Patents

Literature

284results about "Calcination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

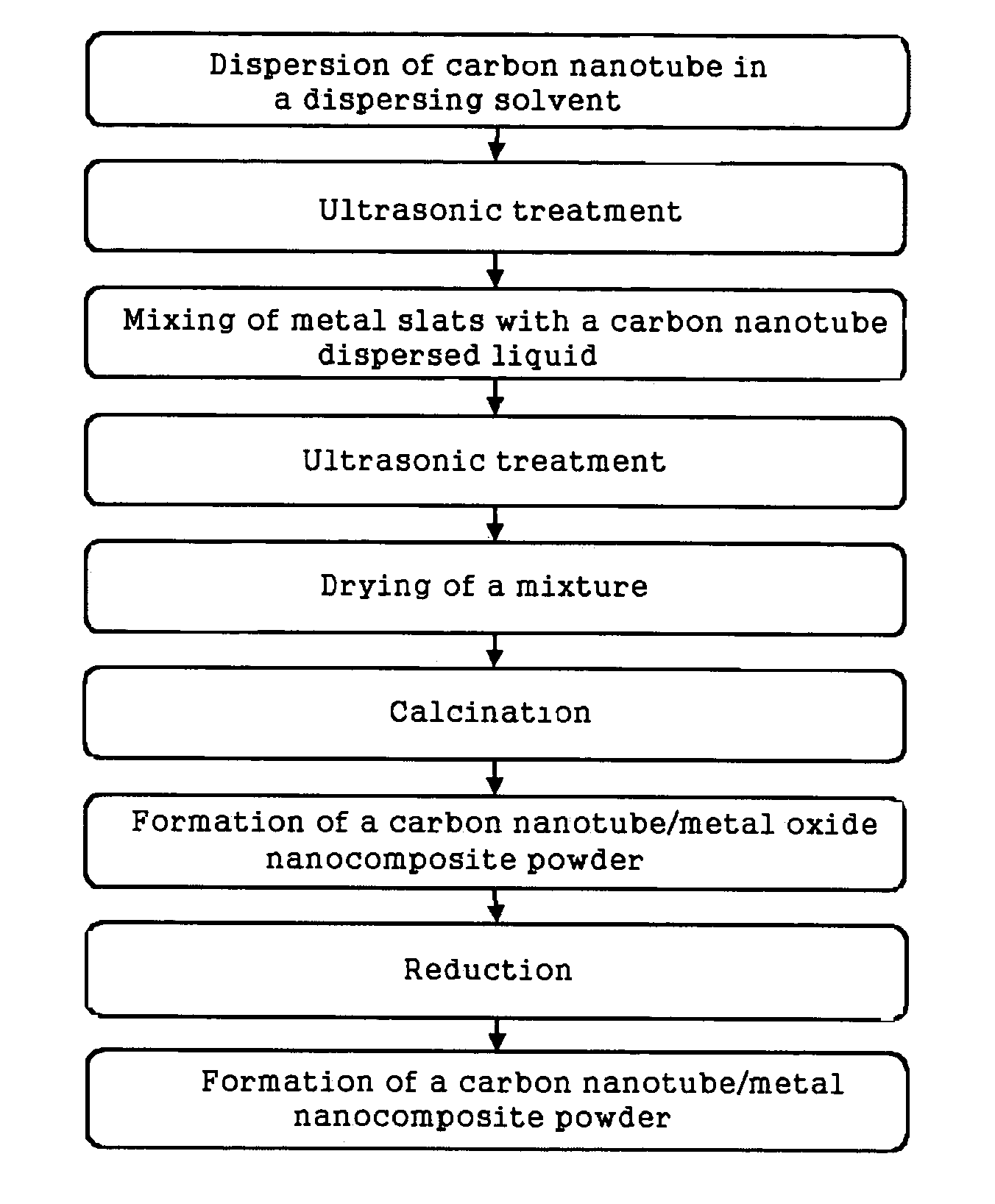

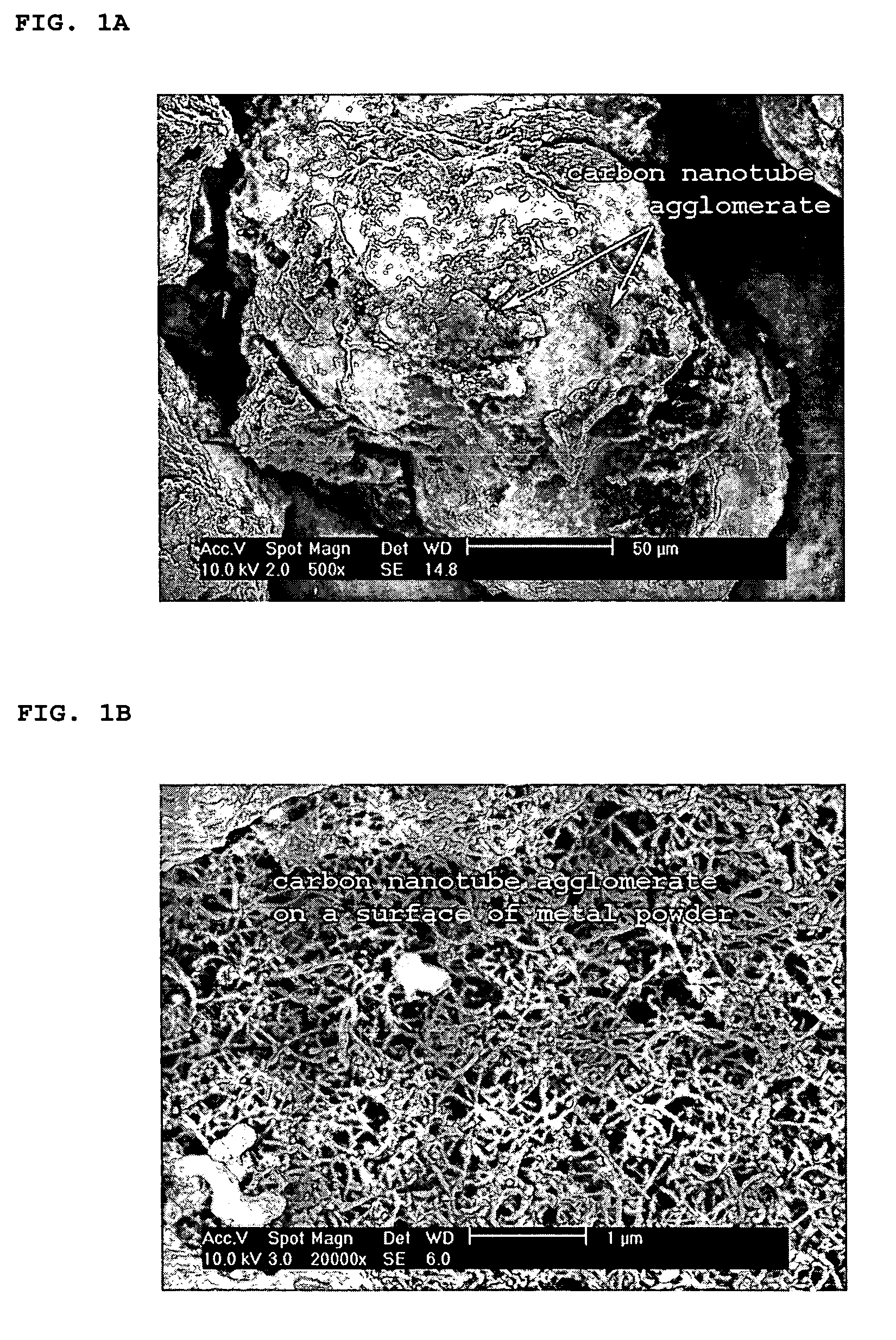

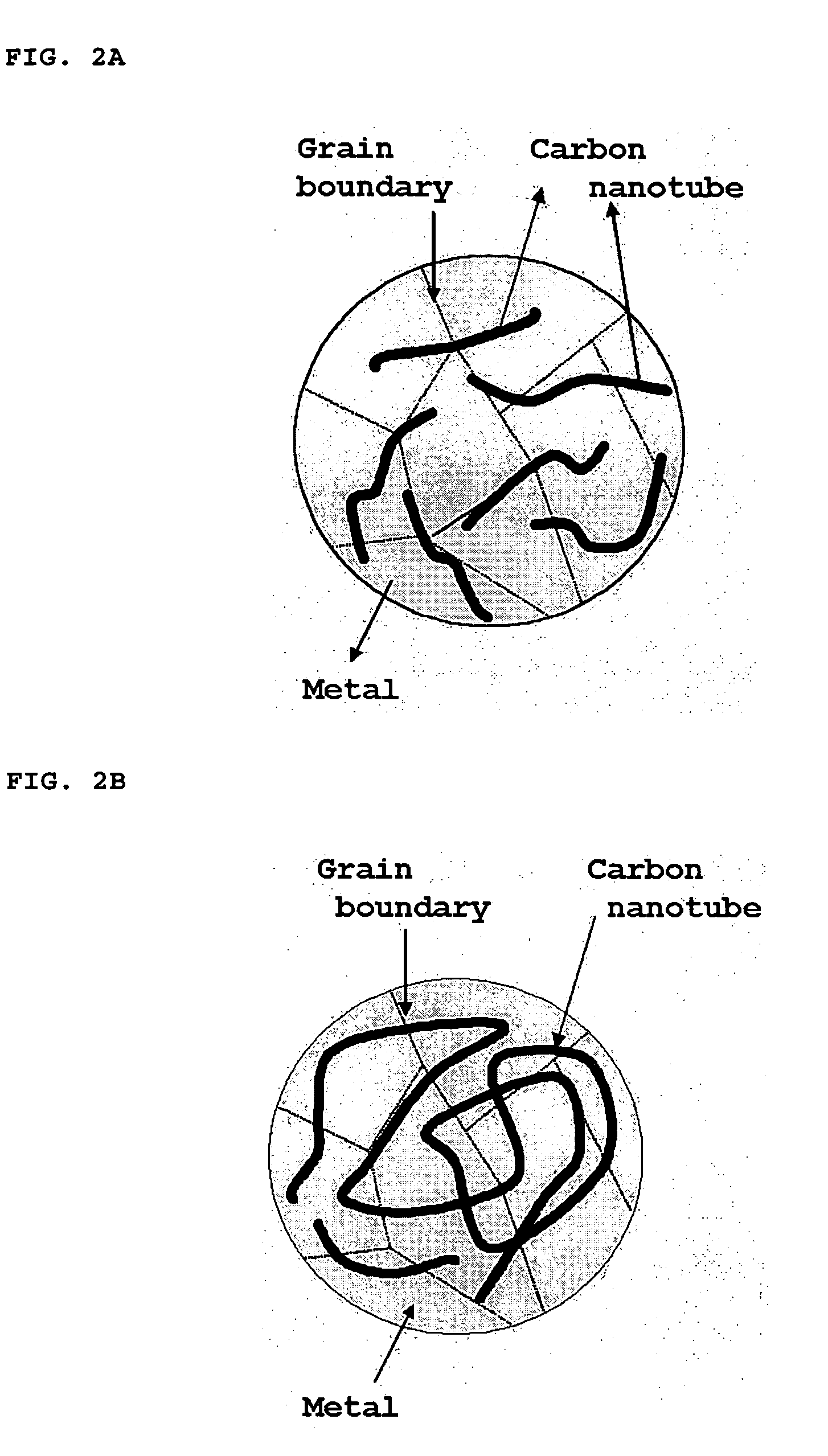

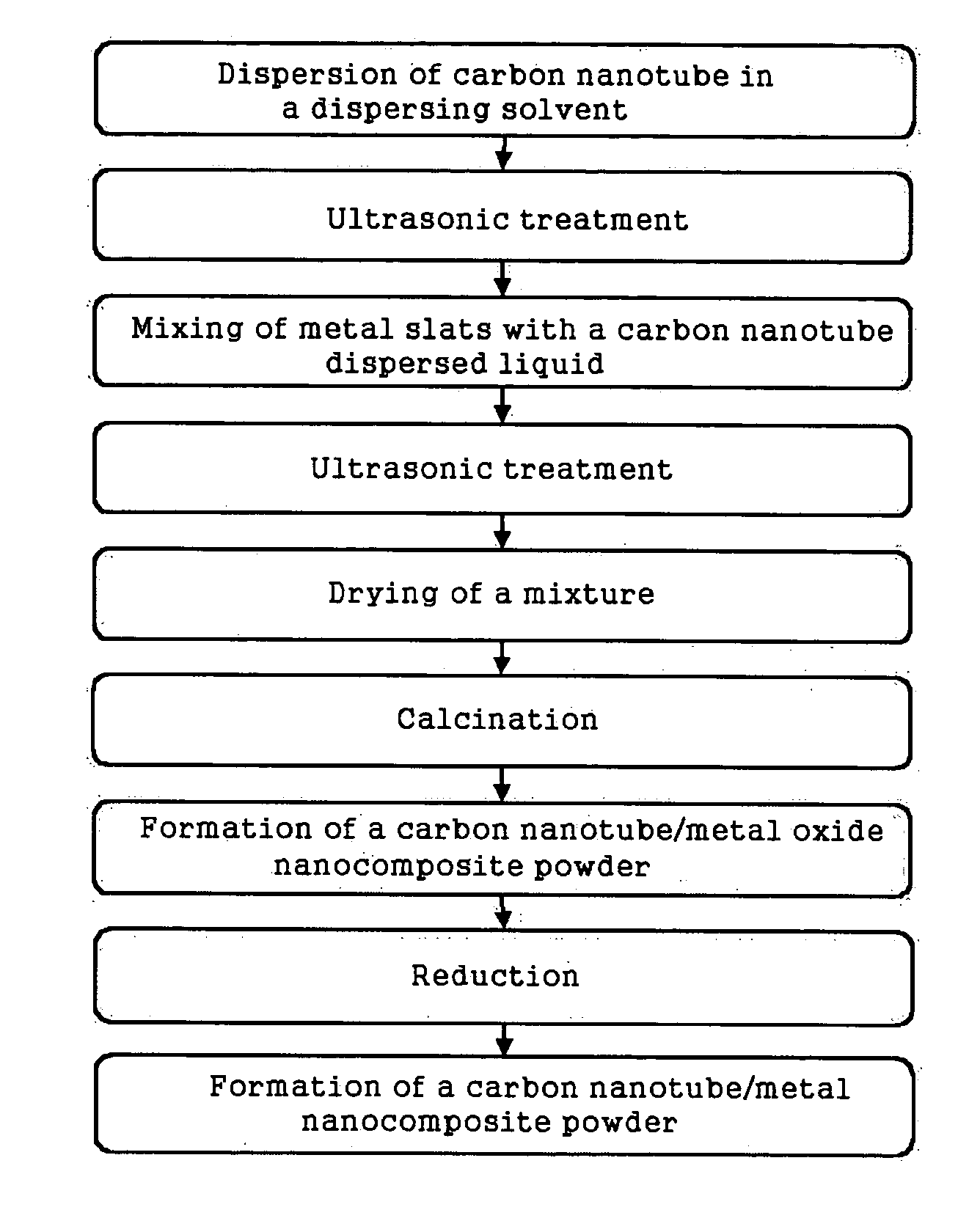

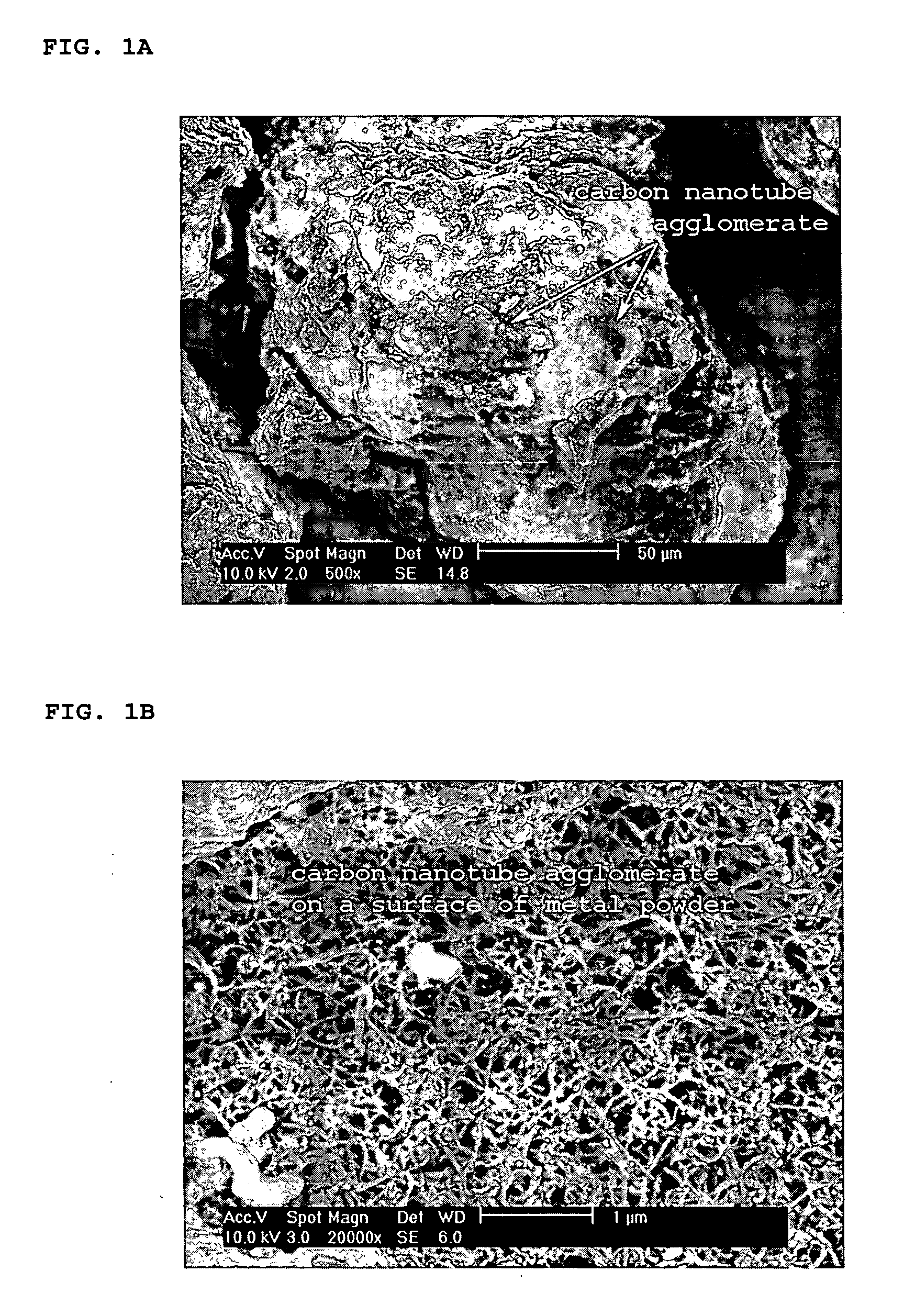

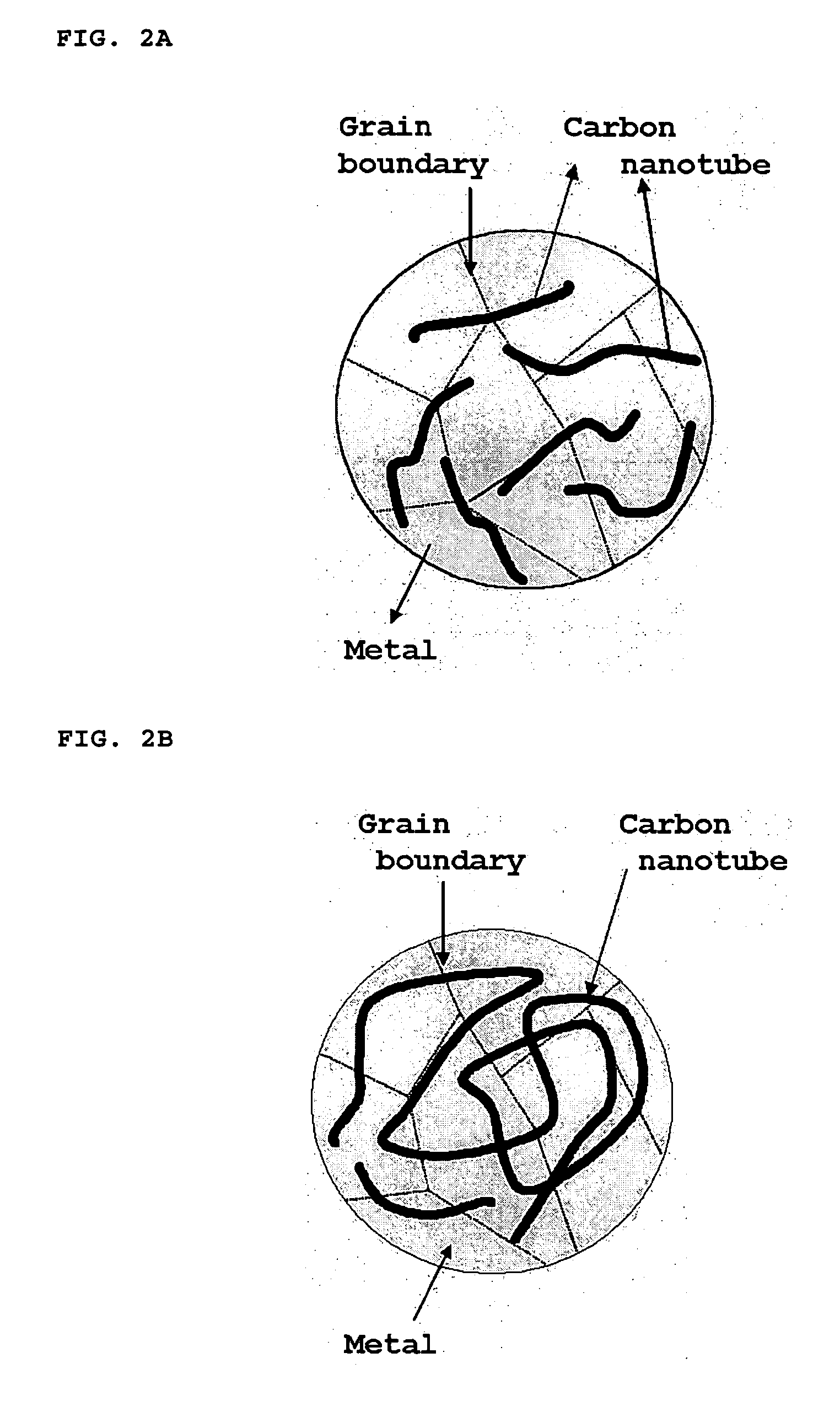

Method of producing metal nanocomposite powder reinforced with carbon nanotubes and the power prepared thereby

The present invention relates to a metal nanocomposite powder reinforced with carbon nanotubes and to a process of producing a metal nanocomposite powder homogeneously reinforced with carbon nanotubes in a metal matrix powder.

Owner:KOREA ADVANCED INST OF SCI & TECH

Method of producing metal nanocomposite powder reinforced with carbon nanotubes and the powder prepared thereby

The present invention relates to a metal nanocomposite powder reinforced with carbon nanotubes and to a process of producing a metal nanocomposite powder homogeneously reinforced with carbon nanotubes in a metal matrix powder.

Owner:KOREA ADVANCED INST OF SCI & TECH

Process for material treatment

InactiveUS20070059199A1Solid waste managementIon-exchanger regenerationThermal treatmentMaterials science

The invention discloses a process for material treatment, which includes the step of subjecting used siliceous material to heat to obtain treated siliceous material. The process may be used to recycle used siliceous material. The invention also discloses a material treatment apparatus for treating used siliceous material, which includes heating means for heating used siliceous material to obtain treated siliceous material. The used siliceous material may be perlite and / or diatomaceous earth.

Owner:LABUSCHAGNE FRANCOIS JACQUES

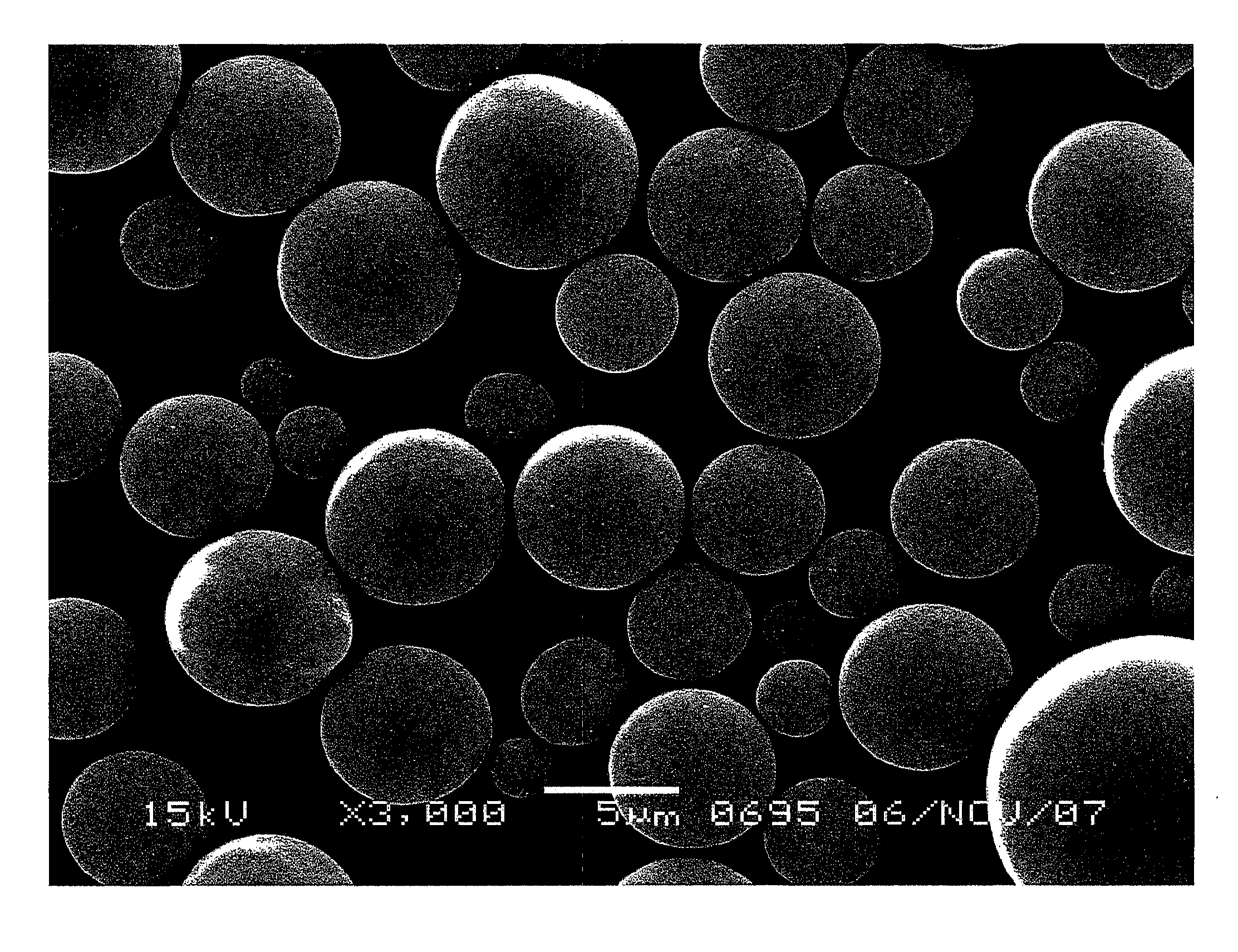

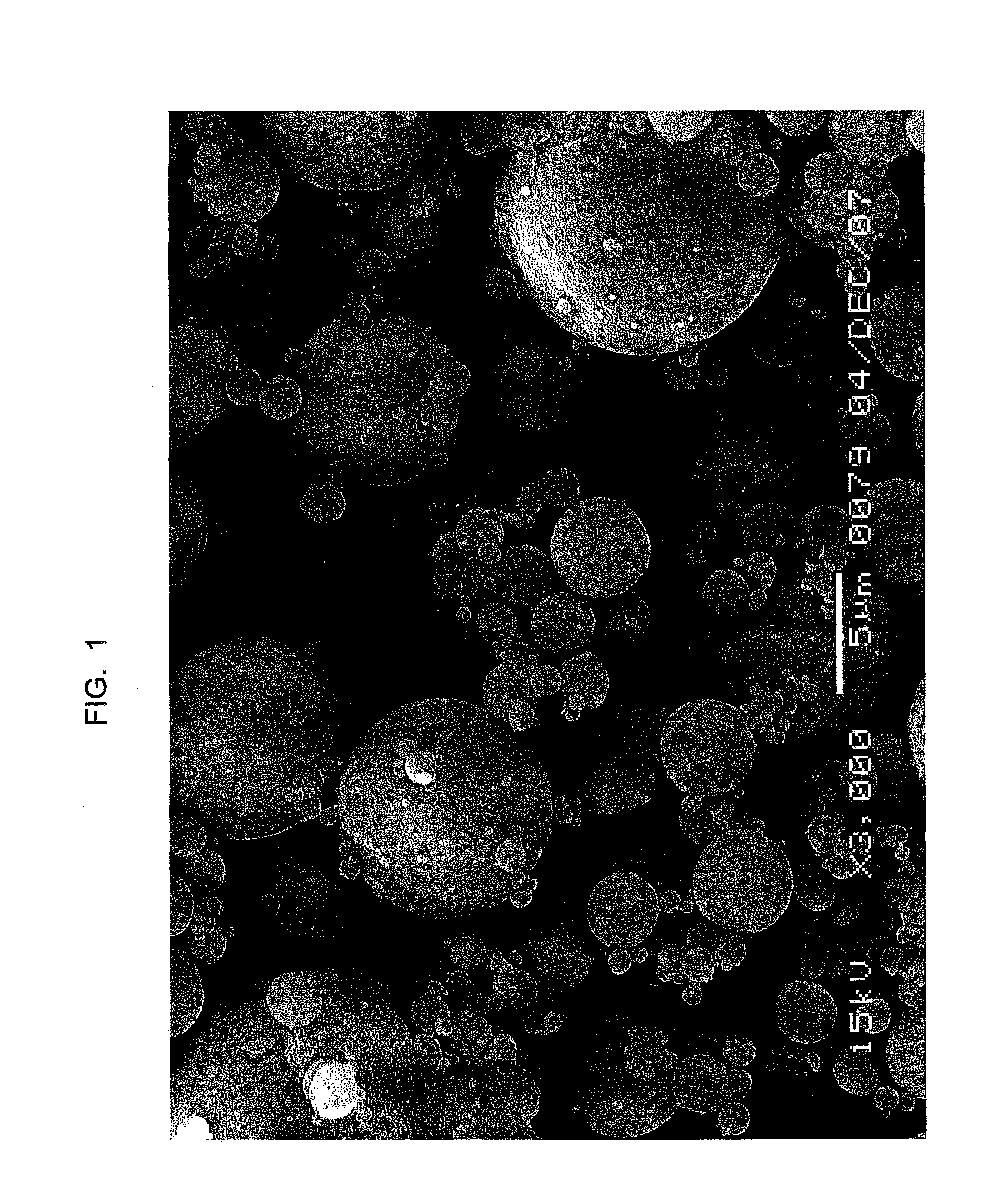

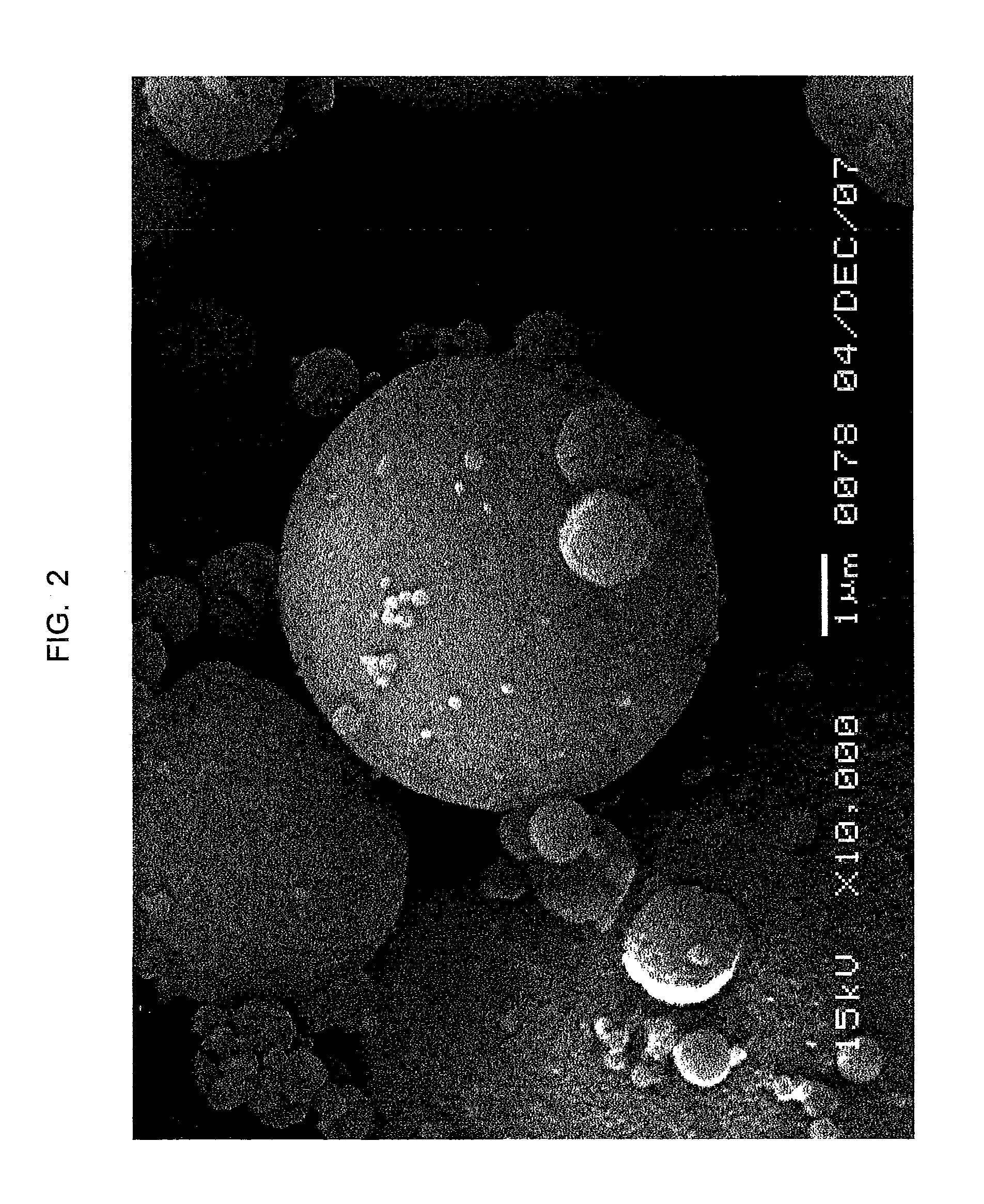

Porous Silica-Based Particles Having Smooth Surface, Method for Production Thereof and Cosmetic Comprising Such Particles

Disclosed are porous silica-based particles having high surface smoothness, a method for producing the porous silica-based particles, and a cosmetic comprising the porous silica-based particles. The porous silica-based particles have an average particle diameter of 0.5 to 30 μm and have a surface smoothness of a level to such an extent that, when the entire surface of the particle is observed from a photograph thereof taken by a scanning electron microscope (SEM) with a magnifying power of 10,000, a foreign matter attached to the surface thereof can be hardly seen.

