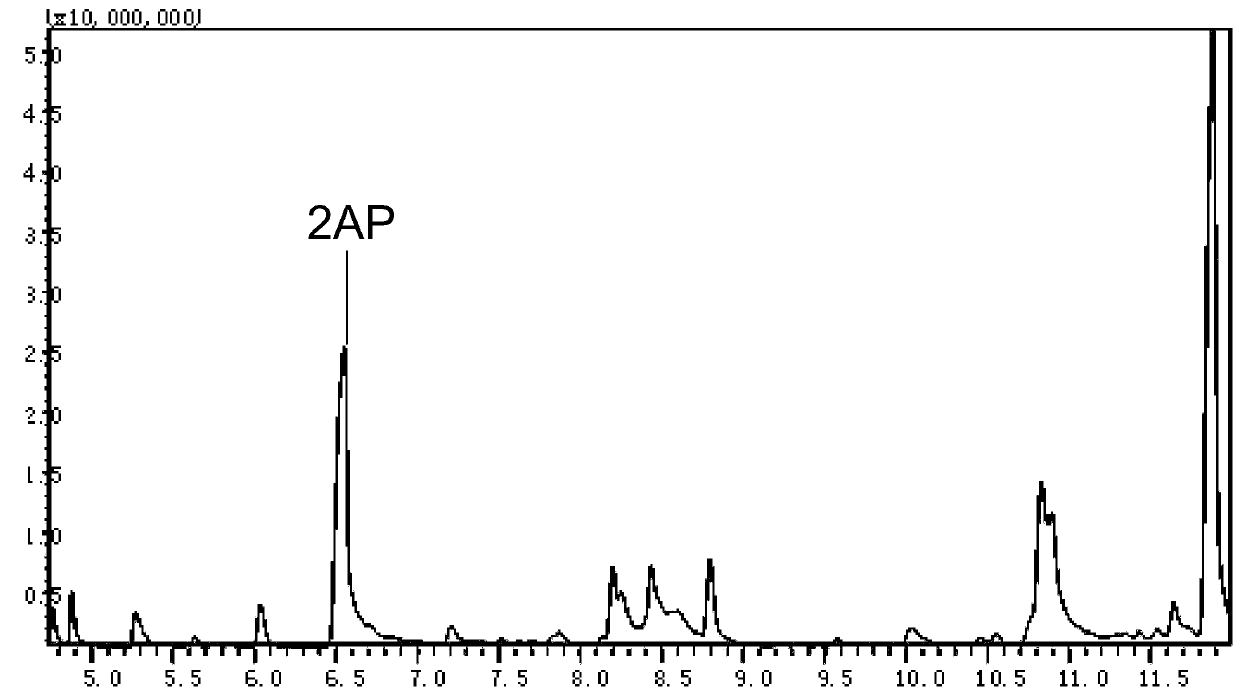

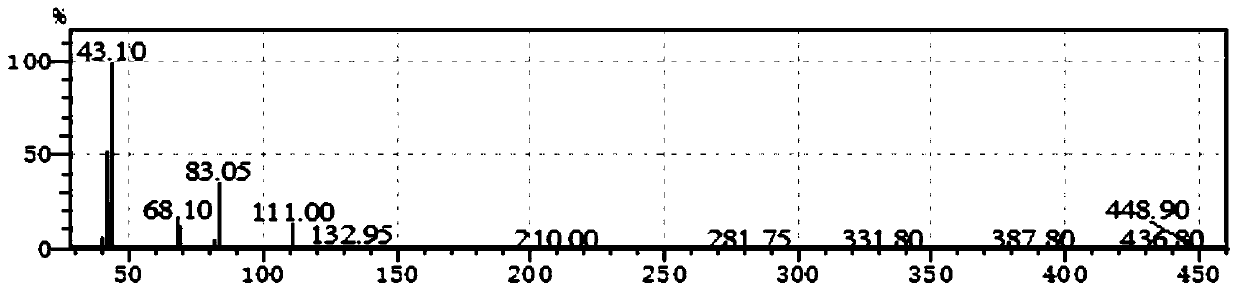

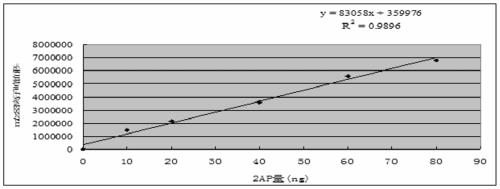

Gas chromatography-mass spectrometry method for determining content of 2-acetyl-1-pyrroline in fragrant rice leaves by external standard multipoint process

A technology of pyrroline and multi-point method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of many target interferences, time-consuming and labor-intensive, target loss, etc., to overcome cumbersome steps, good application prospects, and easy loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Step 1: The plants of rice variety 1 are taken from the top and first full leaves before heading, cut into pieces and immediately ground into powder with liquid nitrogen.

[0084] Step 2: Weigh 100 mg of the sample into a 20 ml screw top headspace vial and tighten it with a magnetic metal cap with a PTFE / blue silicone septum.

[0085] Step 3: Carry out the automatic solid-phase microextraction stage, and the extraction is divided into three stages:

[0086] The first stage: keep preheating at 70°C for 5 minutes.

[0087]The second stage: the type of extraction head adopts carbon molecular sieve / divinybenzene / polydimethylsiloxane (carboxen / divinybenzene / polydimethylsiloxane, CAR / DVB / PDMS; 50 / 30 µm, 1 cm long) at 70°C, with a rotation speed of 250 rpm / min. The depth of the extraction head into the vial is 18 mm. This extraction phase lasted 30 min.

[0088] The third stage: the extract was directly injected into the injection port of the GC-MS instrument, the inject...

Embodiment 2

[0097] Step 1: The flag leaves after heading are taken from the plants of rice variety 2 and ground with liquid nitrogen.

[0098] Step 2: Weigh 100 mg of the sample into a 20 ml screw top headspace vial and tighten it with a magnetic metal cap with a PTFE / blue silicone septum.

