Hospital department exhaust treatment device and method

A treatment device and departmental technology, applied in botany equipment and methods, heating methods, lighting and heating equipment, etc., can solve the problems of small contact area between reaction reagents and exhaust gas, insufficient sterilization, and not particularly good treatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

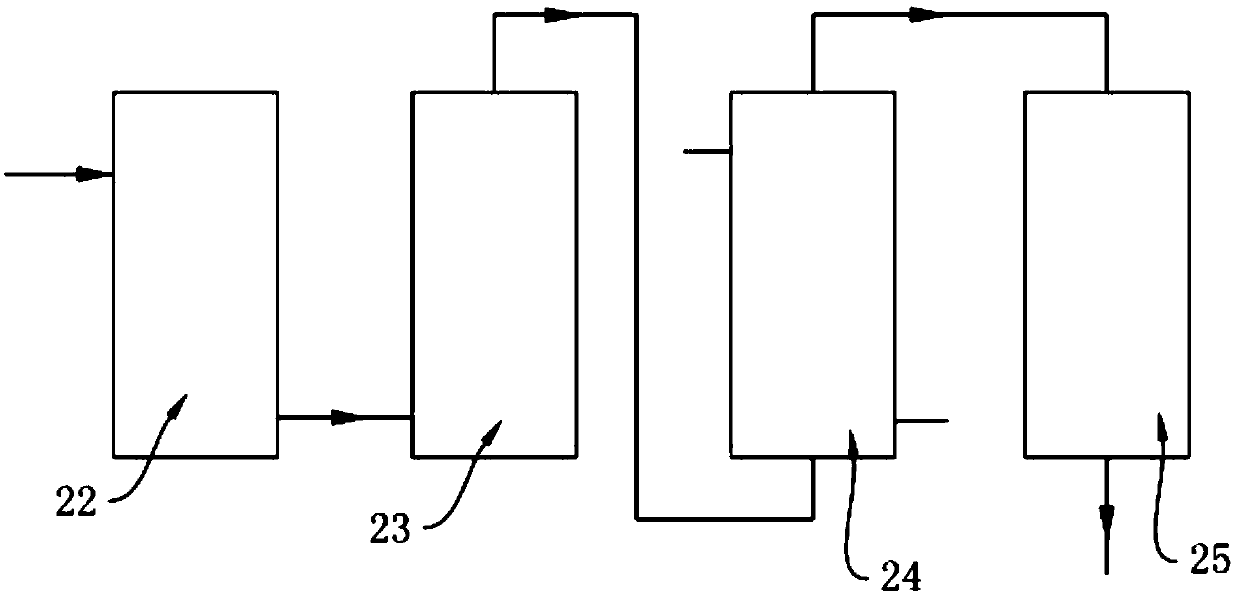

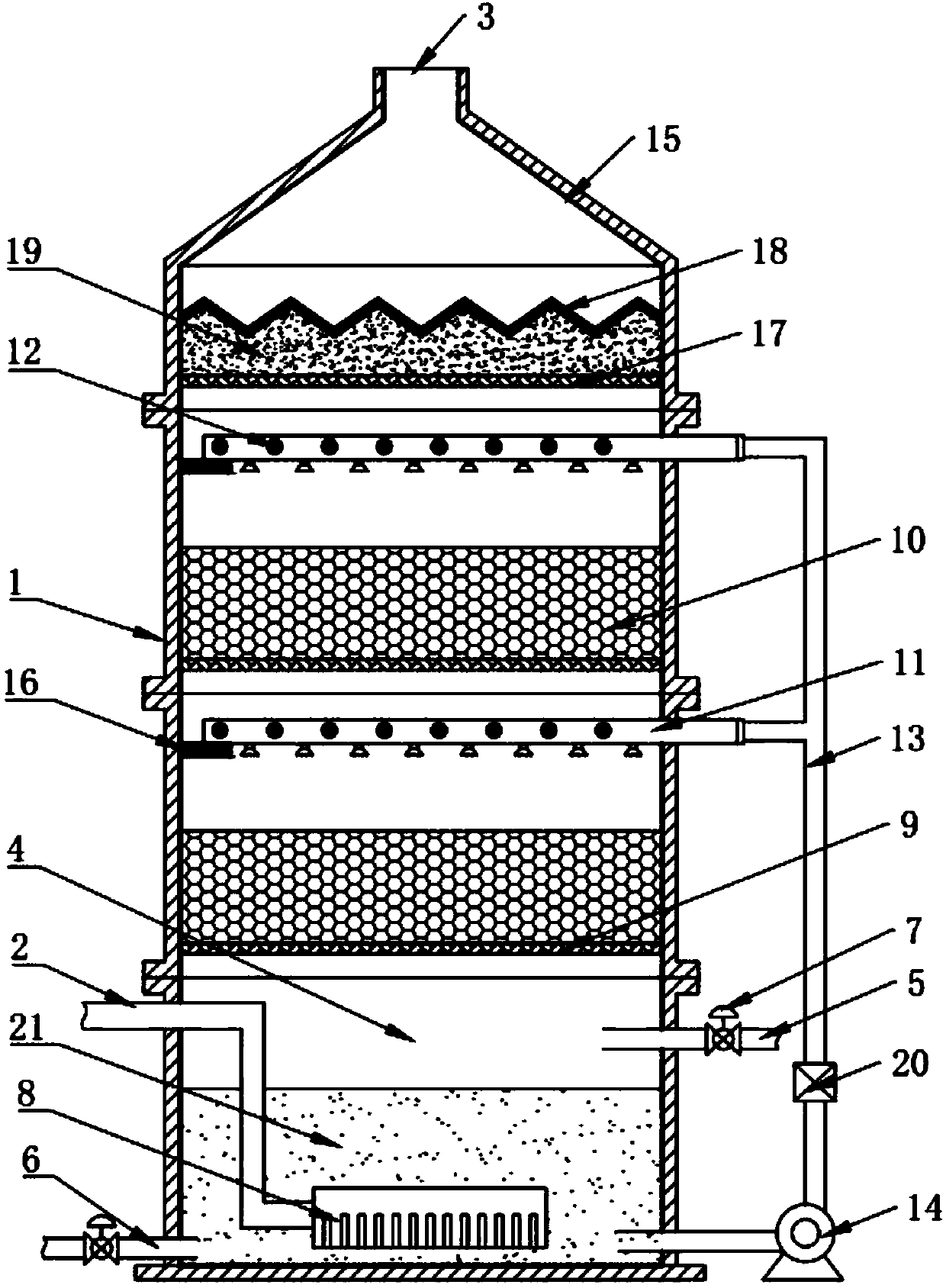

[0101] A method for treating exhaust air in a radiology department of a hospital, which is realized by using the above-mentioned hospital department exhaust air processing device, comprising the following steps:

[0102] S1. Add a special disinfectant solution to the liquid storage chamber of the sterilization and disinfection unit. The liquid level of the disinfectant solution is higher than the gas distributor, and turn on the liquid delivery pump to circulate the disinfectant solution for 30 minutes to fully wet the defogging section of the filler. Wherein, the radiology department is mostly trauma patients, and the components of its special disinfectant solution are: betadine 1.35wt%; C-12-14-16-18 alkyl dimethyl ethyl benzyl ammonium chloride 2.45wt% ; C12-14 alkyl dimethyl ethyl benzyl ammonium chloride 2.55wt%; sodium carbonate 0.9wt%; edetate disodium 0.30wt%; the balance is pure water;

[0103] S2. Introduce the waste gas in the department to the electrostatic precipita...

Embodiment 2

[0108] A method for treating exhaust air in a hospital nursing department, which is realized by using the above-mentioned hospital department exhaust air processing device, comprising the following steps:

