, dolomite and a small amount of apatite .

[0026] Weigh 100g of the ore sample crushed to -2mm, and use a three-roller four-barrel rod mill to grind -200 mesh, accounting for 55%, and then pre-select the ground ore sample in a strong magnetic separator with a magnetic field strength of 1T. Magnetic minerals Enter the strong magnetic concentrate, non-magnetic minerals enter the tailings, and remove the tailings in advance;

[0027] The strong magnetic concentrate is re-grinded to -325 mesh, accounting for 75%, and then filtered;

[0028] Take 60mL of the dissimilation-reducing...

Embodiment 2

[0031] Example 2: The main chemical components of a certain high phosphorus oolitic hematite are: TFe 43.50, P 0.85, S 0.028, SiO 2 18.80, Al 2 o 3 6.67, CaO 3.66, MgO 0.67, MnO 0.17, K 2 O, 0.79. Mineral composition: The types of minerals are relatively simple. The iron minerals are mainly hematite, followed by limonite, and occasionally magnetite; the gangue minerals are mostly quartz, followed by oolitic chlorite, illite, and collophosite , dolomite, calcite and kaolinite.

[0032] Weigh 100g of the ore sample crushed to -2mm, and use a three-roller four-barrel rod mill to grind -200 mesh, accounting for 55%, and then pre-select the ground ore sample in a strong magnetic separator with a magnetic field strength of 1T. Magnetic minerals Enter the strong magnetic concentrate, non-magnetic minerals enter the tailings, and remove the tailings in advance;

[0033] The strong magnetic concentrate is re-grinded to -325 mesh, accounting for 75%, and then filtered;

...

Embodiment 3

[0038] Example 3: The main chemical composition of a kidney-shaped lean hematite is: TFe 29.28, P 0.09, S 0.07, SiO2 52.94, Al2O3 1.67, CaO 1.01, MgO 1.02, MnO 0.08. Mineral composition: The structure of the ore is relatively complex, mainly in the form of granular, plate-like, sheet-like, needle-like, columnar, scale-like and fibrous crystal structures. The structure is dominated by banded structures, followed by rubbish and breccia structures superimposed on the basis of banded structures; there are also a small amount of massive structures.

[0039] (1) Weigh 100g of the ore sample crushed to -2mm, and use a three-roller four-barrel rod mill to grind -200 mesh, accounting for 55%, and then pre-select the ground ore sample in a strong magnetic separator with a magnetic field strength of 1.2T. Magnetic minerals enter the strong magnetic concentrate, non-magnetic minerals enter the tailings, and the tailings are removed in advance;

[0040] The strong magnetic concentrate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com