Preparation method of SiC/Co heterogeneous composite nanowires

A nanowire and heterogeneous technology, which is applied in the field of preparation of composite nanowires, can solve the problems of large deposited particle size, cumbersome steps, and poor controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

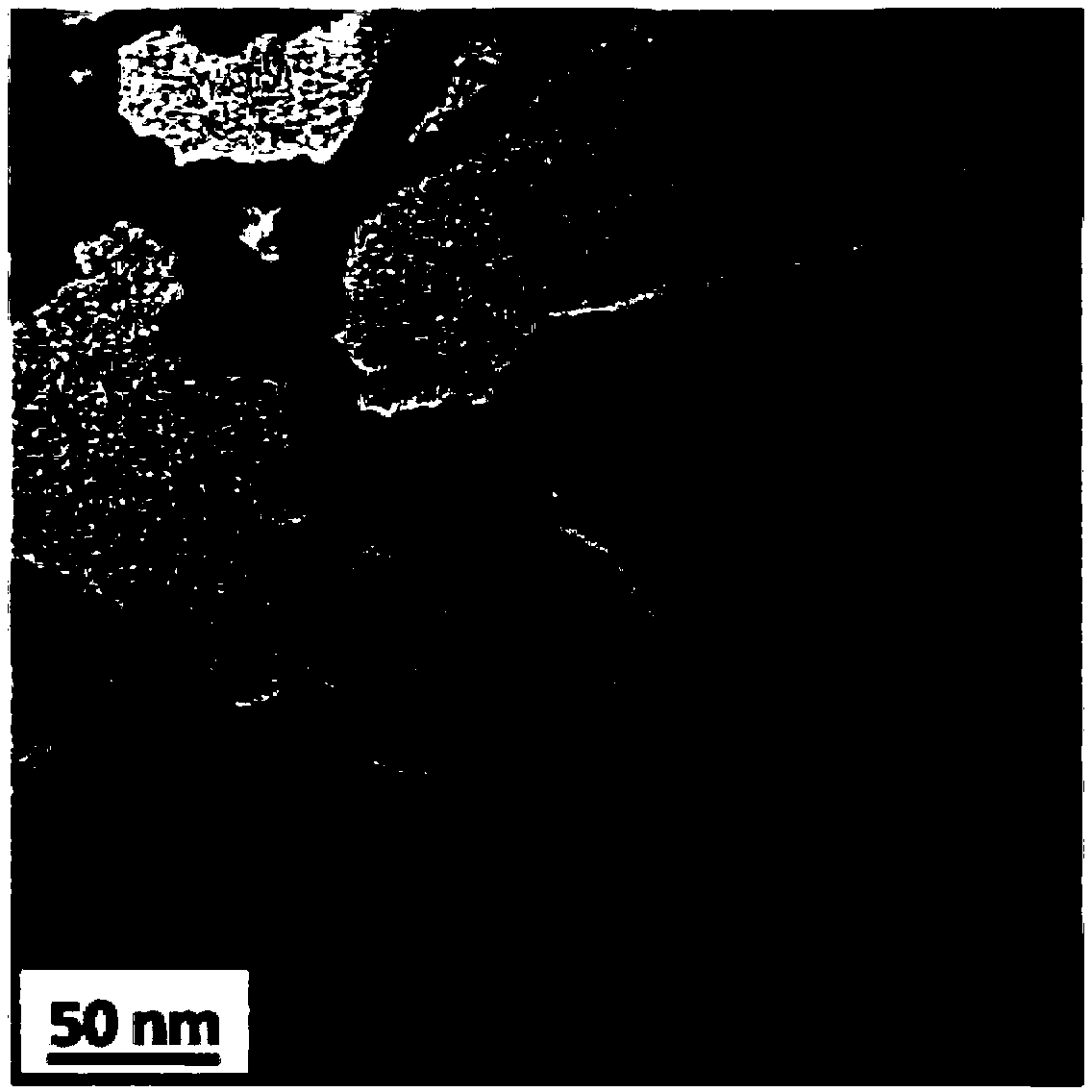

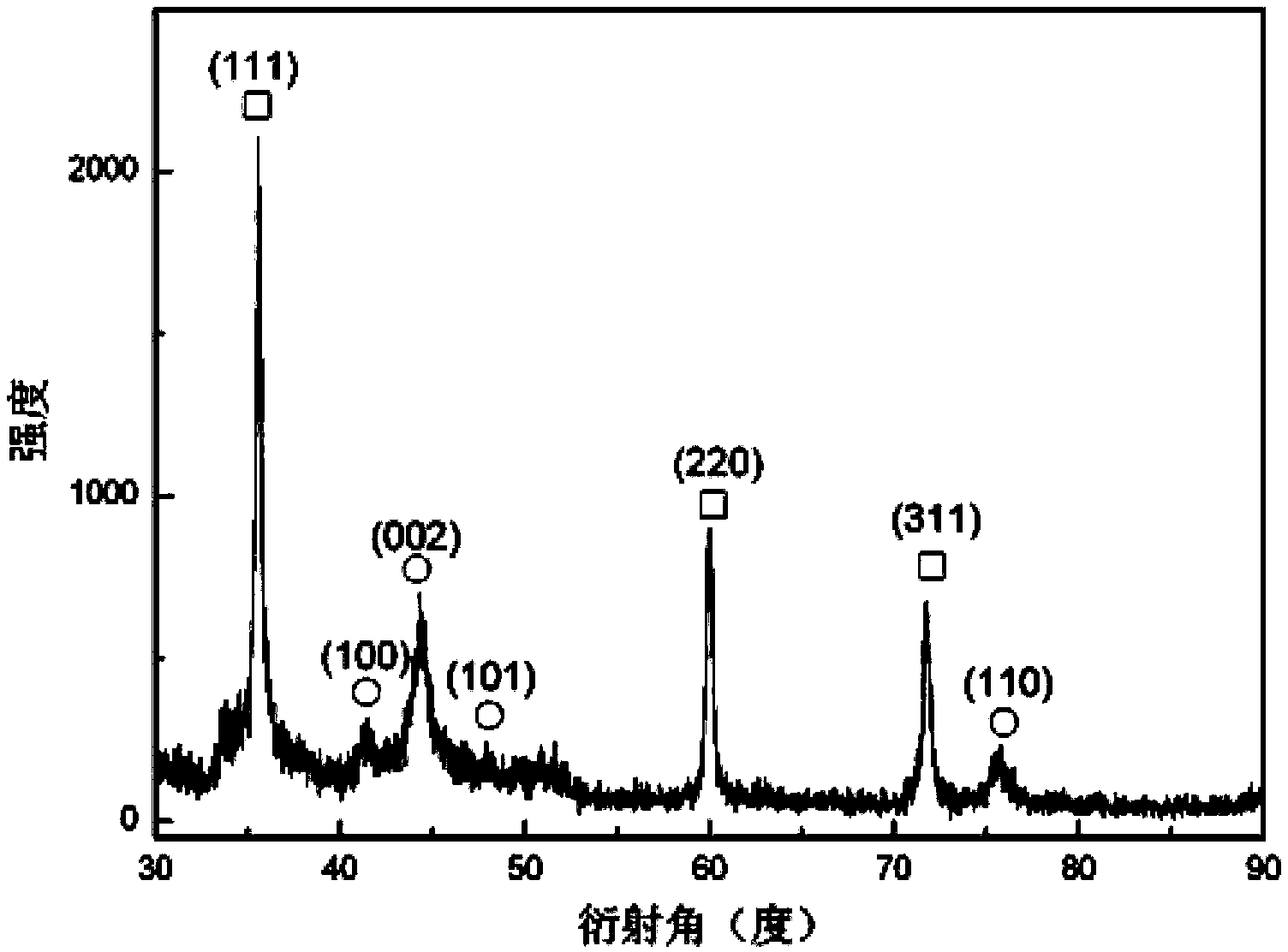

[0012] Specific Embodiment 1: This embodiment is a method for preparing SiC / Co heterogeneous composite nanowires, which is specifically prepared according to the following steps:

[0013] 1. Mixing: first add SiC nanowires and cobalt-containing compounds to the polyol, and mix to obtain the mixture; the mass ratio of SiC nanowires and cobalt-containing compounds described in step 1 is 1: (0.2~5); step The volume ratio of the mass of the SiC nanowires described in 1 to the polyol is 1mg: (0.1mL~3mL);

[0014] 2. Reflux reaction: heat the mixture under the protection of inert gas, heat to boiling at a heating rate of 3°C / min-10°C / min, and reflux for 0.1h-2h to obtain the reaction product;

[0015] 3. Magnetic separation: first, the reaction product is cooled to room temperature, and then magnetic separation is performed. The solid obtained by magnetic separation is washed 2 to 5 times with deionized water, and the washed solid is dried. SiC / Co heterogeneous composite can be obta...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cobalt-containing compound described in step 1 is cobalt acetylacetonate or cobalt acetate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the polyhydric alcohol described in step 1 is diethylene glycol, triethylene glycol or tetraethylene glycol. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com