[0099] Step 3: Carry out the automatic solid-phase microextraction stage, and the extraction is divided into three stages:

[0100] The first stage: keep preheating at 80 ℃ for 10 min.

[0101] The second stage: the type of extraction head adopts carbon molecular sieve / divinybenzene / polydimethylsiloxane (carboxen / divinybenzene / polydimethylsiloxane, CAR / DVB / PDMS; 50 / 30 µm, 1 cm long) at 80 ℃, rotating speed 220 rpm / min, shake for 20 s, and stop for 5 s at intervals. The depth distance of the extraction head into the vial is 22 mm. This extraction phase lasted 40 min.

[0102] The third stage: the extract was directly injected into the injection port of the GC-MS instrument, the injection time was...

Embodiment 3

[0112] Step 1: The plants of rice variety 3 are taken from flag leaves after heading, and ground with liquid nitrogen.

[0113] Step 2: Weigh 100 mg of the sample into a 20 ml screw top headspace vial and tighten it with a magnetic metal cap with a PTFE / blue silicone septum.

[0114] Step 3: Carry out the automatic solid-phase microextraction stage, and the extraction is divided into three stages:

[0115] The first stage: keep preheating at 80 ℃ for 15 minutes.

[0116] The second stage: the type of extraction head adopts carbon molecular sieve / divinybenzene / polydimethylsiloxane (carboxen / divinybenzene / polydimethylsiloxane, CAR / DVB / PDMS; 50 / 30 µm, 1 cm long) at 80 ℃, rotating speed 250 rpm / min. The depth of the extraction head into the vial is 23 mm. This extraction phase lasted 50 min.

[0117] The third stage: the extract was directly injected into the injection port of the GC-MS instrument, the injection time was 1.5 min, and the injection temperature was 250°C.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com