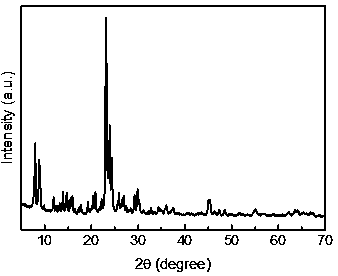

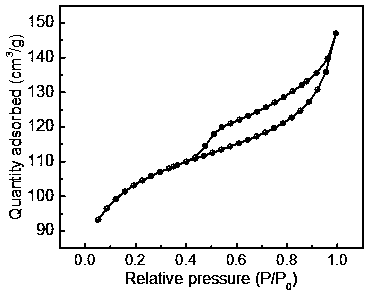

Preparation method and application of mesoporous FeCu-ZSM-5 molecular sieve

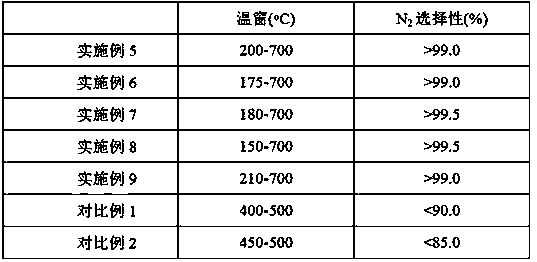

A fecu-zsm-5, molecular sieve technology, applied in separation methods, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of blocking active sites, narrow denitration temperature window, and complicated steps, so as to alleviate the release of polluted gases, Conducive to the effect of full contact and high N2 selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1.32 g Fe(NO 3 ) 3 9H 2 O, 0.26 g Cu(NO 3 ) 2 ·3H 2 O, 36.55 g H 2 O, 1.473 g TPABr, 14.18 g water glass (27.6 wt% SiO 2 ), 2.2 g of 2-hydroxy-propanetricarboxylic acid were added to the beaker to adjust the pH to 12, 30 o C for aging for 4 h, then add 1.2 g of 2-hydroxy-propanetricarboxylic acid to adjust the pH to 9,70 o C aging for 4 h, then transferred to a stainless steel autoclave lined with PTFE at 170 o C was crystallized for 48 h. After the crystallization was completed, the crystallized product was cooled, filtered and washed until neutral, and then placed in an oven at 120 o C was dried overnight to obtain sodium molecular sieves.

[0036] Sodium molecular sieves were mixed with 1 M NH 4 The Cl solution was ion-exchanged according to the mass ratio of 1:20, at 70 o Stir in a constant temperature water bath at C for 4 h, filter, wash, and dry at 520 o After C was calcined for 5 h, the hydrogen-type FeCu-ZSM-5 molecular sieve was obtained, which was...

Embodiment 2

[0038] This embodiment provides a FeCu-ZSM-5 catalyst, the preparation steps are the same as in Embodiment 1, only some parameters are adjusted, as follows:

[0039] Molecular sieve preparation: 2.18 g Fe(NO 3 ) 3 9H 2 O, 0.13 g Cu(NO 3 ) 2 ·3H 2 O, 10 g H 2 O, 5.20 g cetyltrimethylammonium bromide, 1.069 g sodium aluminate, 14.18 g water glass (27.6 wt% SiO 2 ), 2.2 g H 2 SO 4 Add to the beaker to adjust the pH to 11, 40 o C for 2 h, then add 1.2 g of sulfuric acid to adjust the pH to 8,80 o C aging for 4 h, and then transferred to a stainless steel autoclave lined with PTFE at 160 o C was crystallized for 24 h. After the crystallization was completed, the crystallized product was cooled, filtered and washed until neutral, and then placed in an oven at 120 o C was dried overnight to obtain sodium molecular sieves.

[0040] Sodium molecular sieves were mixed with 1 M NH 4 The Cl solution was ion-exchanged according to the mass ratio of 1:20, at 70 o Stir in a con...

Embodiment 3

[0042] This embodiment provides a FeCu-ZSM-5 catalyst, the preparation steps are the same as in Embodiment 1, only some parameters are adjusted, as follows:

[0043] Molecular sieve preparation: 5.2 g Fe(NO 3 ) 3 9H 2 O, 0.11 g Cu(NO 3 ) 2 ·3H 2 O, 18.3 g H 2 O, 8.67 gTPABr, 2.27 g aluminum sulfate, 14.18 g water glass (27.6 wt% SiO 2 ), 2.2 g H 2 SO 4 Add to the beaker to adjust the pH to 13, 50 o C aging for 5 h, then adding 3.2 g of sulfuric acid to adjust the pH to 7, 60 o C aging for 6 h, then transferred to a stainless steel autoclave with a Teflon liner at 170 o C was crystallized for 48 h. After the crystallization was completed, the crystallized product was cooled, filtered and washed until neutral, and then placed in an oven at 90 o C was dried overnight to obtain sodium molecular sieves.

[0044] Sodium molecular sieves were mixed with 1 M NH 4 The Cl solution was ion-exchanged according to the mass ratio of 1:15, at 70 o Stir in a constant temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| External specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com