Owner:JGC CATALYSTS & CHEM LTD

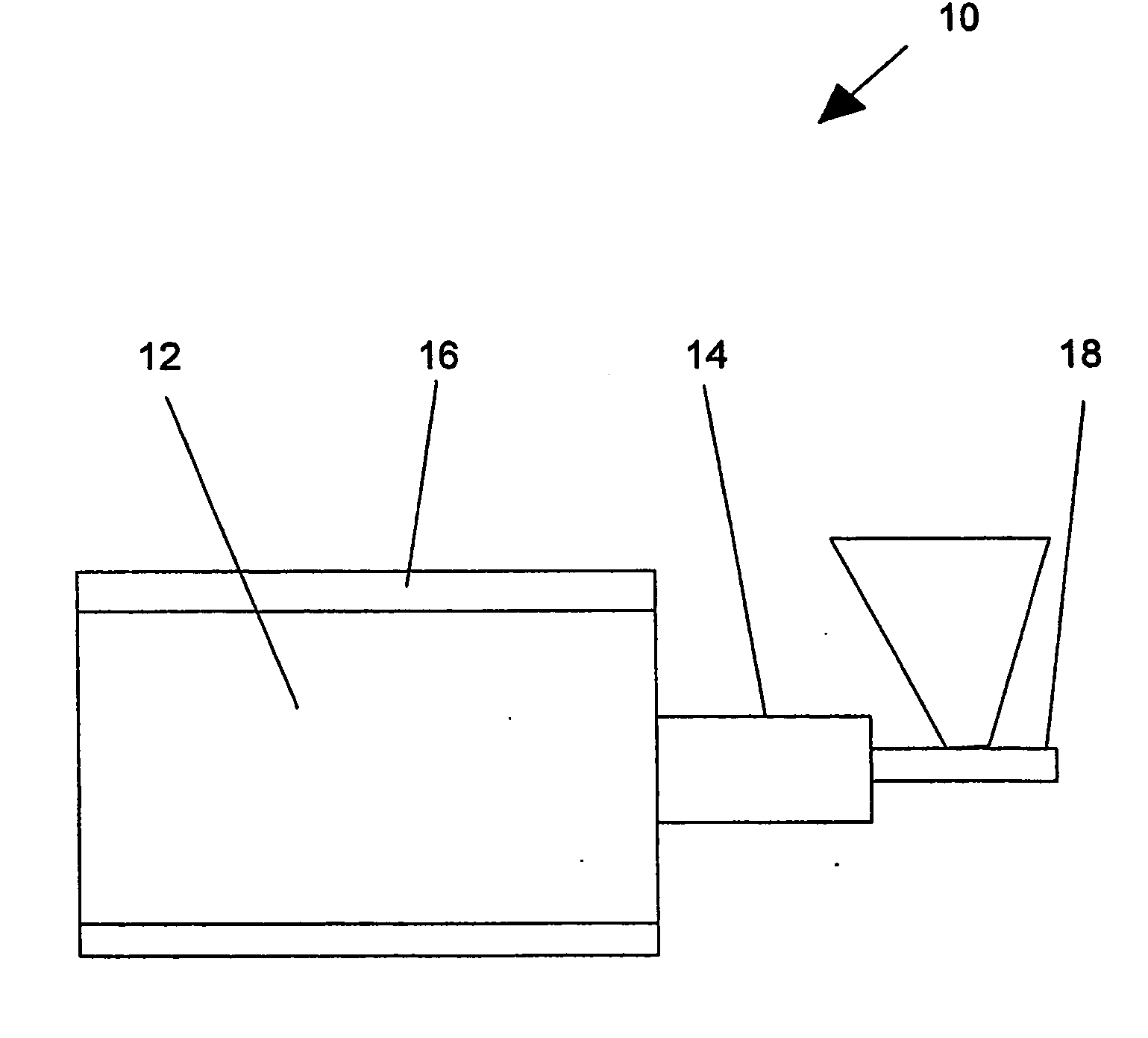

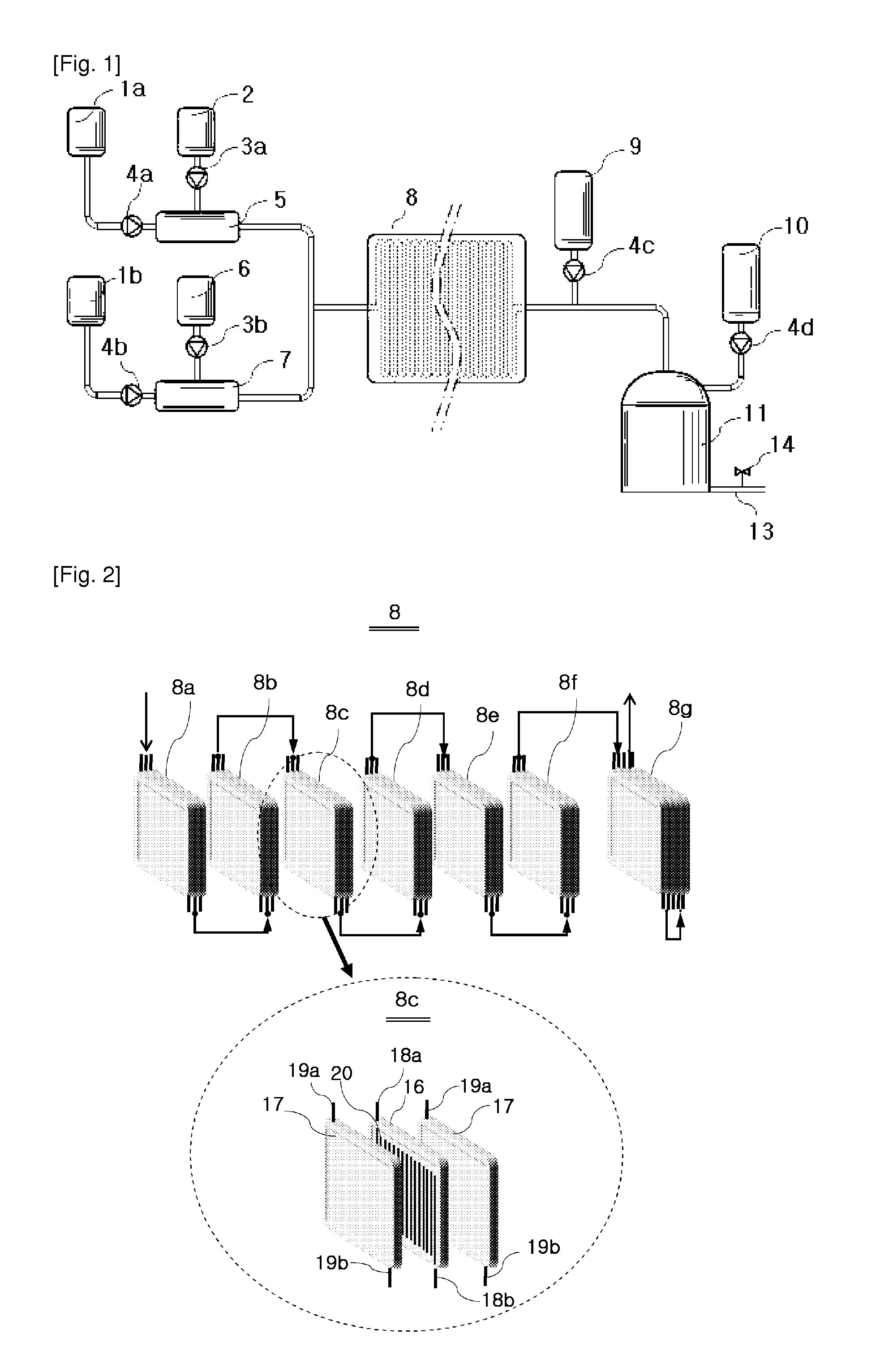

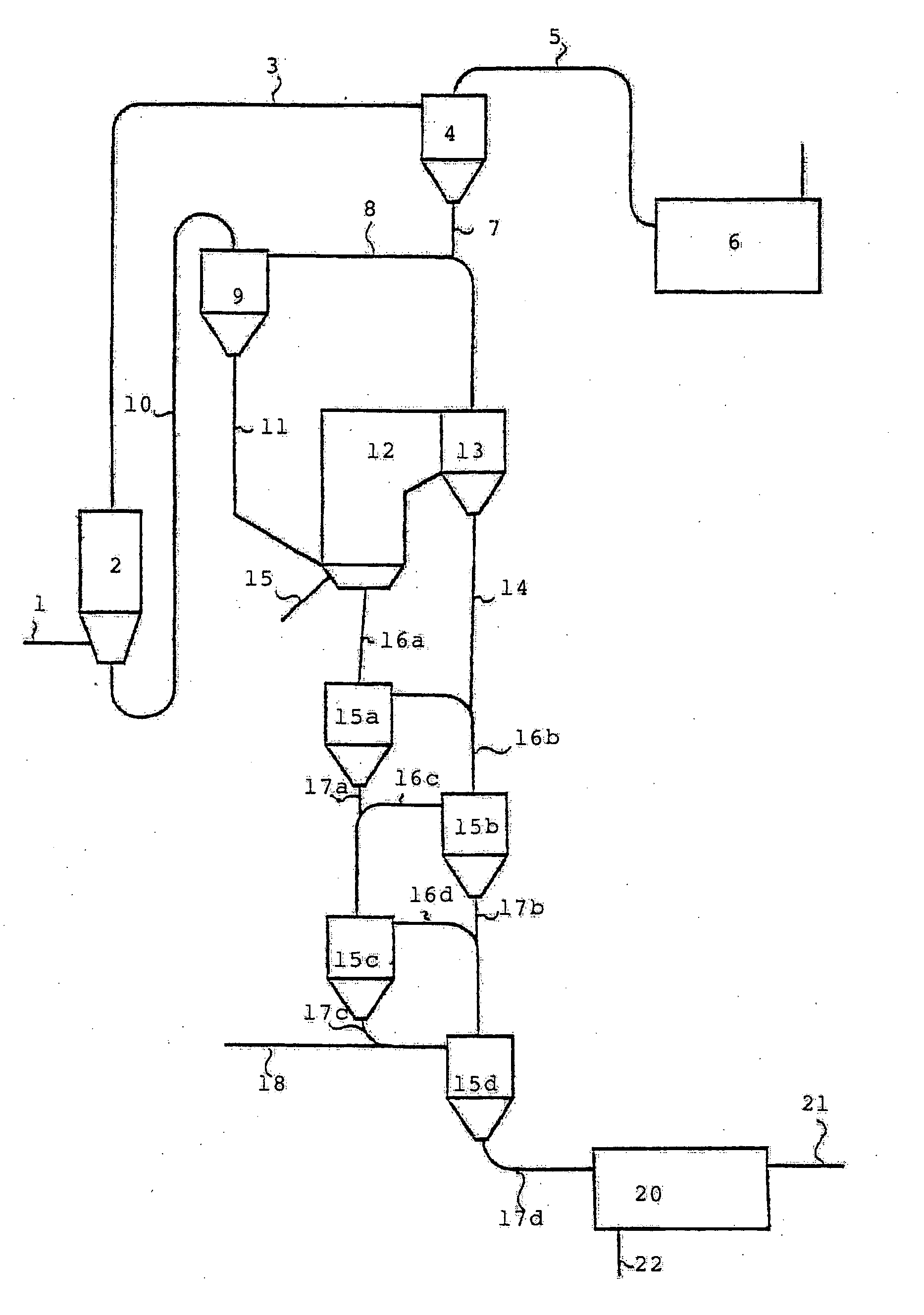

Method of producing nano-size graphene-based material and an equipment for producing the same

InactiveUS20120201738A1Good dispersionMass productionMaterial nanotechnologyGraphiteCarbon nanotubeSlurry

The present invention is directed to a method of producing nano-size graphene-based material and an equipment for producing the same. The present invention provides a method of producing graphitic oxide by forcing graphite sulfuric slurry and KMnO4 sulfuric solution into a lengthy micro-channel and by sustaining the mixture of the said graphite sulfuric slurry and the said KMnO4 sulfuric solution in the said micro-channel at predetermined temperatures, by putting the said aqua solution of hydrogen peroxide to the reaction mixture to terminate oxidation, and by washing and drying the reaction mixture. The present invention provides a method of producing nano-size graphene-based material by exfoliating graphitic oxide by thermal shock in a vertical fluidized furnace. According to the present invention, graphitic oxide can be produced massively without risks of explosion by forcing all reagents as liquid phase continuously into a lengthy micro-channel surrounded and thermally controlled strictly by heat exchangers. Nano-size graphene-based material derived by exfoliating thus produced graphitic oxide can be imported into compositions and composites for various uses since it has physical characteristics comparable to carbon nanotube and dispersibility superior to carbon nanotube via residual functional groups.

Owner:STANDARDGRAPHENE

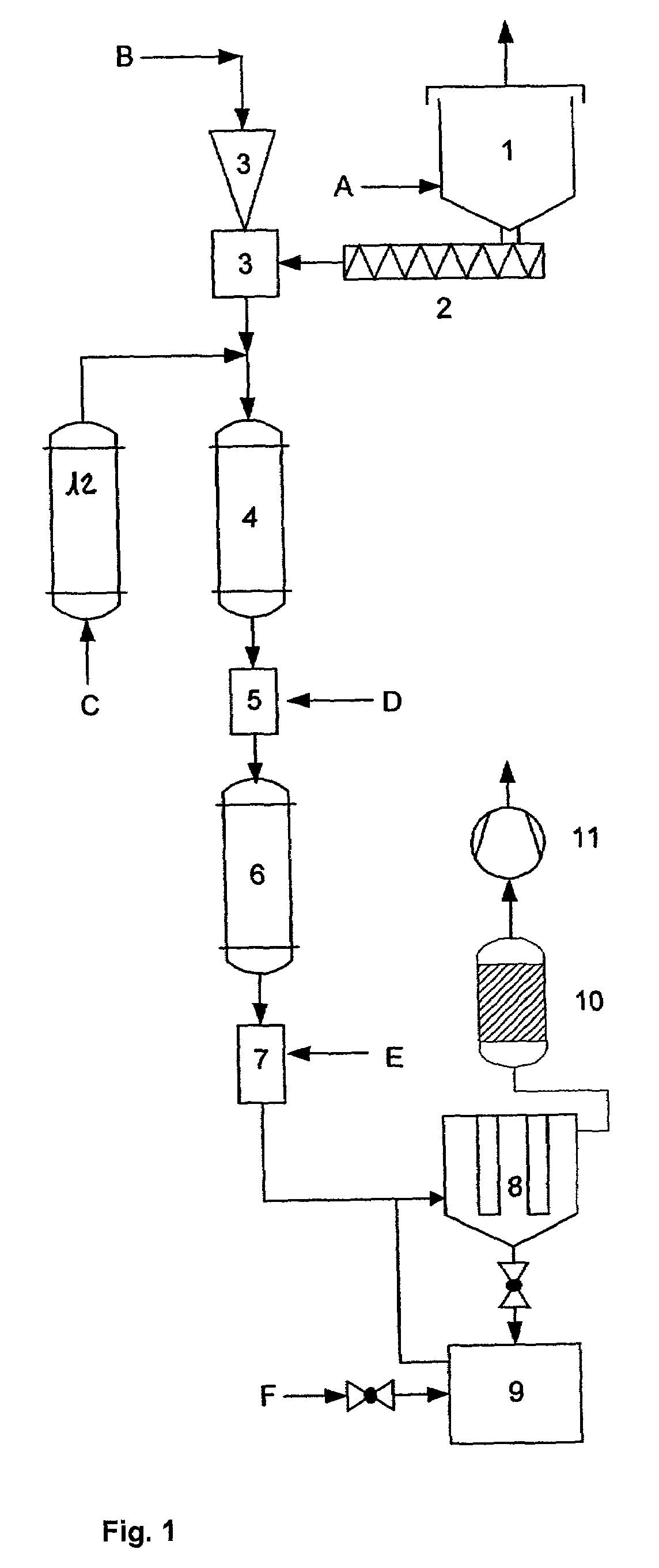

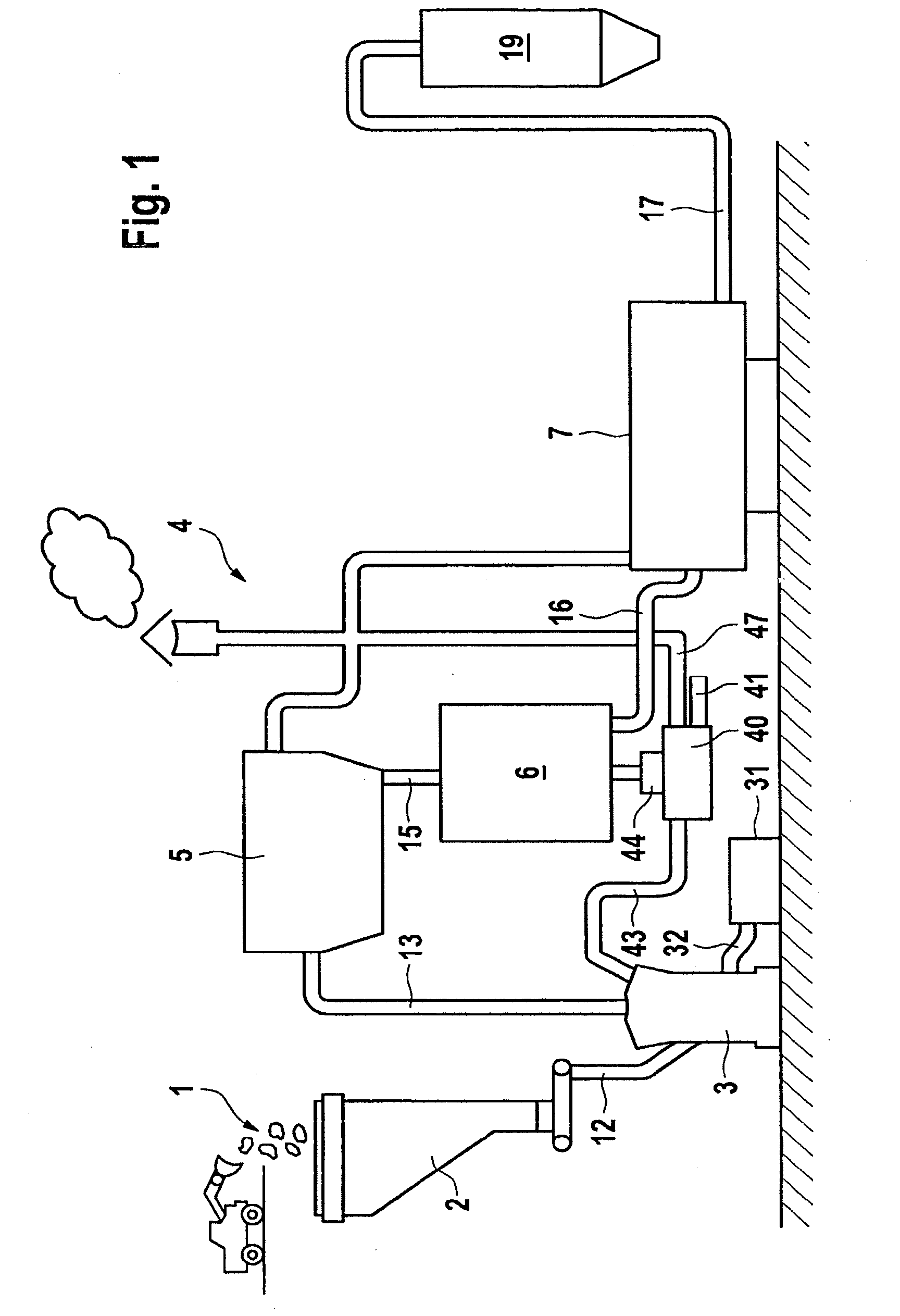

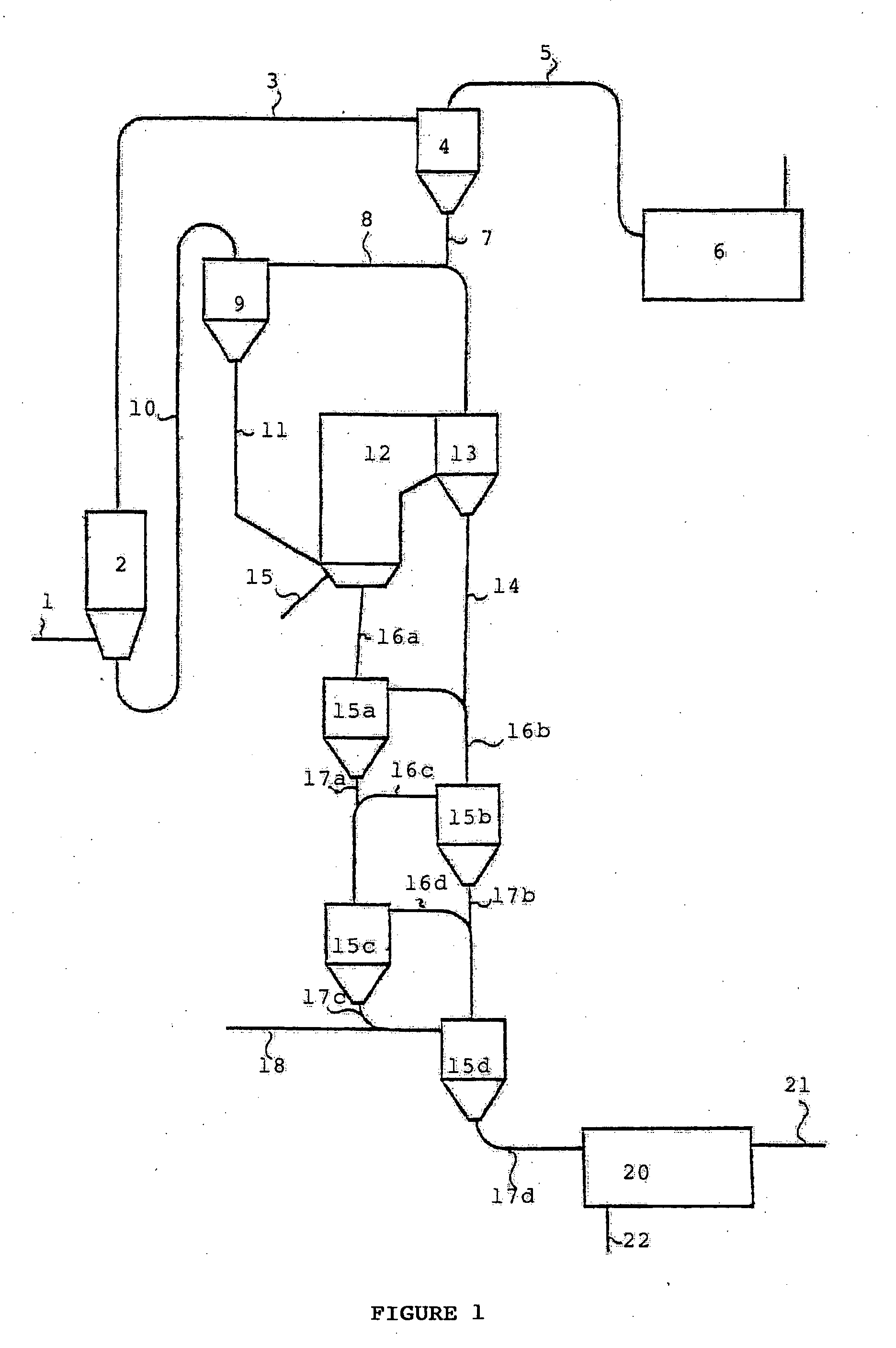

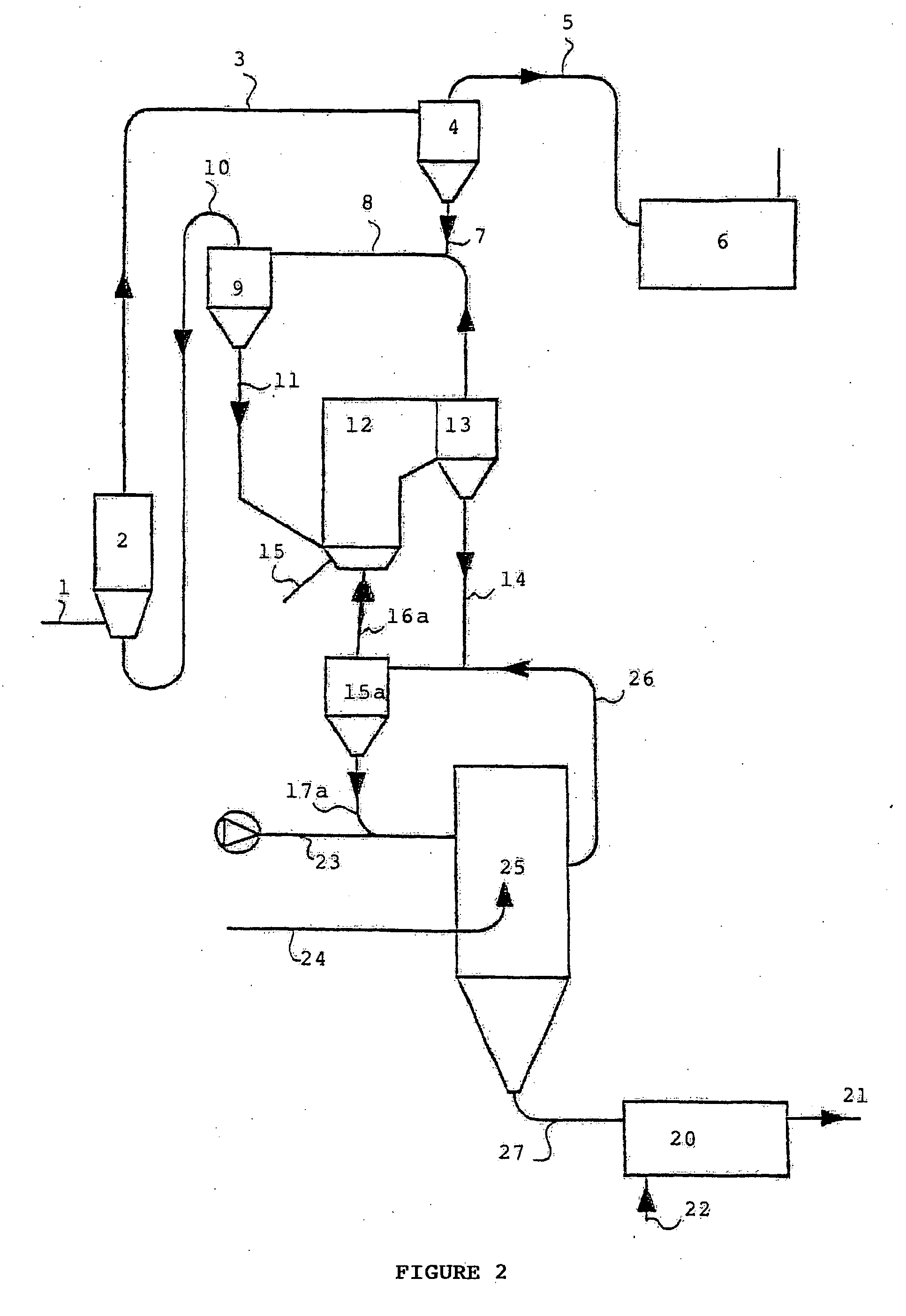

Process and apparatus for the thermal treatment of pulverulent substances

InactiveUS7288501B2Safe handlingMaterial nanotechnologyCatalyst activation/preparationGas solidThermal treatment

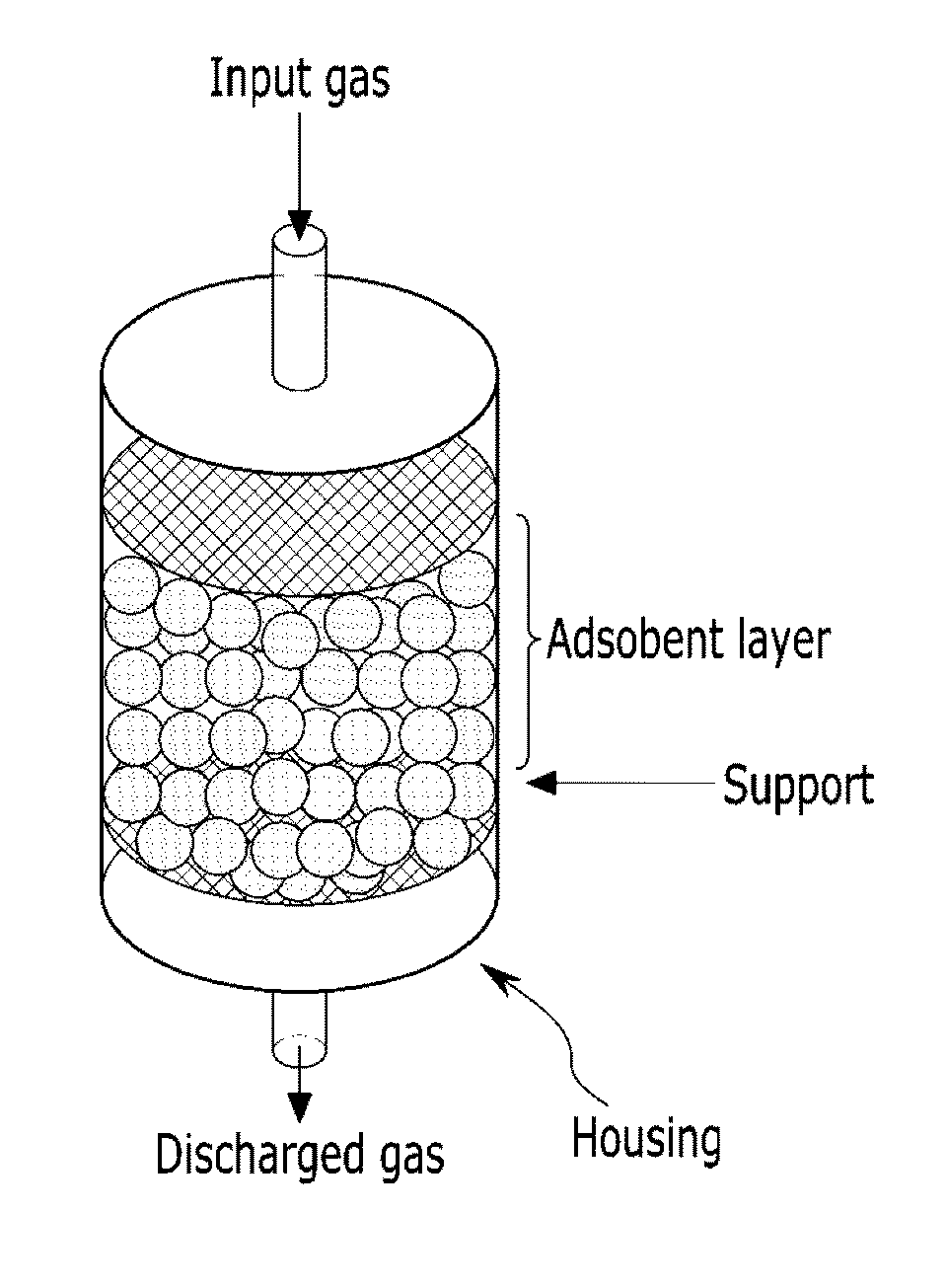

Process and apparatus for the thermal treatment of pulverulent substances, in which the pulverulent substance is dispersed in a carrier gas and is passed in a continuous manner through a heated reactor where it is thermally treated and is then quenched by a cooling medium and is collected in a gas-solids separating unit.

