Efficient snail-killing type organic fertilizer produced from tea seed cakes and preparation method thereof

A technology of organic fertilizer and tea seed meal, which is applied in the production of high-efficiency snail-killing organic fertilizer and its preparation from tea seed meal, can solve the problems of destroying the ecological balance of nature, unstable molluscicide effect, and threats to human health, so as to promote photosynthesis effect, improving rice disease resistance and stress resistance, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

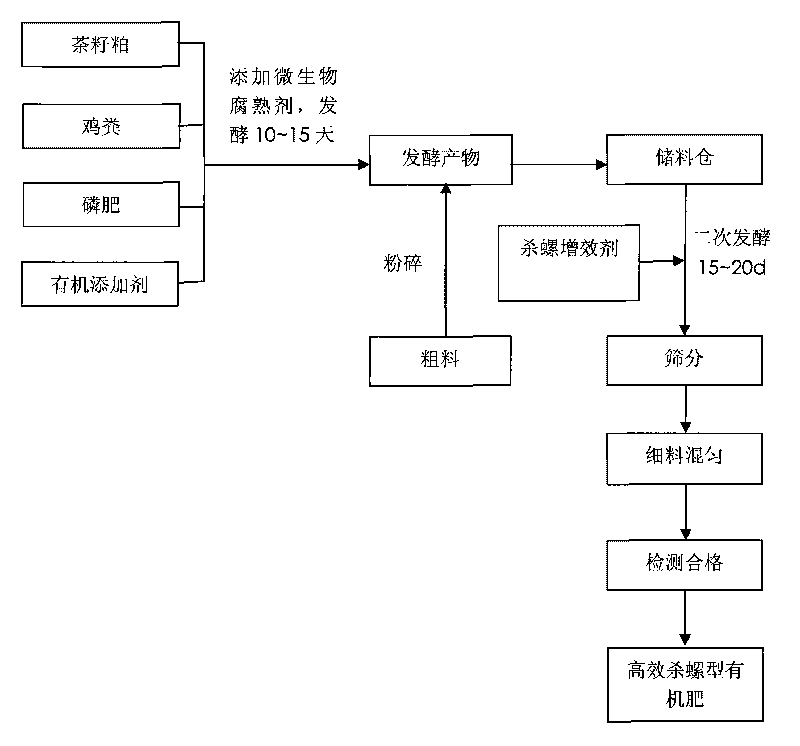

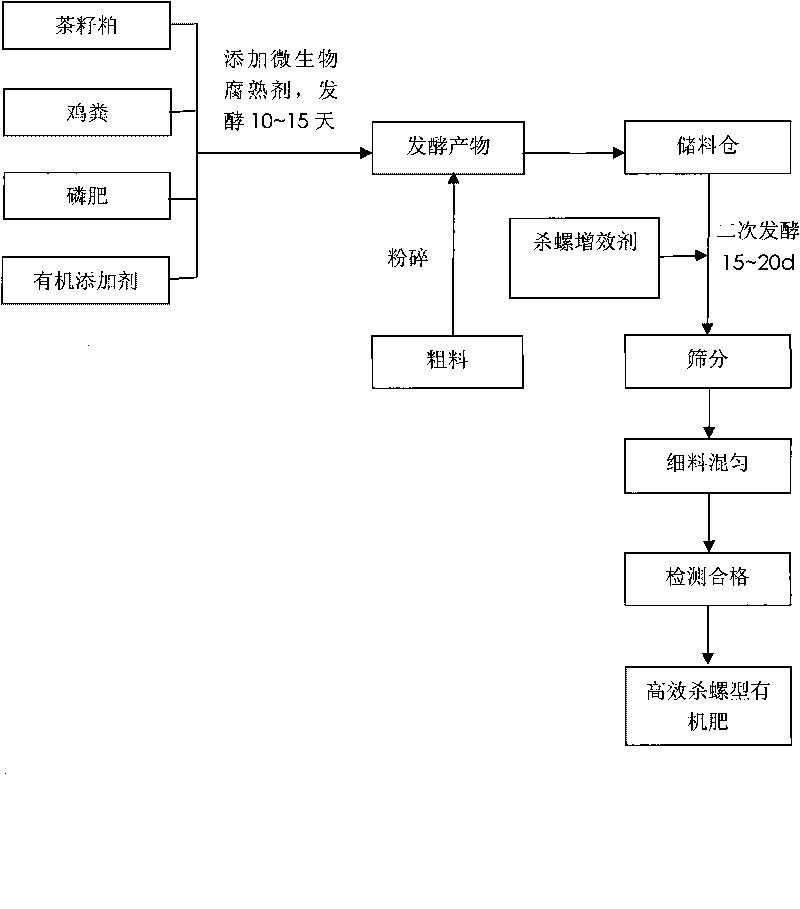

[0027] Please read figure 1 (1) Get 45% tea seed meal, 45% chicken manure, 0.5% common calcium superphosphate and calcium magnesium phosphate fertilizer, 5% molasses and yeast waste liquid and granulated sugar, beer residue and potassium humate by weight percentage, common superphosphoric acid Calcium and calcium magnesium phosphate fertilizer can be in any mass ratio, and molasses, yeast waste liquid, sugar, beer dregs and potassium humate can also be in any mass ratio. The above raw materials are crushed and mixed uniformly to obtain a mixture; The cake mainly contains sugar, protein and a certain amount of nitrogen, phosphorus, and potassium, and the chicken manure is chicken manure that meets the pollutant control standard GB4284.84 for sludge agricultural use;

[0028] (2) The carbon-to-nitrogen ratio of the mixture obtained in step (1) is adjusted to 25:1 with ammonium bicarbonate and diammonium phosphate, wherein the ammonium bicarbonate added accounts for 0.2% of the t...

Embodiment 2

