Process and plant for the heat treatment of fine-grained mineral solids

A solid and mineral technology, applied in the field of heat treatment of fine-grained mineral solids, can solve problems such as short residence time and inability to realize material properties, and achieve the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

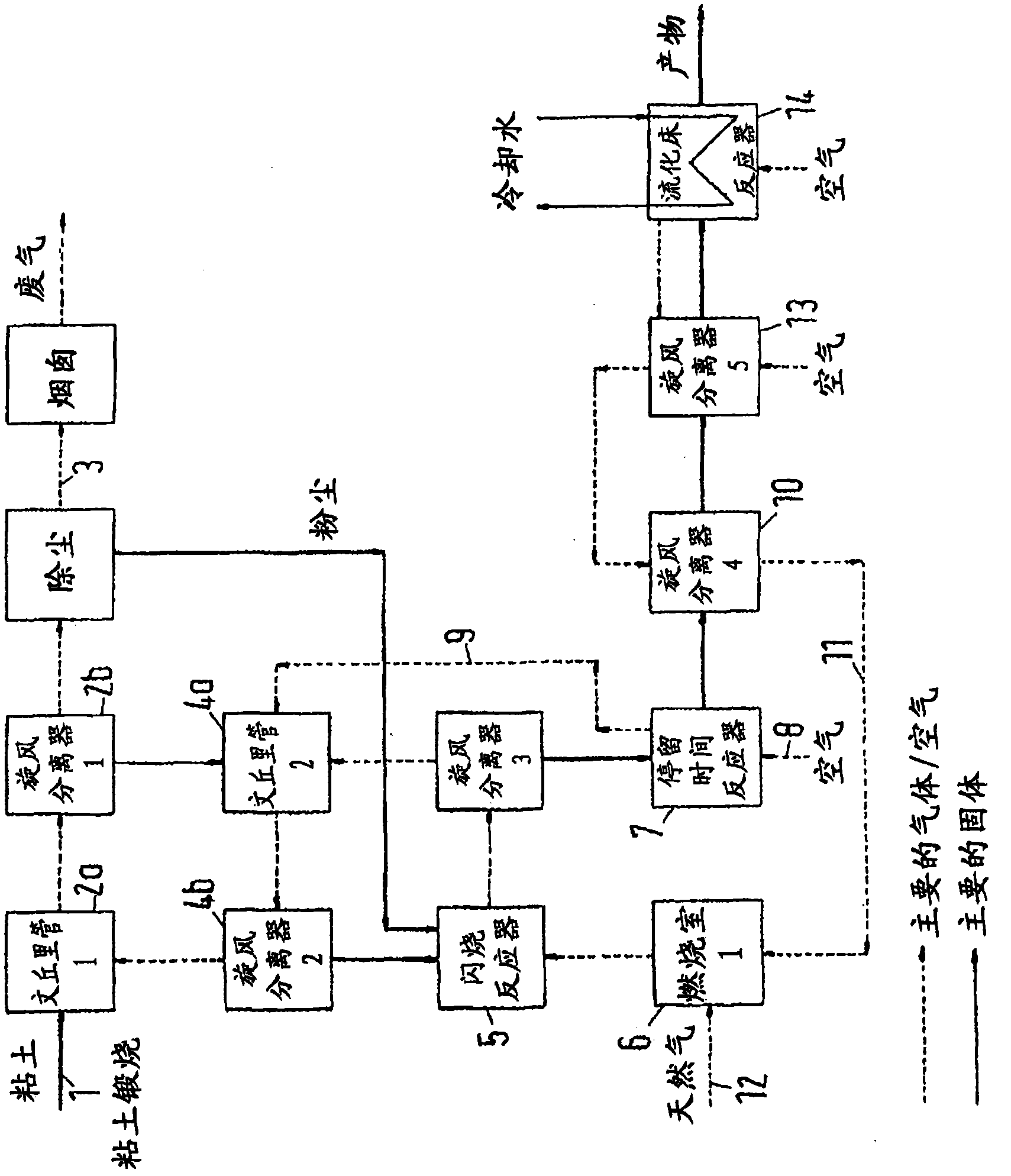

[0051] Embodiment 1 (calcination of clay)

[0052] exist figure 2 The plant schematically shown in , for the production of 1300 tons of calcined clay per day operates with natural gas with a net calorific value (NCV) of 50000 kJ / kg.

[0053] The kaolin-rich clay-based feedstock is preheated to a temperature of 500°C under 7% humidity and fed to flash reactor 5 in two consecutive preheating stages powered by Venturi Inner tube preheater 2a, 4a and cyclone separator 2b, 4b. The flash reactor operates at 650°C to 700°C with a residence time of 5 seconds. The residence time reactor 7 is configured as a fixed fluidized bed reactor and operates at 630°C to 680°C. A particle Froude number of 3 is desired, which is in the range of 2 to 4 in practice due to variations in particle size. The residence time is from 13 minutes to 22 minutes, preferably from 16 minutes to 20 minutes.

