Manufacturing method of magnetic matrix box for vertical ring high-intensity magnetic separator

A technology of magnetic gathering medium and production method, which is applied in the field of mineral processing machinery and equipment, can solve the problems of long drilling time, reduced service life, and low processing efficiency, and achieve the goals of reducing electrochemical corrosion rate, increasing service life, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

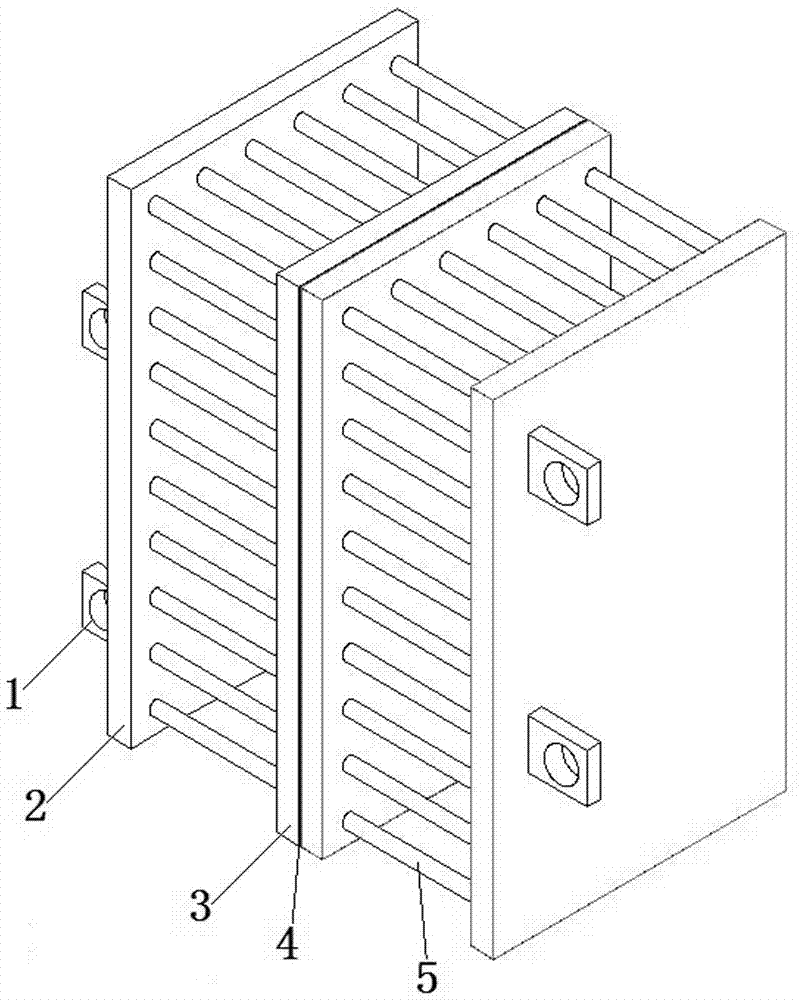

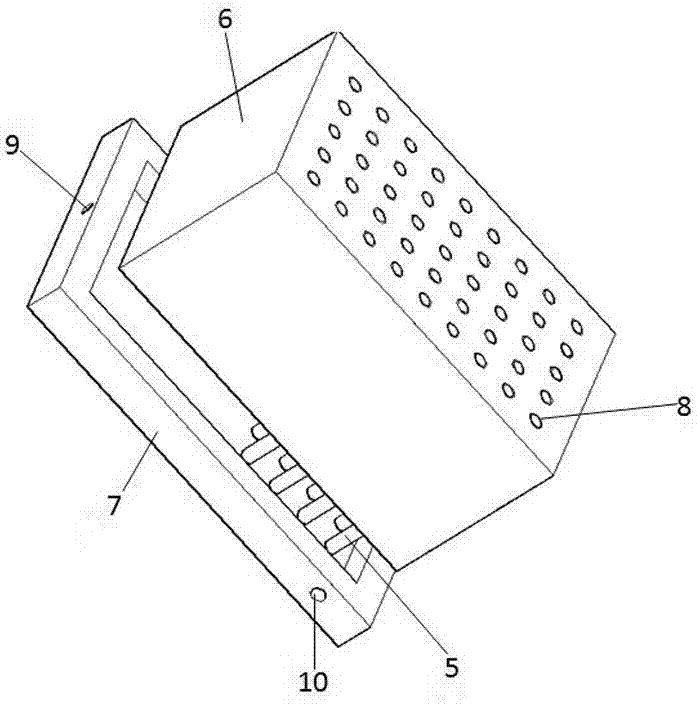

[0017] Such as figure 1 As shown, a method for making a magnetic-gathering medium box for a vertical ring strong magnetic separator, the magnetic-gathering medium box is composed of more than two sub-medium boxes, and the sub-medium boxes are composed of lifting lugs 1, panels with lifting lugs 2, The panel 3 without lifting lugs and the magnetic gathering medium wire 5 are composed, and the manufacturing process is as follows: 1) The mold is first manufactured according to the size of the sub-medium box, and the mold is divided into an upper mold and a lower mold. Add lifting lugs to make the module area, the upper mold has perforations, the lower mold has rectangular grooves, and the length and width of the upper mold are larger than the length and width of the rectangular grooves; 2) Pass the magnetic-gathering dielectric wires through the perforations on the upper mold according to the arrangement requirements And stretch out a section, the upper and lower molds are fasten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com