[0034] Please read figure 1 , (1) get 50% tea seed dregs, 30% chicken manure, 1.5% superphosphate and calcium magnesium phosphate fertilizer and phosphate rock powder, 15% monosodium glutamate waste residue and distiller's grains and brewer's residue and humic acid by weight percentage, heavy superphosphoric acid Calcium, calcium magnesium phosphate fertilizer and phosphate rock powder can be in any mass ratio, fine waste residue, distiller's grains, beer residue and humic acid can also be in any mass ratio, and the above raw materials are pulverized and mixed to obtain a mixture;

[0035](2) The carbon-nitrogen ratio of the mixture obtained in step (1) is adjusted to 32:1 with urea, ammonium bicarbonate and diammonium phosphate, wherein the urea added accounts for 0.05% of the total mass of the mixture, and ammonium bicarbonate accounts for 0.5% of the total mass of the mixture , diammonium phosphate accounts for 0.1% of the total mass of the mixture;

[0036] (3) The mixtur...

Embodiment 3

[0041] Please read figure 1 (1) Get 52% tea seed meal, 32% chicken manure, 2.5% phosphate rock powder, and 10% soy sauce residue by weight percentage, pulverize the above-mentioned raw materials, and mix to obtain a mixture;

[0042] (2) The carbon-nitrogen ratio of the mixture obtained in step (1) is adjusted to 28:1 with urea and ammonium bicarbonate; wherein the added urea accounts for 0.2% of the total mass of the mixture, and ammonium bicarbonate accounts for 0.4% of the total mass of the mixture;

[0043] (3) The mixture obtained in step (2) is adjusted with water so that the water content of the mixture is 45%, and the total weight of the mixture obtained in step (2) is added with 1.8% of the Ruilaite microbial septic, Fubei compound bacteria, and enzyme bacteria quick rot Agent and VT-1000 bacterial agent, mixed evenly, Reilite microbial septic, Fubei complex bacteria, enzyme bacteria quick rot agent and VT-1000 bacterial agent can be in any mass ratio;

[0044] (4) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com