Owner:UMICORE AG & CO KG

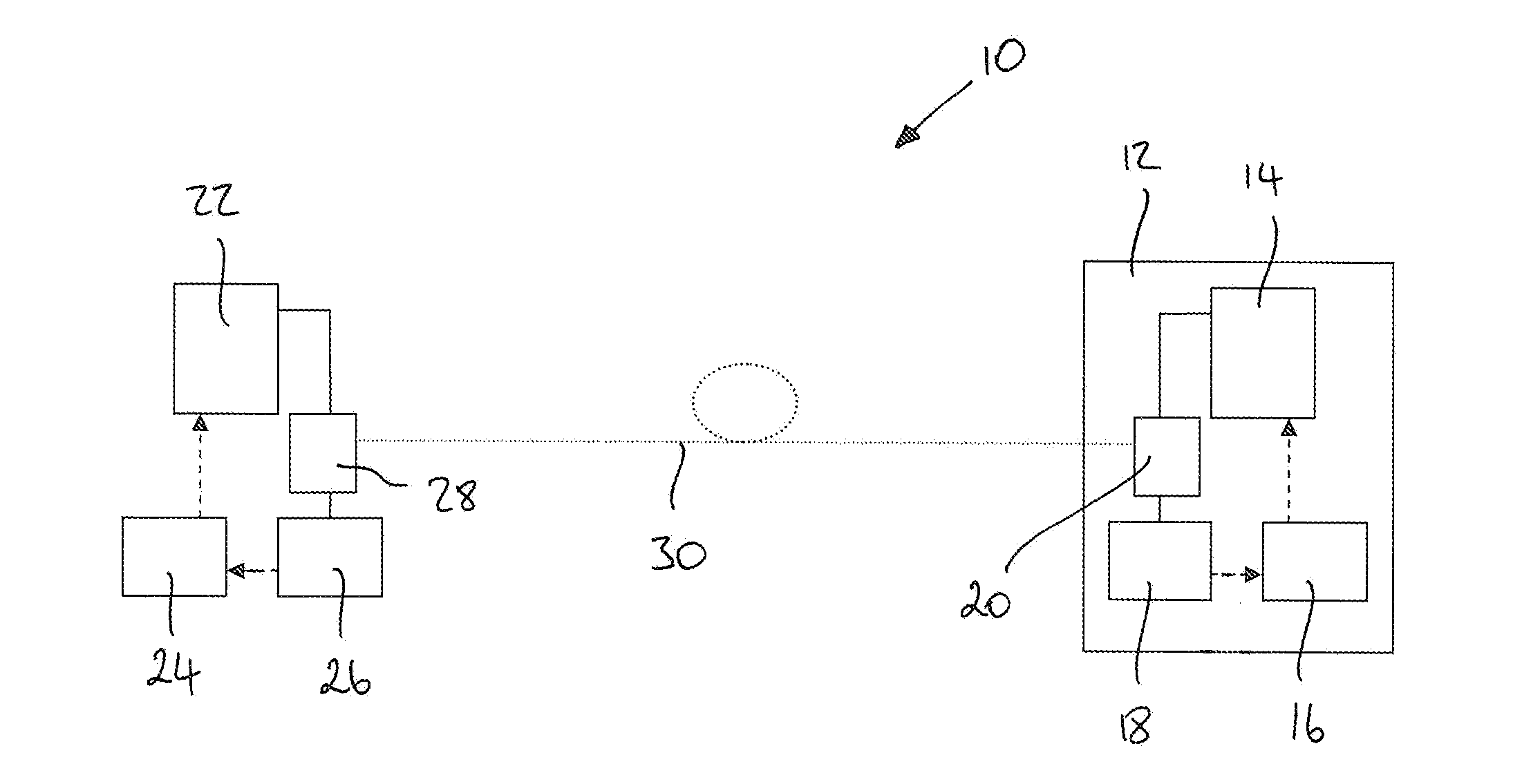

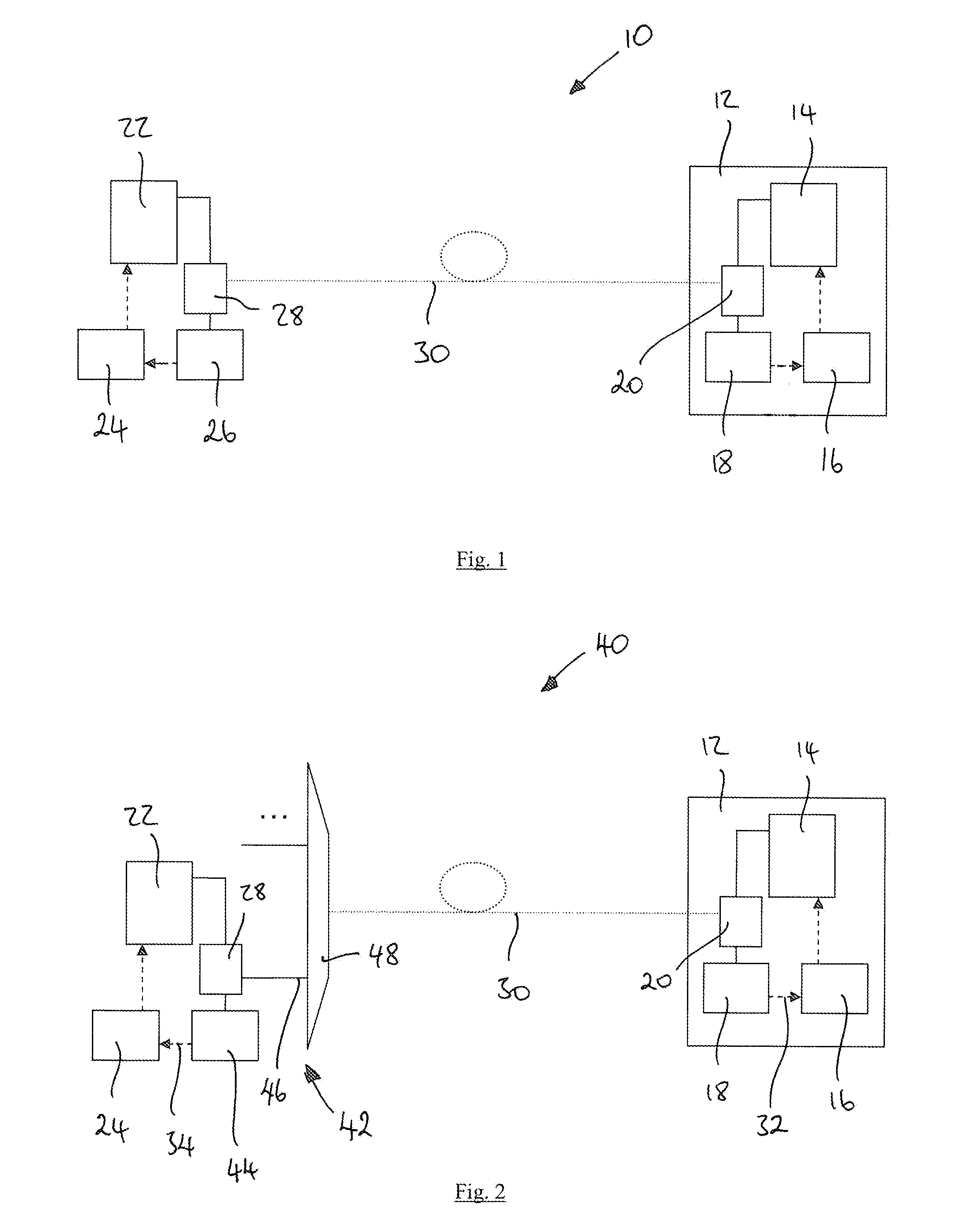

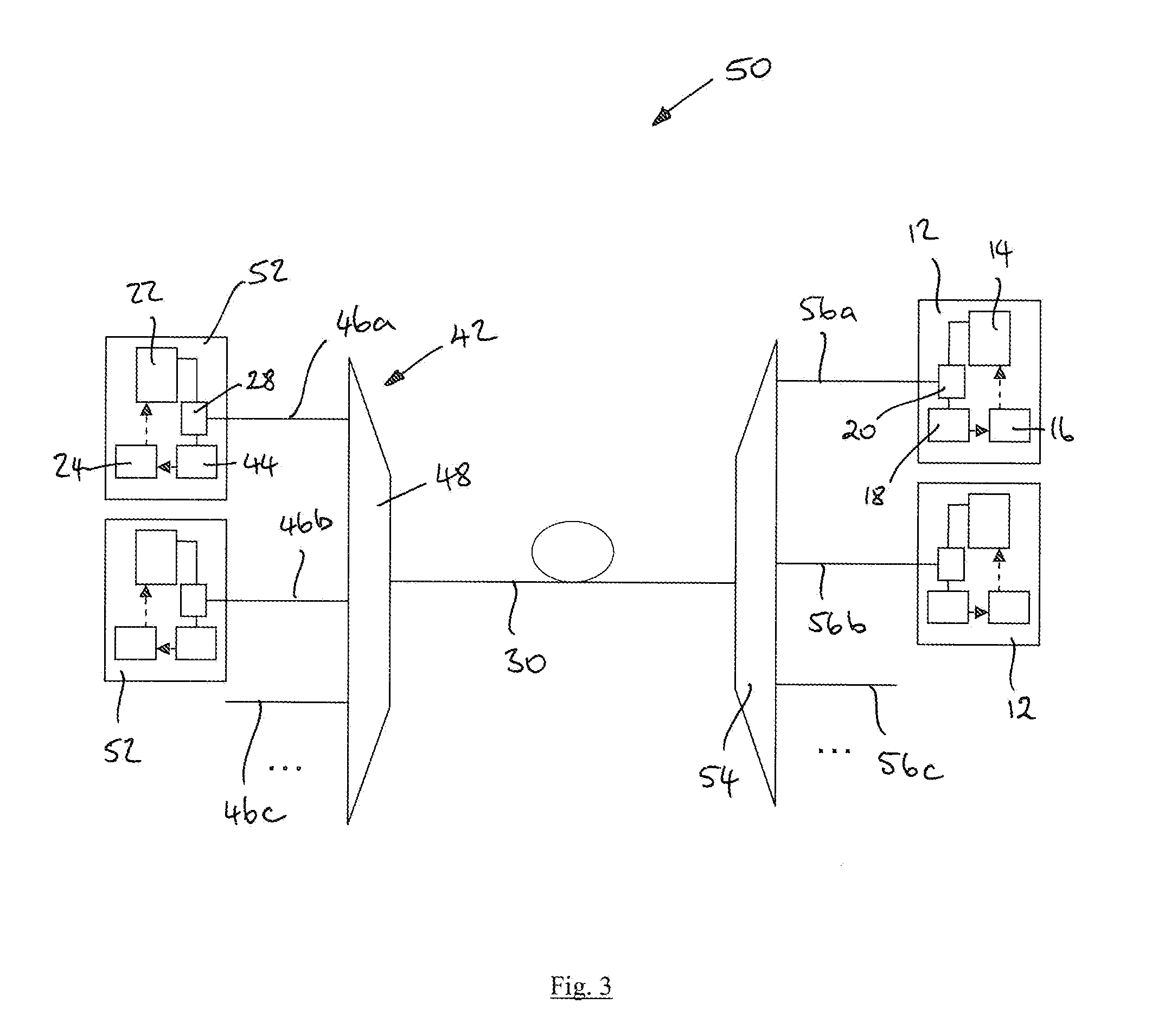

Optical networks

ActiveUS20120224850A1Control power consumptionRotary drum/kiln gasifiersCalcinationLength waveOptical transmitter

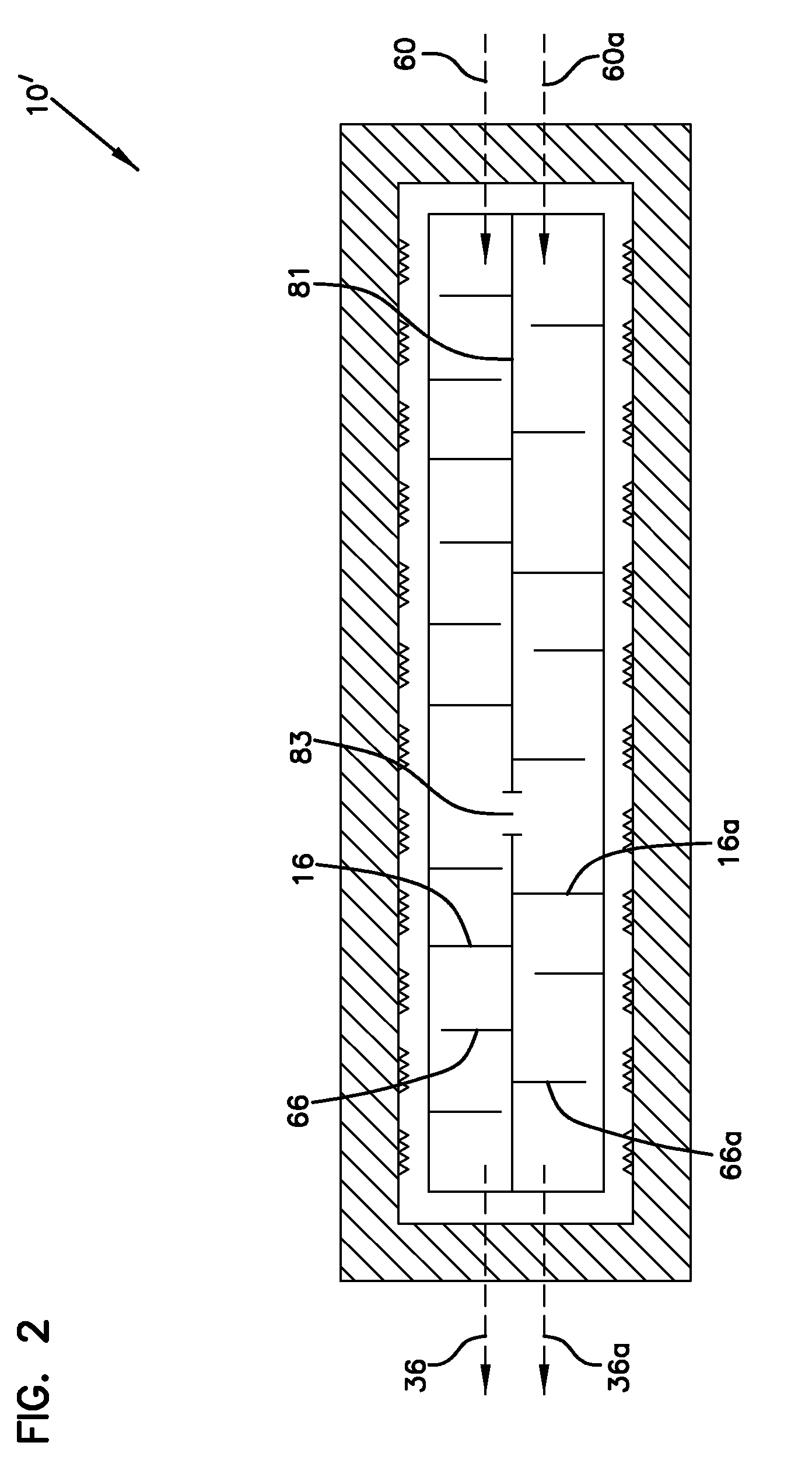

An optical network (10) comprising an optical network element (12) comprising a first optical transmitter (14), a first controller (16), an optical receiver (18), a second optical transmitter (22), a second controller (24) and optical receiver apparatus (26). Said first controller is arranged to control said first optical transmitter to generate and transmit a first optical signal in response no second optical signal being detected. Said first controller is arranged to iteratively generate and transmit said first optical signal at different wavelengths of a plurality of wavelengths until said second optical signal is detected, and is further arranged to subsequently maintain generation and transmission of said first optical signal at said wavelength at which said second optical signal is detected. Said second controller is arranged to control said second optical transmitter to generate and transmit said second optical signal following detection of said first optical signal by said optical receiver apparatus.

Owner:TELEFON AB LM ERICSSON (PUBL)

Visible-light response hybrid aerogel and preparation method and application thereof in waste gas processing

ActiveUS20200016585A1Low costEasily recombinedMaterial nanotechnologyGas treatmentPollutionMaterials science

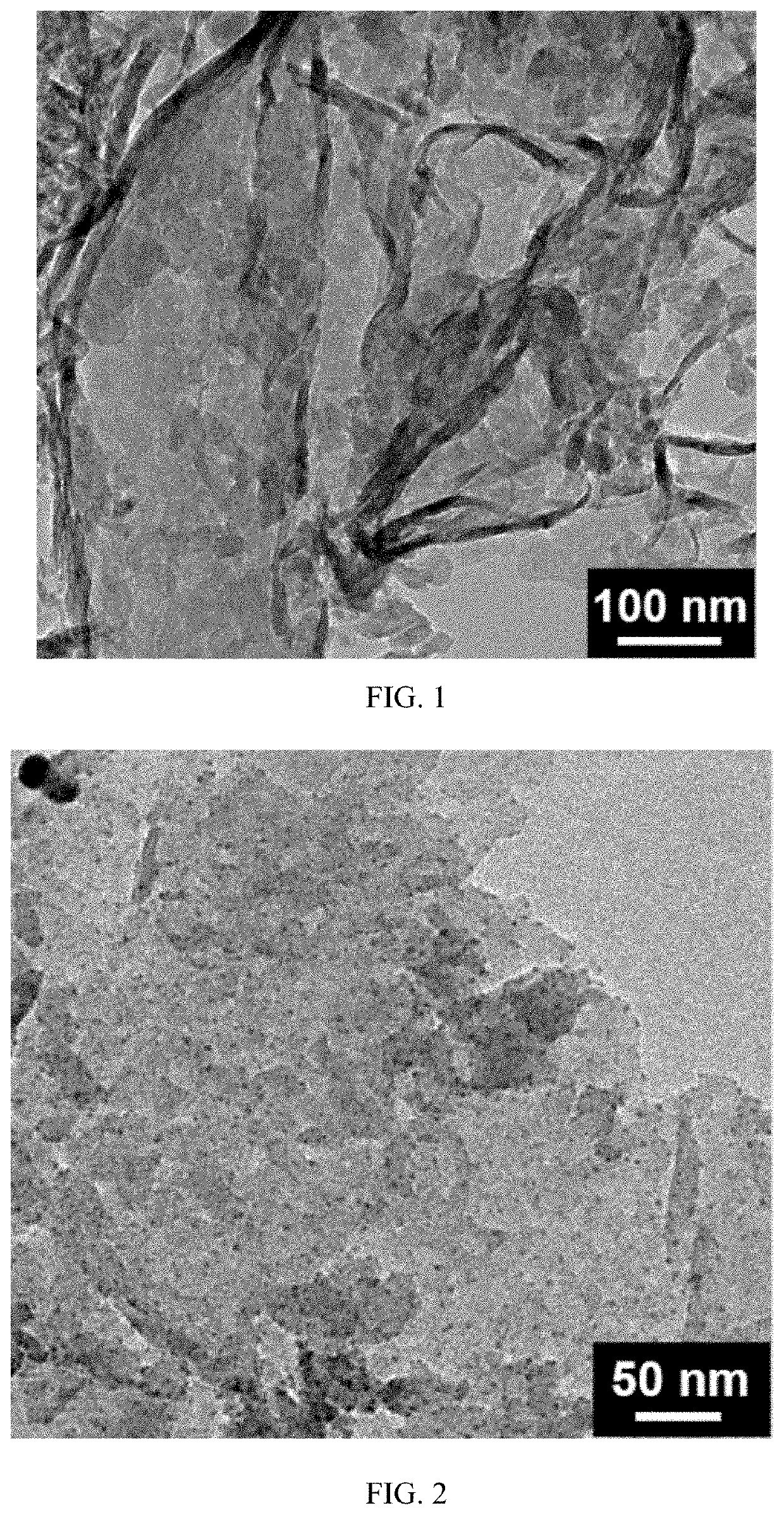

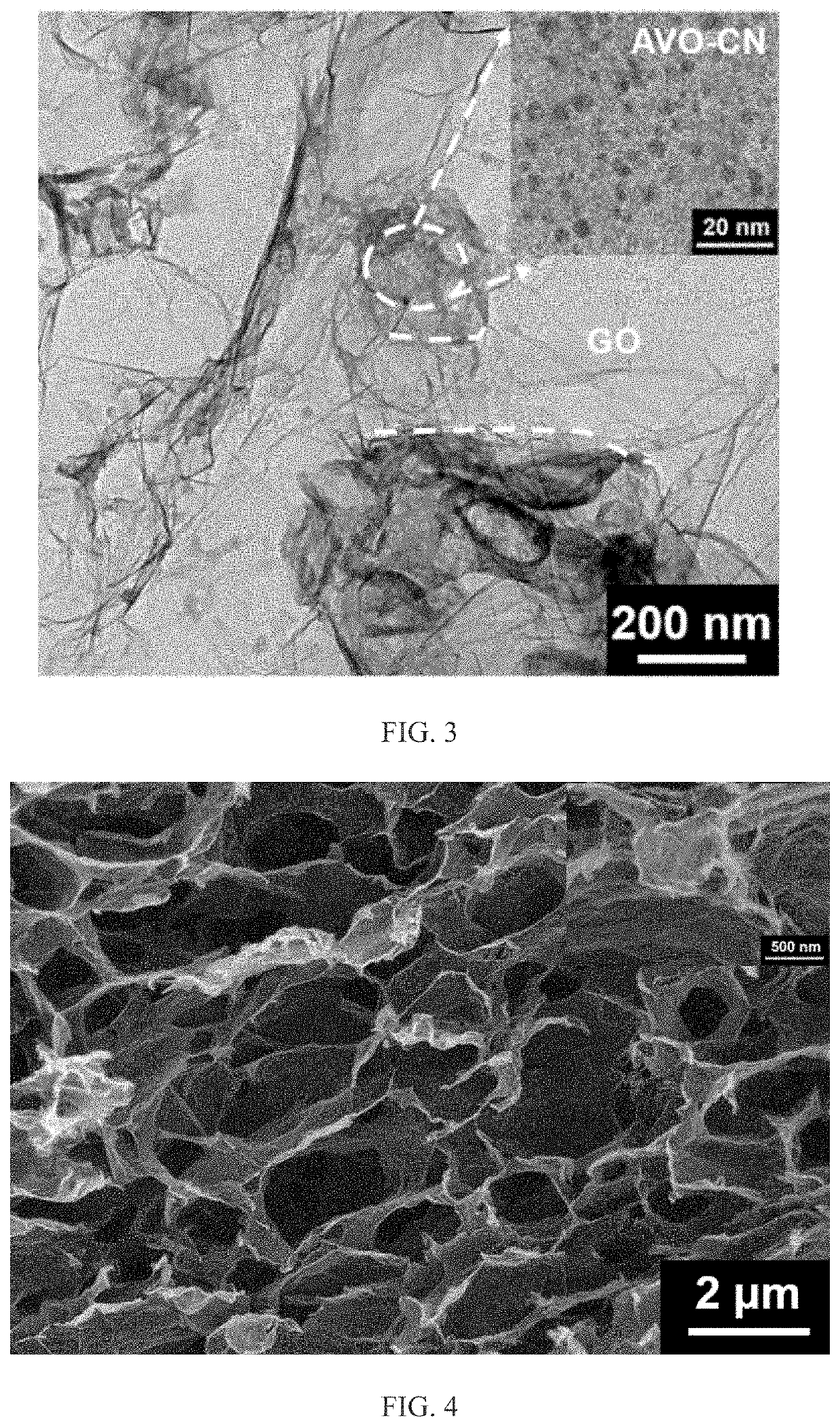

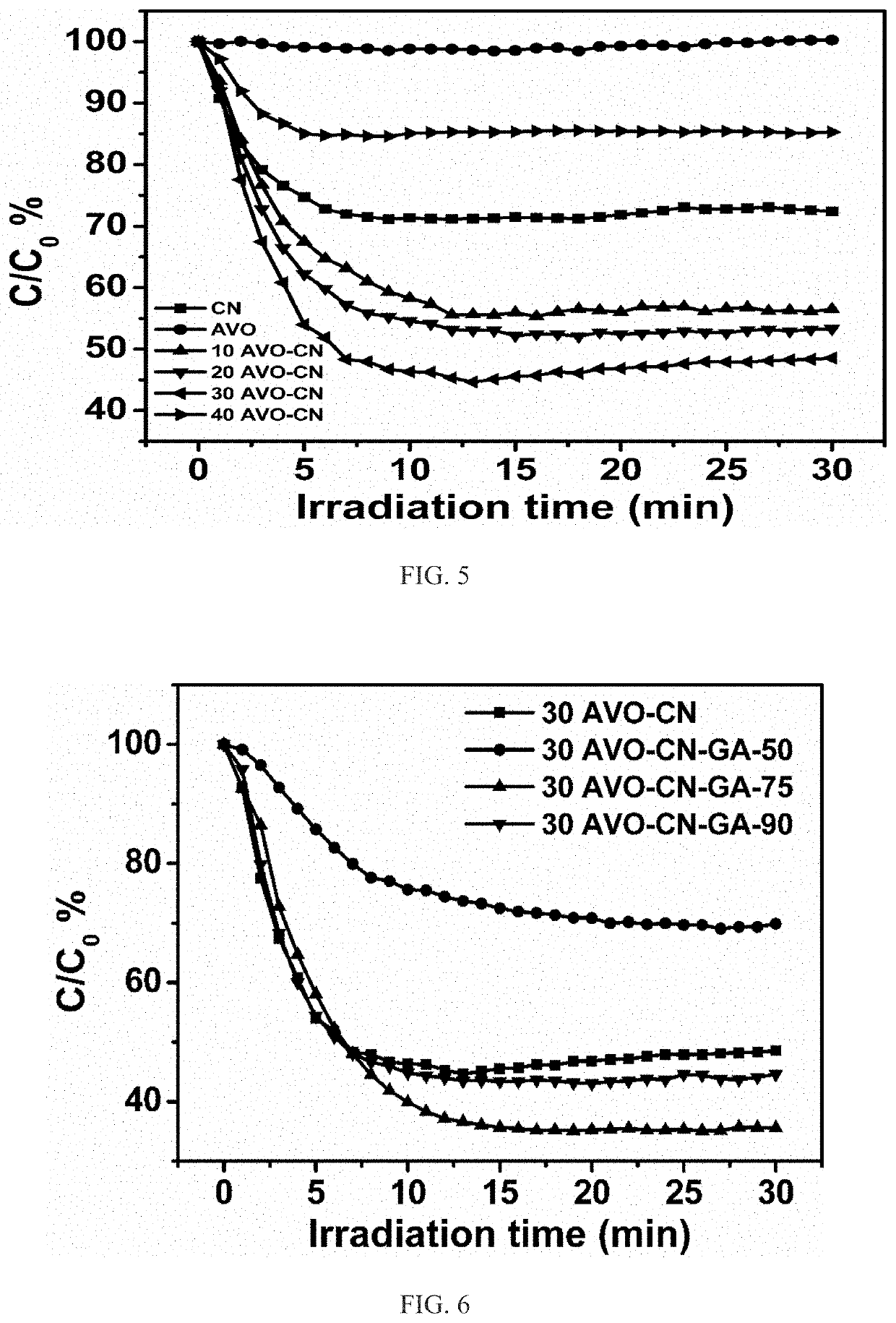

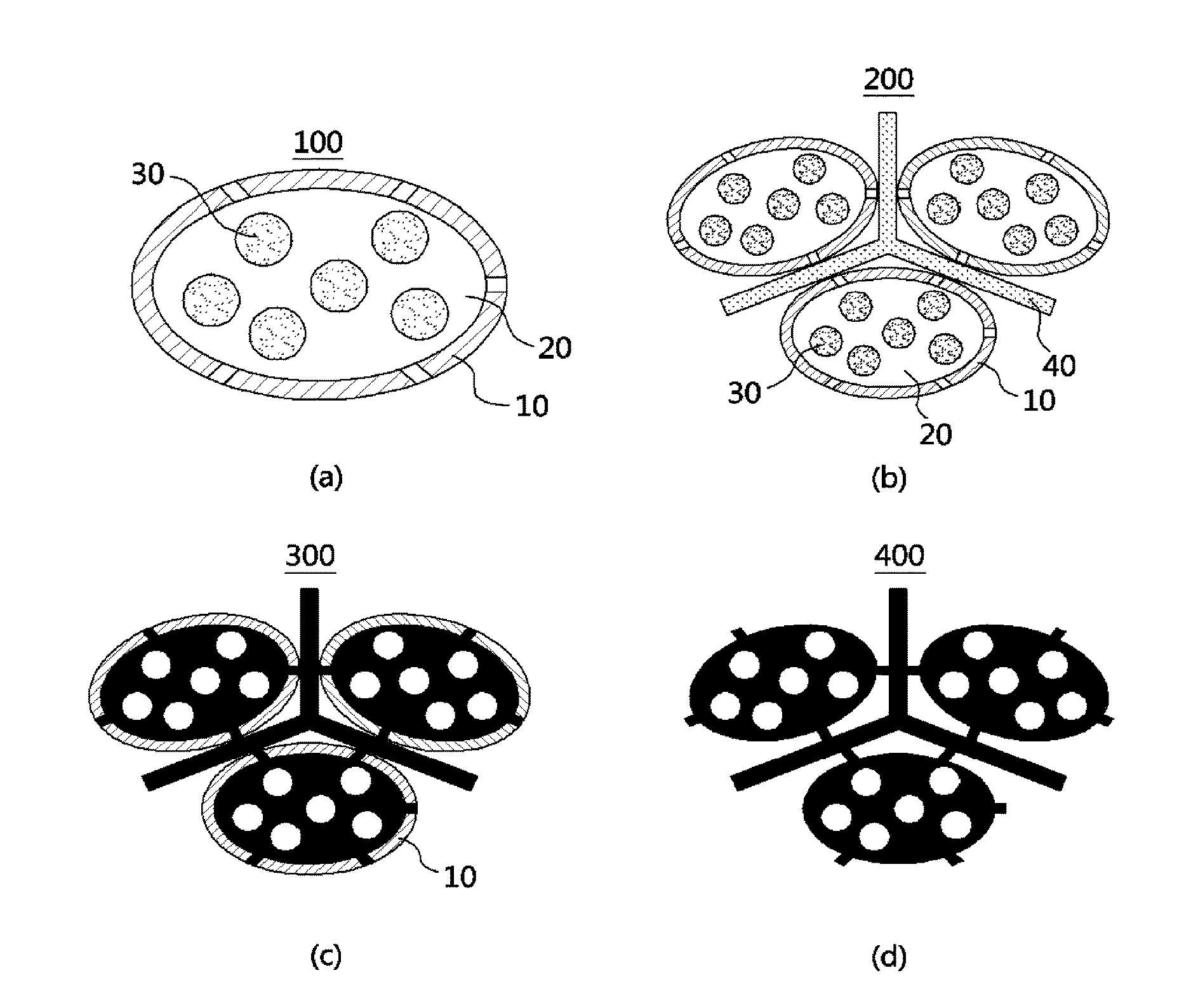

Visible-light response hybrid aerogel and a preparation method and application thereof in waste gas processing are disclosed. Dicyandiamide is taken as a precursor and is calcined in two times to prepare a carbon nitride nanosheet; the carbon nitride nanosheet is dispersed in water, silver metavanadate quantum dots are subjected to in-situ growth to prepare a silver metavanadate quantum dot / carbon nitride nanosheet composite material; the silver metavanadate quantum dot / carbon nitride nanosheet composite material and graphene oxide carry out hydrothermal reaction, and are then frozen and dried to prepare silver metavanadate quantum dot / carbon nitride nanosheet / graphene hybrid aerogel which is the visible-light response hybrid aerogel. The problems of large reduction dosage, serious secondary pollution, complexity in operation and the like generated when waste gas is processed by a traditional flue gas denitration technology are overcome.

Owner:SUZHOU UNIV

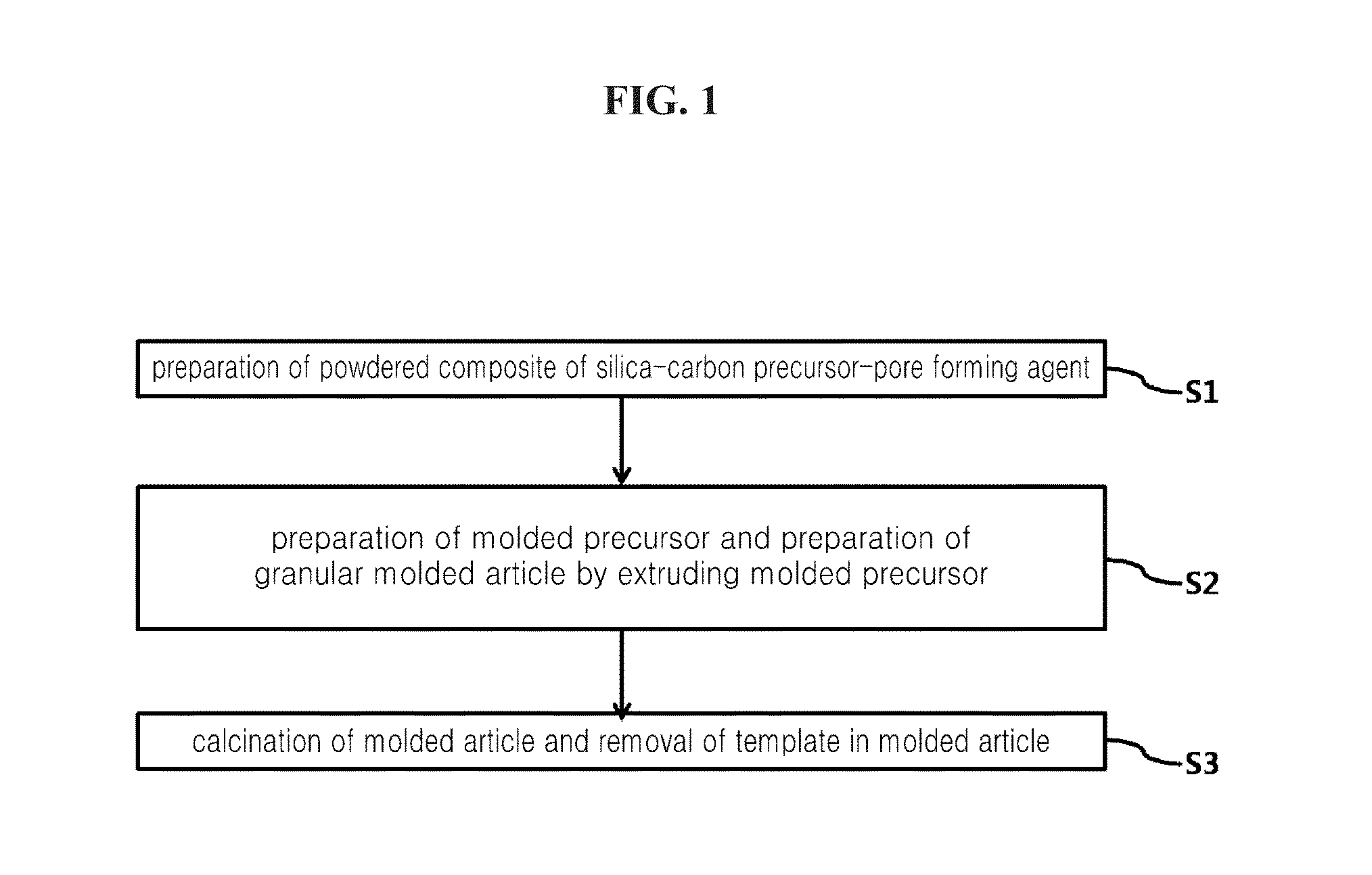

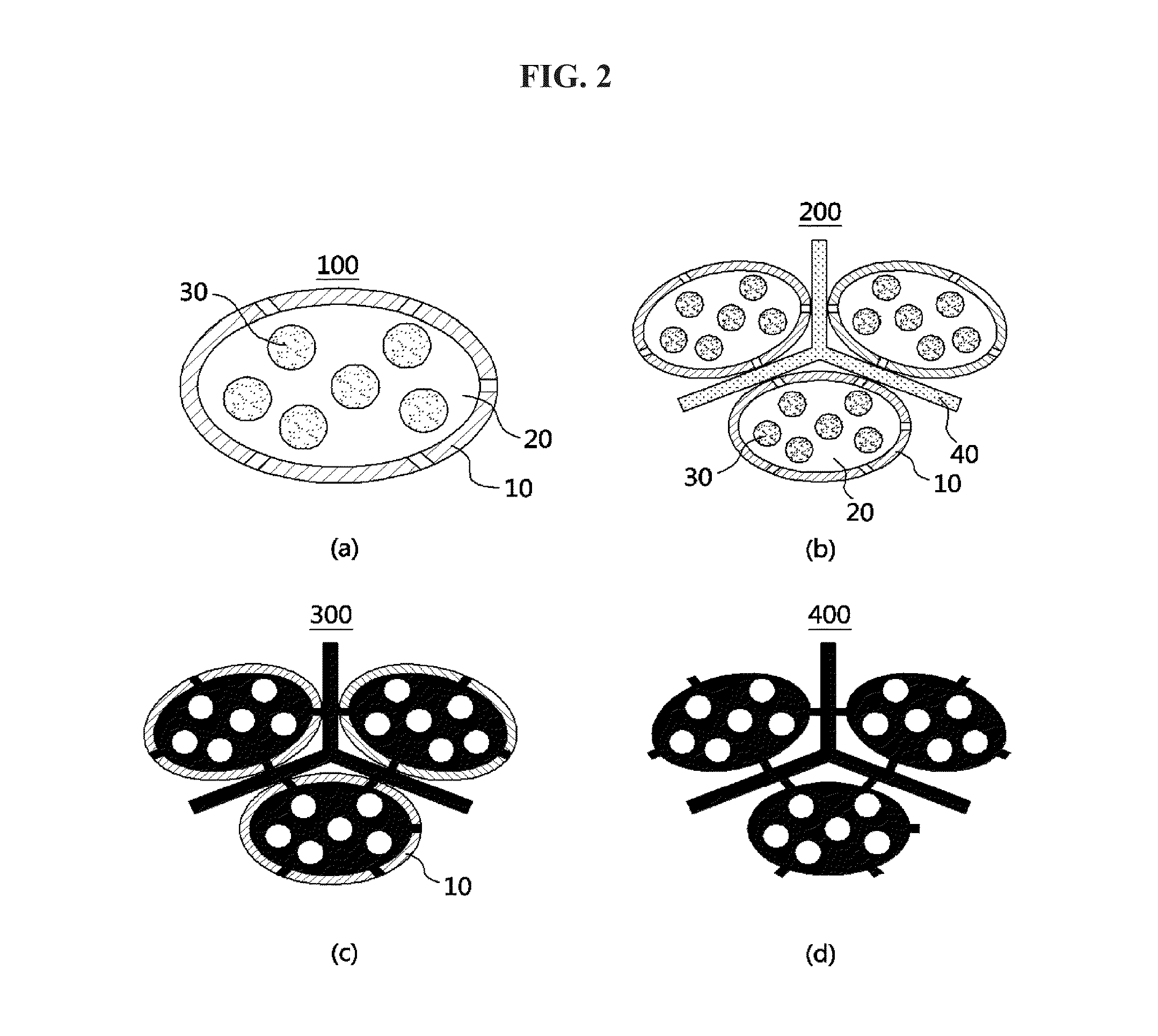

Preparation method for granular carbon mesoporous structure

ActiveUS20130096001A1Simple processLow costMaterial nanotechnologyCarbon compoundsSilicon dioxideMaterials science

Disclosed is a preparation method for a granular carbon mesoporous structure. The preparation method includes the steps of preparing a powdered composite of silica-carbon precursor-pore forming agent by using a mixture including a silica precursor, a carbon precursor and a pore forming agent, preparing a molded precursor by mixing the composite with an organic additive, preparing a granular molded article by extruding or injection-molding the molded precursor, calcinating the molded article, and etching silica included in the calcinated molded article.

