Patents

Literature

45results about How to "Overcoming controllability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

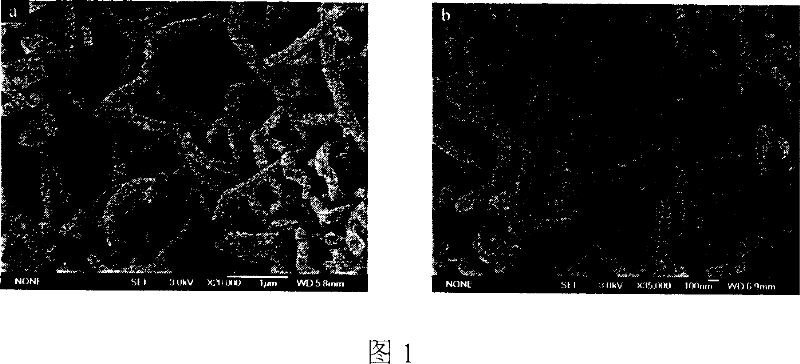

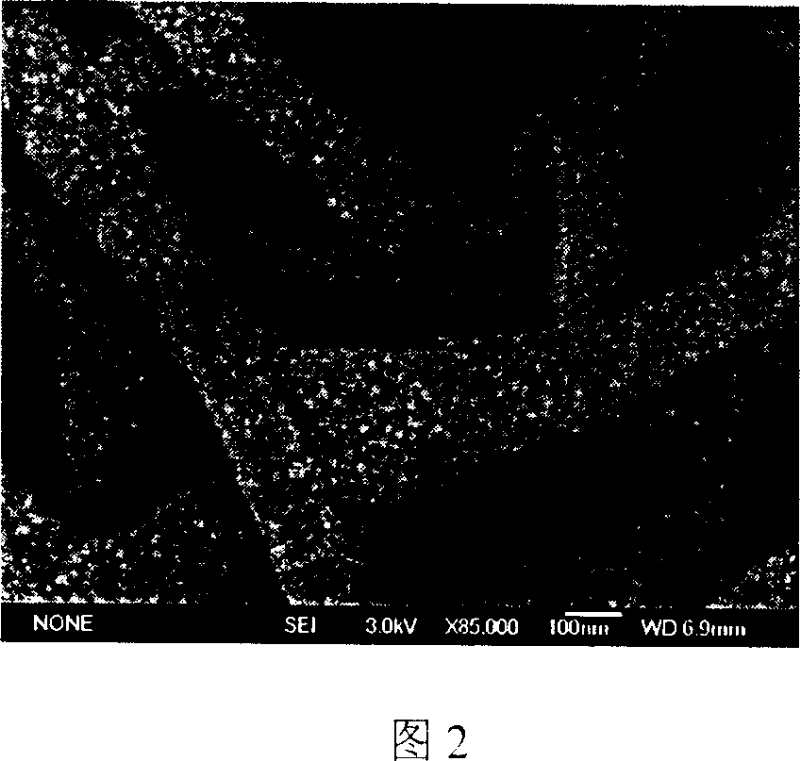

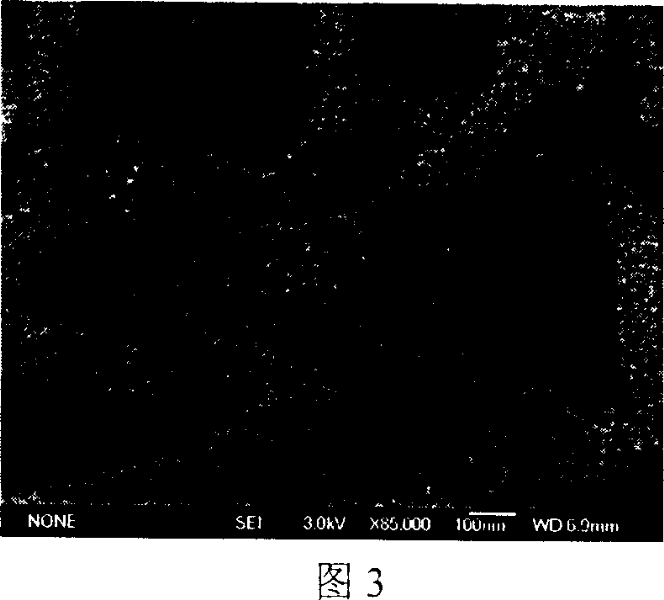

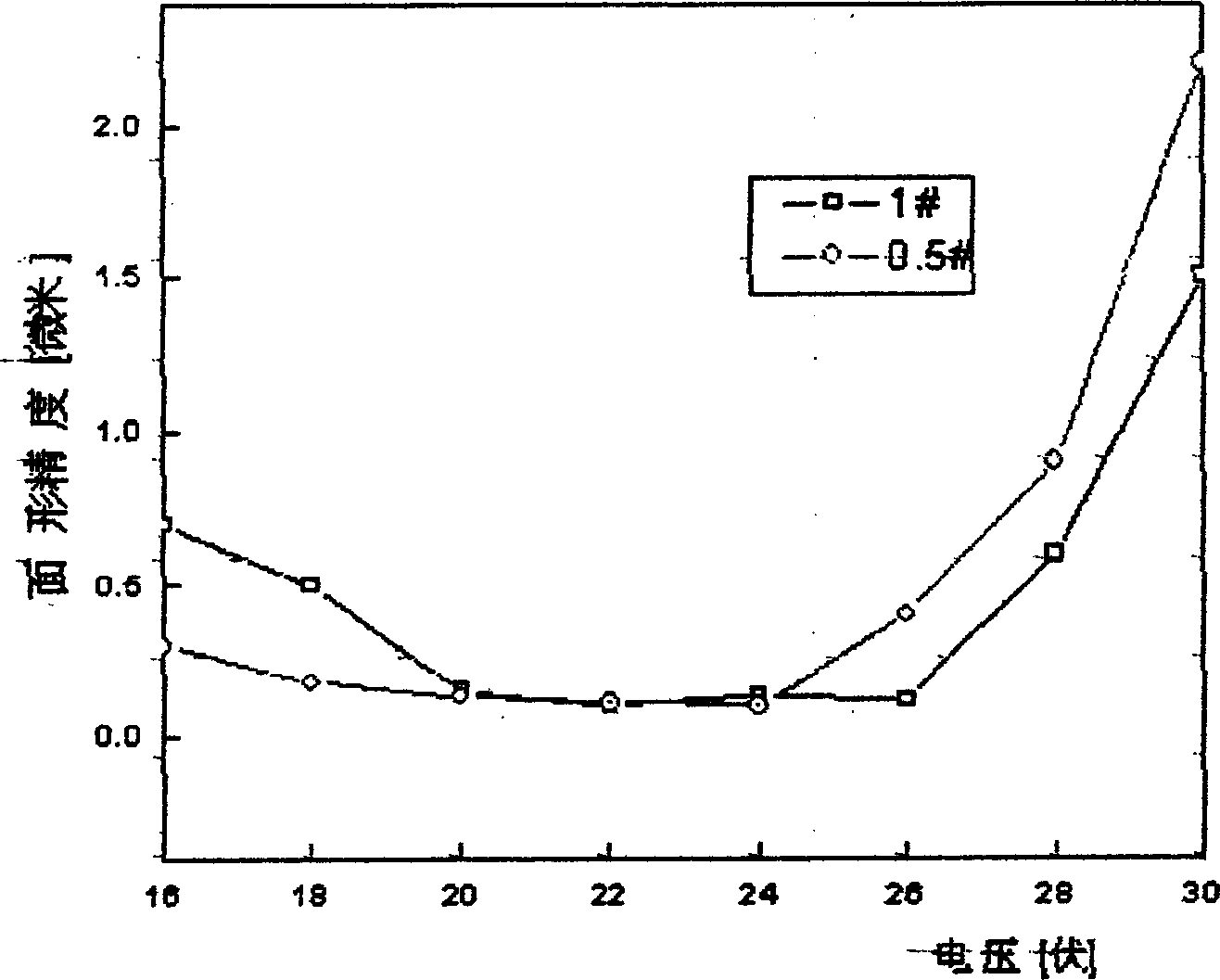

Preparation method of size-controllable nano structural conductive polyaniline

The invention relates to a method of preparing size-controllable nano structure conductive polyaniline, which includes steps: adding solution of monomer aniline to solution of oxidant under temperature of 0-5 DEG C, carrying polymerization reaction according conventional interfacial polymerization method or homopolymerization method, after conventional post-treatment, obtaining the size-controllable nano structure conductive polyaniline. The oxidant is selected according to diameter