Method and system for concentrating and separating two segments of low-intensity magnetic separation iron tailings to obtain ilmenite

A technology of iron tailings and weak magnetic separation, applied in separation methods, chemical instruments and methods, solid separation, etc., can solve the problems of low recovery rate of titanium concentrate, poor classification effect, low classification efficiency, etc., and achieve overflow The effect of reducing roughness, improving recovery rate and improving classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

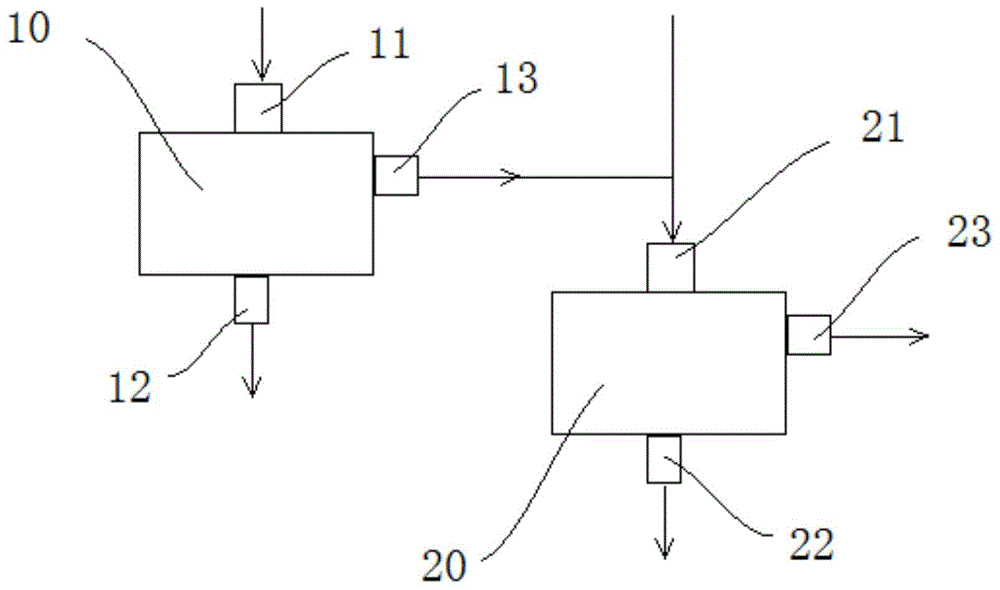

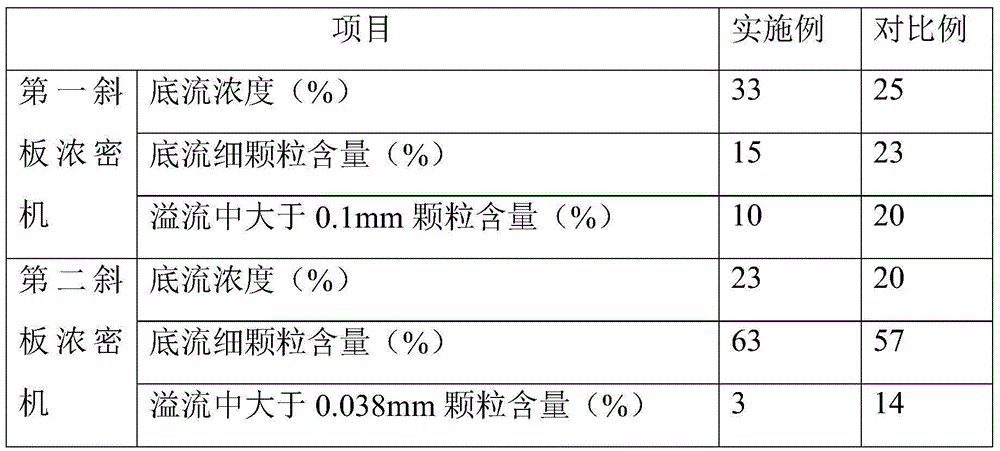

[0037] Feed the first stage of weak magnetic separation iron tailings into the first inclined plate thickener (model and specification: KMLF-130m 2 ), the flow rate of the first stage of weak magnetic separation iron tailings is 4600m 3 / Hour, the concentration is 17%, the content of fine particles is 40% (that is, the content of -200 mesh particles is 40%), the overflow of the first inclined plate thickener enters the second inclined plate thickener (model and specification: KMLF- 800m 2 ), and at the same time feed the second stage of weak magnetic separation iron tailings into the second inclined plate thickener, and the flow of the second stage of weak magnetic separation iron tailings is 4400m 3 / Hour, the concentration is 2.8%, the content of fine particles is 70% (that is, the content of -200 mesh particles accounts for 70%), intercept the production data of 8 hours, and get the underflow concentration of the first inclined plate thickener and the second inclined plate thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com