Owner:GWANGJU INST OF SCI & TECH

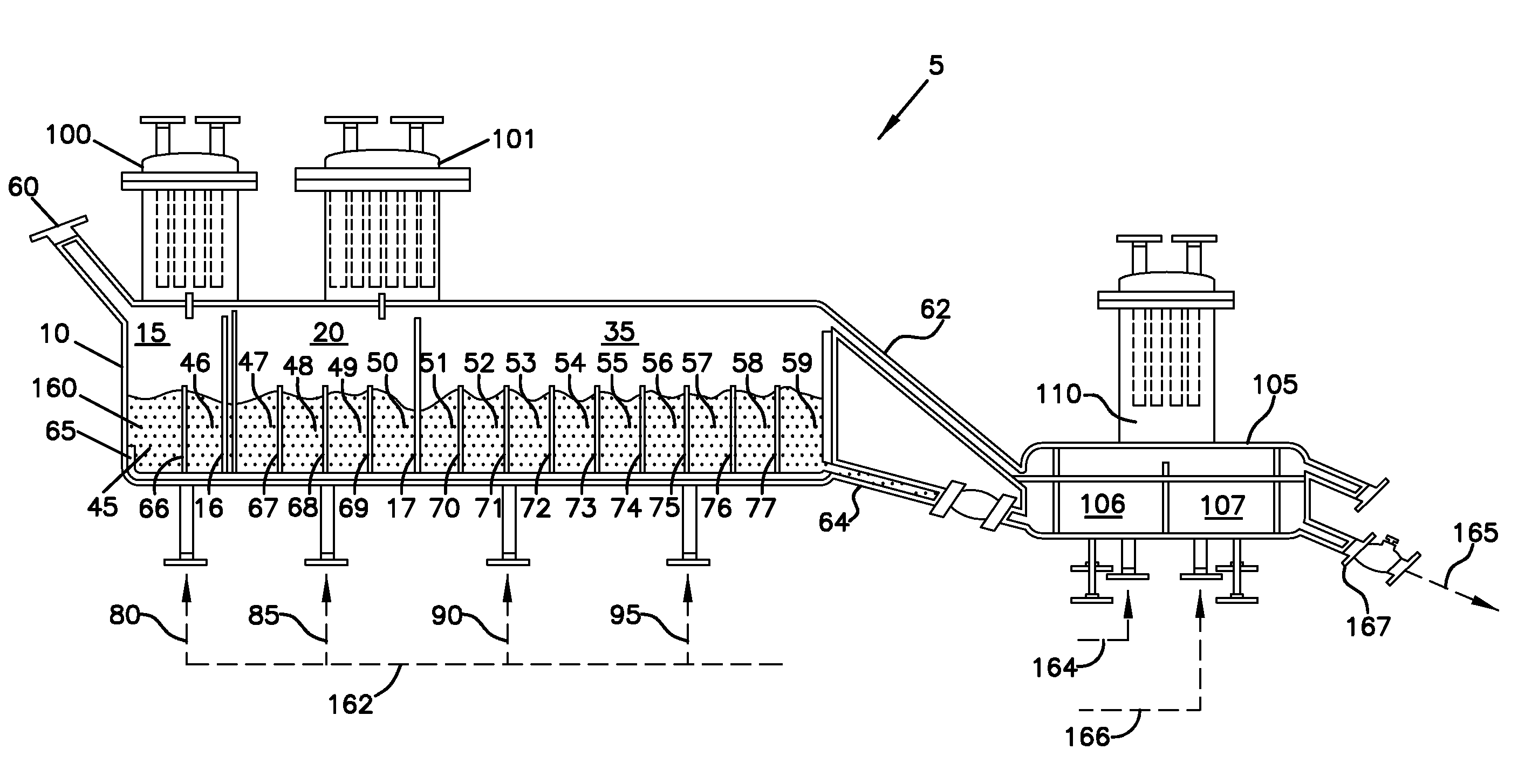

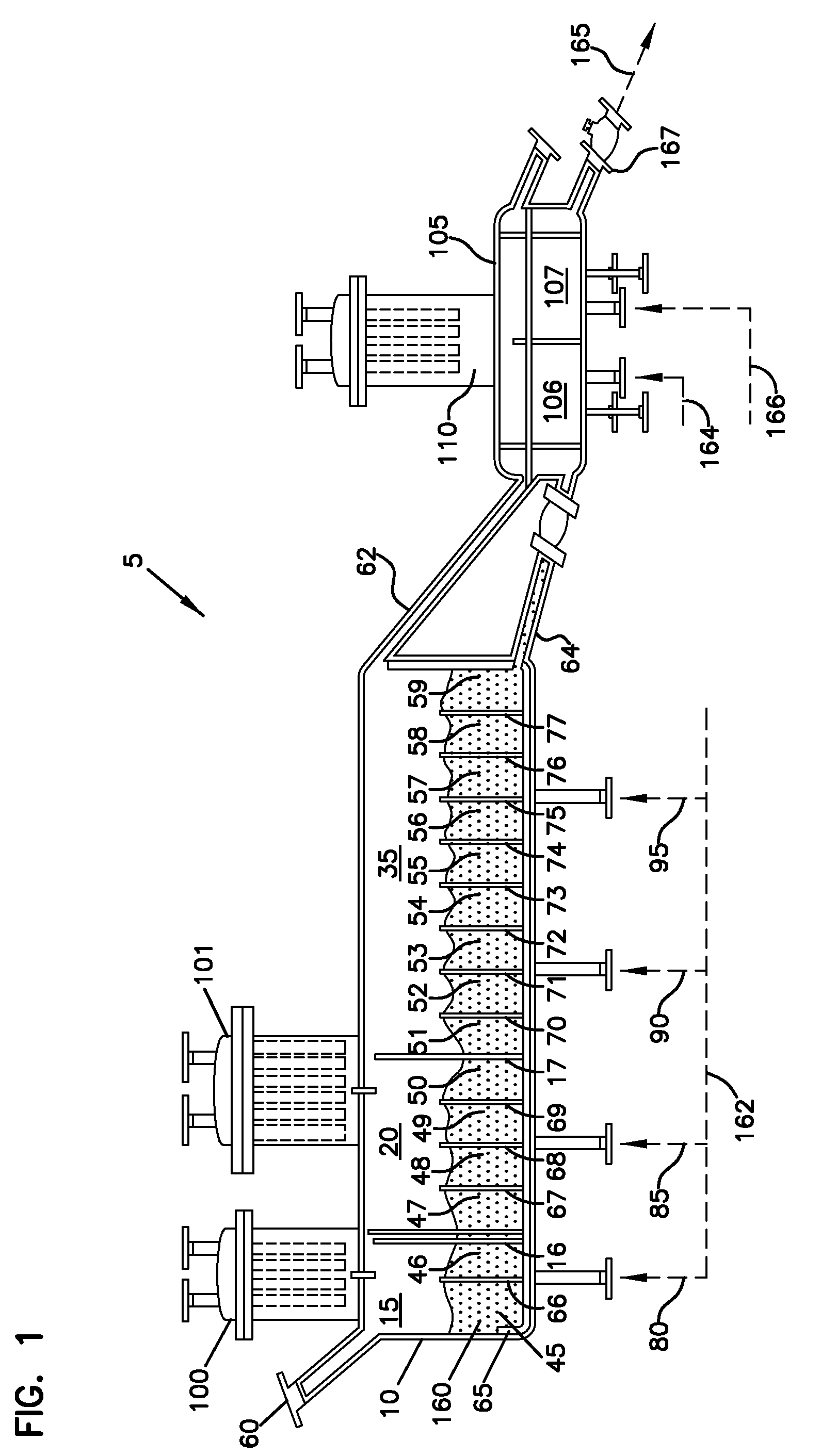

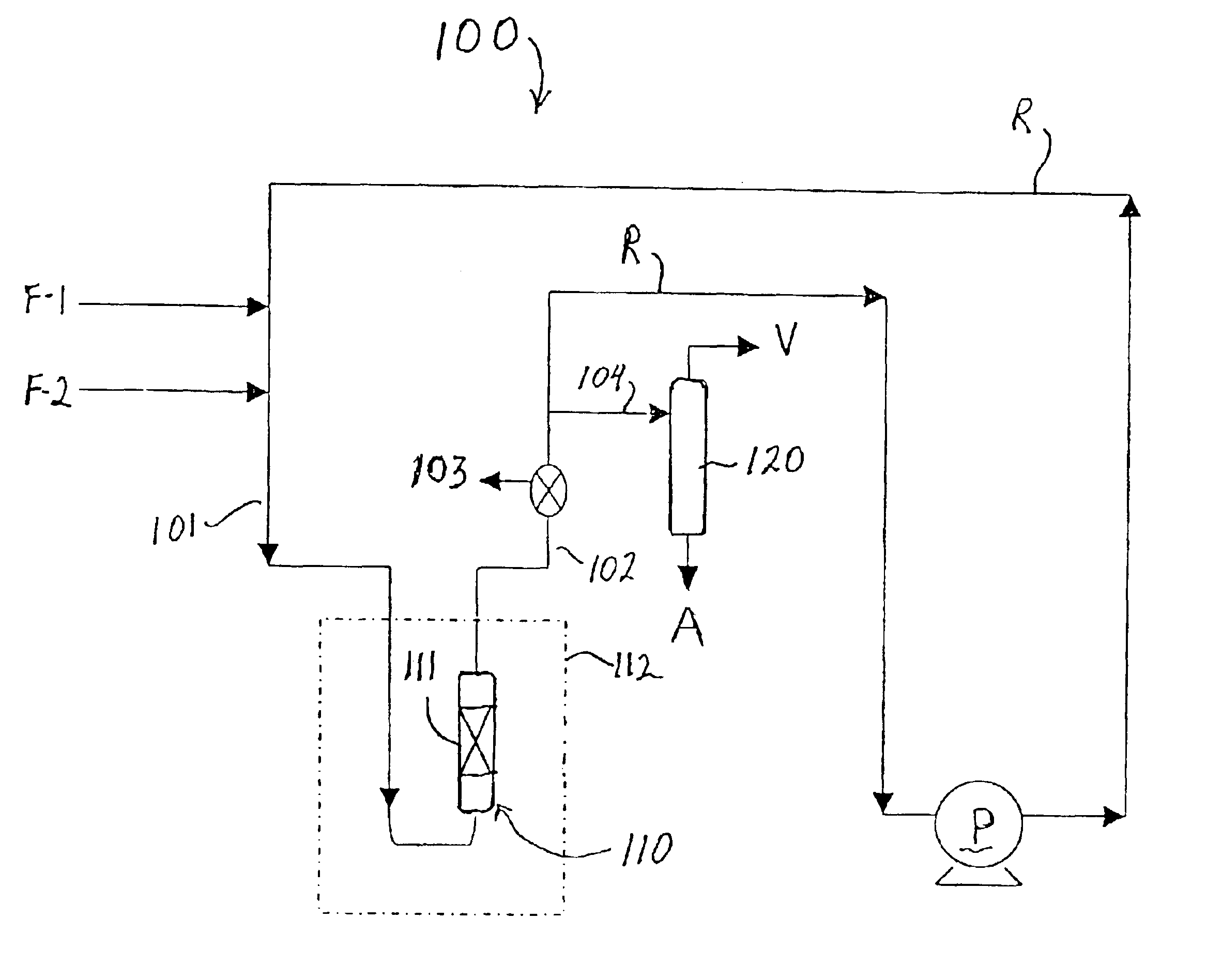

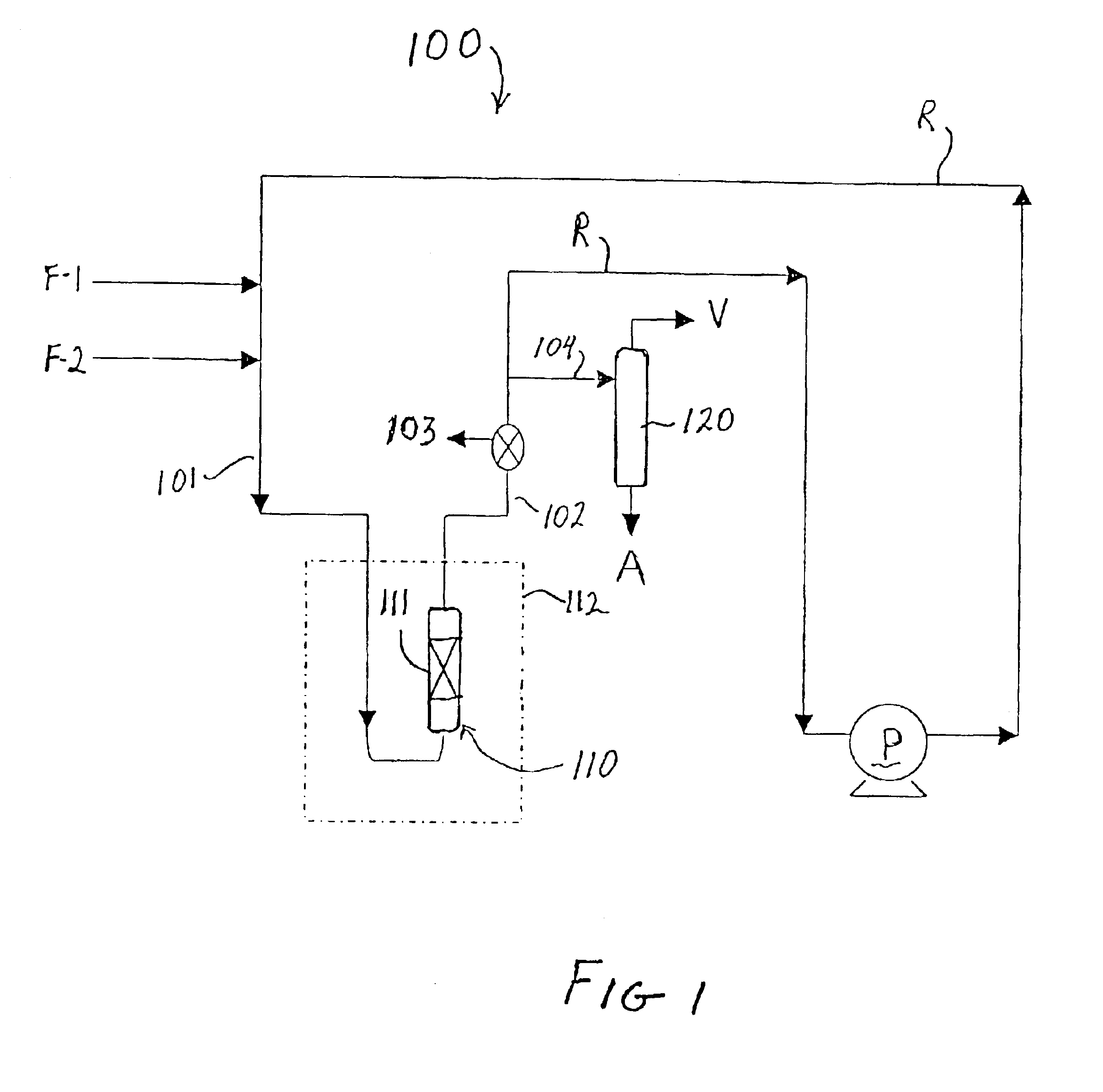

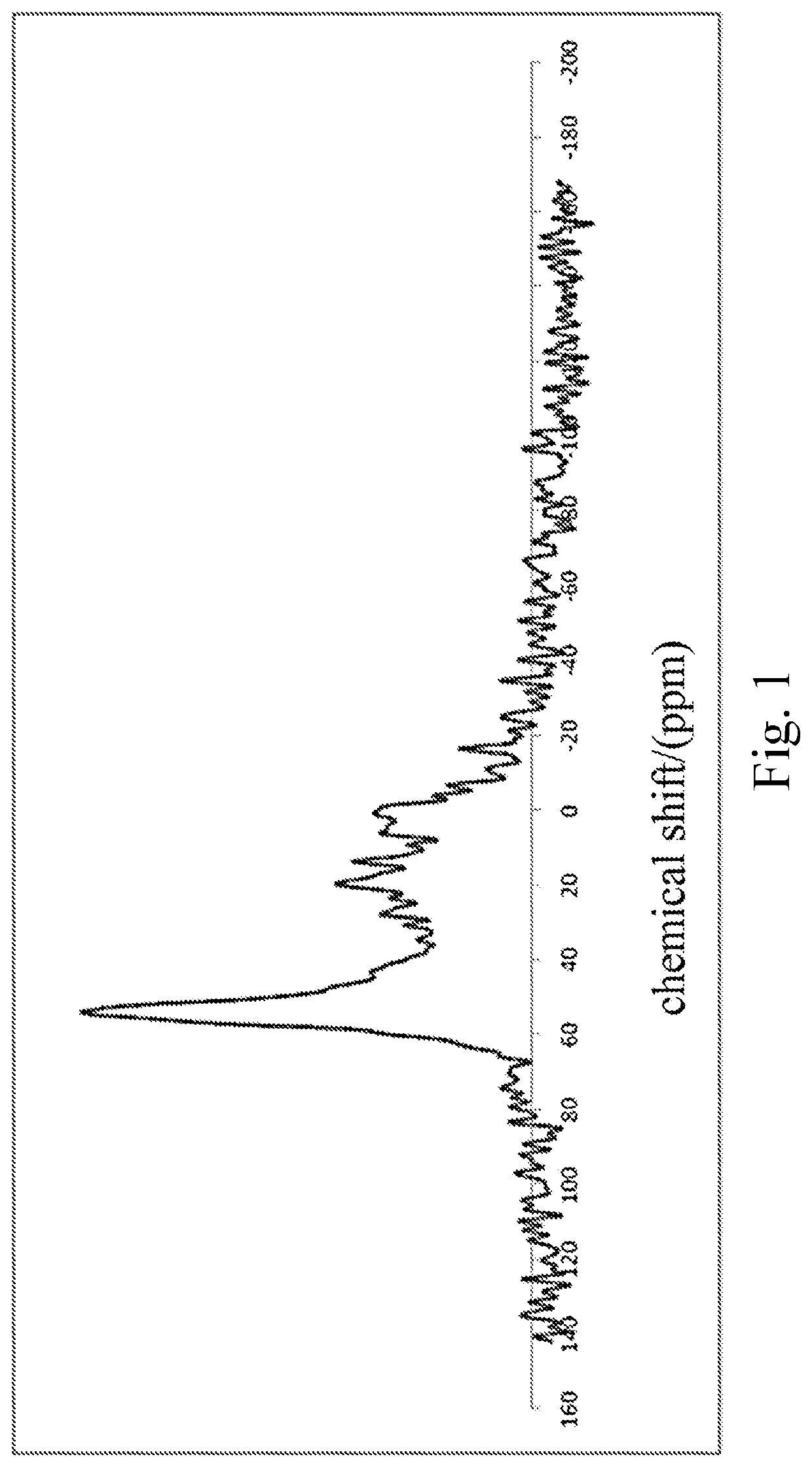

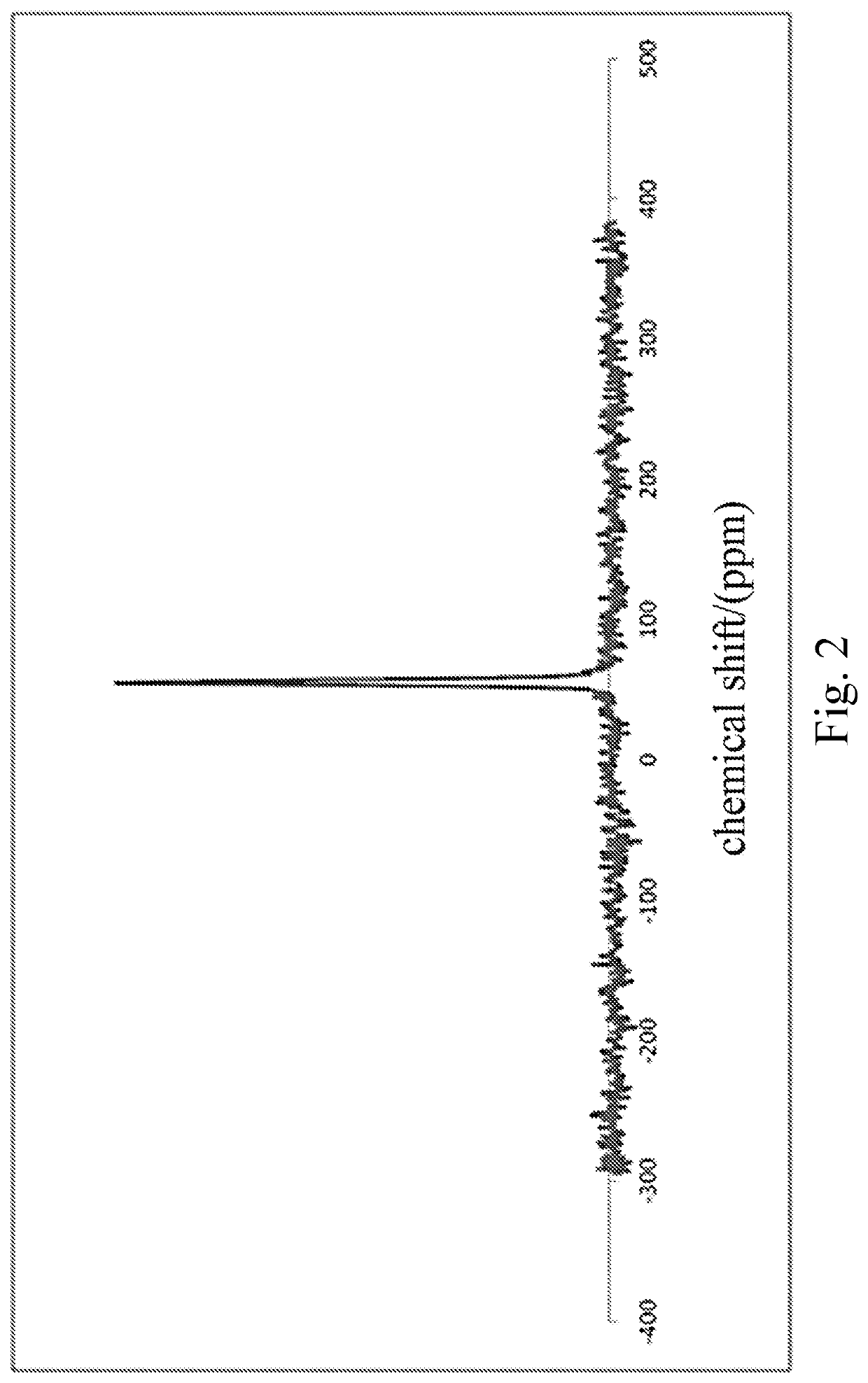

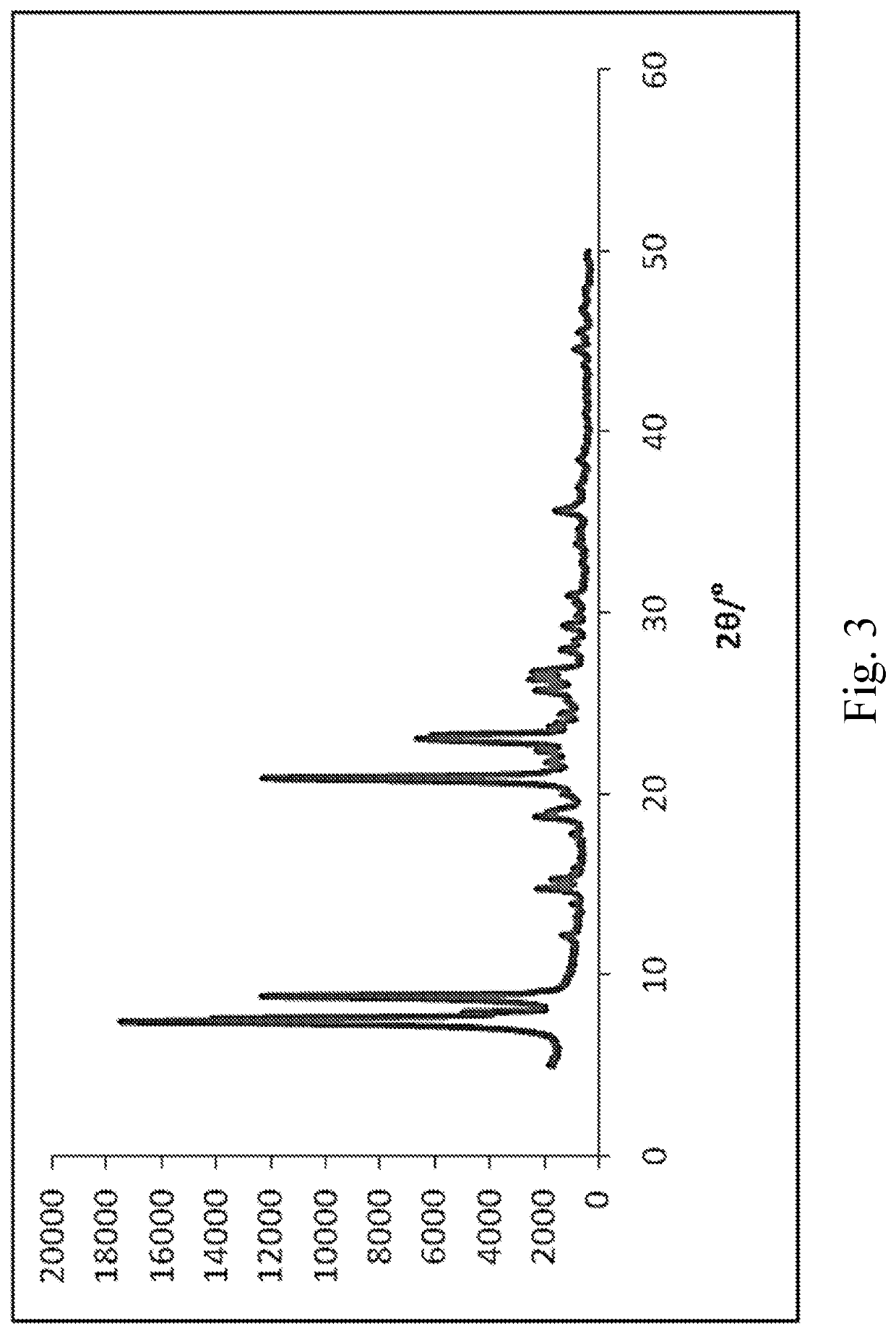

Continuous preparation of calcined chemically-treated solid oxides

The present invention discloses a continuous calcination vessel which can be used to prepare calcined chemically-treated solid oxides from solid oxides and chemically-treated solid oxides. A process for the continuous preparation of calcined chemically-treated solid oxides is also provided. Calcined chemically-treated solid oxides disclosed herein can be used in catalyst compositions for the polymerization of olefins.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

