Online cleaning machine for high intensity magnetic separator medium box

A cleaning machine and medium box technology, applied in the direction of high gradient magnetic separator, etc., can solve the problems of metal loss, poor sorting effect, etc., and achieve the effect of reducing usage, convenient installation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

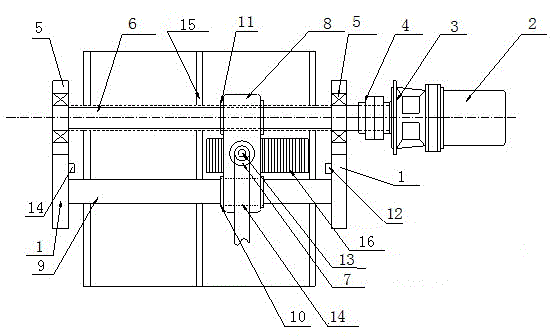

[0014] Example: such as figure 1 Shown, a kind of in-line cleaning machine that is used for the medium box of strong magnetic machine, comprises frame 1, electric transmission device, high-pressure water gun device, and described electric transmission device is made up of motor 2, reducer 3, handle 4, bearing seat 5, The transmission screw rod 6 is composed of, and the transmission screw rod 6 is respectively provided with 5 bearing seats, and the bearing housing 5 is connected to the upper part of the frame 1; the motor 3 and the speed reducer 4 are connected to the transmission screw rod 6 through a handle 5, Located on the outside of the bearing seat 5; the high-pressure water gun device is composed of a high-pressure water gun 7, a water gun walking frame 8, a water gun stabilizing bar 9, a stabilizing snap ring 10, and a transmission screw nut 11. The high-pressure water gun 7 is fixed on the water gun walking Frame 8; the upper part of the water gun walking frame 8 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com