of the needed polyaniline nano structure by following formula: log d=0.69+0.71Eox, wherein d is diameter of nano structure polyaniline, Eox is oxidation-reduction potential of used oxidant. Compared with traditional ''template method'' and ''soft template method'', advantages of the invention are: template and post-treatment thereof is avoided, reaction medium is simplified, method is more simple and low-cost, defect of bad controllability to production configuration and size of traditional template-free method is overcomed, and size completely controllable conductive polyaniline nano fiber can be prepared by selecting oxidant with fitting oxidation-reduction potential.

Owner:INST OF CHEM CHINESE ACAD OF SCI

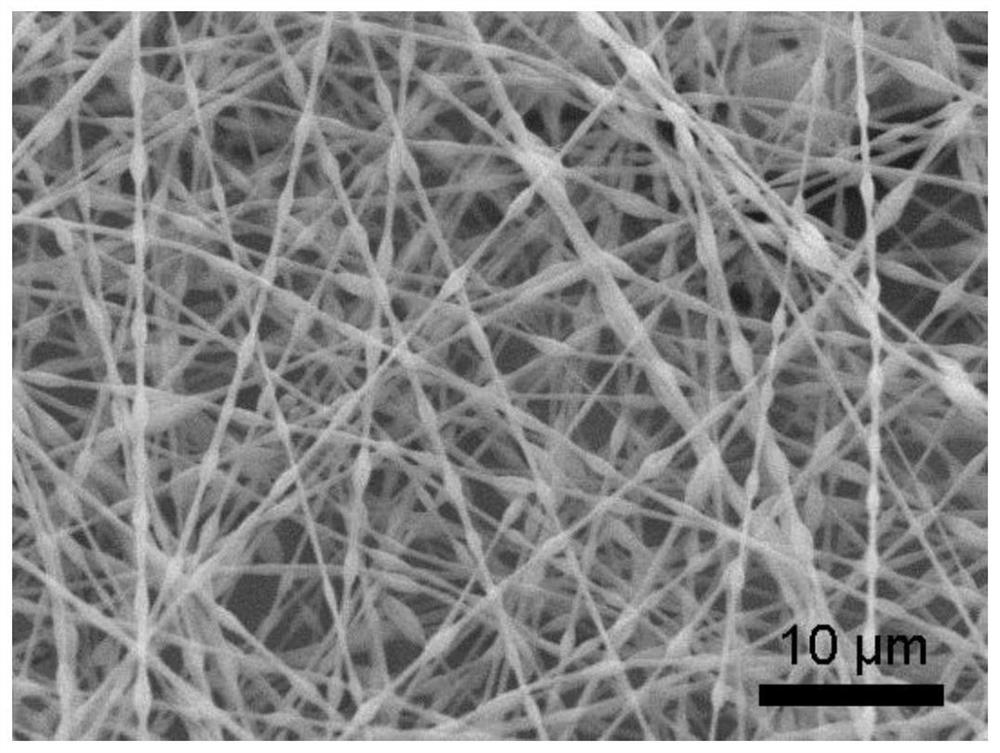

Preparation method of high temperature resistant silicon dioxide nanometer fiber filtering membrane