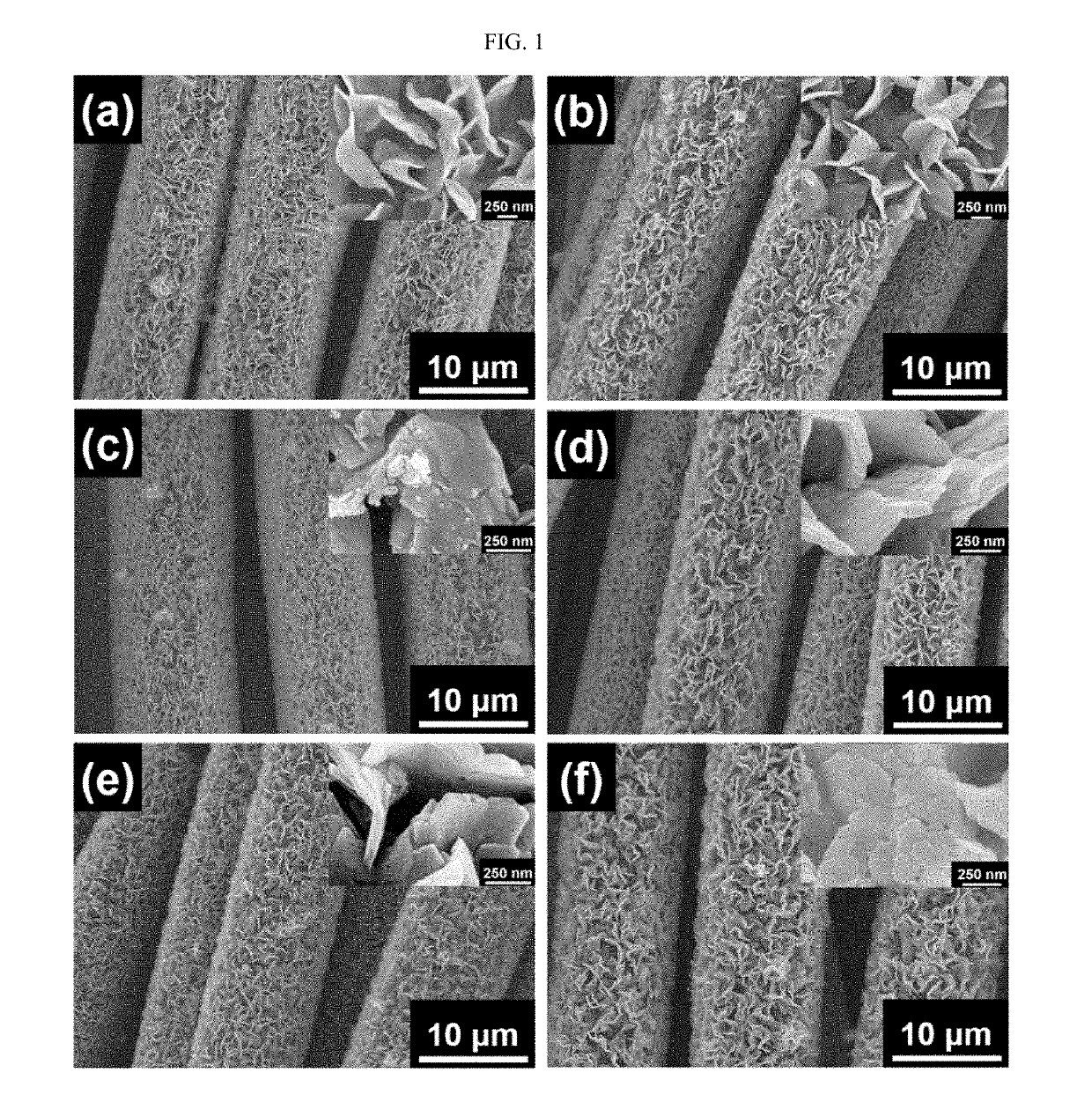

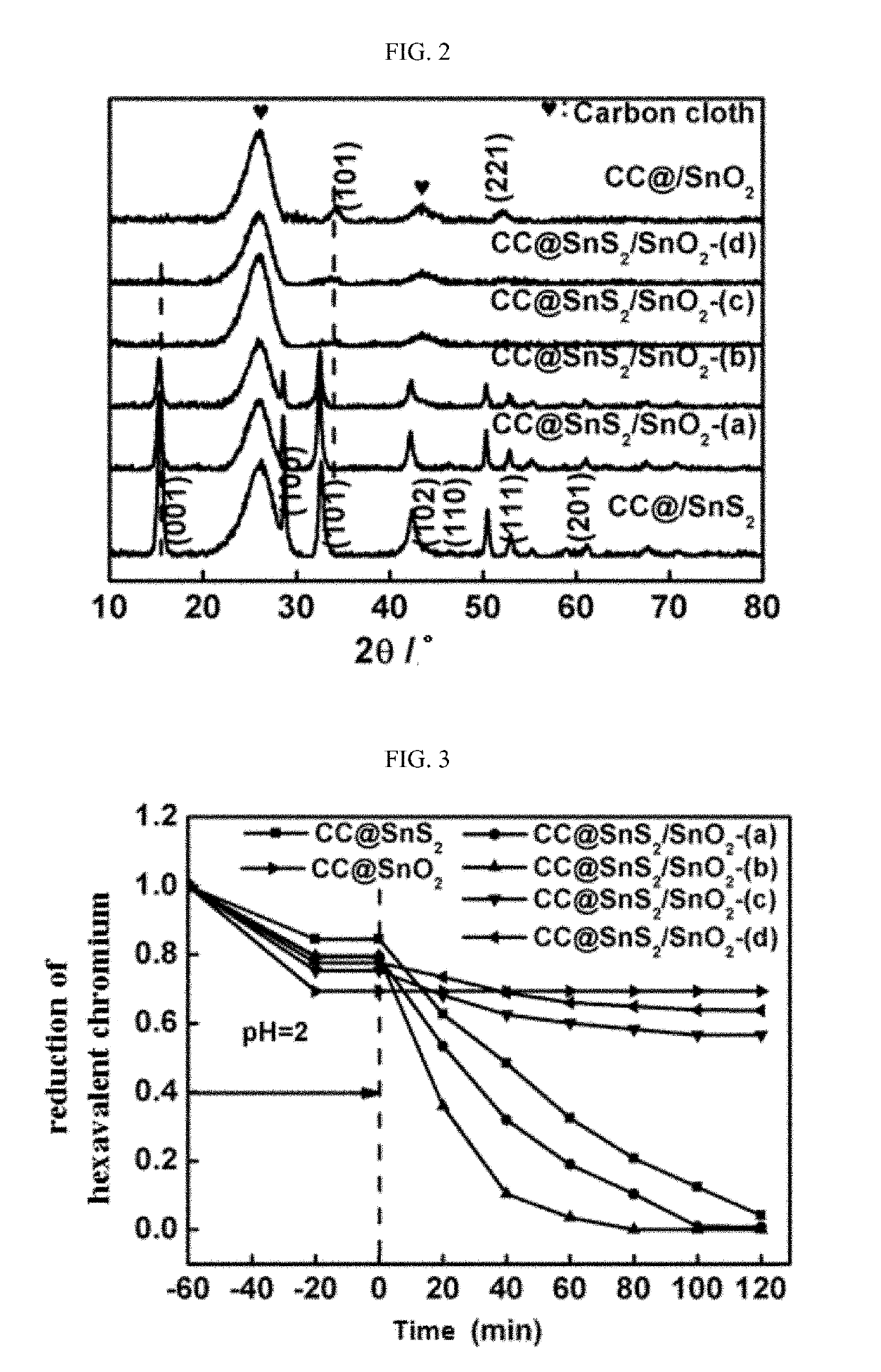

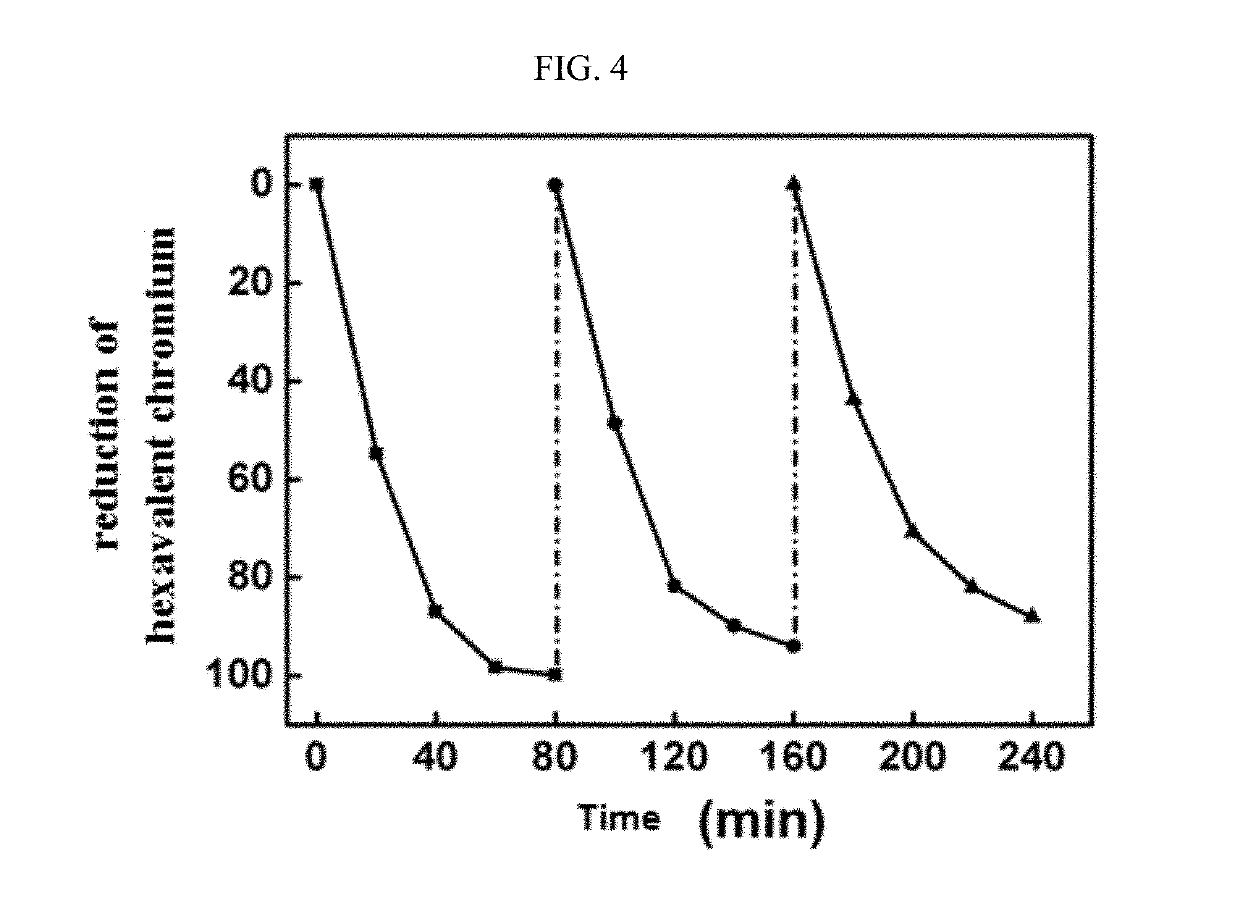

Preparation method of a visible-light-driven cc@sns2/sno2 composite catalyst, and application thereof

ActiveUS20190126243A1Easy to makeAbundant sourcesWater/sewage treatment by irradiationWater treatment compoundsFiberElectrolysis

The present invention disclosed preparation method of a visible-light-driven CC@SnS2 / SnO2 composite catalyst, and application thereof, comprising the following steps: preparing CC@SnS2 composite material in a solvent by using SnCl4.5H2O and C2H5NS as raw materials and carbon fiber cloth as a supporting material; calcining said CC@SnS2 composite material to obtain the visible-light-driven CC@SnS2 / SnO2 composite catalyst. The present invention overcomes defects of the traditional methods of treating chromium-containing wastewater, including chemical precipitation, adsorption, ion exchange resin and electrolysis, and the photocatalytic technology can make full use of solar light source or artificial light source without adding adsorbent or reducing agent. In this case, the use of semiconductor photocatalyst to convert hexavalent chromium in chromium wastewater into less toxic and easily precipitated trivalent chromium greatly reduces the cost and energy consumption.

Owner:SUZHOU UNIV

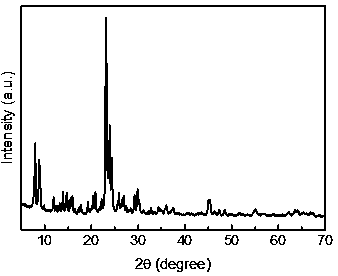

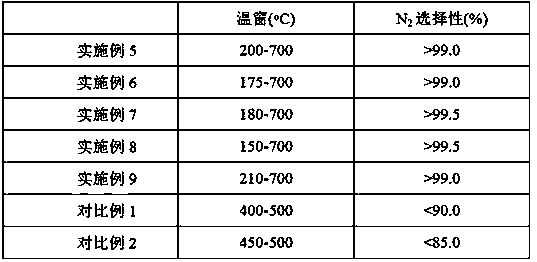

Preparation method and application of mesoporous FeCu-ZSM-5 molecular sieve

PendingCN109317188AOvercoming cumbersome stepsOvercome costsNitrous oxide captureGas treatmentIon exchangeZSM-5

The invention belongs to the technical field of green preparation of environmental-friendly catalysts, discloses a preparation method and application of a mesoporous FeCu-ZSM-5 molecular sieve, and particularly relates to a method for synthesizing the mesoporous FeCu-ZSM-5 molecular sieve through a one-pot method, and the application of the mesoporous FeCu-ZSM-5 molecular sieve in selective catalytic reduction (SCR) denitration reaction. Two times of roasting carried out after demoulding and ion exchange are firstly combined into one, namely, through exchanging and one-time roasting the synthesized raw powder, the FeCu-ZSM-5 molecular sieve with the characteristics of wide temperature window, low cost, good hydrothermal stability, high SCR denitration activity and the like can be directlyprepared, the defects of complicated steps, high cost and high pollutant discharge of a traditional dipping or ion exchange method are overcome, and during the synthesis process, no meso(large)poroustemplate agent is used, and no post-treatment method is adopted to construct a mesopore, so that the method provided by the invention not only has the advantages of simple process, simplicity and convenience in operation and the like, and has favorable economic and environment benefits.

Owner:FUZHOU UNIV

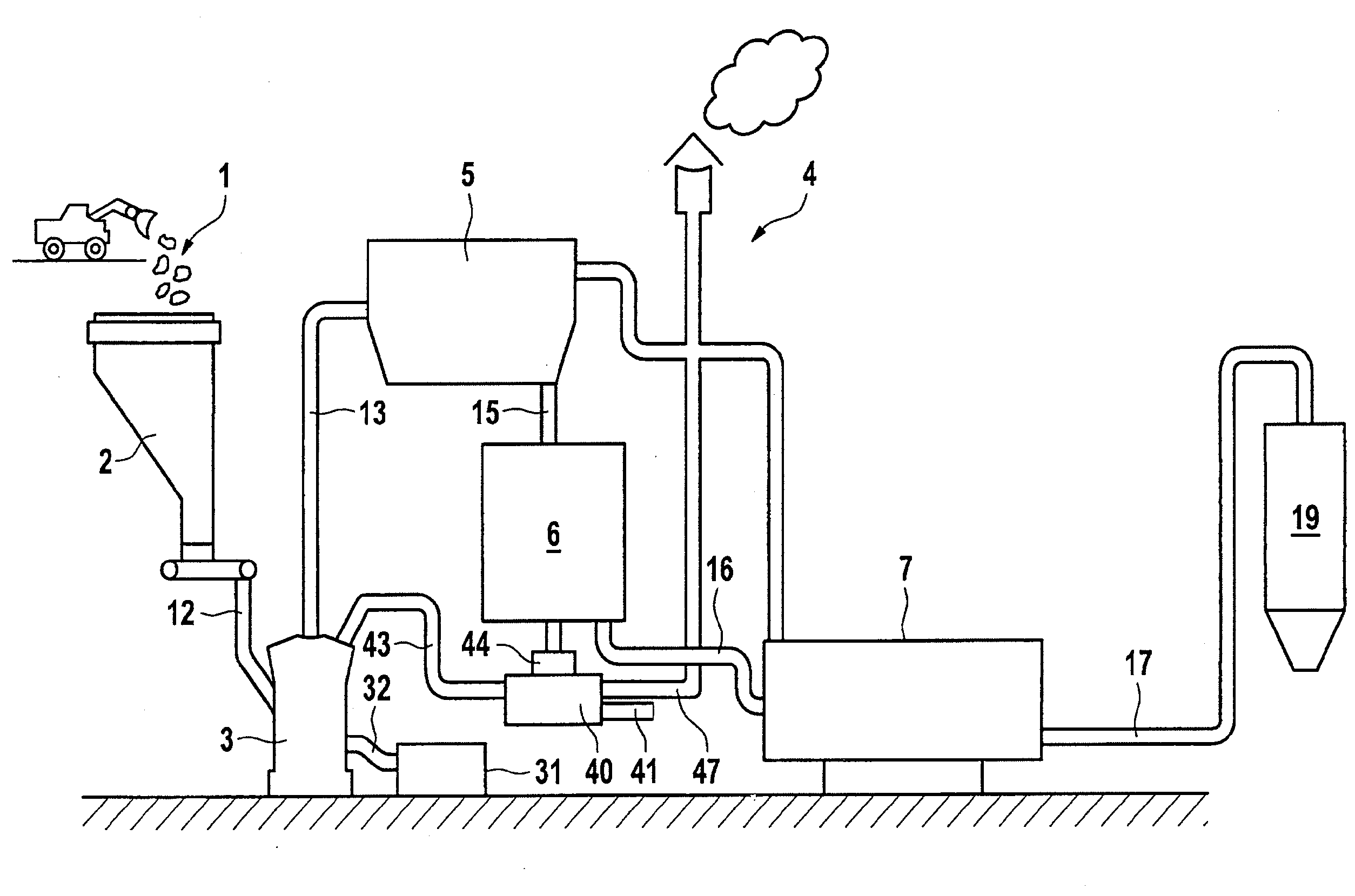

Calcination method and system

InactiveUS20110150750A1Save energyImprove product qualityGaseous chemical processesCalcium/strontium/barium sulfatesCalcinationGypsum

A method for the calcination of powdery or fine-particled plaster includes steps in which the plaster is subjected to a flash-calcination in a calcinator and then post-calcinated in a reaction vessel. The post-calcination is carried out in the reaction vessel by adding humid gas, the reaction vessel not being heated. This post-calcination takes place over a long period of time, that is at least 10 times, preferably 50-100 times longer than, the amount of time taken for flash calcination. Complete calcination can take place without expending additional energy, and the remaining dihydrate produced during the flash calcination is also transformed into semi-hydrate and undesired anhydrite fractions are reduced. The method ensures consistency in the product quality and also increases product quality. The temperature in the upstream calcinator can be lowered to save energy. The method can also be used to accelerate the ageing of calcined plaster.

Owner:CLAUDIUS PETERS PROJECTS

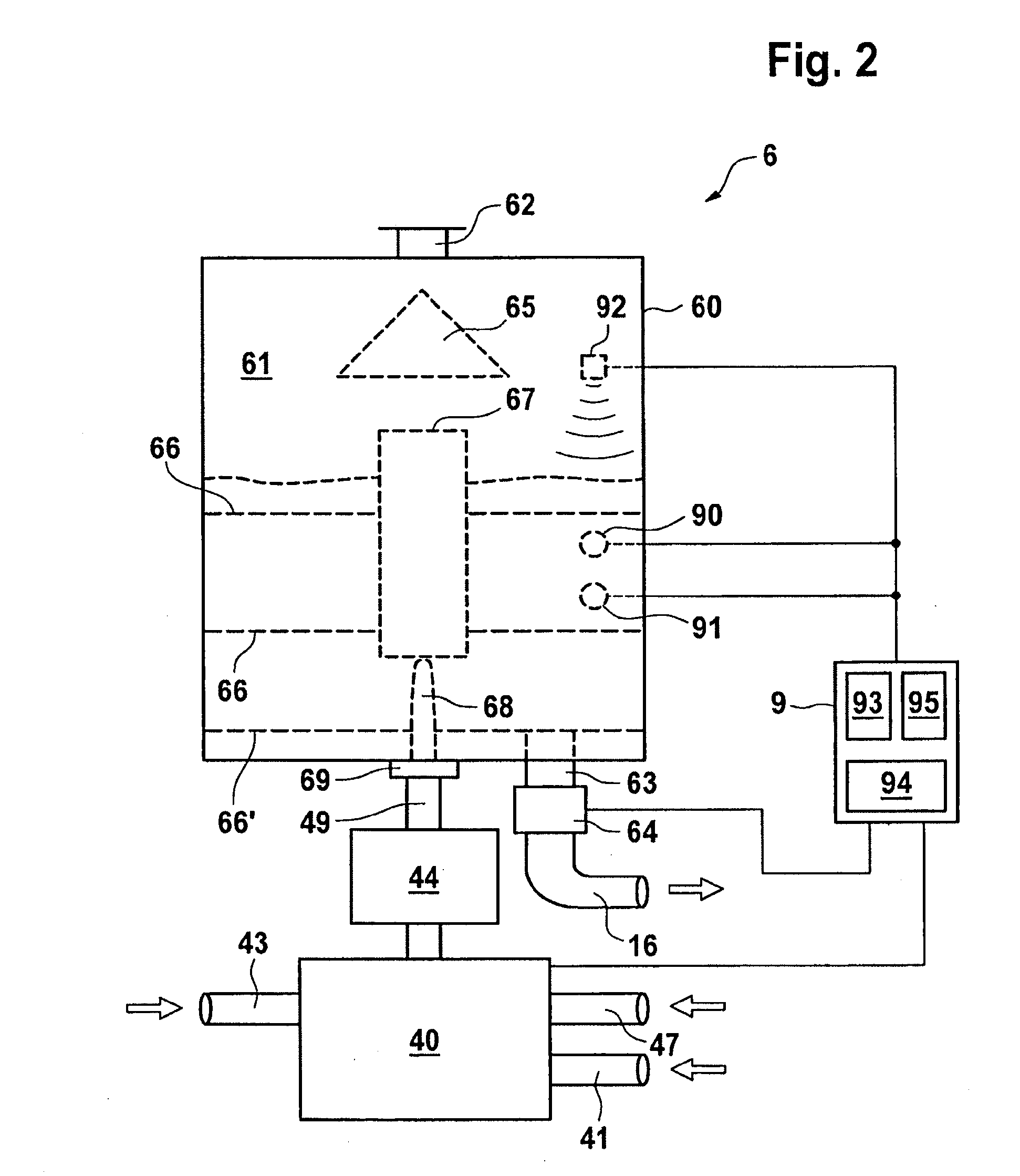

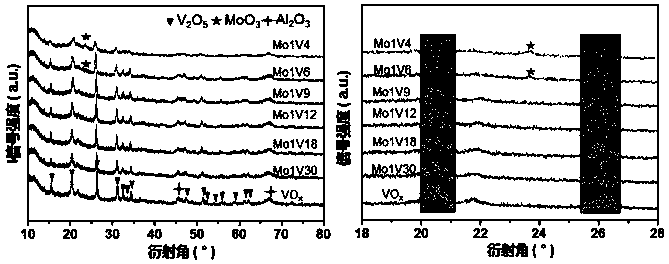

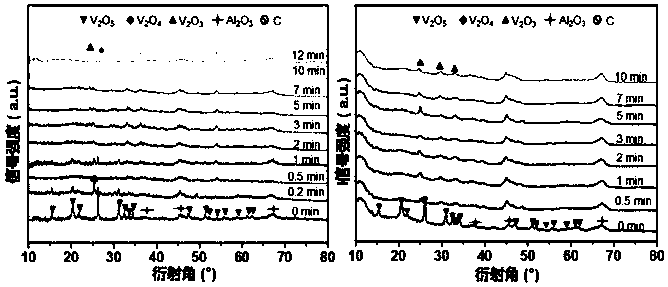

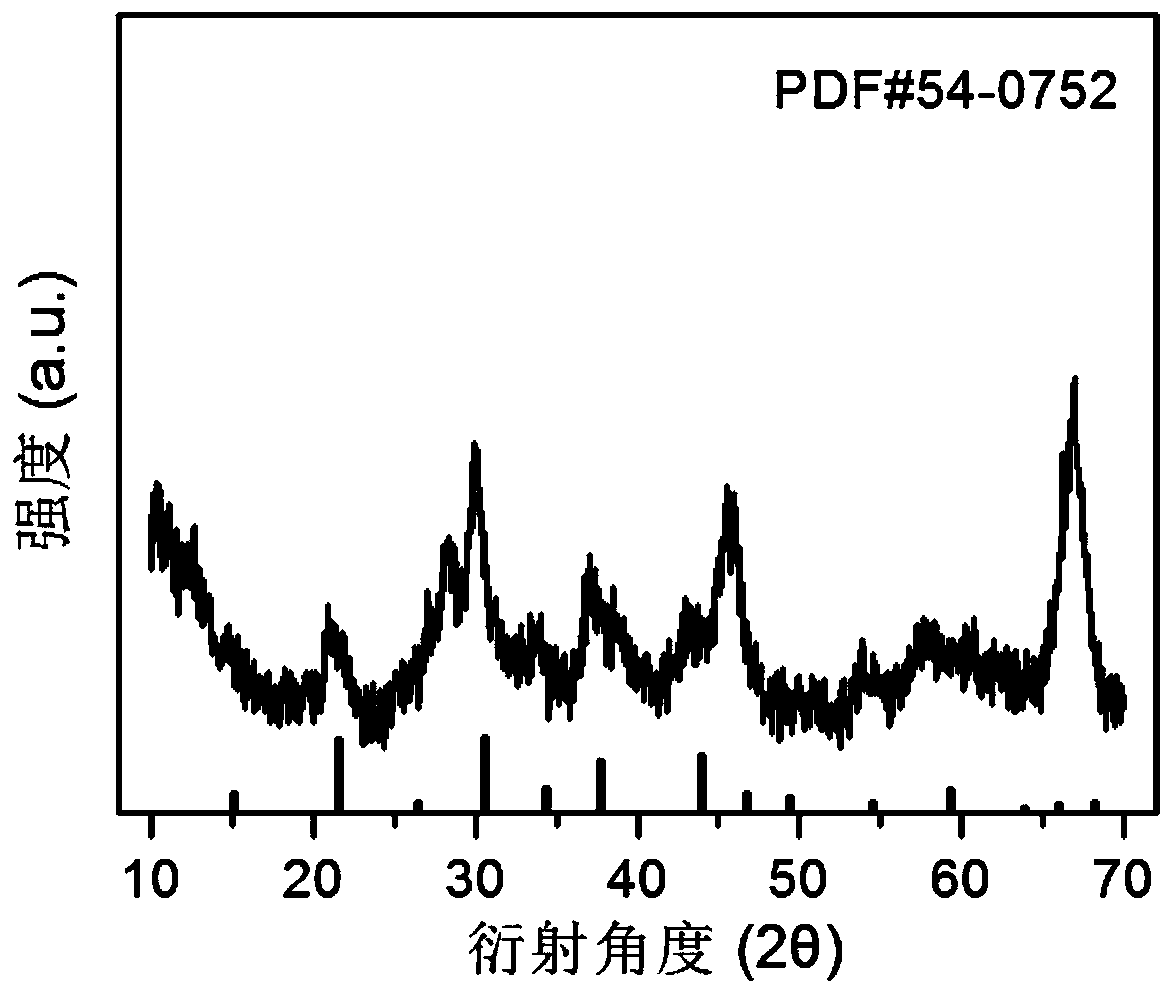

Molybdenum-vanadium double-metal oxide catalyst and application of same to chemical-chain dehydrogenation of light alkanes

ActiveCN109382090AHigh selectivityImprove conversion rateCatalyst regeneration/reactivationCatalystsAlkaneLattice oxygen

The invention discloses a molybdenum-vanadium double-metal oxide catalyst and application of the same to chemical-chain dehydrogenation of light alkanes. The molybdenum-vanadium double-metal oxide catalyst has a molecular formula of Mo1Vy, wherein y represents a molar ratio of vanadium atoms to molybdenum atoms; the molybdenum-vanadium double-metal oxide catalyst is prepared by using a dipping method; and the Mo1Vy oxygen carrier is prepared through dipping, drying, calcining and tableting. When the loaded molybdenum-vanadium double-metal oxide is applied to the dehydrogenation reaction of light alkanes for preparation of olefins and a reaction temperature is kept at 450-550 DEG C, high-activity high-selectivity oxidative dehydrogenation of propane into propylene can be achieved, the conversion rate of propane is maintained at 30 -40%, and the selectivity of propylene is 80-90%. After the fresh oxygen carrier reacts with propane, the fresh oxygen carrier turns from a high valence stateto a low valence state; a low-valence-state oxygen carrier reacts with air or oxygen and is oxidized into a high valence state, and lattice oxygen is regained and is circulated again; and after repeated regeneration, the oxygen carrier still has stable reaction performance. The catalyst provided by the invention can be used in reaction units such as fixed-bed reactors, moving-bed reactors or circulating fluidized beds.

Owner:TIANJIN UNIV

Alkylation process

Owner:ABB LUMMUS GLOBAL INC

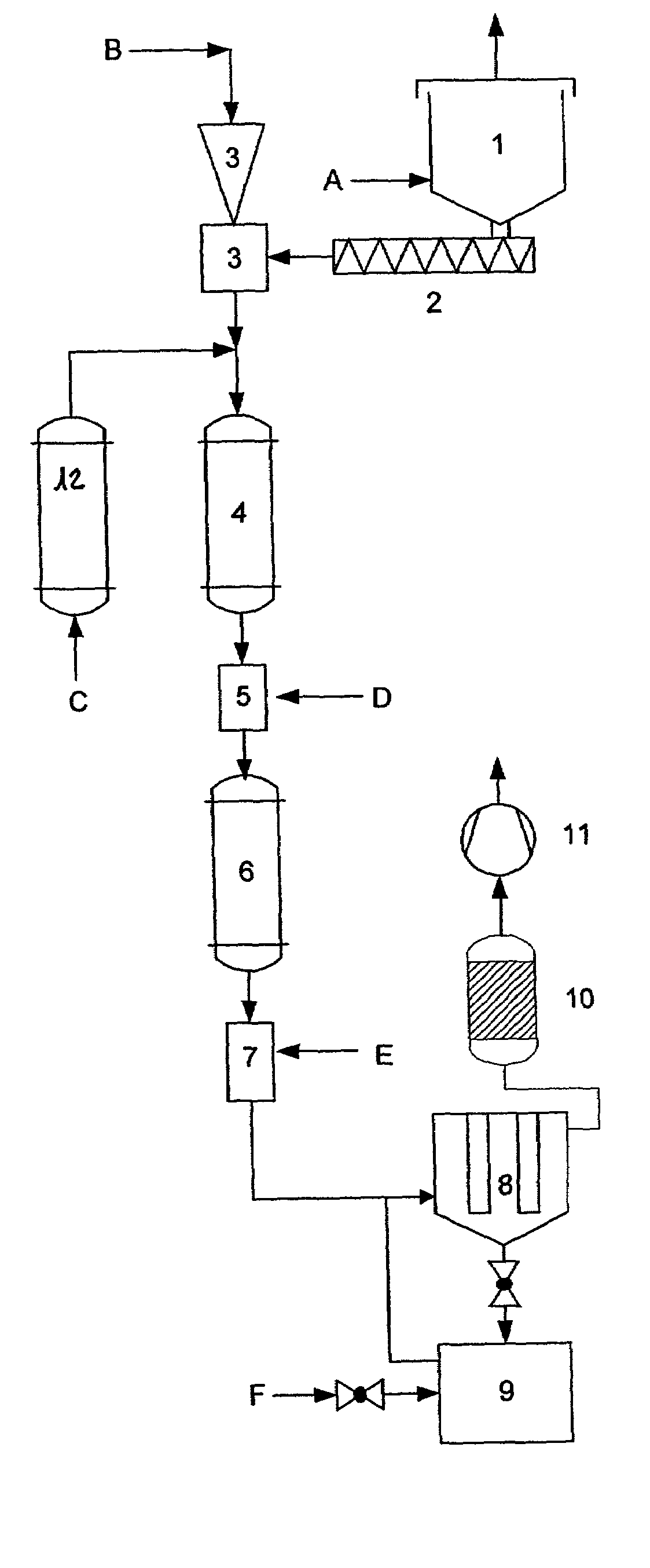

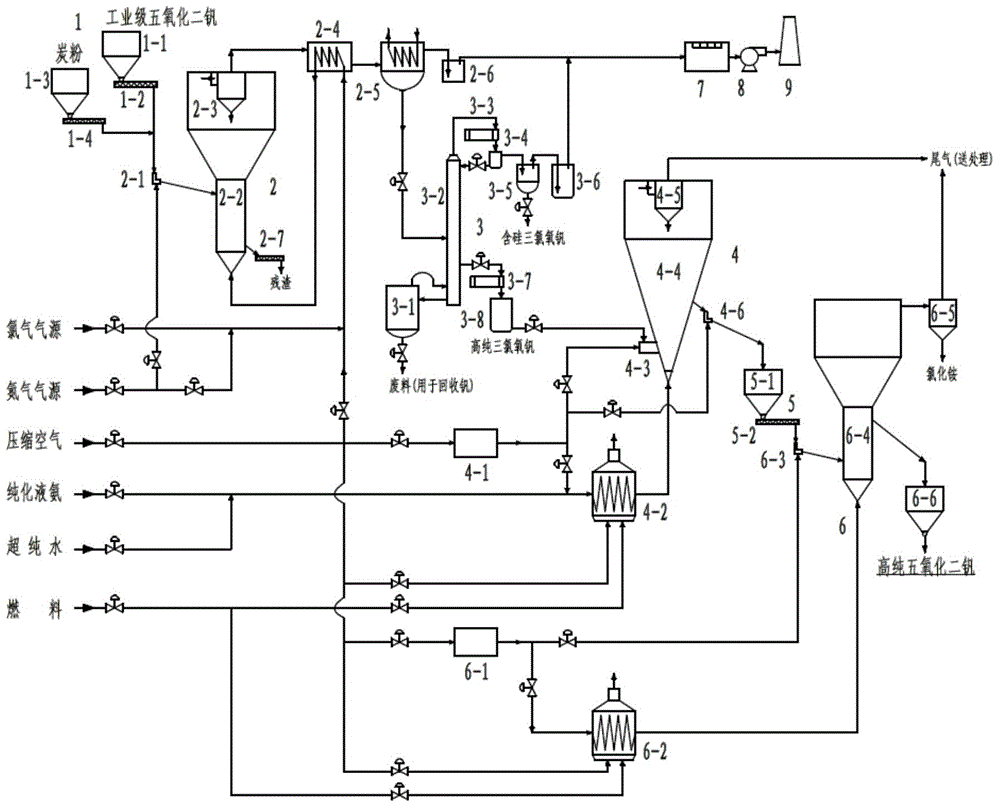

System and method for purifying and producing high-purity vanadium pentoxide powder

ActiveCN105984896AAchieve warm-upUniform temperature distributionNitrogen compoundsTransportation and packagingDistillationCalcination

The invention discloses a system and method for purifying and producing high-purity vanadium pentoxide powder, belonging to the fields of chemical engineering and materials. According to the invention, fluidizing low-temperature chlorination is used for converting industrial-grade vanadium pentoxide into vanadium oxytrichloride; through heat exchange between fluidization gas and chlorination flue gas, chlorination gas is preheated; a proper amount of air is added to allow a part of coke powder to combust, thus providing a balanced supply of heat during the process of chlorination, improving chlorination efficiency, and ensuring good selectivity of low-temperature chlorination; and the vanadium oxytrichloride is subjected to fluidized-vapor-phase ammoniation after distillation and purification and further to fluidized calcination to produce a high-purity vanadium pentoxide product. The system and method have the advantages that raw materials are good in adaptability, only a small amount of ammonia-nitrogen wastewater is discharged, low energy consumption in production and low cost in operation are realized, product quality is stable, etc.; and the system and method are applicable to large-scale industrial production of high-purity vanadium pentoxide having a purity of 4N or higher and have good economic benefits and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

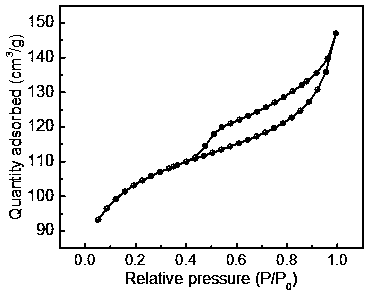

Molecular sieve having mesopores, preparation method therefor, and application thereof

ActiveUS20200325029A1Increased proportion of volumeHigh catalytic efficiencyHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveIsomerization

A molecular sieve has a silica / alumina molar ratio of 100-300, and has a mesopore structure. One closed hysteresis loop appears in the range of P / P0=0.4-0.99 in the low temperature nitrogen gas adsorption-desorption curve, and the starting location of the closed hysteresis loop is in the range of P / P0=0.4-0.7. The catalyst formed from the molecular sieve as a solid acid not only has a good capacity of isomerization to reduce the freezing point, but also can produce a high yield of the product with a lower pour point. The process for preparing the catalyst involves steps including crystallization, filtration, calcination, and hydrothermal treatment.