[0109] S1. Add special disinfectant solution to the liquid storage chamber of the sterilization and disinfection unit. The liquid level of the disinfectant solution is higher than the gas distributor, and turn on the liquid delivery pump to circulate the disinfectant solution for 35 minutes to fully wet the defogging section of the filler. ; Among them, nursing departments are mostly common cold patients, and the components of the special disinfectant are:

[0110] C-12-14-16-18 alkyl dimethyl ethyl benzyl ammonium chloride 2.45wt%; C12-14 alkyl dimethyl ethyl benzyl ammonium chloride 2.60 wt%; sodium carbonate 0.95 wt%; Disodium edetate 0.40wt%; The remainder is pure water;

[0111] S2. Introduce the waste gas in the department to the electrostatic precipitator, and contr...

Embodiment 3

[0116] A method for treating the exhaust air of a department of pediatric pneumonia in a hospital, which is realized by adopting the above-mentioned exhaust air processing device of the hospital department, comprising the following steps:

[0117] S1. Add special disinfectant solution to the liquid storage chamber of the sterilization and disinfection unit. The liquid level of the disinfectant solution is higher than the gas distributor, and turn on the liquid delivery pump to circulate the disinfectant solution for 45 minutes to fully wet the demisting section of the filler. ; Among them, the pediatric pneumonia department is a pediatric patient suffering from pneumonia, and the components of its special disinfectant are: levofloxacin 0.05wt%; moxifloxacin 0.07wt%; C-12-14-16-18 alkyl dimethyl ethyl Benzyl ammonium chloride 2.30wt%; C12-14 alkyl dimethyl ethyl benzyl ammonium chloride 2.75wt%; sodium carbonate 0.87wt%; edetate disodium 0.45wt%; ;

[0118] S2. Introduce the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com