InactiveCN102652903AShort manufacturing timeOvercoming controllabilitySemi-permeable membranesHigh pressureSilicon dioxide

The invention provides a preparation method of a high temperature resistant silicon dioxide nanometer fiber filtering membrane. The preparation method is characterized by comprising the specific steps of: adding organosilicone, water, ethanol and inorganic acid at room temperature into a stirring kettle so as to obtain a mixed solution, and adding inorganic salt; stirring the mixed solution so as to obtain a precursor colloidal sol; inputting the precursor colloidal sol in a spinning head of electrostatic spinning equipment, simultaneously wherein the spinning head is connected with a high-voltage power supply so as to carry out electrostatic spinning to obtain the nanometer fibrous membrane; placing the nanometer fibrous membrane into a vacuum drying chamber to dry, then placing into a box resistance furnace to carry out warming for calcination, namely obtaining the high temperature resistant silicon dioxide nanometer fiber filtering membrane. The preparation method provided by the invention has the advantages that the preparation process is simple, the cost is cheap, the fiber diameter of the acquired high temperature resistant silicon dioxide nanometer fiber filtering membrane is small, the fire resisting quality is good, and the high temperature resistant silicon dioxide nanometer fiber filtering membrane has good structural stability; and the filter efficiency of high temperature smoke dust particles the sizes of which are more than 0.24 mum achieves 99.9% at 1500 DEG C, and the high temperature resistant silicon dioxide nanometer fiber filtering membrane has extensive application prospects in the fields such as high-temperature insulation, individual protection, and aerospace.

Owner:DONGHUA UNIV

Controlled-release carbon source material for repairing polluted underground water organisms and preparation method thereof

ActiveCN102491497AGuaranteed uptimeNutritionally stableBiological water/sewage treatmentMicroorganismNutrition

The invention discloses a controlled-release carbon source material for repairing polluted underground water organisms and a preparation method thereof and belongs to the field of underground water repairing. The controlled-release carbon source material comprises a core and a shell wrapping the core, wherein the core comprises the following components in percentage by weight: 40 to 86 percent ofcarbon releasing raw material, 1 to 25 percent of nutritional raw material, 5 to 45 percent of plastic bonding raw material, 5 to 20 percent of high-permeability raw material and the balance of water; the shell comprises the following components in percentage by weight: 10 to 40 percent of carbon releasing raw material, 1 to 10 percent of nutritional raw material, 20 to 80 percent of plastic bonding raw material, 0 to 40 percent of high-permeability raw material and the balance of water; and the controlled-release carbon source material is prepared by a compound formula consisting of the carbon releasing raw materials, nutritional elements and multi-component inorganic combined raw materials. The controlled-release carbon source material meets a microbial nutrition demand and requirementsfor long-time stable material supply during underground water repairing, certain mechanism strength and uniform sphericity; furthermore, the defects of high carbon loss, uncontrollable releasing rateand the like in the conventional carbon source compensation method are overcome; and the continuity of the underground water organism repairing effect is realized.

Owner:HOHAI UNIV +1

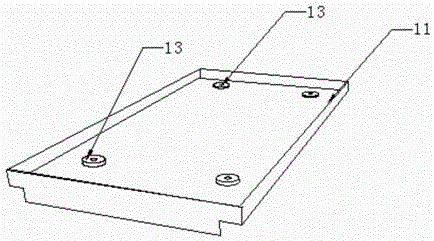

Paper-based microfluidic chip and preparation method thereof

The invention discloses a paper-based microfluidic chip. The paper-based microfluidic chip comprises a paper-based chip and a paper-based substrate, wherein the paper-based chip is provided with a microfluidic channel, the paper-based substrate is correspondingly adhered to the bottom of the paper-based chip, and the paper-based chip and the paper-based substrate are respectively subjected to cross-linking and solidifying treatment through liquid glue. The invention also discloses a three-dimensional paper-based microfluidic chip which is formed by stretching or folding the paper-based microfluidic chip. The paper-based microfluidic chip disclosed by the invention has the advantages of low cost, easiness in preparation, controllable liquid flow and the like, and is applicable to microfluidic analysis experiments.