Owner:CHINA PETROCHEMICAL CORP +1

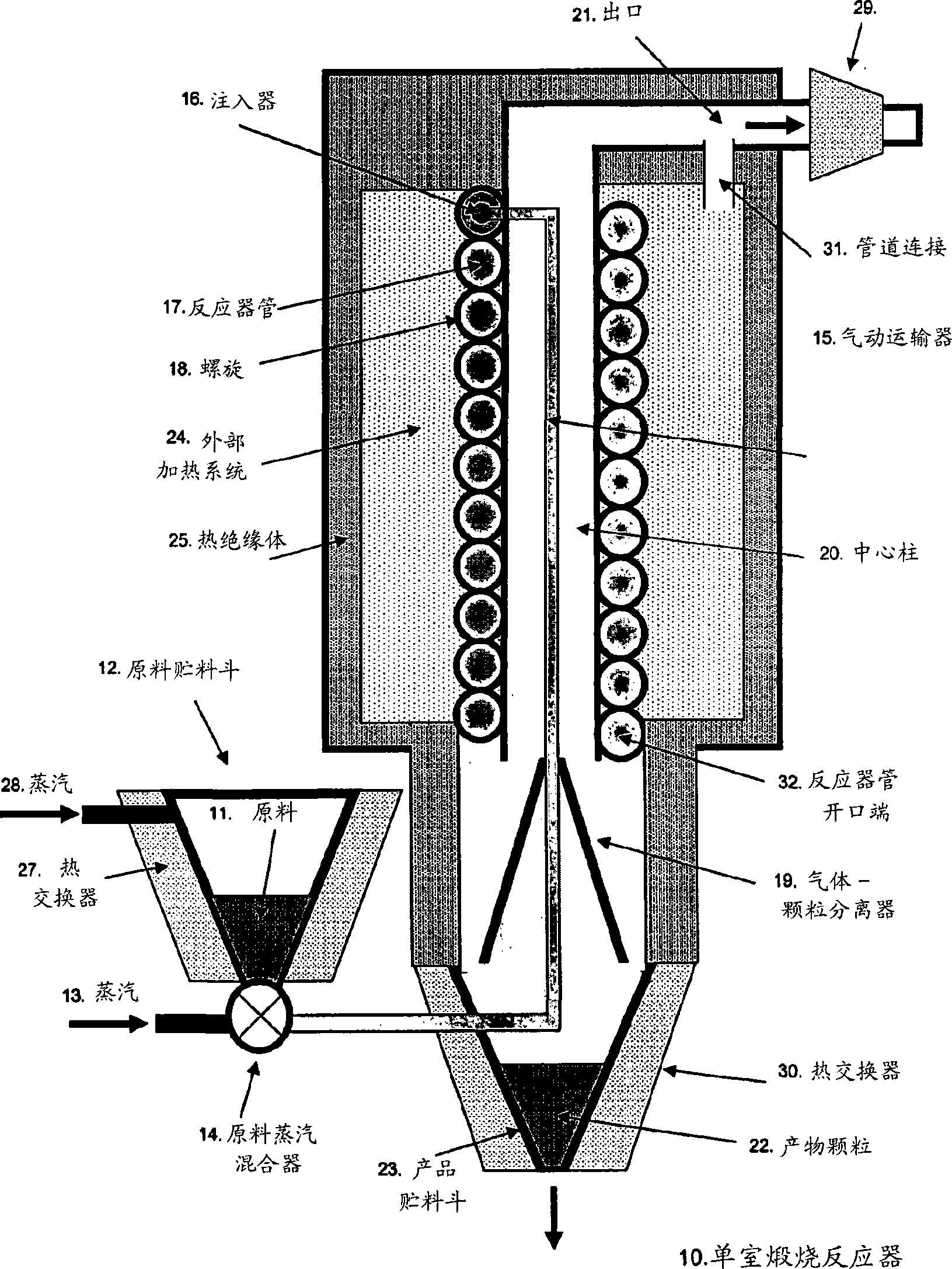

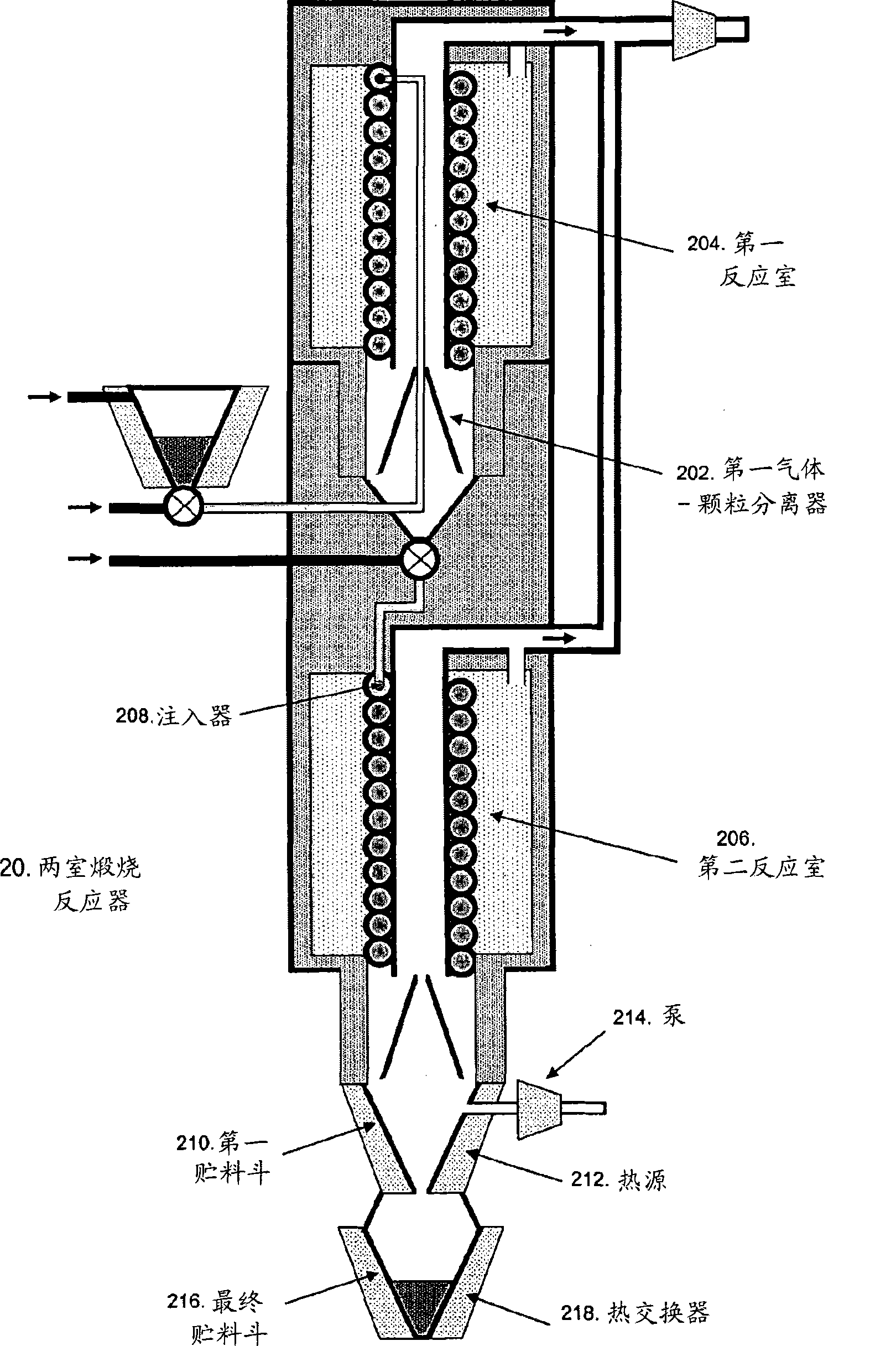

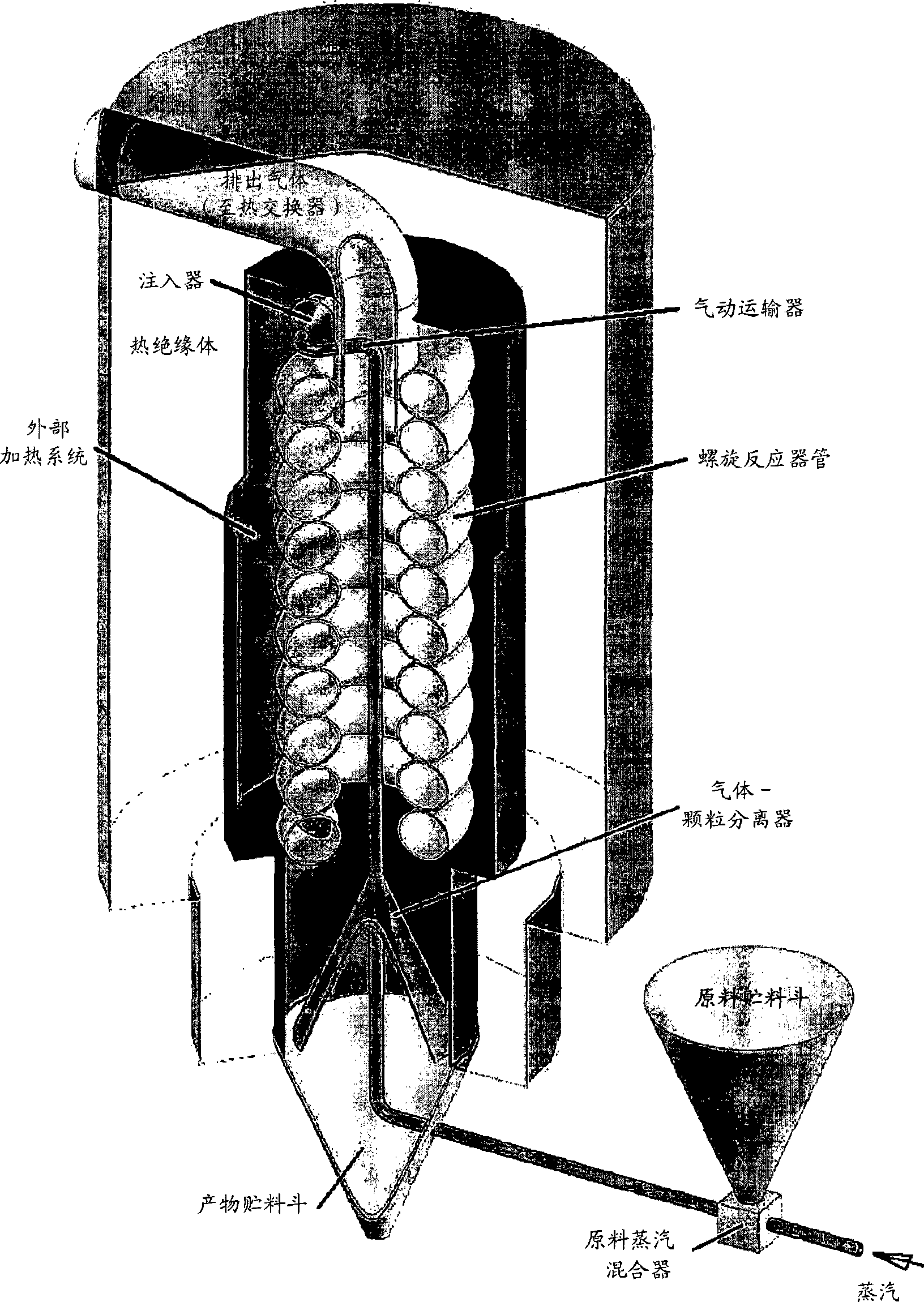

System and method for the calcination of minerals

ActiveCN101466461ACalcium/strontium/barium carbonatesOxide/hydroxide preparationHorizontal forceNuclear engineering

A system and method for the calcination of minerals. The system comprises a vertically disposed reactor segment configured to impart horizontal forces on particles passing through the reactor segment in a vertical direction; an injector unit for receiving granular feedstock, the injector unit being disposed at a top portion of the reactor segment, whereby granules of the feedstock move through the reactor segment in a granular flow under at least one of a group consisting of a force of steam, gravitational force and a centrifugal force; a reactor heat exchange unit thermally coupled to a wall of the reactor segment for providing heat to the flowing granules inside the reactor segment through heat transfer through the wall of the reactor segment; one or more inlets formed in the reactor segment for introducing a superheated gas into the reactor segment to create conditions of a gas-solid multiphase system; and one or more exhaust openings formed in the retort segment such that gas products are at least partially flushed from the reactor segment under the flow of the superheated gas from the inlets to the exhaust openings.

Owner:CALIX PTY LTD

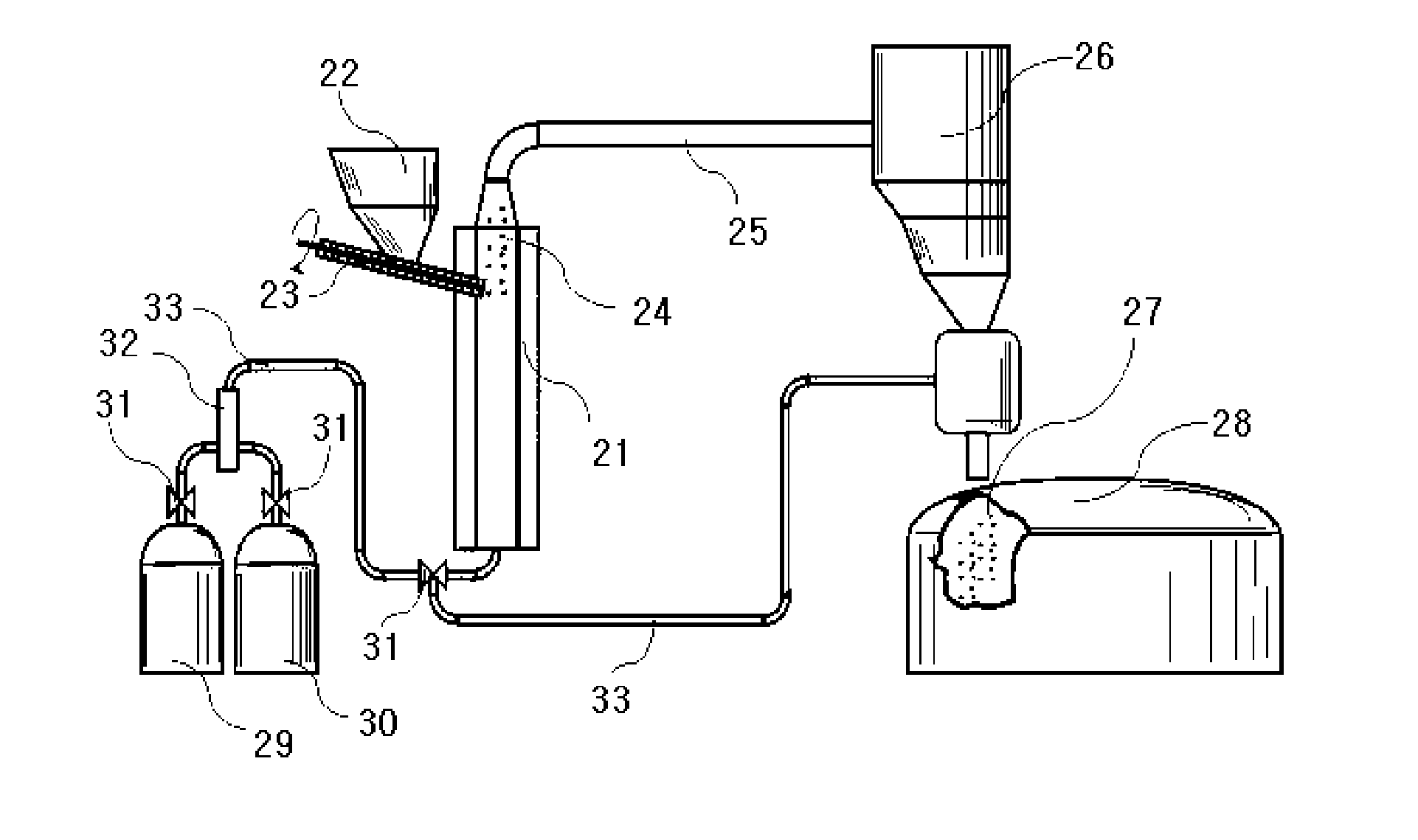

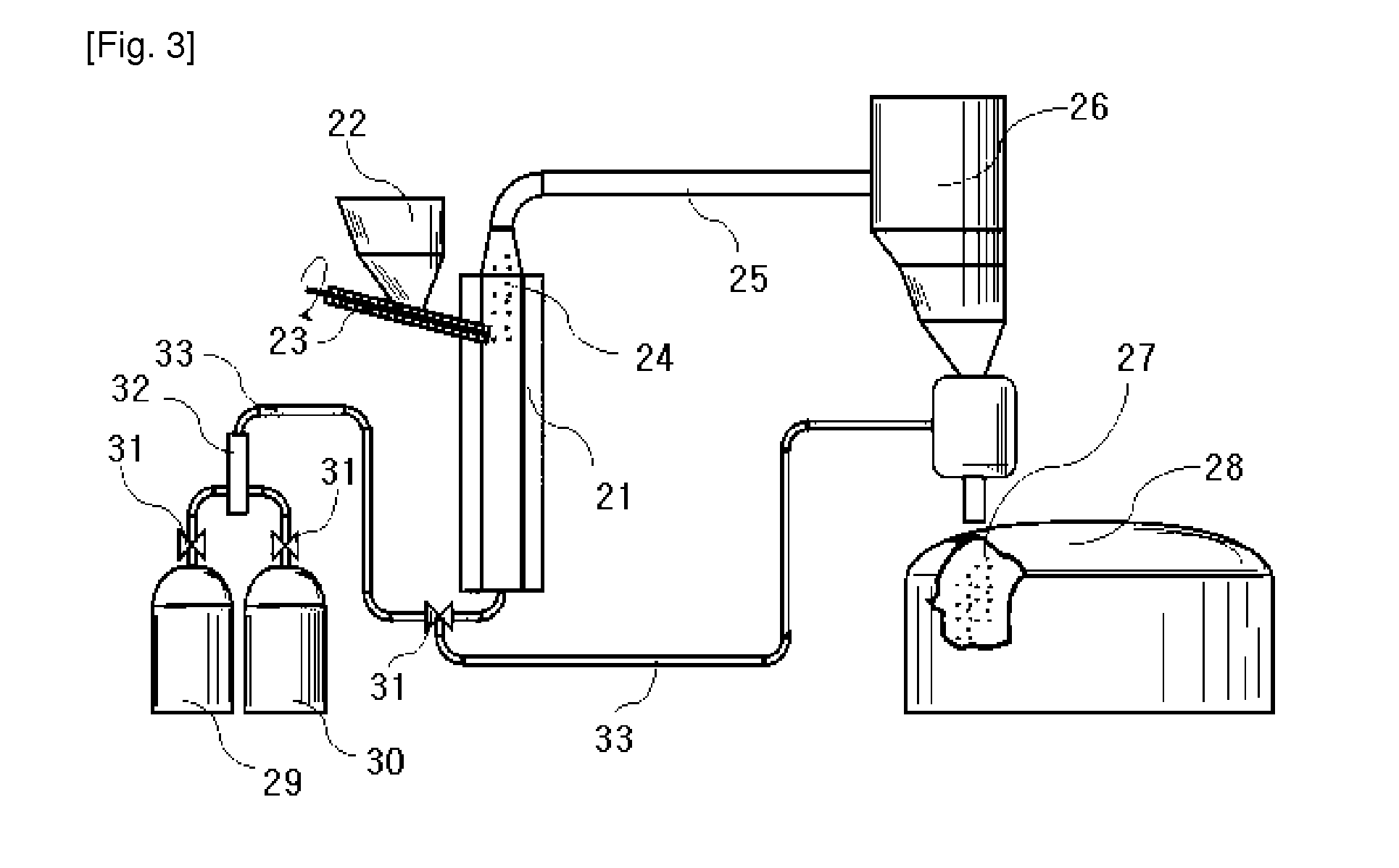

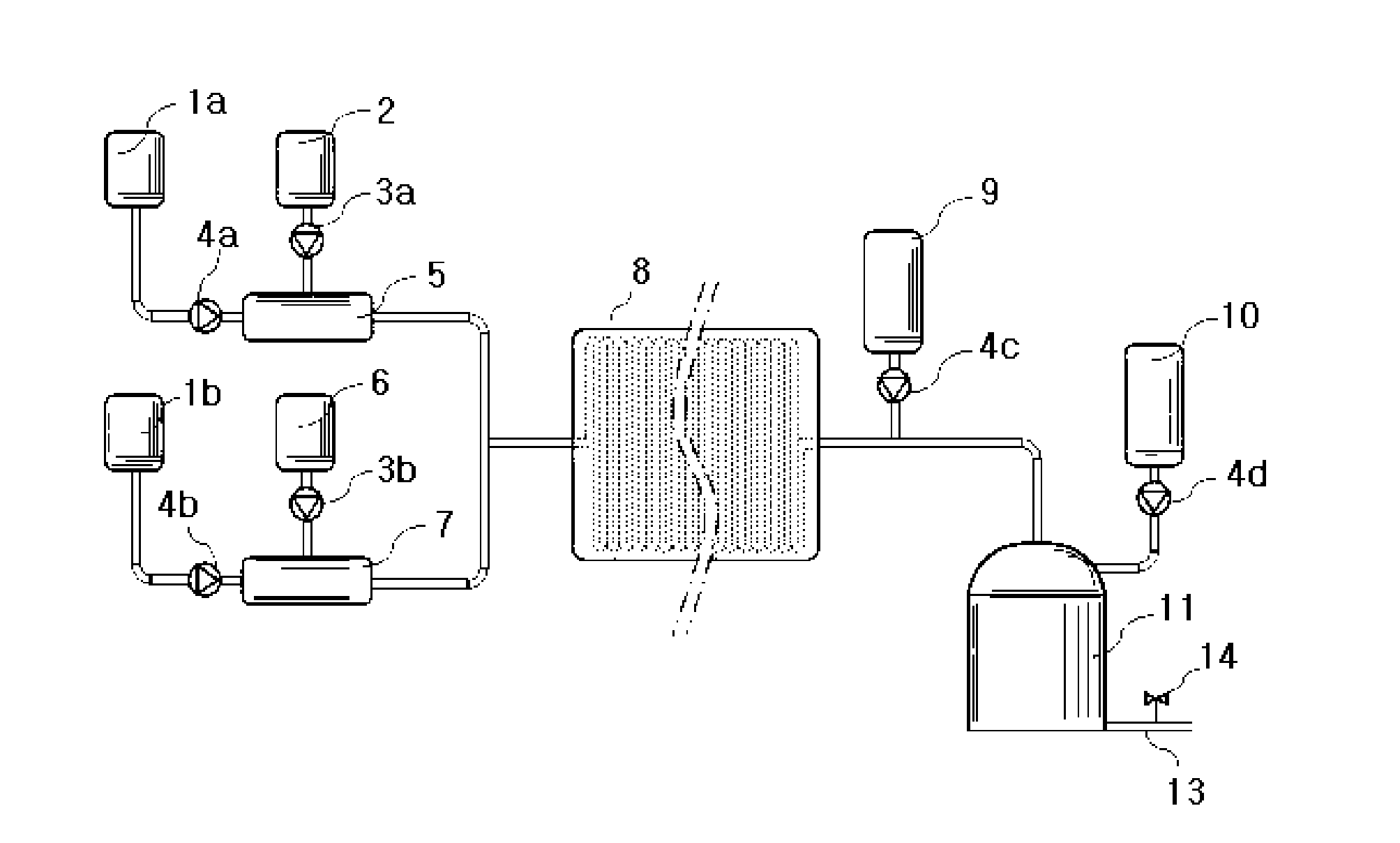

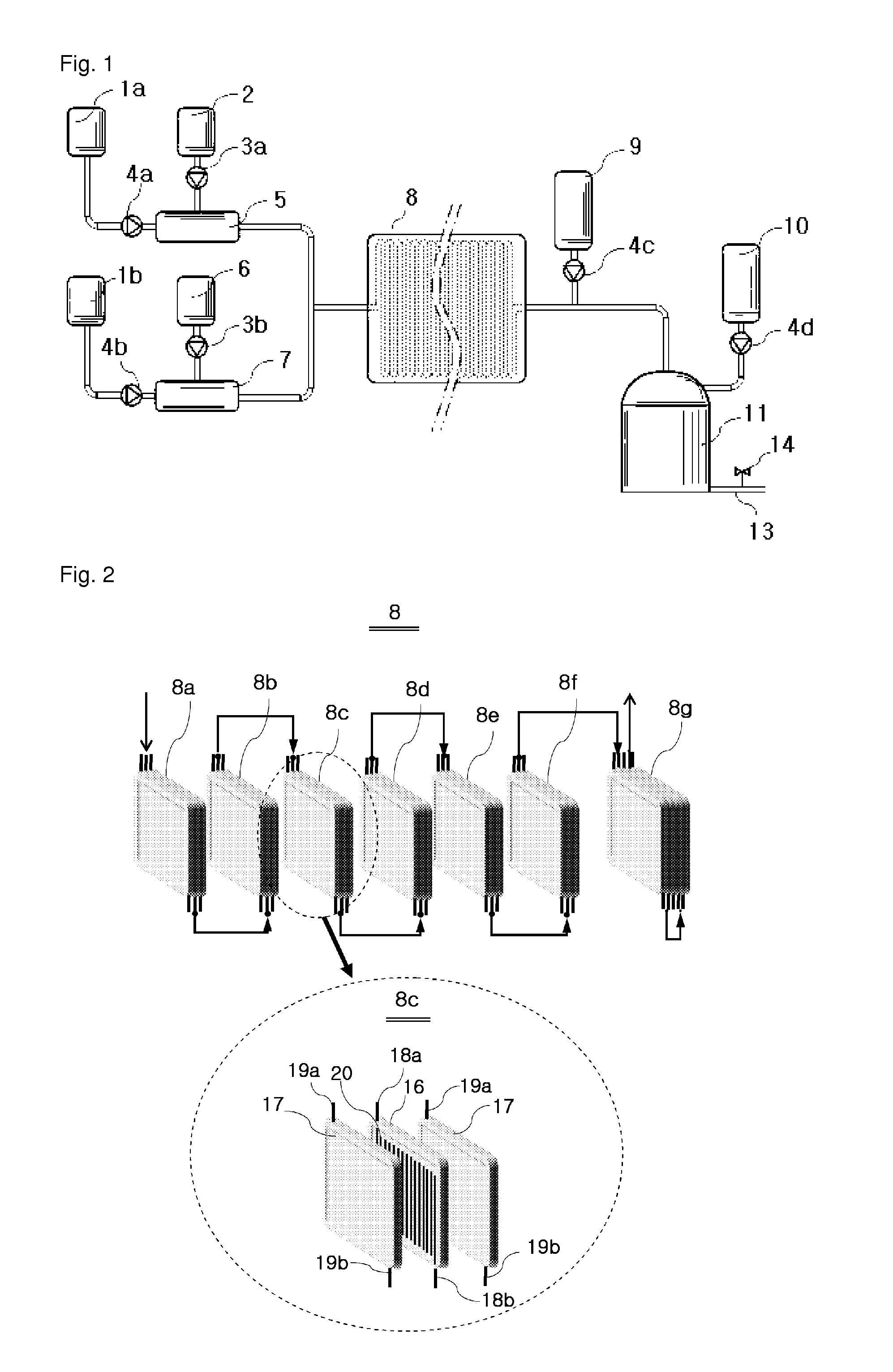

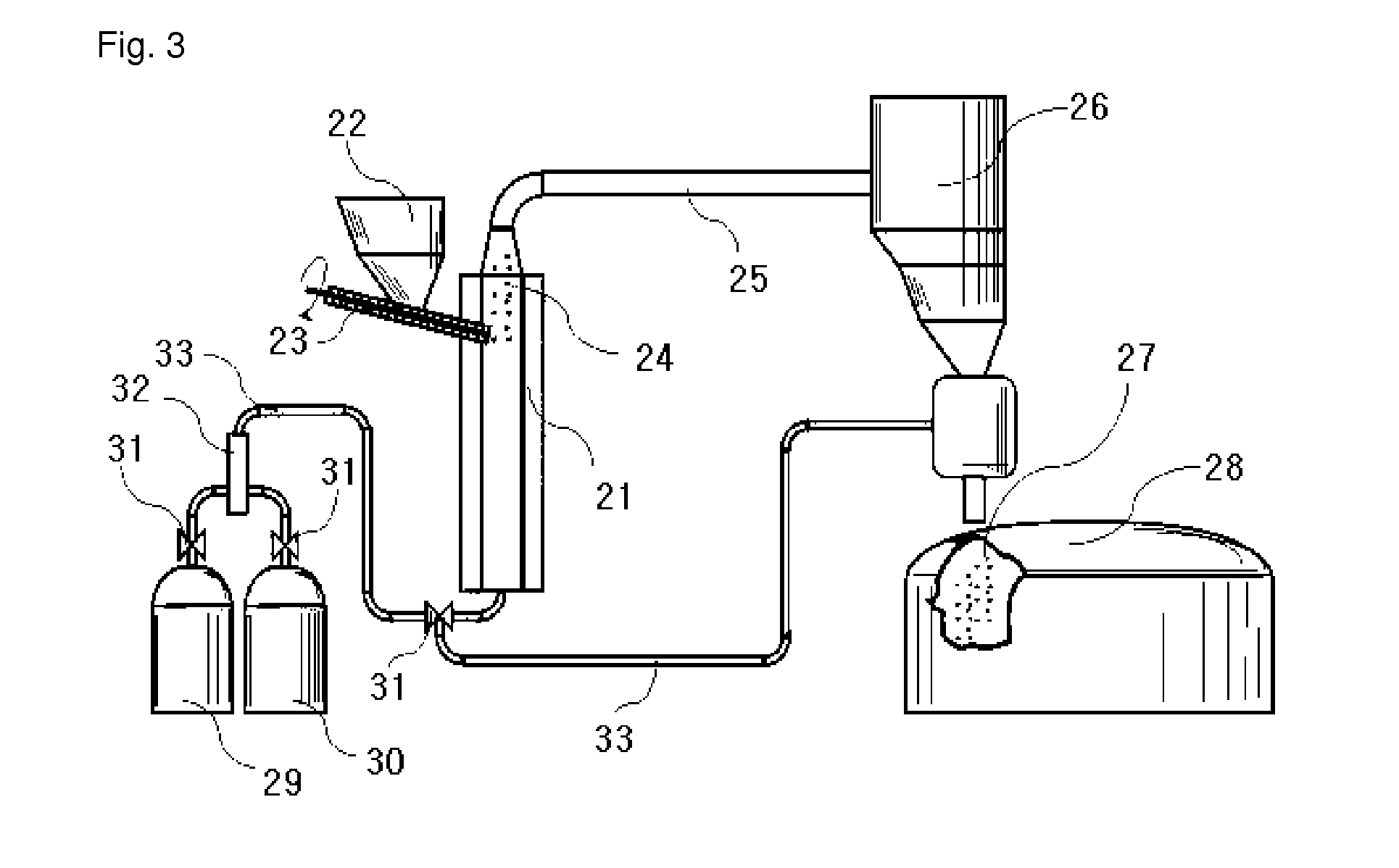

Method of producing nano-size graphene-based material and an equipment for producing the same

The present invention is directed to a method of producing nano-size graphene-based material and an equipment for producing the same. The present invention provides a method of producing graphitic oxide by forcing graphite sulfuric slurry and KMnO4 sulfuric solution into a lengthy micro-channel and by sustaining the mixture of the said graphite sulfuric slurry and the said KMnO4 sulfuric solution in the said micro-channel at predetermined temperatures, by putting the said aqua solution of hydrogen peroxide to the reaction mixture to terminate oxidation, and by washing and drying the reaction mixture. The present invention provides a method of producing nano-size graphene-based material by exfoliating graphitic oxide by thermal shock in a vertical fluidized furnace. According to the present invention, graphitic oxide can be produced massively without risks of explosion by forcing all reagents as liquid phase continuously into a lengthy micro-channel surrounded and thermally controlled strictly by heat exchangers. Nano-size graphene-based material derived by exfoliating thus produced graphitic oxide can be imported into compositions and composites for various uses since it has physical characteristics comparable to carbon nanotube and dispersibility superior to carbon nanotube via residual functional groups.

Owner:STANDARDGRAPHENE

Preparation method and application of propylene epoxidation catalyst

ActiveCN107715868ALow costReduce unit consumptionOrganic chemistryMolecular sieve catalystsTitaniumSilanization

The invention discloses a preparation method a propylene epoxidation catalyst. The preparation method includes the steps: performing prehydrolysis on silicon sources; adding titanium sources to reactthe silicon sources and the titanium sources to form colloidal sol; spraying atomized colloidal sol into liquid ammonia to form; performing pore expanding, drying, roasting and silanization treatmentto obtain the Ti-SiO2 composite oxide catalyst. The catalyst is applied to the chemical process of preparing propylene epoxide by propylene epoxidation, the average selectivity of the propylene epoxide reaches up to 97.5%, and the catalyst has industrial application prospects.