[0054] Hot air is generated in the combustion chamber 6 for regulating the process temperature requi...

Embodiment 2

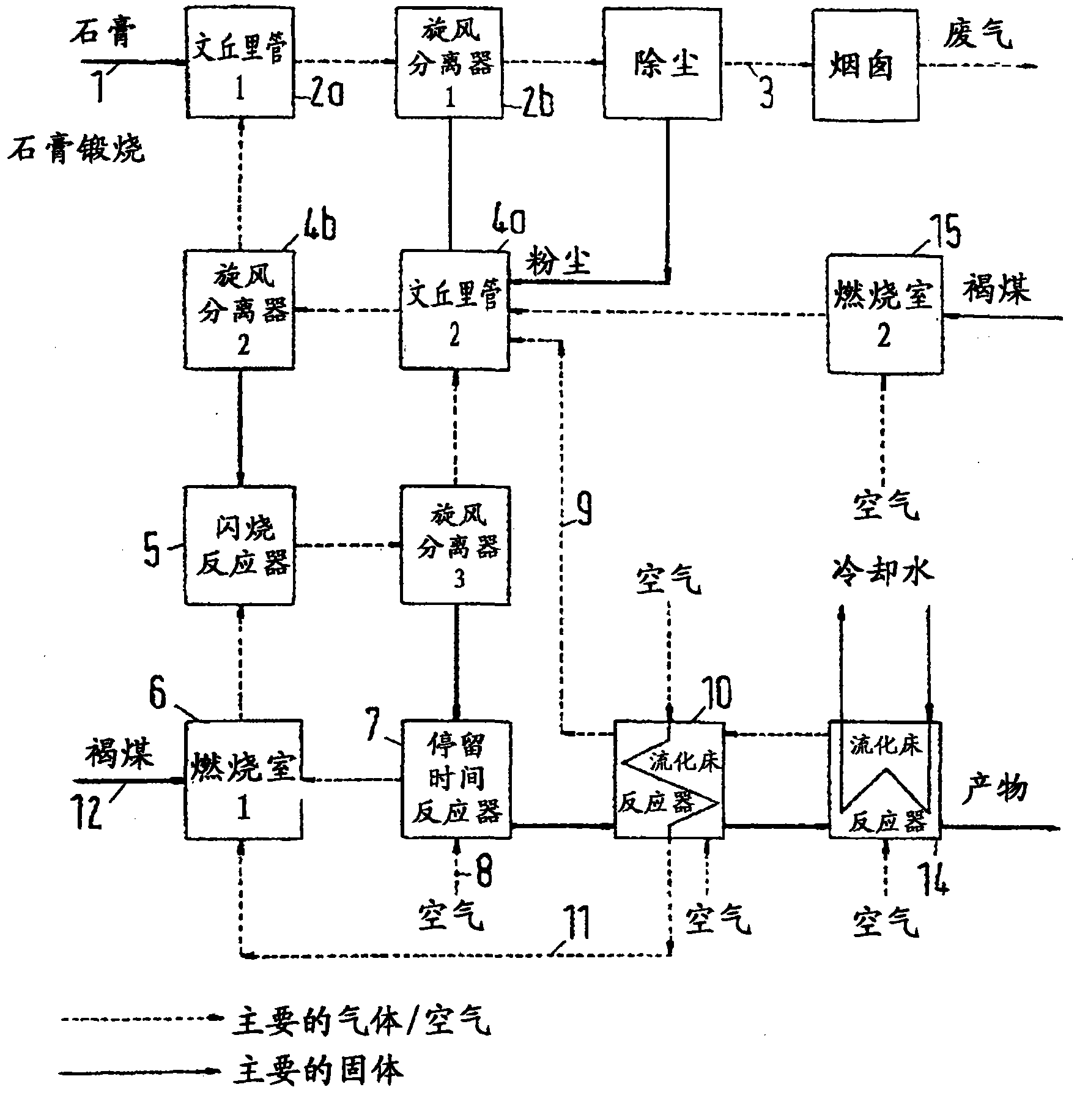

[0055] Embodiment 2 (calcination of gypsum)

[0056] exist image 3 The plant for the production of 700 tons of calcined gypsum per day, shown schematically in , operates using lignite coal with a net calorific value (NCV) of 22100 kJ / kg.

[0057] Raw materials are preheated to a temperature of 320°C and precalcined in two successive preheating stages separated by Venturi tube preheaters 2a, 4a and cyclones at 8% humidity 2b, 4b; additional heat is supplied to the Venturi 4a by supplying hot gas at 1050°C to the Venturi 4a, wherein 0.5t / h of lignite and 7500Nm are used in the combustion chamber 15 3 / h of air produces this hot air. The preheated and precalcined solids are fed to the flash reactor 5 . The flash reactor operates at 700°C to 750°C with a residence time of 10 seconds. The residence time reactor 7 was configured as a fixed fluidized bed reactor and operated at 700°C. A particle Froude number of 3 is desired, which is in the range of 2 to 4 in practice due to v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com