Owner:GUANGDONG XIAN JIAOTONG UNIV ACADEMY +1

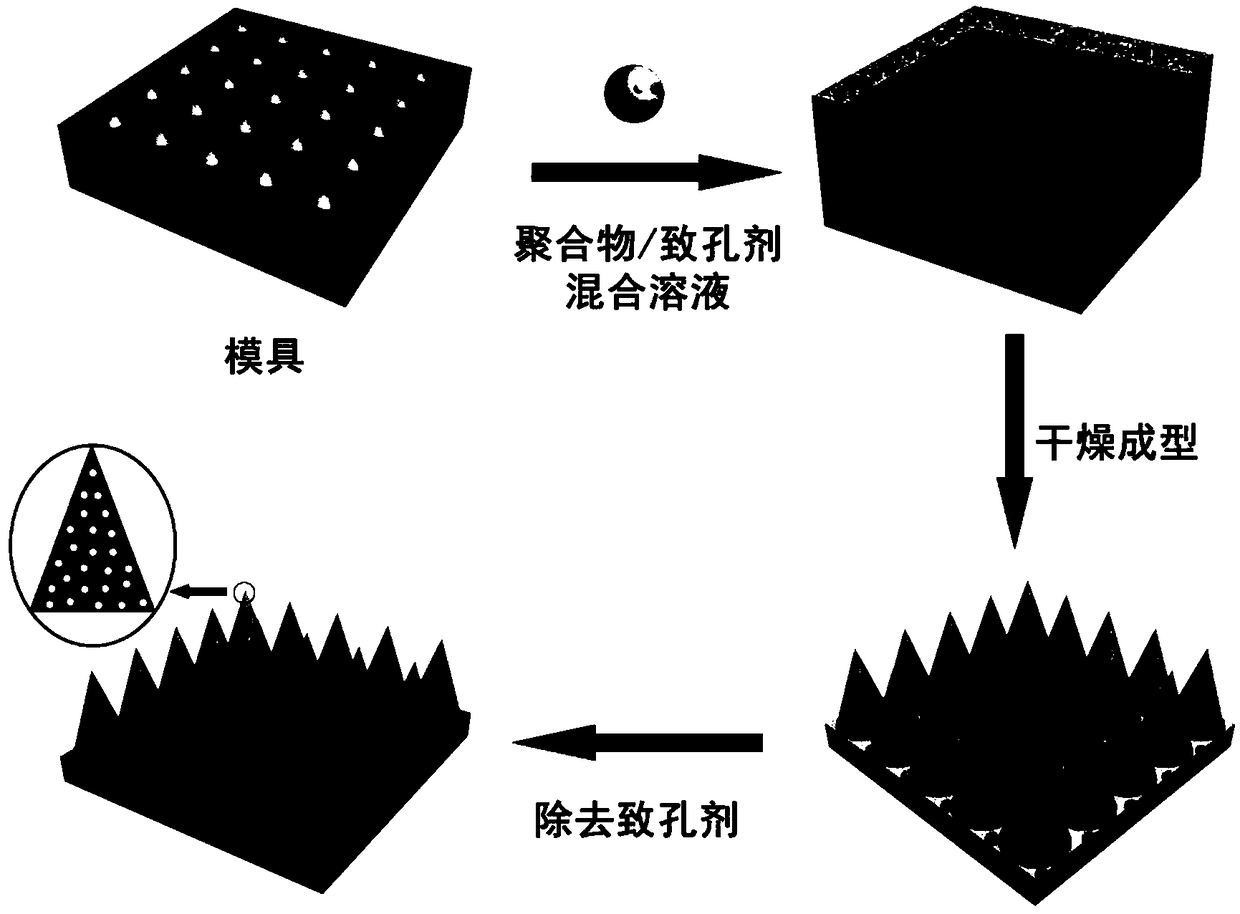

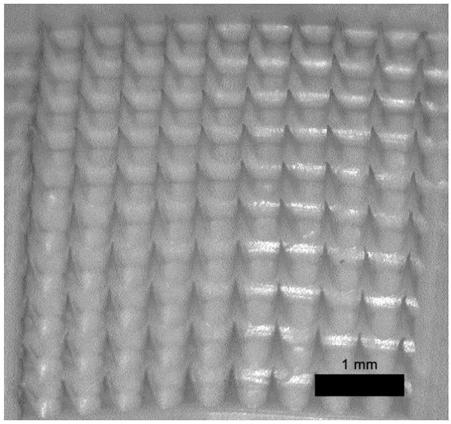

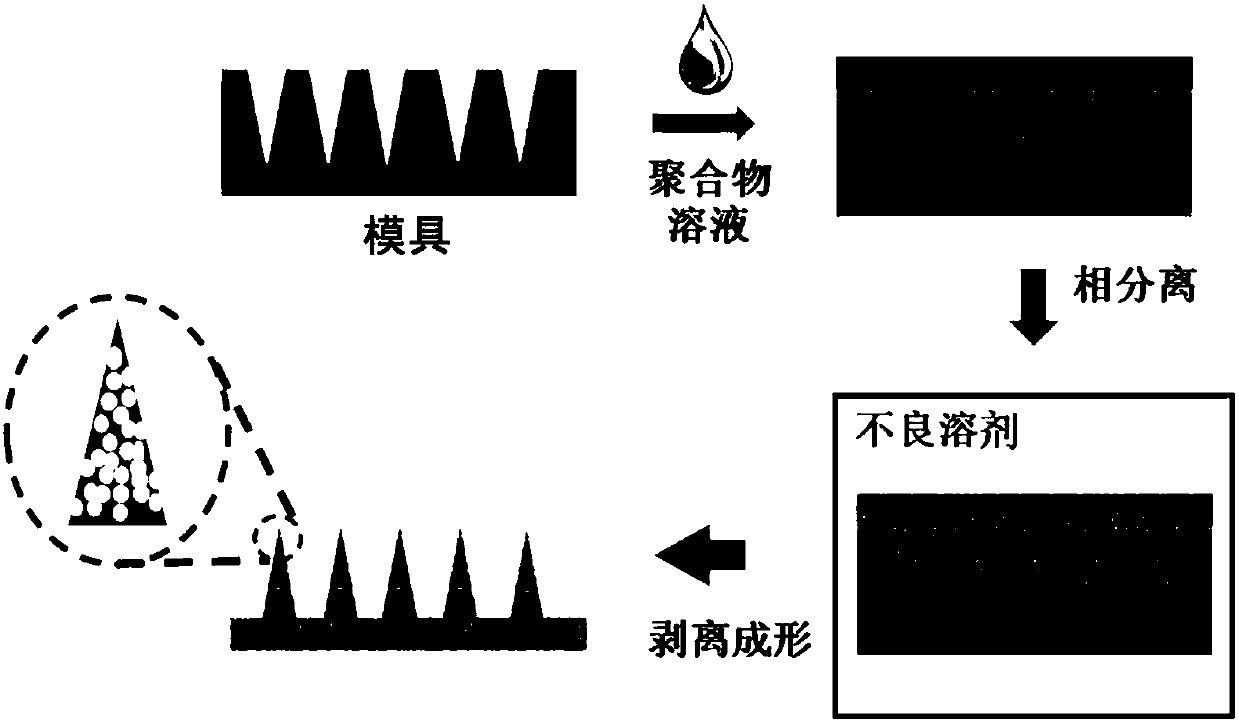

Method for preparing porous polymer micro needle by using template method and application thereof

InactiveCN109364366AOvercome the cumbersome preparation processOvercome the conditionsMicroneedlesPharmaceutical delivery mechanismTissue fluidHair growth

The invention discloses a method for preparing a porous polymer micro needle by using a template method and an application thereof. The method comprises the following steps of: (1) dissolving a polymer and a template agent in a solvent to prepare a polymer solution; (2) filling the polymer solution into a micro needle mould; (3) removing the solvent in the obtained micro needle mould to obtain a solid micro needle; (4) removing the template agent in the obtained solid micro needle to obtain the porous polymer micro needle. By improving the overall process flow design of the preparation method,the method can solve the technical problems of a complex preparation process, harsh conditions, a complicated process, high price, difficult control of the pore structure and size, difficult large-scale production and application and the like of the porous polymer micro needle, the obtained porous polymer micro needle can be used for tissue fluid extraction and transdermal administration, such asskin tissue fluid and blood extraction and transdermal administration of proteins, polypeptides and small molecular drugs in cosmetic, hair growth, immunity, treatment and other applications.