Owner:WANHUA CHEM GRP CO LTD

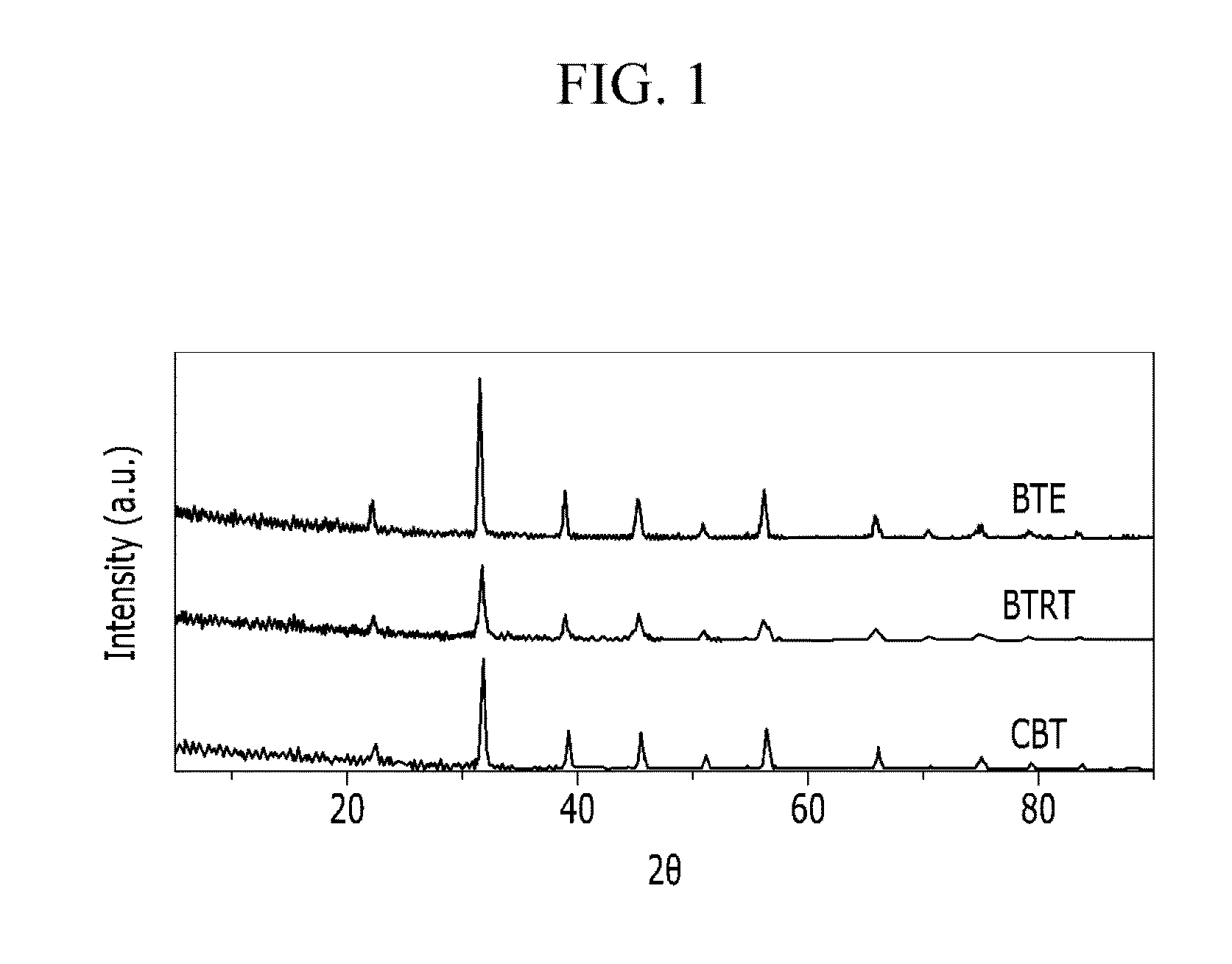

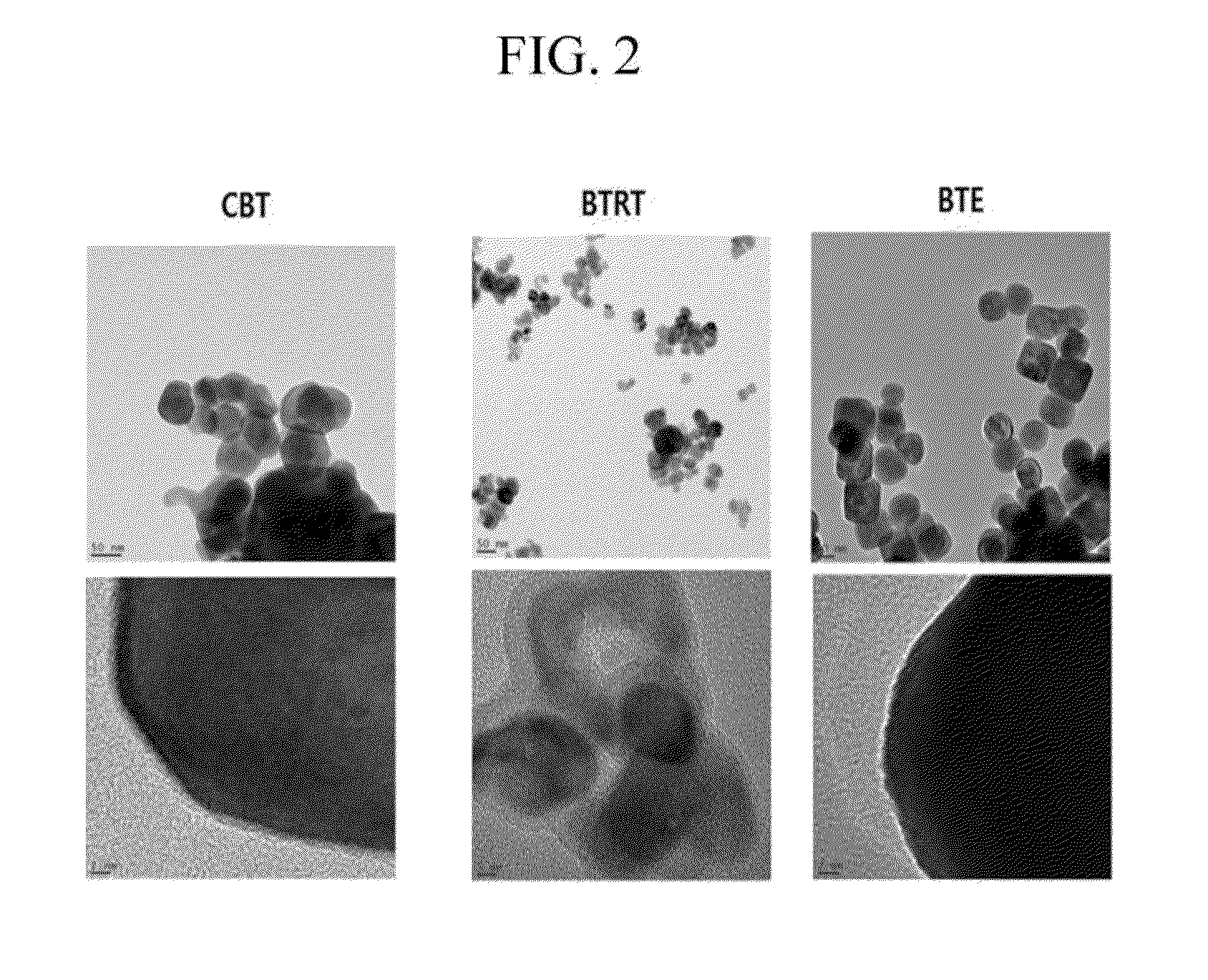

Carbon dioxide adsorbent including barium titanate, carbon dioxide capture module including the same, and methods for separating carbon dioxide using the same

A carbon dioxide adsorbent may include a complex oxide including barium and titanium, wherein the complex oxide has a perovskite crystalline structure and is represented by the general formula BaxTiyOz, and an atomic ratio of Ba / Ti ranges from about 0.95 to about 1.7. The carbon dioxide adsorbent may be included in a carbon dioxide capture module. The carbon dioxide adsorbent may also be used in a method of separating carbon dioxide.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

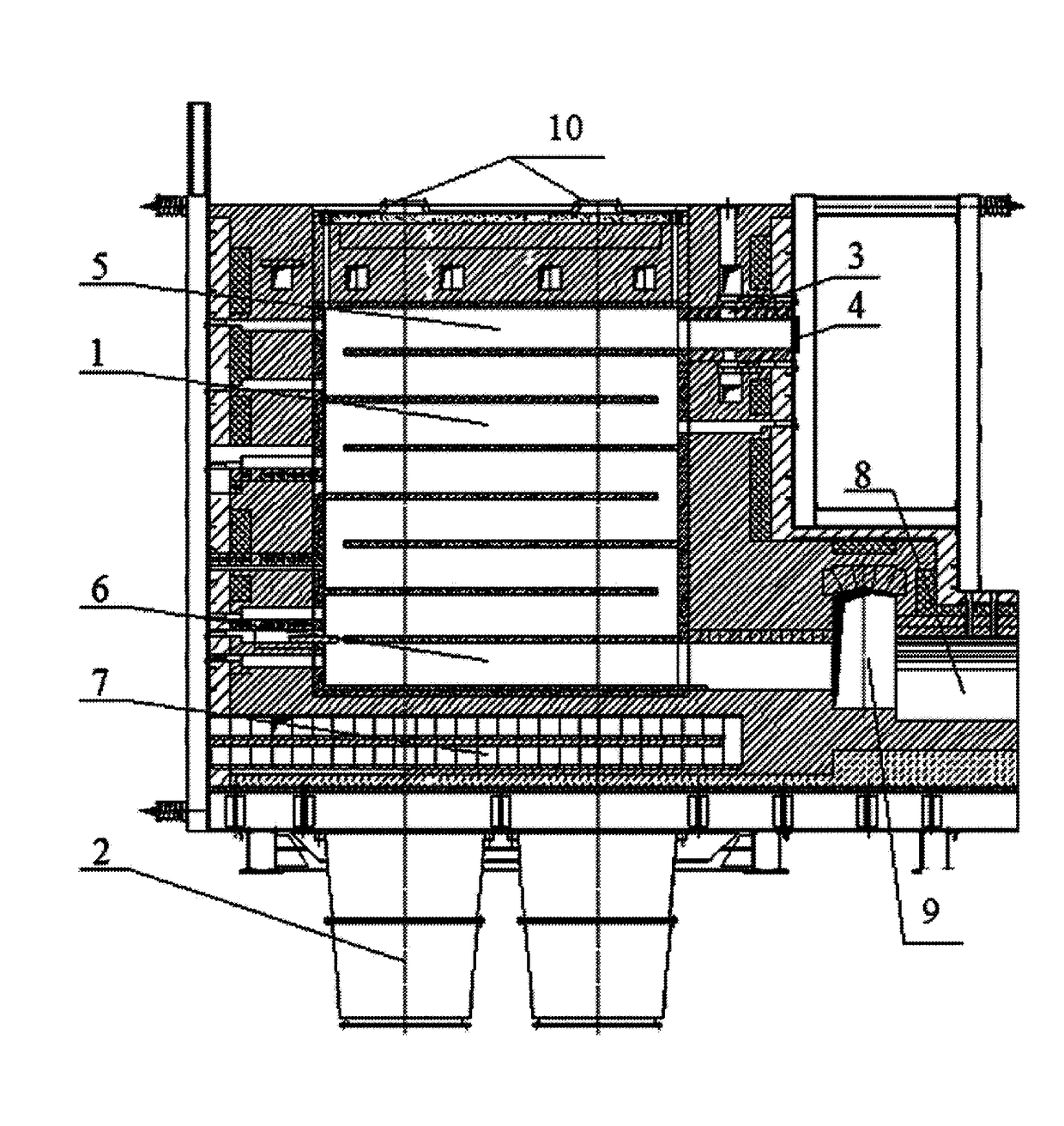

Pot Furnace for Calcining Petroleum Coke at Low Temperature

ActiveUS20170261262A1Reduce the amount requiredReduce corrosionCoke ovensCharge composition/stateFlue gasWater jacket

A pot furnace for calcining petroleum coke at low temperature may include a pot, and a cooling water jacket and a flame path below the pot. The flame path may include eight layers. An inlet of a first flame path layer may be in communication with a volatile channel in the front wall, and is provided with a first flame path layer flashboard. An eighth flame path layer may be in communication with a communication flue. Flue gas may be discharged out of the furnace body through a main flue. A furnace bottom cooling channel may be provided below the eighth flame path layer.

Owner:CHINA ALUMINUM INT ENG CORP

Process and apparatus for the production of alumina

InactiveUS20050238571A1Easy to separateInstallation economyFlat flow vortexCalcinationCalcinationOne stage

A process for the production of alumina from aluminum trihydrate in which the trihydrate is dried and pre-heated, after which the remaining free and chemically-bonded water is removed when the trihydrate is converted by calcination to form hot calcined alumina which is cooled to about 50-100° C. in one or more stages. In at least one stage the hot calcined alumina is cooled in a countercurrent cyclone

Owner:ALCOA WORLD ALUMINIA LLC +1

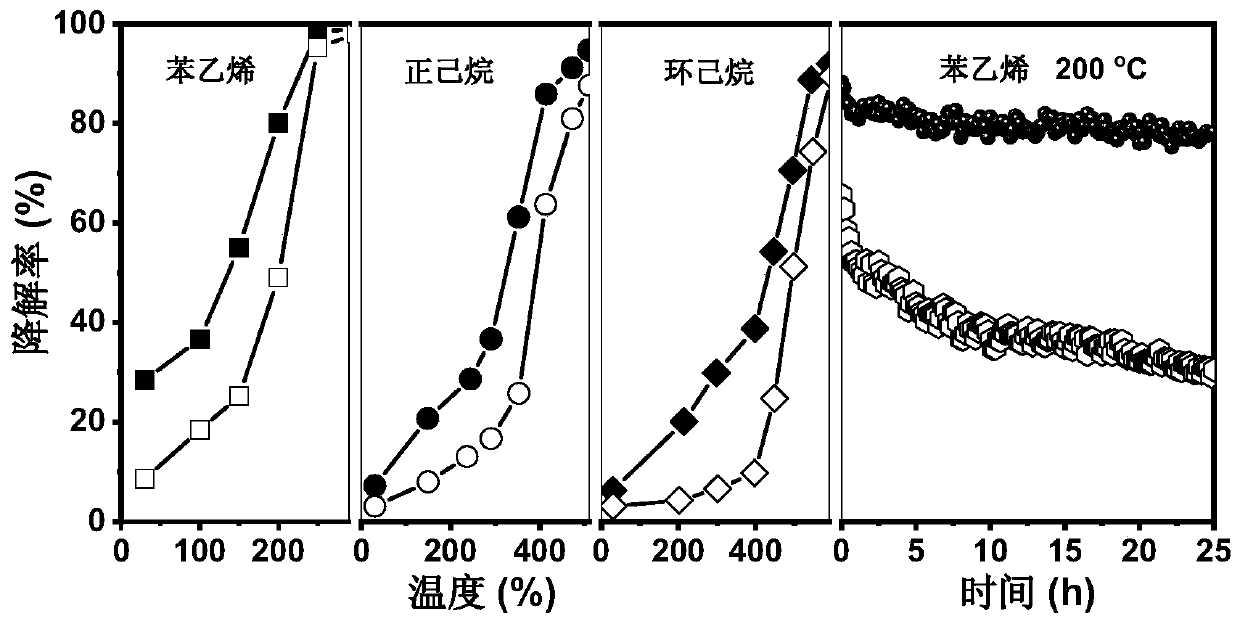

Three-dimensional ordered macroporous oxygen-deficient cerium dioxide catalyst, preparation method and applications thereof

ActiveCN110975857AControlling the concentration of oxygen vacanciesImprove redox abilityGas treatmentDispersed particle separationPtru catalystOxygen vacancy

The invention belongs to the field of environmental catalysis and preparation of inorganic metal catalyst materials, and discloses a three-dimensional ordered macroporous oxygen-deficient cerium dioxide catalyst, a preparation method and applications thereof. The catalyst is prepared by adopting a polymethyl methacrylate (PMMA) colloidal crystal template method, calcining in a reducing / oxidizing atmosphere and treating with water vapor, and shows excellent activity and excellent stability in photo-thermal catalytic purification of typical atmospheric pollutants such as styrene, n-hexane, cyclohexane and the like. The method has the characteristics of cheap and easily available raw materials and simple preparation process, and the obtained material has characteristics of controlled oxygen vacancy, controlled surface acid amount, controlled acid strength, excellent photo-thermal catalytic performance and the like.

Owner:GUANGDONG UNIV OF TECH

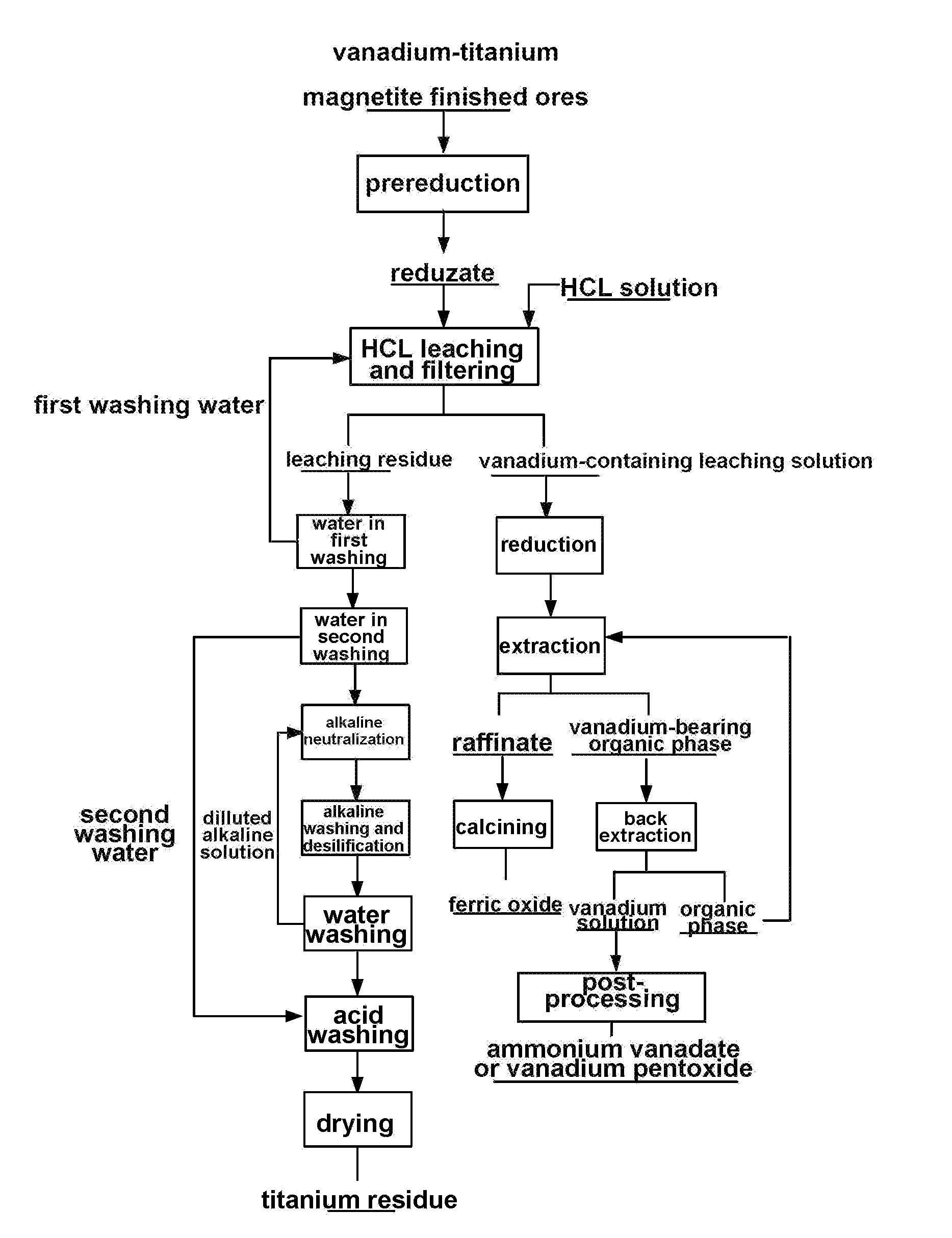

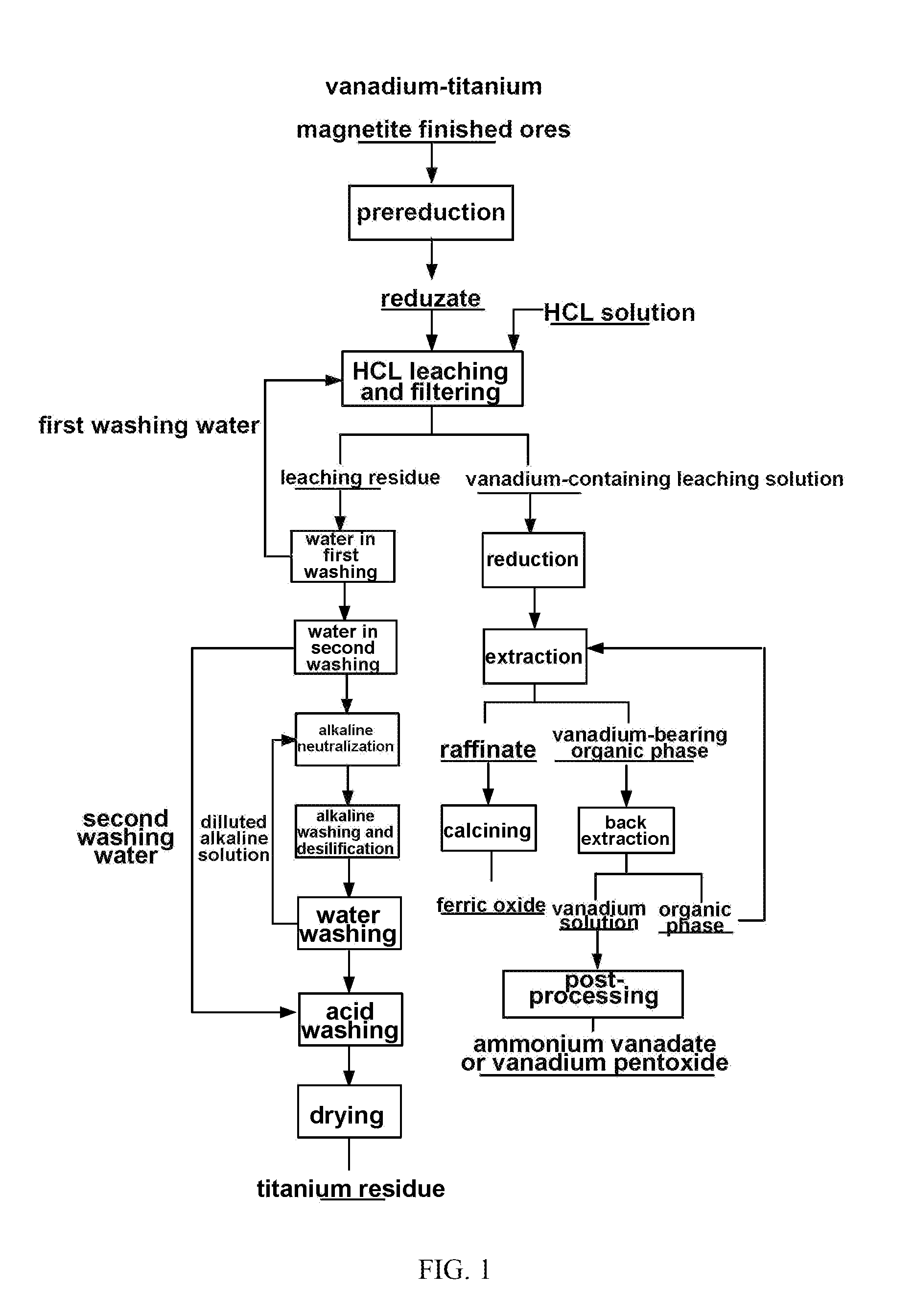

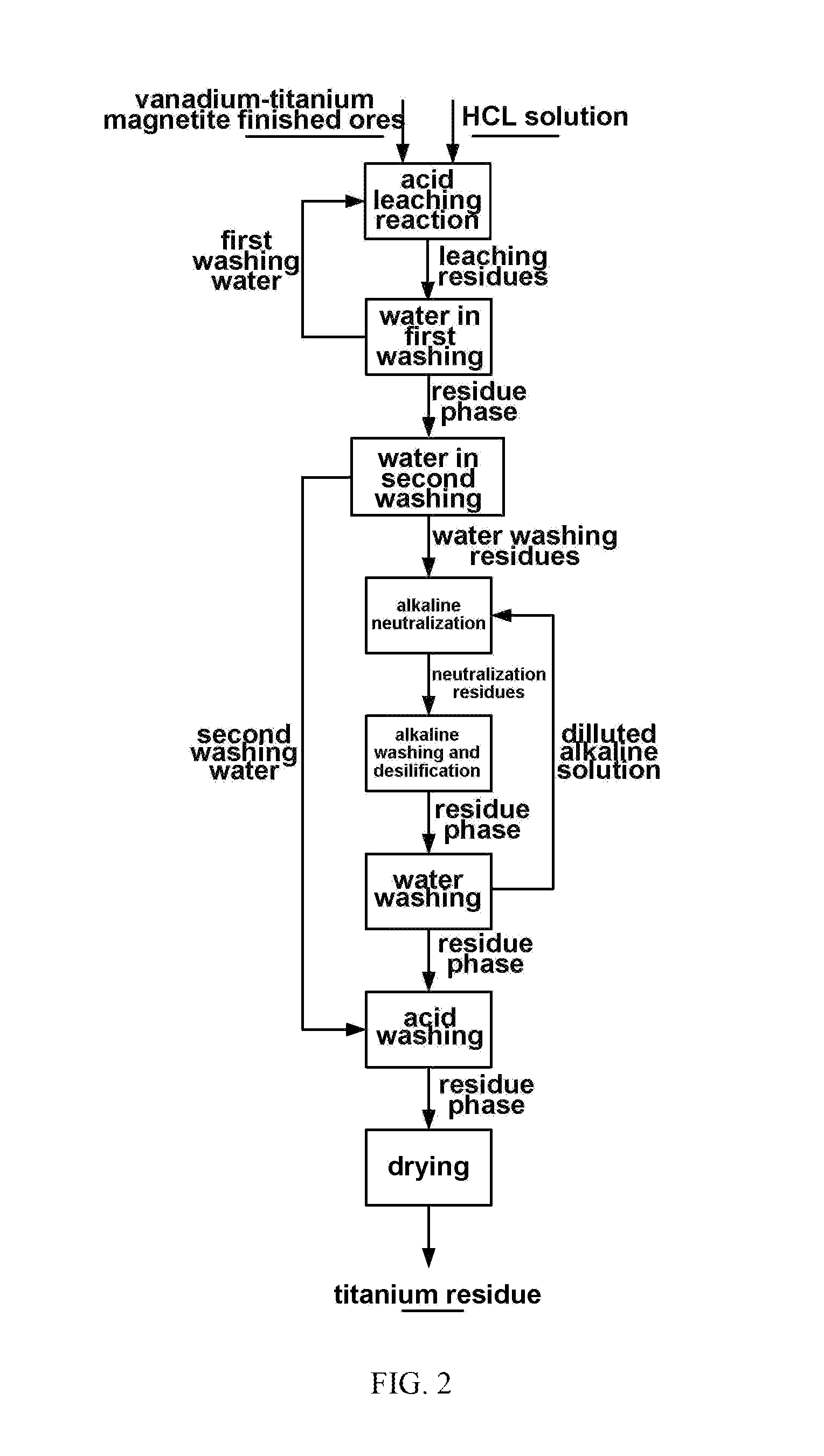

Method for processing vanadium-titanium magnetite finished ores by using wet process

ActiveUS20160060728A1Low costHigh energy consumptionRecovering materialsVanadium oxidesMagnetiteTitanium

A method for processing vanadium-titanium magnetite finished ores by using a wet process. The method comprises the steps: extracting vanadium from vanadium-titanium magnetite finished ores and processing, by using the vanadium extraction method, obtained leaching residue by using a wet process, so as to obtain titanium; and calcining the remaining liquid extracted during the vanadium extraction, so as to prepare ferric oxide. The flow of the method is short, and the energy consumption is low, thereby avoiding waste of a titanium resource.

Owner:HEBEI ZHONGKE TONGCHUANG VANADIUM &TITANIUM TECH CO LTD

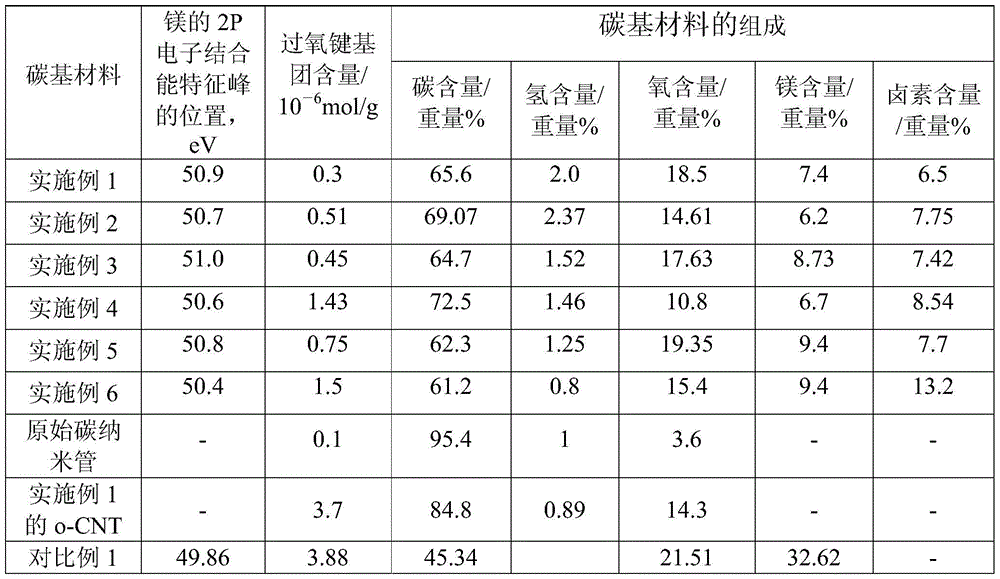

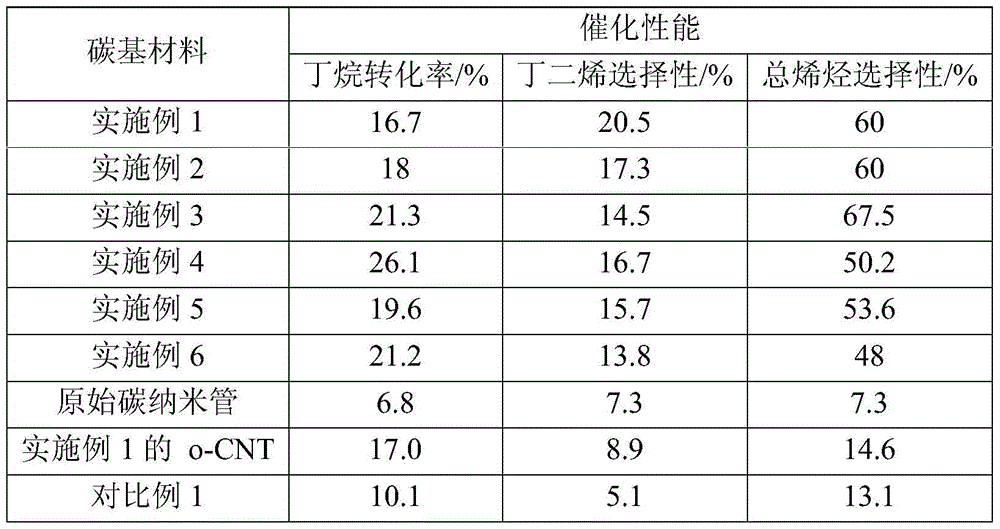

Carbon-based material, preparation method thereof and purpose thereof

ActiveCN105817243ALow peroxy group (-O-O-) contentHigh hydrocarbon catalytic oxidation performanceCatalystsHydrocarbon preparation catalystsSolid carbonGrignard reagent

The invention provides a carbon-based material, a preparation method thereof and purpose thereof. The carbon-based material includes the elements of C, O, Mg, and Cl, and the content of peroxide in the carbon-based material is less than 2*10<-6>mol / g. The preparation method of the carbon-based material comprises making solid carbon source and Grignard reagent touch with each other for a certain time at non-activated atmosphere, removing the redundant Grignard reagent with a solvent, and drying the product. The carbon-based material can be used for performing oxydehydrogenation of hydrocarbon to prepare alkene. The carbon-based material used for performing oxydehydrogenation to prepare alkene has quite high conversion rate and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

