Anti-podal permanent magnetic high-intensity magnetic separator

A strong magnetic separation and pole-aligning technology, which is applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of complex structure, cumbersome operation, and narrow application range of magnetic substance measuring instruments, and achieve simple and practical devices, The selection process is simple and the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

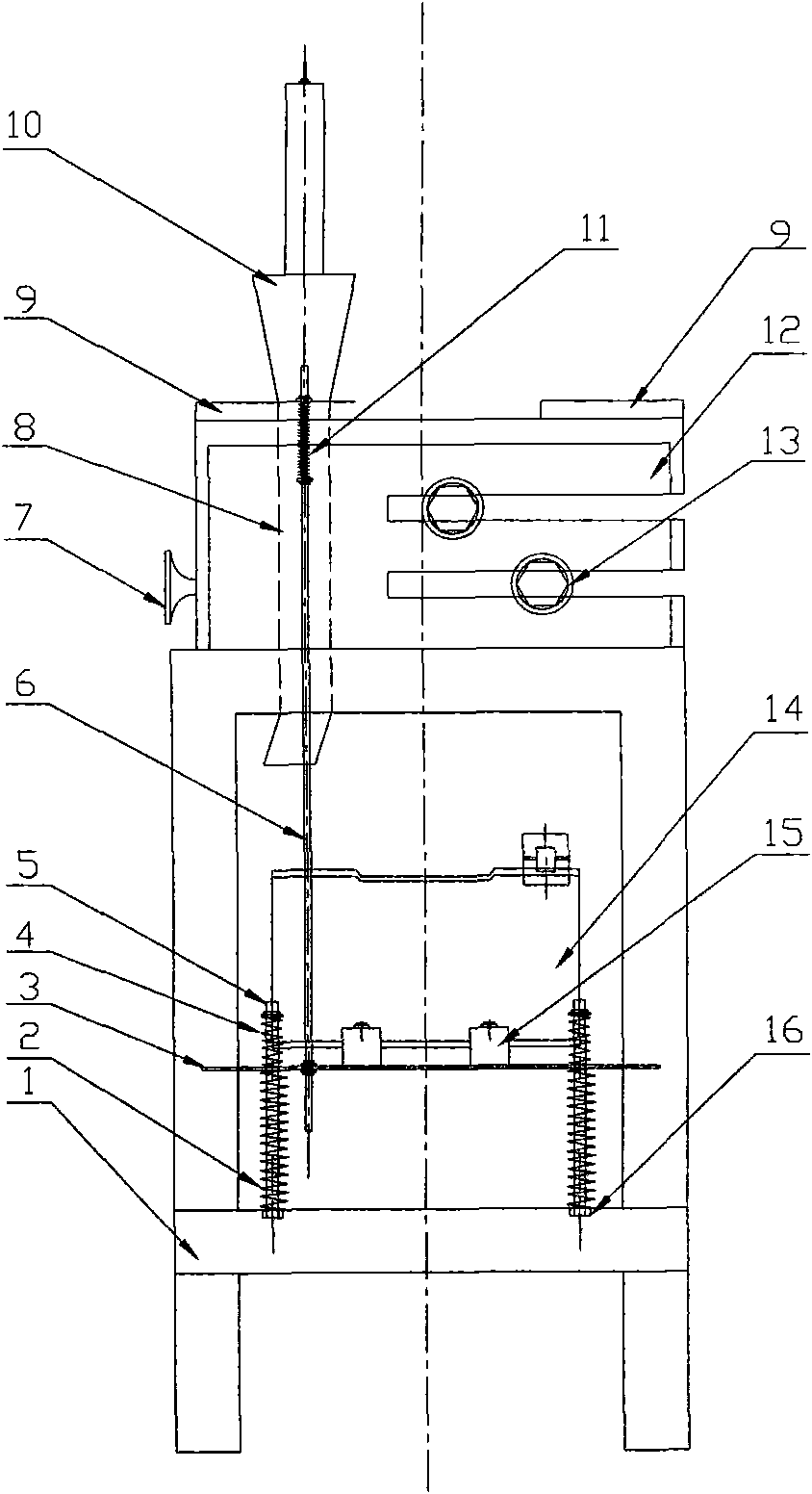

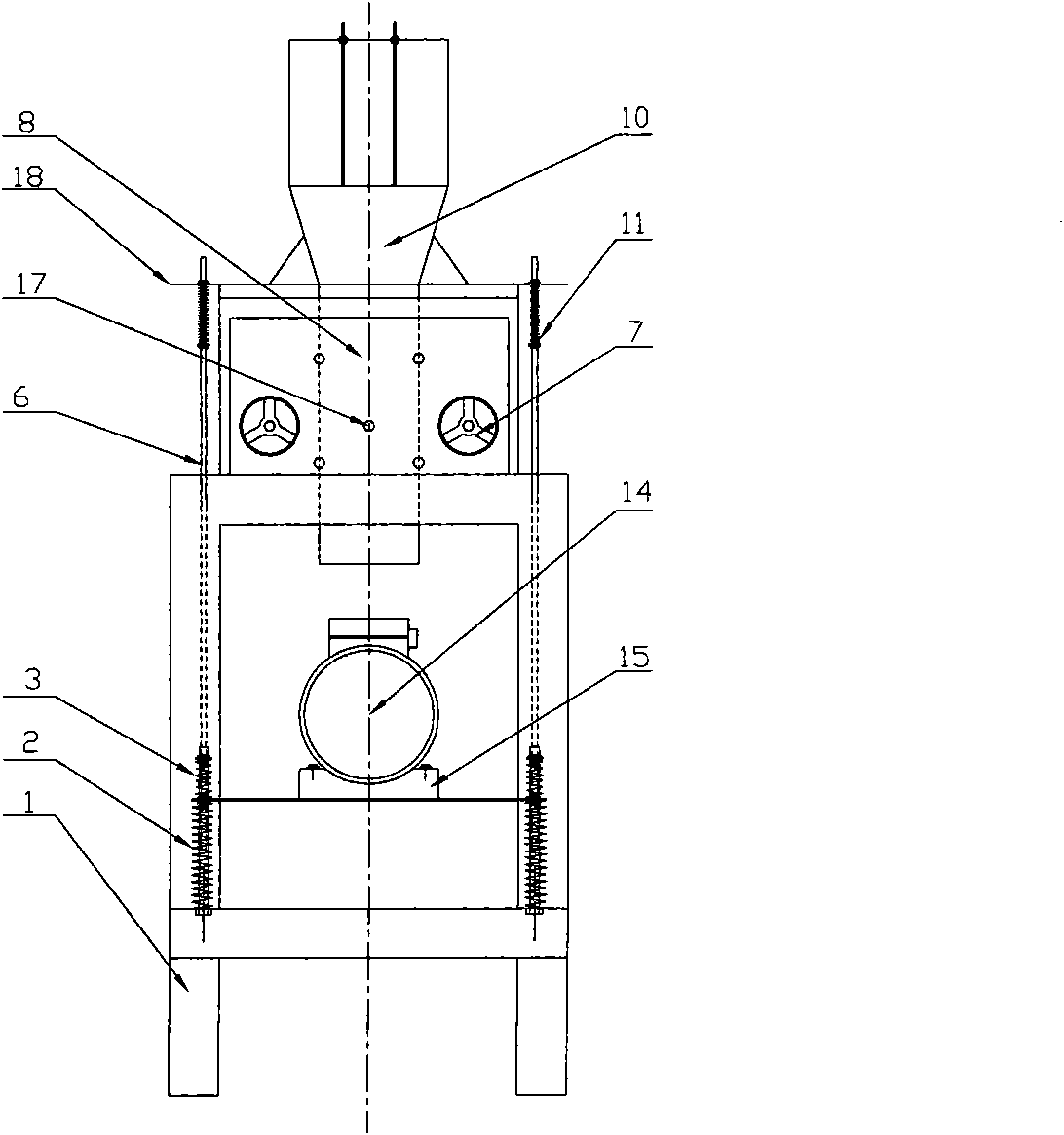

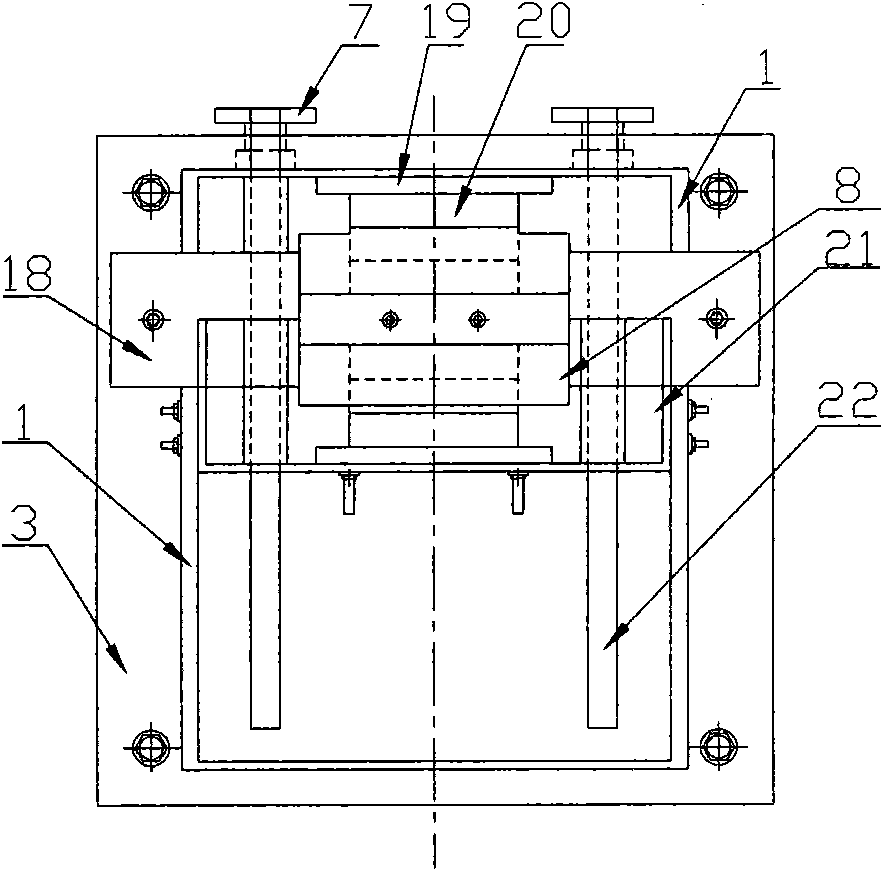

[0033] Such as figure 1 , 2 , shown in 3, opposite pole type permanent magnet strong magnetic separator of the present invention comprises frame 1, is installed in the dynamic vibrating mechanism of frame middle part, is installed in the permanent magnet magnetic system of frame top, is positioned at the permanent magnet magnetic system top The vibrating support frame 18 that is used to install the feed hopper 10 and the magnetic accumulation medium box 8, the vibration support frame 18 is combined with the dynamic vibration mechanism by connecting the supporting bar 6; The axial permanent magnetic steel 20 prepared by NdFeB magnetic material is stacked in two groups by extrusion, and the polarity of each group is arranged as N-S-N-S-N-S or S-N-S-N-S-N, which are distributed on both sides of the magnetic accumulation medium box 8 in the horizontal direction, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com