Owner:HUAZHONG UNIV OF SCI & TECH +1

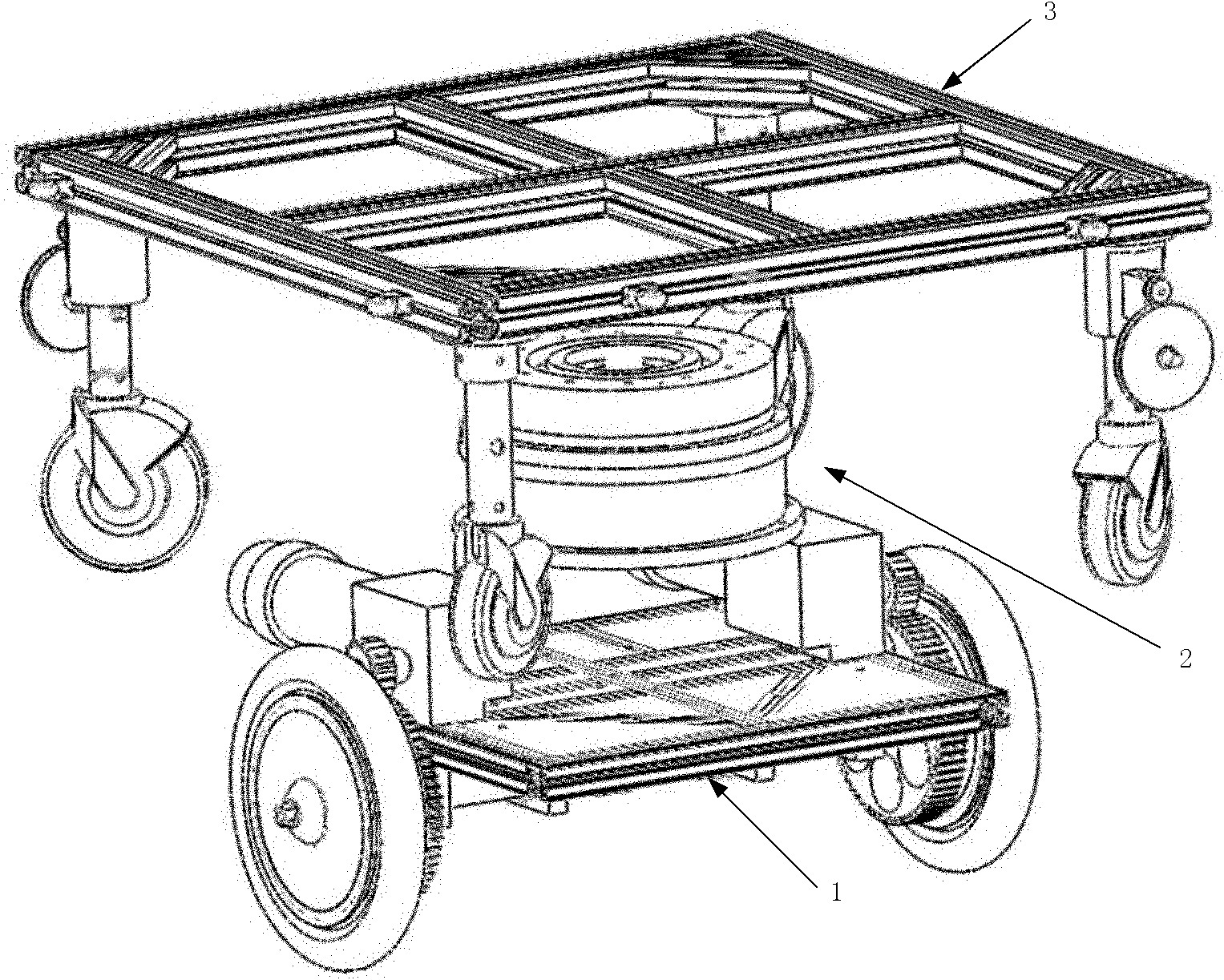

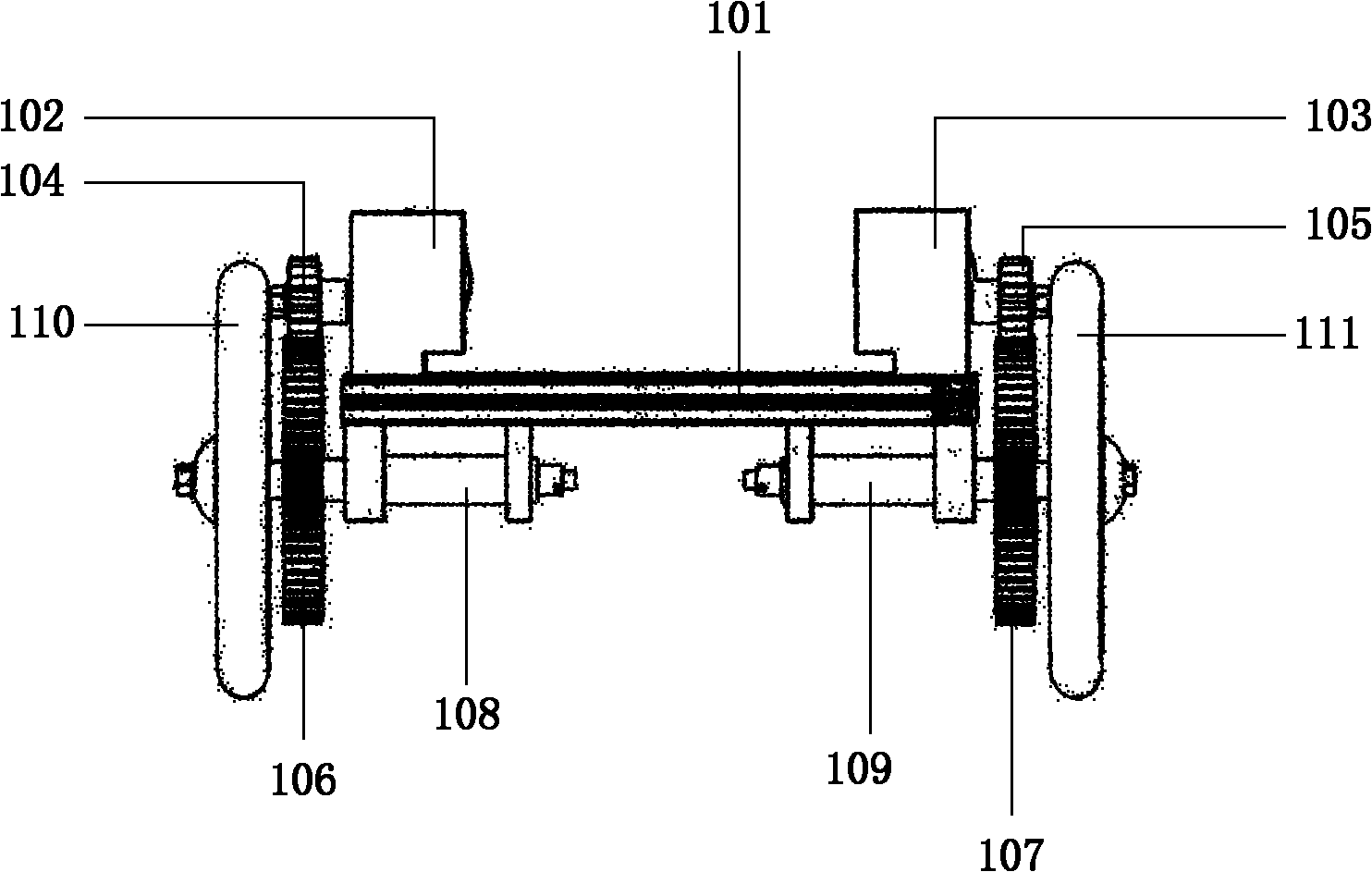