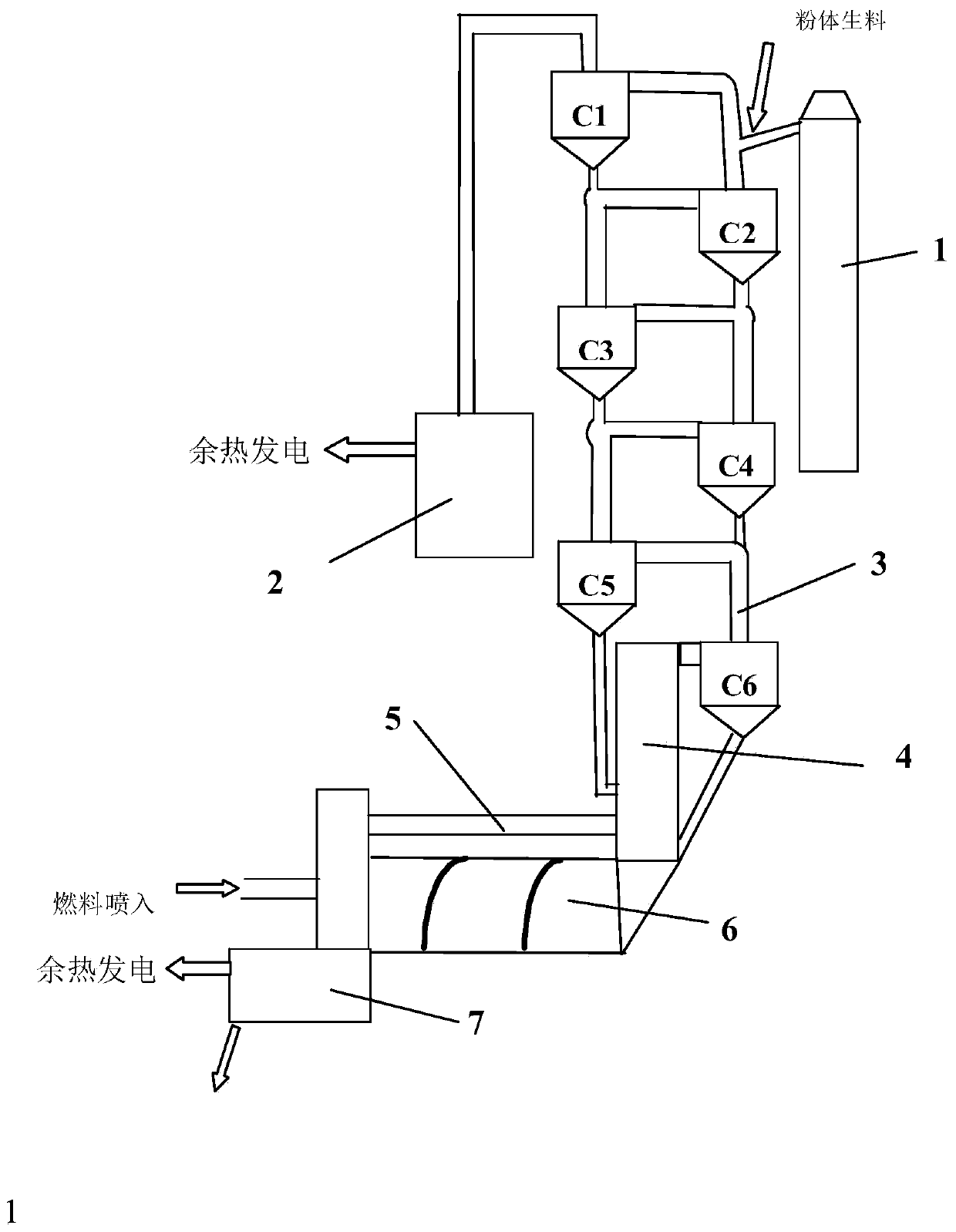

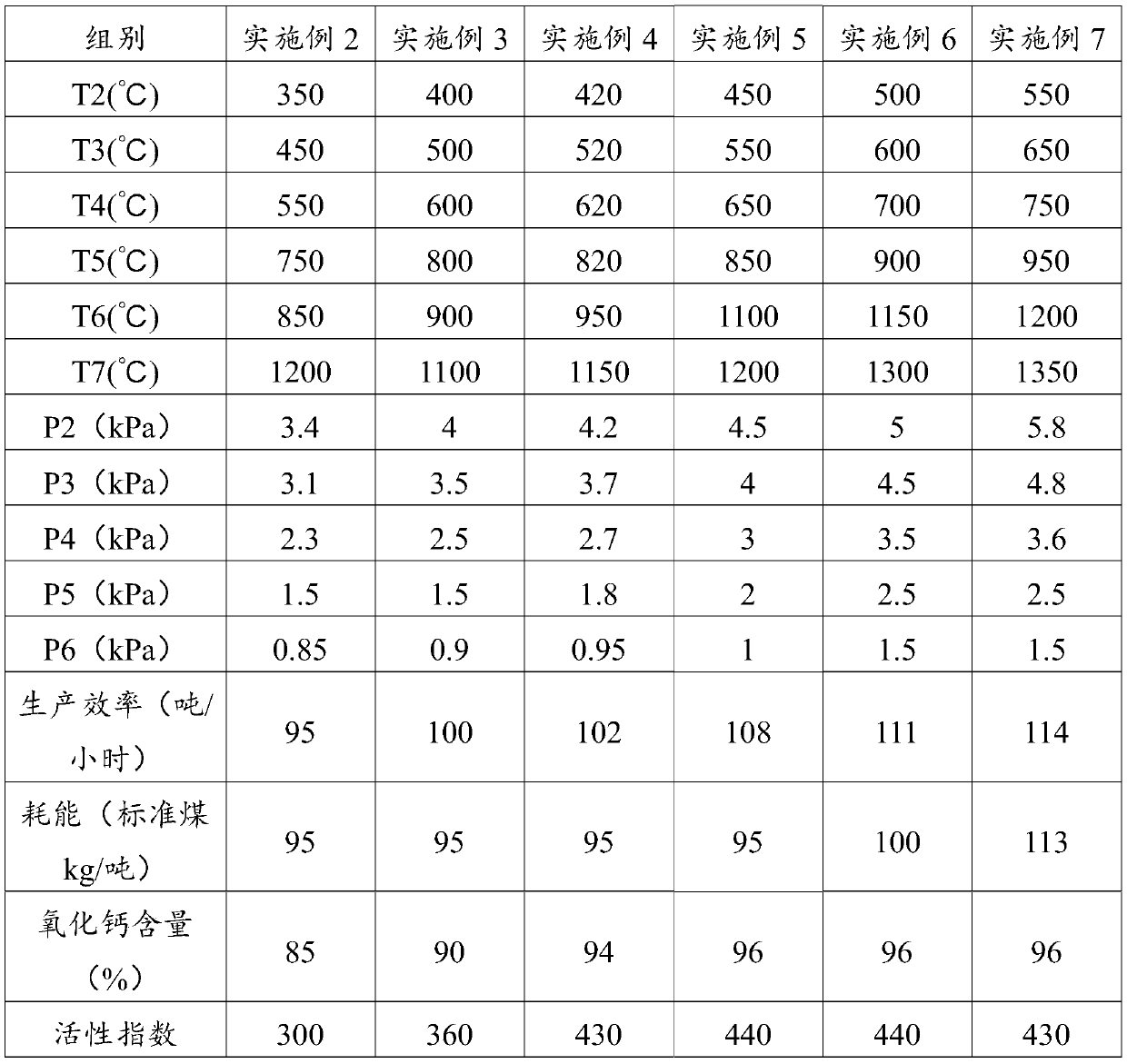

Powder multistage suspension preheating kiln outside calcium oxide calcining method

ActiveCN110498622AIncrease productionDecompose quickly and fullyChemical industryPreheating chargesDecompositionSingle line

The invention discloses a powder multistage suspension preheating kiln outside calcium oxide calcining method. The powder multistage suspension preheating kiln outside calcium oxide calcining method comprises following steps: 1, limestone powder is introduced into a multistage suspension preheating kiln for preheating to 800 to 900 DEG C; 2, the pre-heated material is introduced into a decomposition furnace, and calcining is carried out for 25 to 35s at 900 to 1100 DEG C; 3, the calcined material is conveyed back into a rotary kiln, and is subjected to calcining for 25 to 35min at 1100 to 1300DEG C, and is cooled to obtain calcium oxide. According to the method, the step in the prior art that block limestone is subjected to direct calcining is changed into the above steps that limestone is crushed into powder, and suspension preheating, decomposition furnace calcining decomposition, and rotary kiln calcining slaking are adopted to prepare powdery calcium oxide, the single line production capacity is 5 to 10 times higher than that of the conventional method, and energy saving and environment protection are realized.

Owner:GUANGXI SIWEI MATERIALS TECH CO LTD

Composite luminescent material and preparation method thereof

InactiveCN110903824AReduce manufacturing costEasy to operateMolybdeum compoundsGallium/indium/thallium compoundsQuantum efficiencyLuminous intensity

The invention relates to a composite luminescent material and a preparation method thereof. The composite luminescent material is generated by uniformly mixing a quantum dot precursor and an oxide ora precursor of the oxide according to a certain ratio and then calcining the obtained mixture at a high temperature. Compared with traditional methods, the method of the invention has the advantages of simple synthesis process, low cost, no solvent, high quantum efficiency, and realization of large-scale production; and the prepared luminescent material has a high luminescent intensity, a high luminescent color purity and a good photo-thermal stability, and lays a foundation for theoretical research and application of the material in high-performance photoluminescent devices, lasers and nonlinear optical devices.

Owner:SHANGHAI JIAO TONG UNIV

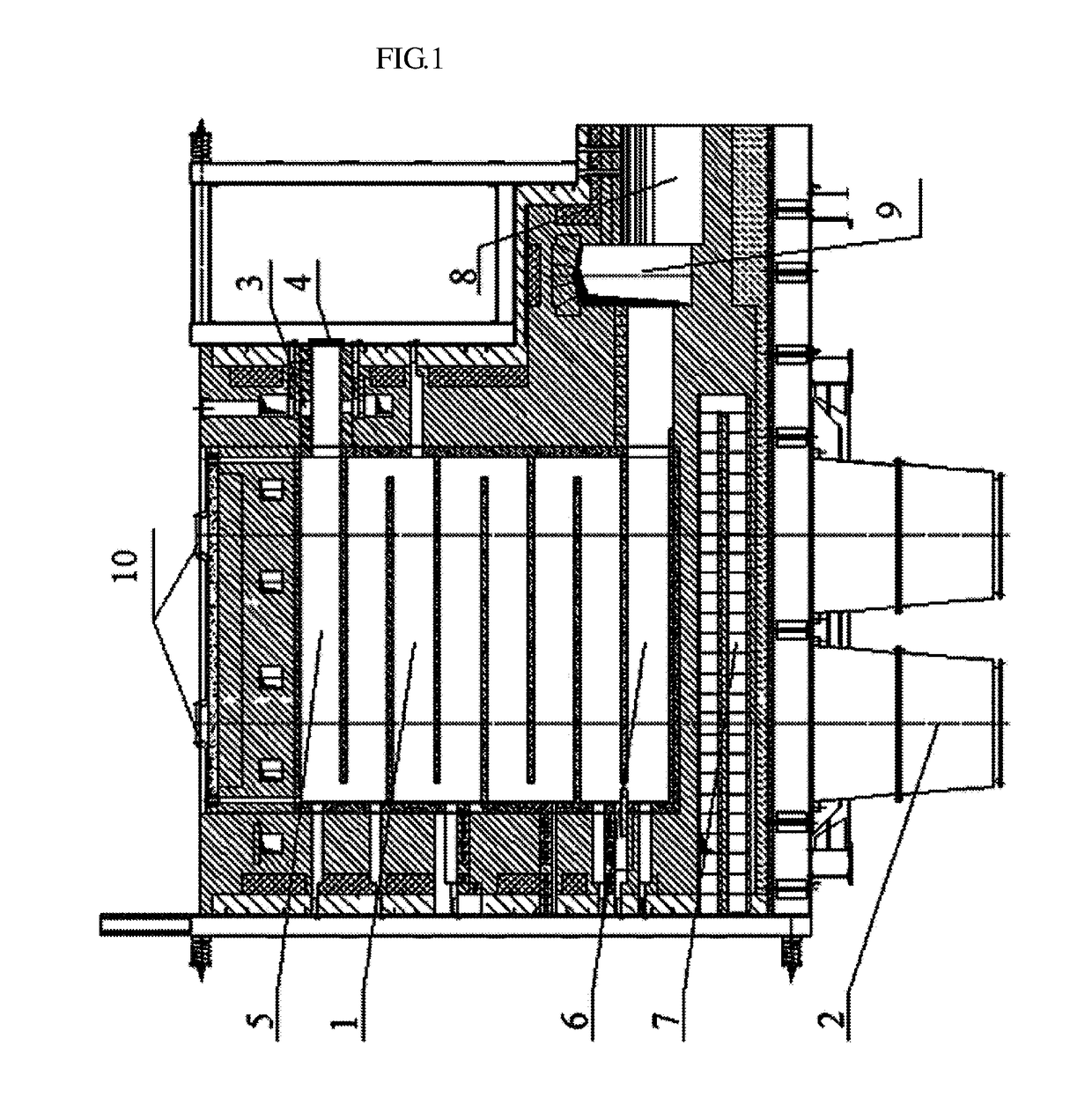

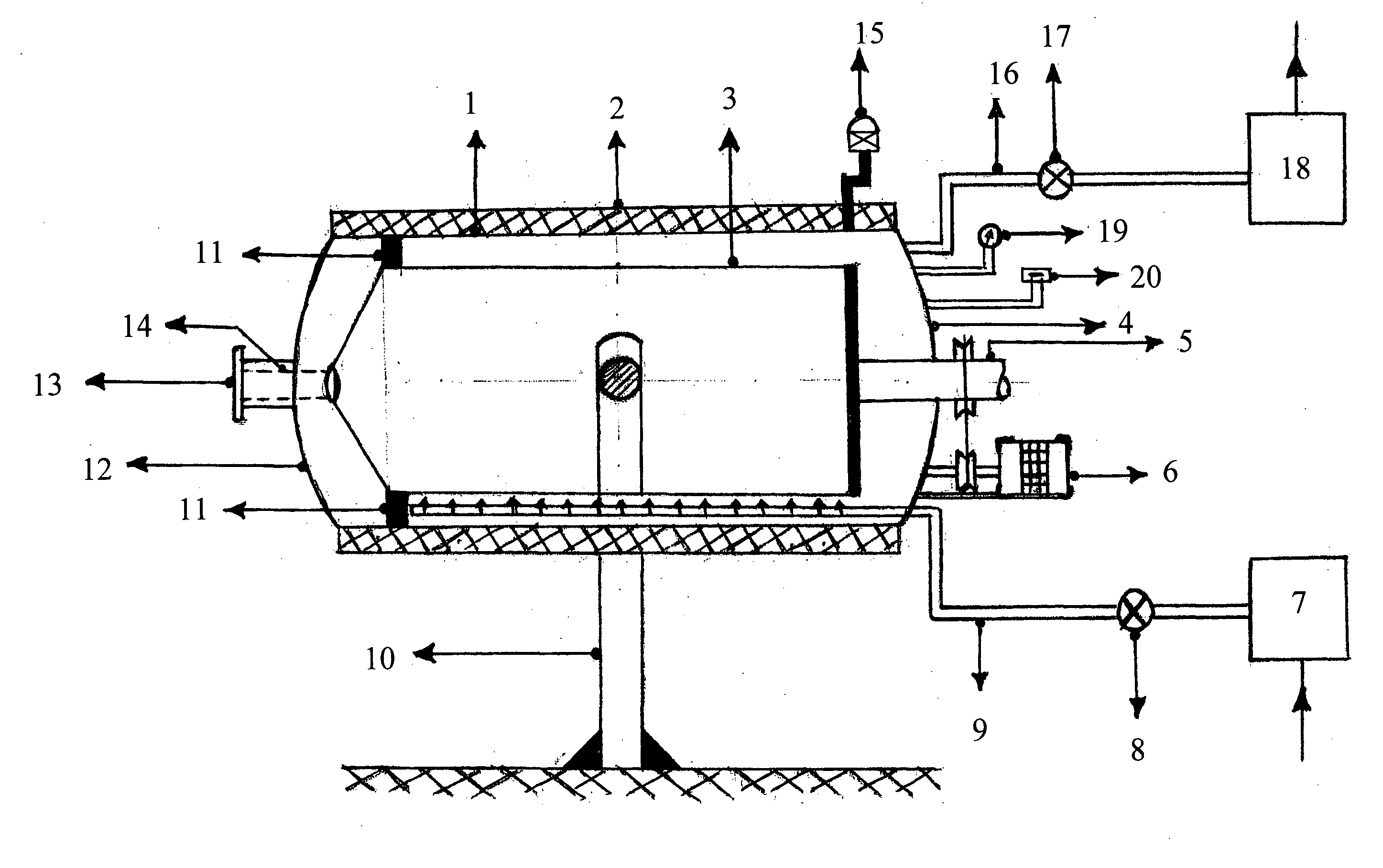

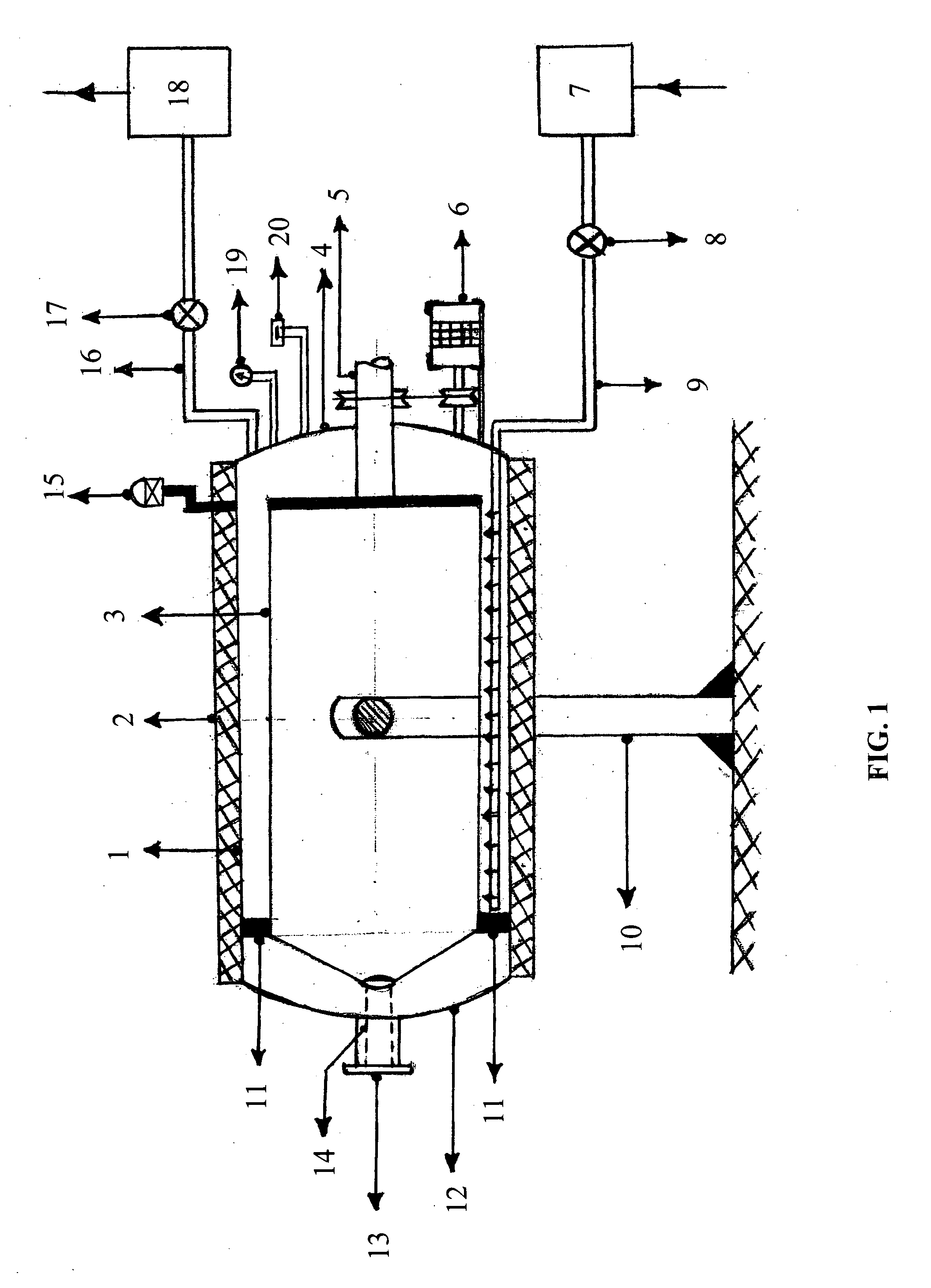

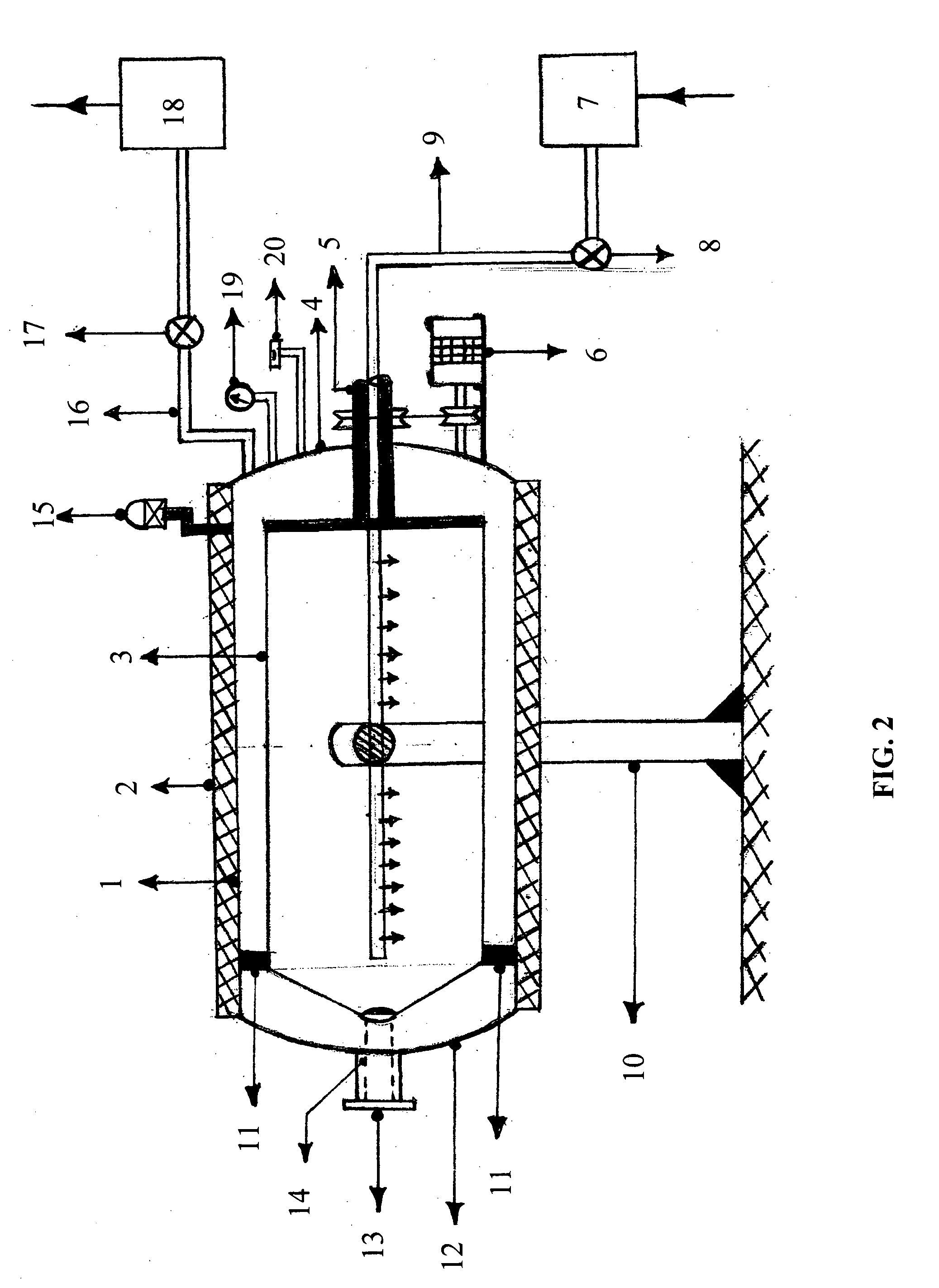

Process and an apparatus for converting solid organic materials into carbon or activated carbon

InactiveUS20110212015A1Easy feedingEasy to removePressurized chemical processSamplingThermal insulationInlet valve

A process and an apparatus for converting solid organic materials into carbon or activated carbon. The processing of solid organic materials is oxygen-free and wholly under endothermic condition. The apparatus comprises a pressure vessel (1), thermal insulation with protective cladding for pressure vessel (2), a perforated or non-perforated rotary drum (3), a sealed dish end (4), a rotating shaft (5), a geared motor with belt or chain drive (6), a steam super heater (7) for generating superheated steam, at least one inlet valve (8) for regulating the super heated steam, at least one feed pipe (9), tilting or swivel support (10), at least one cylindrical roller (11), an open or close door end (12), a feeding or removal port (13), a connecting chute (14), at least one pressure safety valve (15), a gas exit pipe (16), at least one outlet valve (17), a gas treatment unit (18) for treating the generated reaction gases, at least one pressure gauge (19) and at least one temperature indicator (20). The pressure vessel is tilted along with its accessories supported on a tilting or swivel support and solid organic materials are feeded into the rotary drum and then realigned. Gas or steam is feeded inside the pressure vessel till the entire air inside the pressure vessel is purged out and thereafter superheated steam continuously feeded into the rotary drum. The rotary drum is constantly rotated by geared motor and generated reaction gases are evacuated from the pressure vessel to the gas treatment unit wherein the organic solid materials are converted into carbon or activated carbon.

Owner:KRISHNAN BALU RAVI

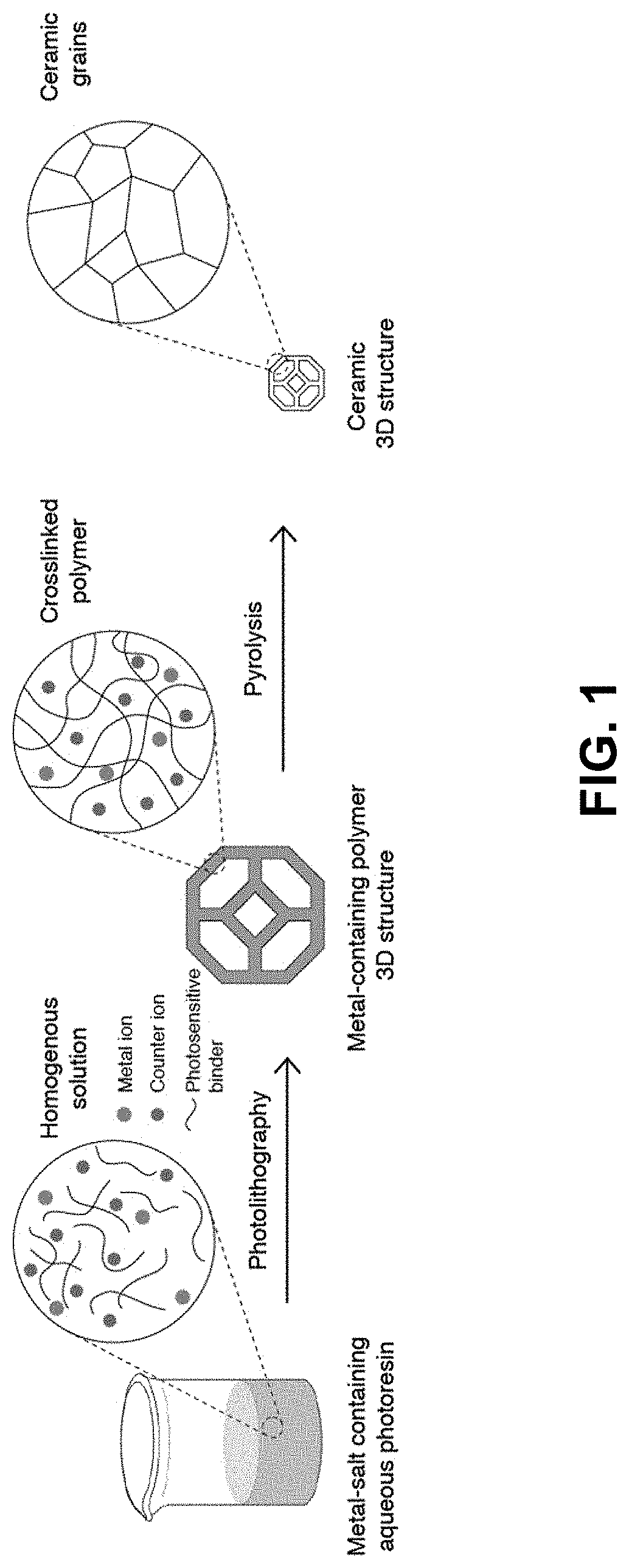

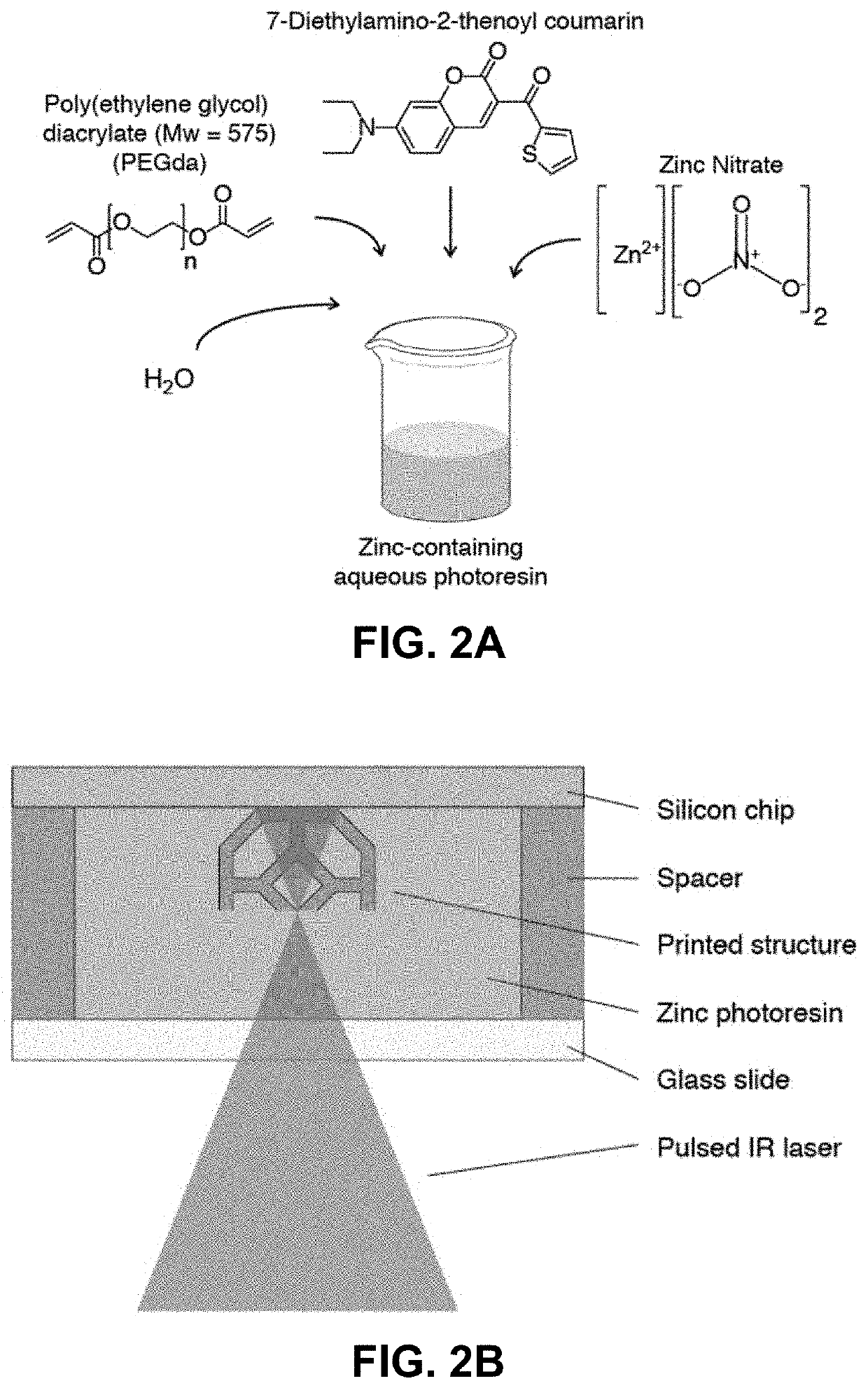

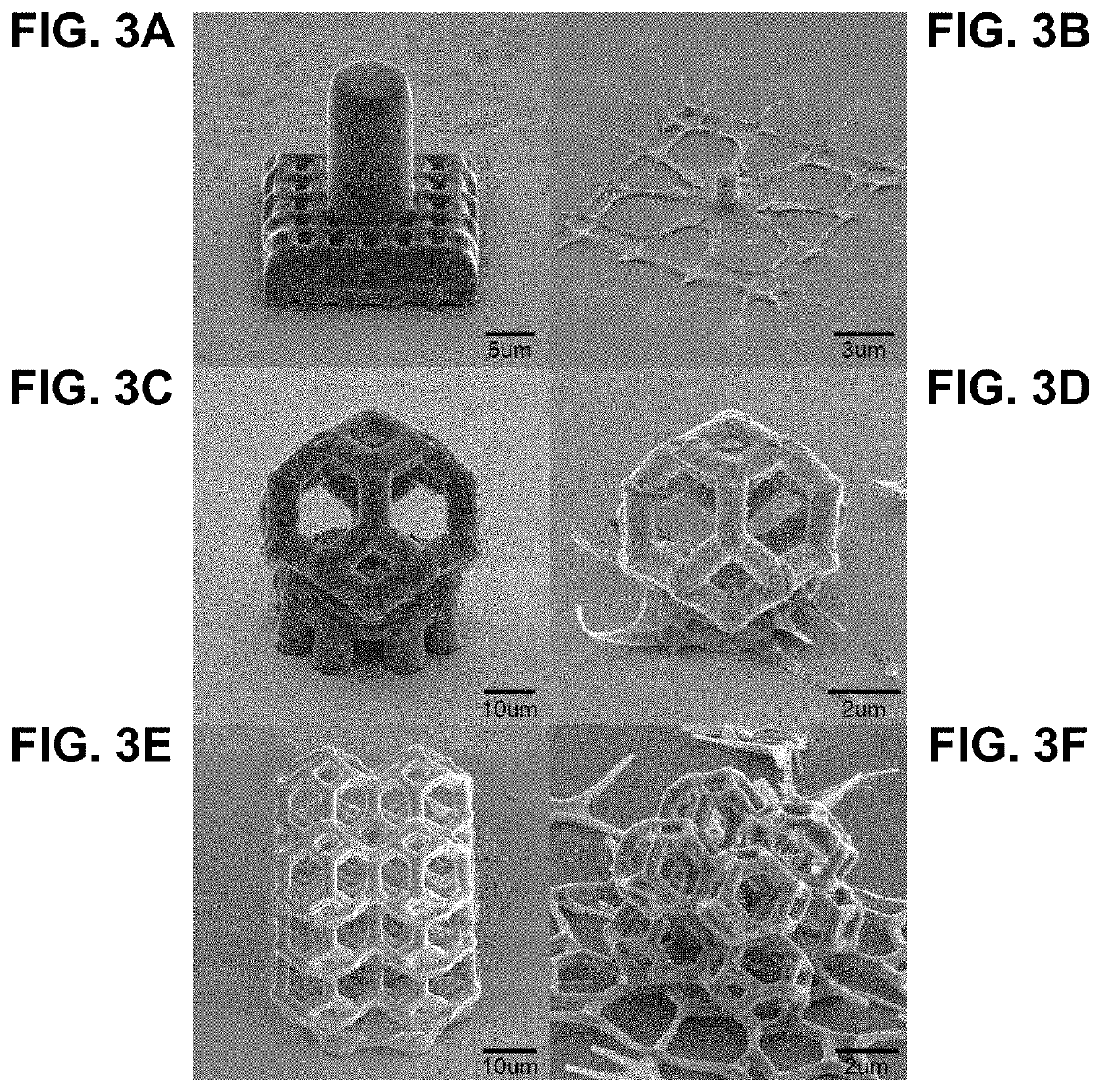

3D printing of metal containing structures

ActiveUS20200156035A1Improve performanceComposition is limitedAdditive manufacturing apparatusGel electrodesOrganic chemistryMaterials science

In an aspect, a method for making a metal-containing material comprises steps of: forming a metal-containing hydrogel from an aqueous precursor mixture using a photopolymerization; wherein the aqueous precursor mixture comprises water, one or more aqueous photosensitive binders, and one or more aqueous metal salts; and thermally treating the metal-containing hydrogel to form the metal-containing material; wherein the metal-containing hydrogel is exposed to a thermal-treatment atmosphere during the step of thermally treating; wherein a composition of the metal-containing material is at least partially determined by a composition of the thermal-treatment atmosphere during the thermally treating step.

Owner:CALIFORNIA INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com