Method and system for recovering low-grade fine-fraction ilmenite

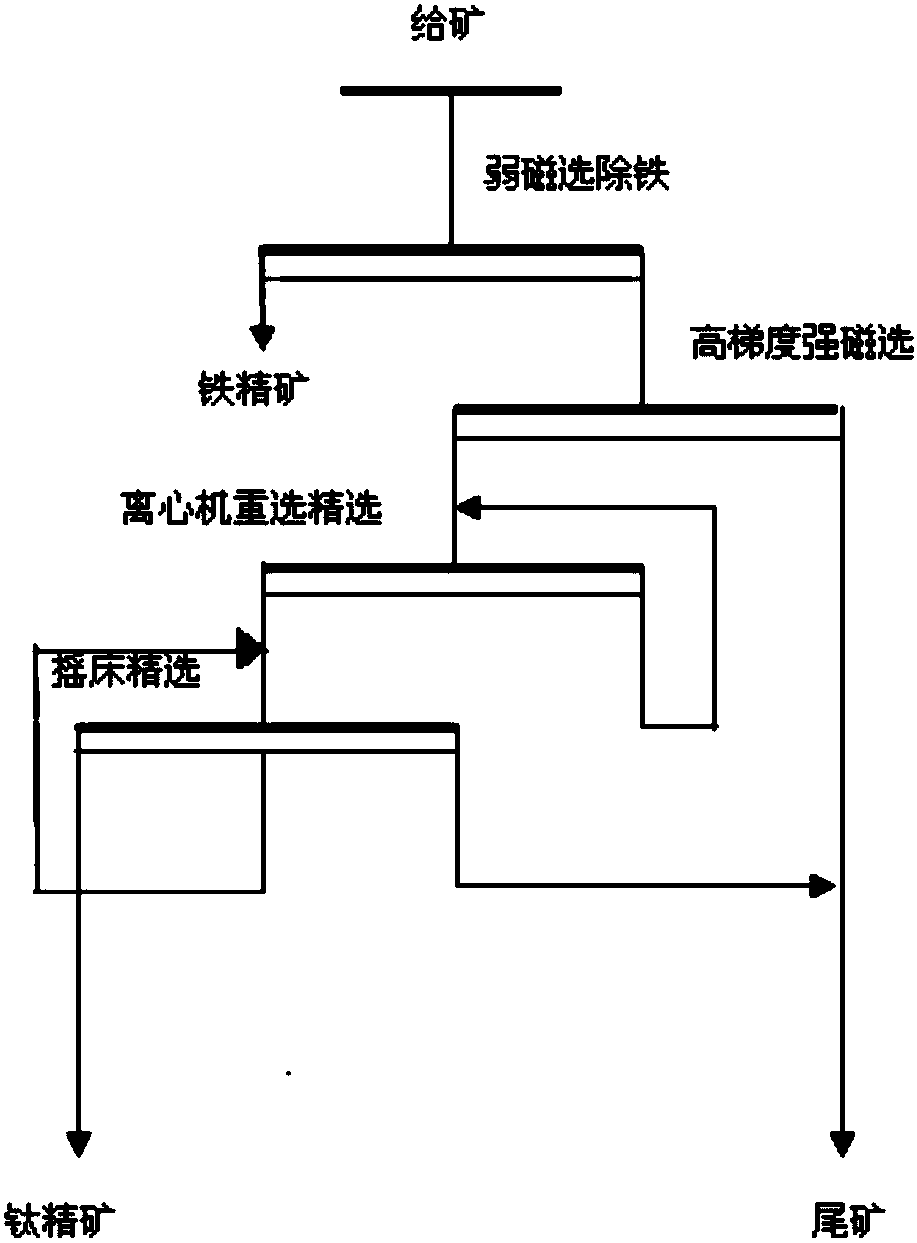

A fine-grained, ilmenite technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of complex process flow, difficult operation, and large number of equipment, and achieve simple and reliable process flow, Widely promote the effect of application value and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] TiO containing after iron selection 2 The tailings slurry (low-grade fine-grained ilmenite) with a grade of about 6.3% is classified with a sieve with an aperture of -0.074mm;

[0055] The product under the sieve is deironed once with a weak magnetic drum magnetic separator with a field strength of 0.2T;

[0056] The tailings after iron removal are separated by a vertical ring high gradient magnetic separator with a field strength of 0.7T;

[0057] The titanium concentrate obtained by strong magnetic separation is then selected with a centrifugal concentrator. The process parameters in the centrifugal gravity separation process are: the centripetal force of the enrichment cone is about 60G; the particle size of the ore is -0.074mm; the concentration of the ore is 10 %, the ore feeding time is 180s; the recoil water volume is 5L / min, and the TiO-containing 2 About 36% titanium concentrate;

[0058] The ilmenite concentrate is then refined using a Yunnan tin shaker, a...

Embodiment 2

[0062] TiO containing after iron selection 2 The tailings slurry (low-grade fine-grained ilmenite) with a grade of about 6.3% is classified with a sieve with an aperture of -0.074mm;

[0063] The product under the sieve is deironed once with a weak magnetic drum magnetic separator with a field strength of 0.15T;

[0064] The tailings after iron removal are separated by a vertical ring high gradient magnetic separator with a field strength of 0.65T;

[0065] The titanium concentrate obtained by strong magnetic separation is then selected by a centrifugal concentrator. The process parameters of the centrifugal gravity separation are: the centripetal force of the enrichment cone is about 65G; the particle size of the ore is -0.074mm; the concentration of the ore is 10.5% , the feeding time is 185s; the recoil water volume is 6L / min, and the TiO-containing 2 About 35% titanium concentrate;

[0066] The titanium concentrate is then refined using a Yunnan tin shaker, and the pro...

Embodiment 3

[0070] TiO containing after iron selection 2 The tailings slurry (low-grade fine-grained ilmenite) with a grade of about 6.3% is classified with a sieve with an aperture of -0.074mm;

[0071] The product under the sieve is deironed once with a weak magnetic drum magnetic separator with a field strength of 0.25T;

[0072] The tailings after iron removal are separated by a vertical ring high gradient magnetic separator with a field strength of 0.75T;

[0073] The titanium concentrate obtained by strong magnetic separation is then selected by a centrifugal concentrator. The process parameters of the centrifugal gravity separation are: the centripetal force of the enrichment cone is about 60G; the particle size of the ore is -0.074mm; the concentration of the ore is 11% , the feeding time is 175s; the recoil water volume is 4L / min, and the TiO-containing 2 About 37% titanium concentrate;

[0074] The ilmenite concentrate is then refined using a Yunnan tin shaker, and the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com