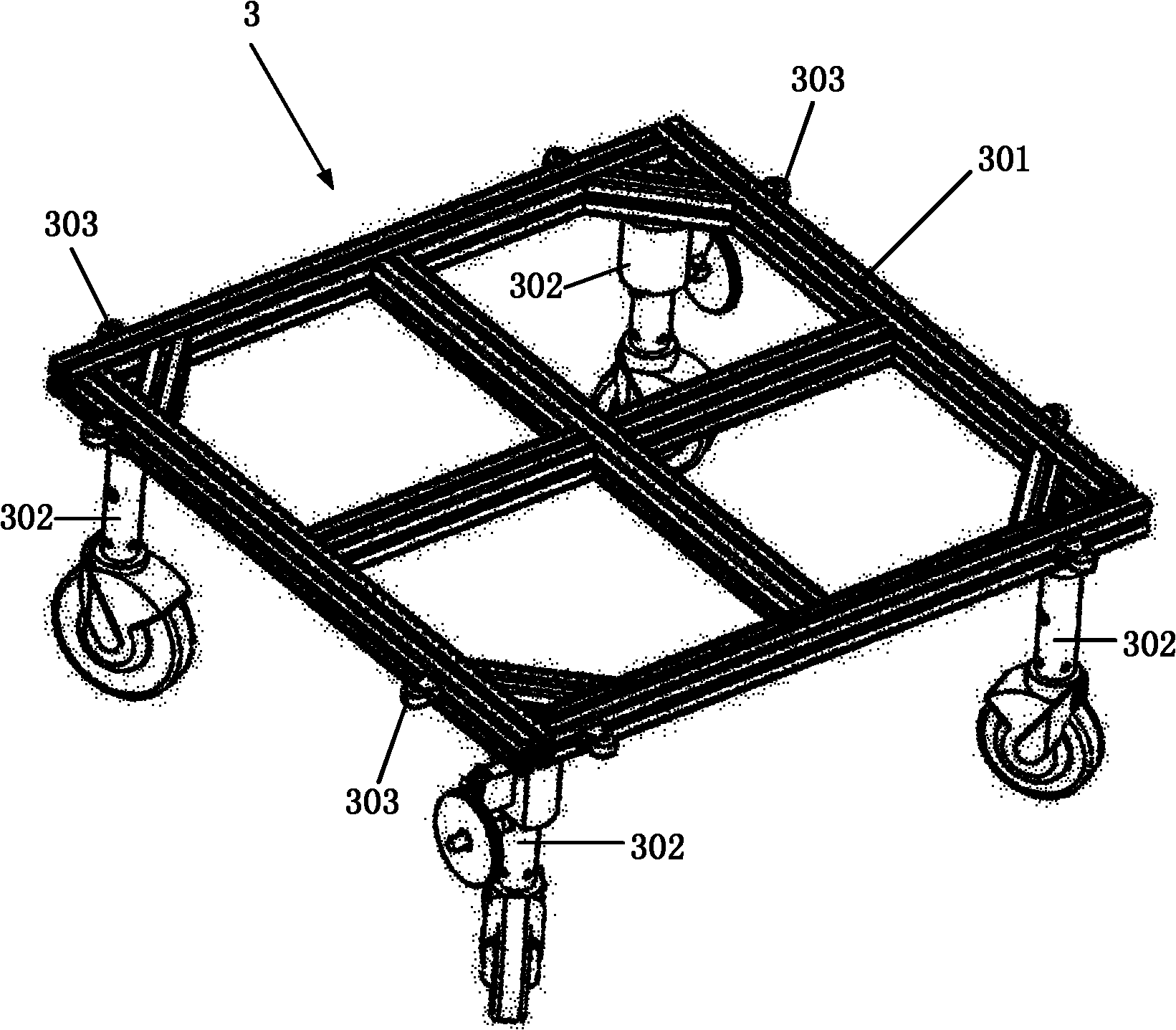

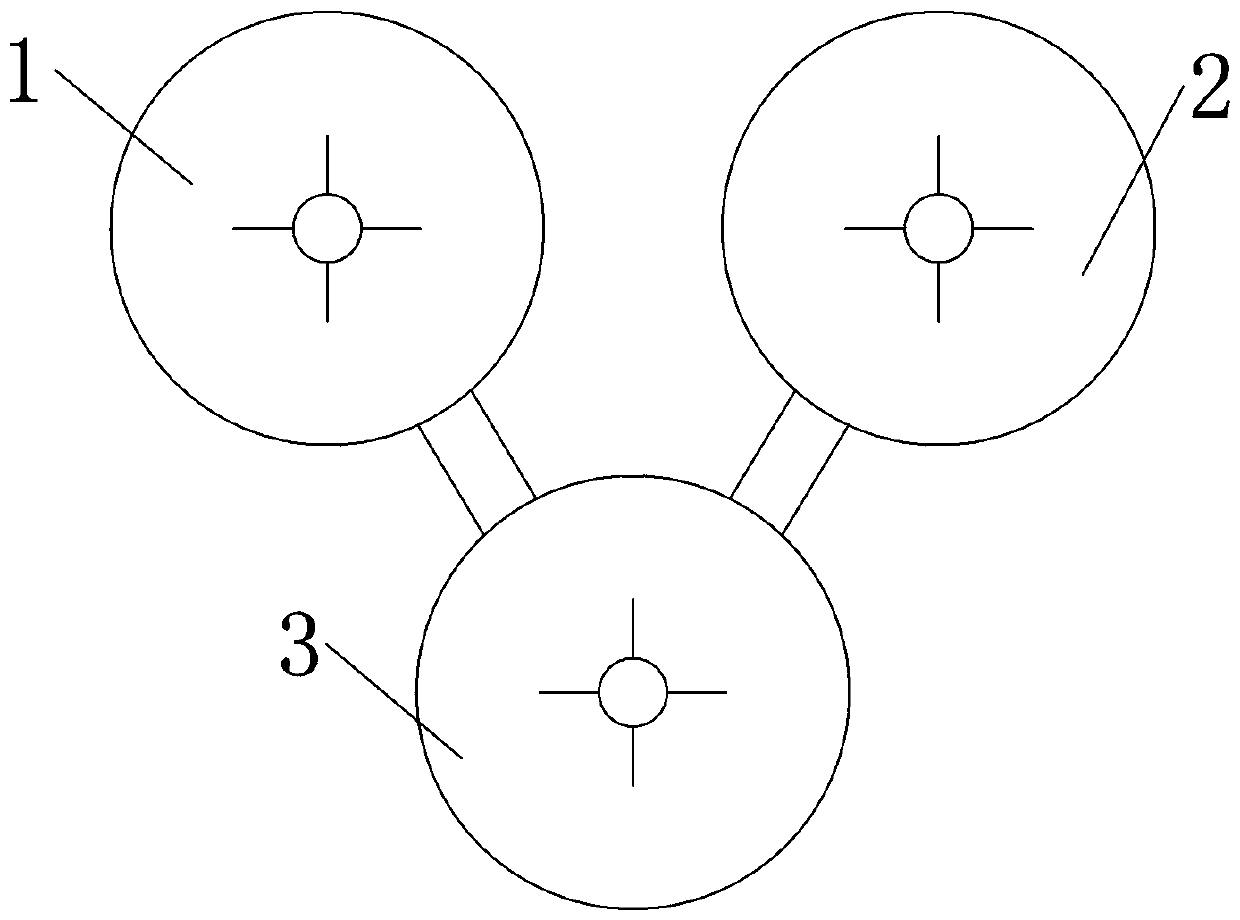

Omnidirectional mobile device for electric wheelchair

InactiveCN102038586AOmni-directional mobile implementationEasy to moveWheelchairs/patient conveyanceOmnidirectional antennaLinear motion

