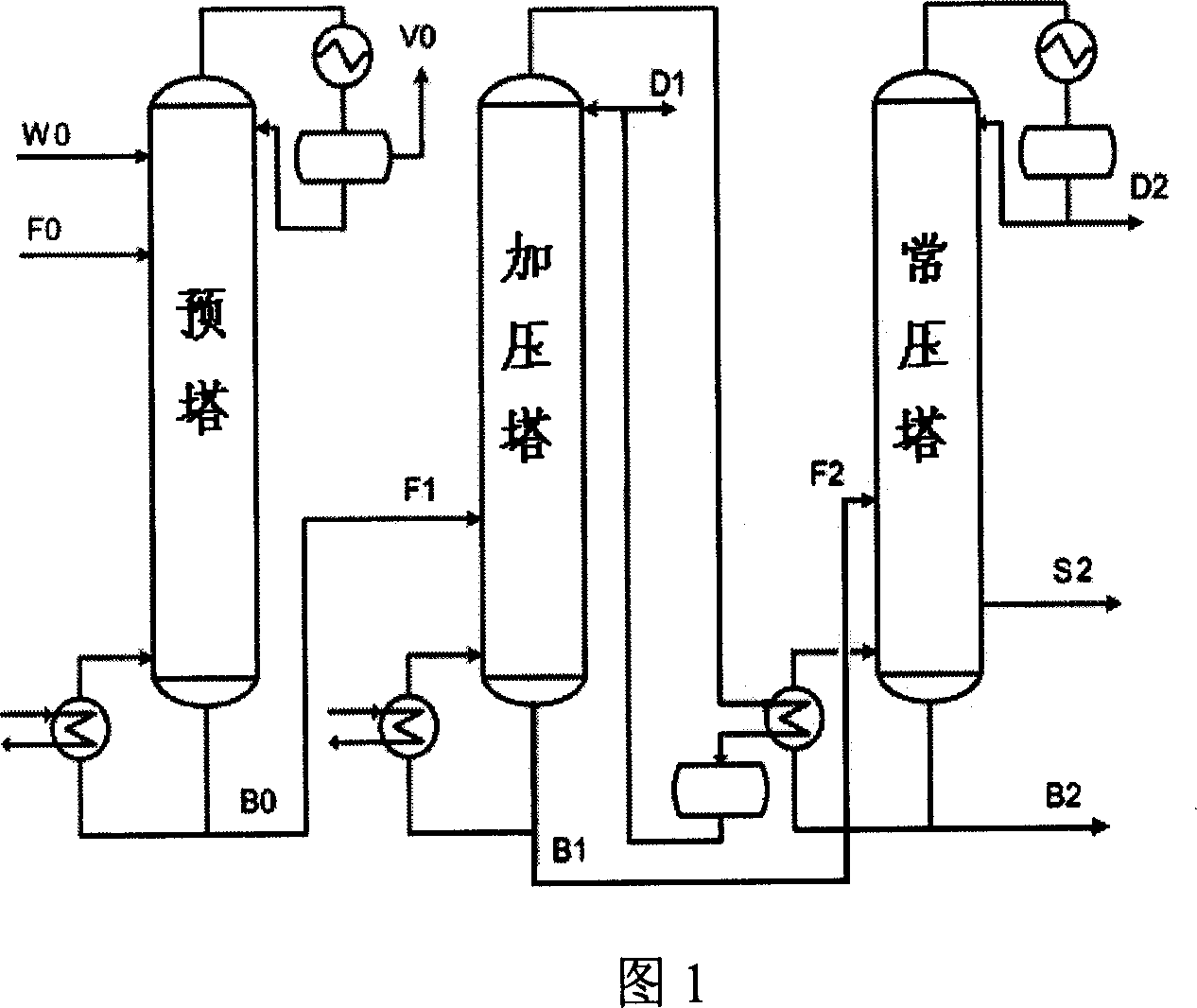

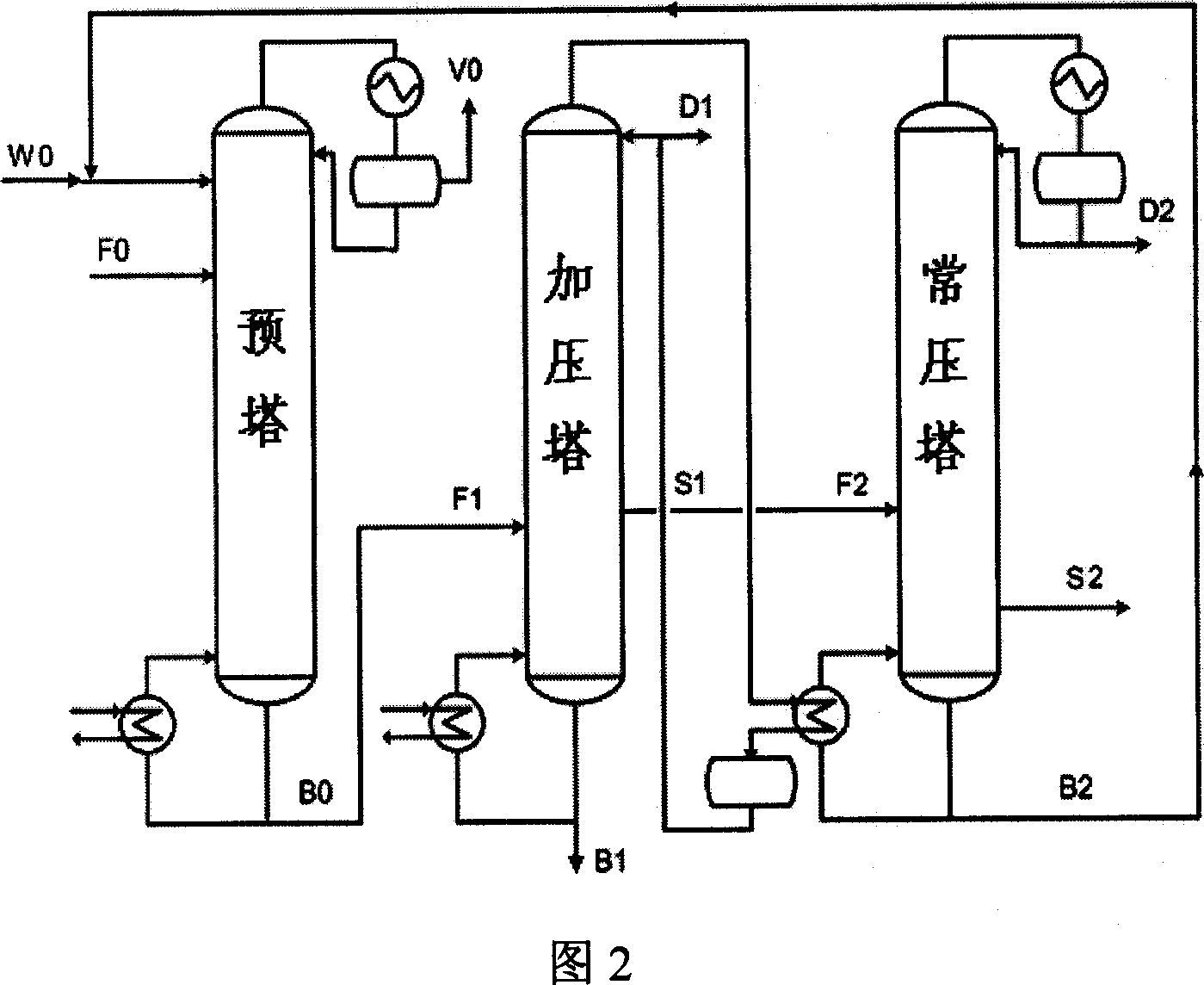

Rectifying and refining process of synthetic coarse methanol

A technology of crude methanol and rectification, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, and preparation of organic compounds. The effect of feed concentration, reduced dosage, and reduced reflux ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Crude methanol feed flow rate is 14000 / kg·h -1 , the composition is shown in Table 1, and the tower equipment parameters are shown in Table 2. Tables 3 to 6 provide the comparative data of two kinds of three-tower processes, wherein Table 3 is the comparison of material flow, Table 4 is the comparison of the feed composition of the atmospheric tower, and Table 5 is the comparison of soft water, steam consumption and methanol loss. Table 6 is a comparison of product quality and wastewater composition. (linked alcohol process)

[0016] Methanol

[0017] Pre-tower

[0018] parameters

[0019] Element

[0020] Soft water consumption (unit kg / h)

[0021] Element

Embodiment 2

[0023] Crude methanol feed flow rate is 14000 / kg·h -1 , the composition is shown in Table 1, and the tower equipment parameters are shown in Table 2. Tables 3 to 6 provide the comparative data of two kinds of three-tower processes, wherein Table 3 is the comparison of material flow, Table 4 is the comparison of the feed composition of the atmospheric tower, and Table 5 is the comparison of soft water, steam consumption and methanol loss. Table 6 is a comparison of product quality and wastewater composition. (coal-to-gas monoalcohol process)

[0024] Methanol

[0025] Pre-tower

[0026] parameters

[0027] Element

[0028] Soft water consumption (unit kg / h)

[0029] Element

[0030] Embodiment 2 illustrates: Embodiment 2 has a different place with embodiment 1 and is that the side line of the atmospheric tower tower draws out a stream of refined methanol S21 with higher ethanol concentration, which is not in embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com