The invention discloses an omnidirectional mobile device for an electric wheelchair, comprising a driving chassis, a swing mechanism and a supporting chassis, wherein a driving gear is installed on the supporting chassis, and the supporting chassis plays a role in supporting; a direction locking caster is arranged on the driving chassis, and the swing mechanism is used for connecting the supporting chassis and the driving chassis and causing the driving chassis to move axially along the swing mechanism. The omnidirectional mobile device for the electric wheelchair implements three modes of linear motion, curvilinear motion and side moving motion through cooperation of the direction locking caster and the driving gear. And the omnidirectional mobile device for the electric wheelchair has the following advantages: the omnidirectional mobile device can implement omnidirectional flexible movement, and has a function of implementing omnidirectional motion without turning radius; the omnidirectional mobile device is high in load capacity, non-slipping, high in controllability, quiet, high in reliability and low in production cost.

Owner:BEIHANG UNIV

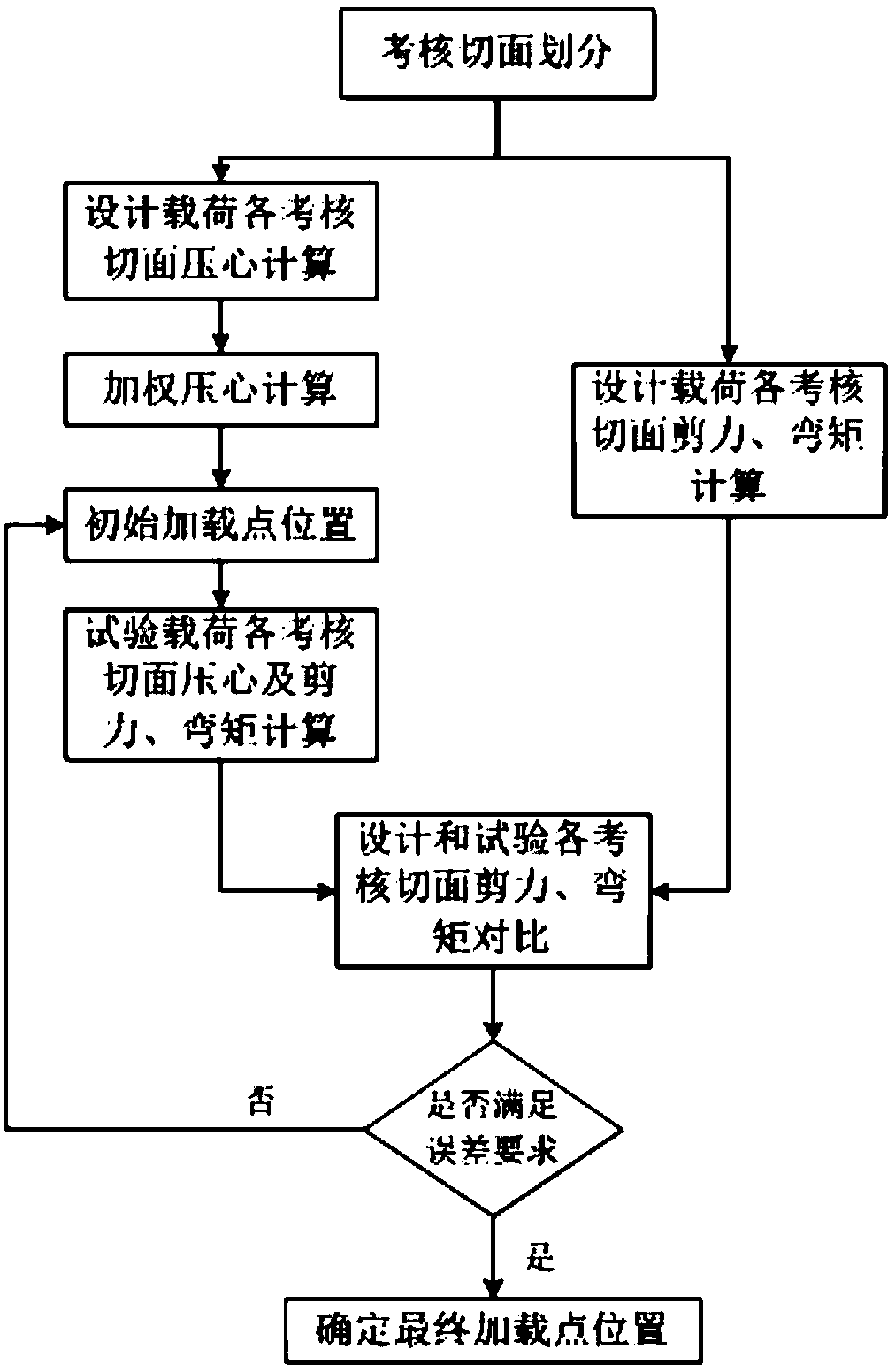

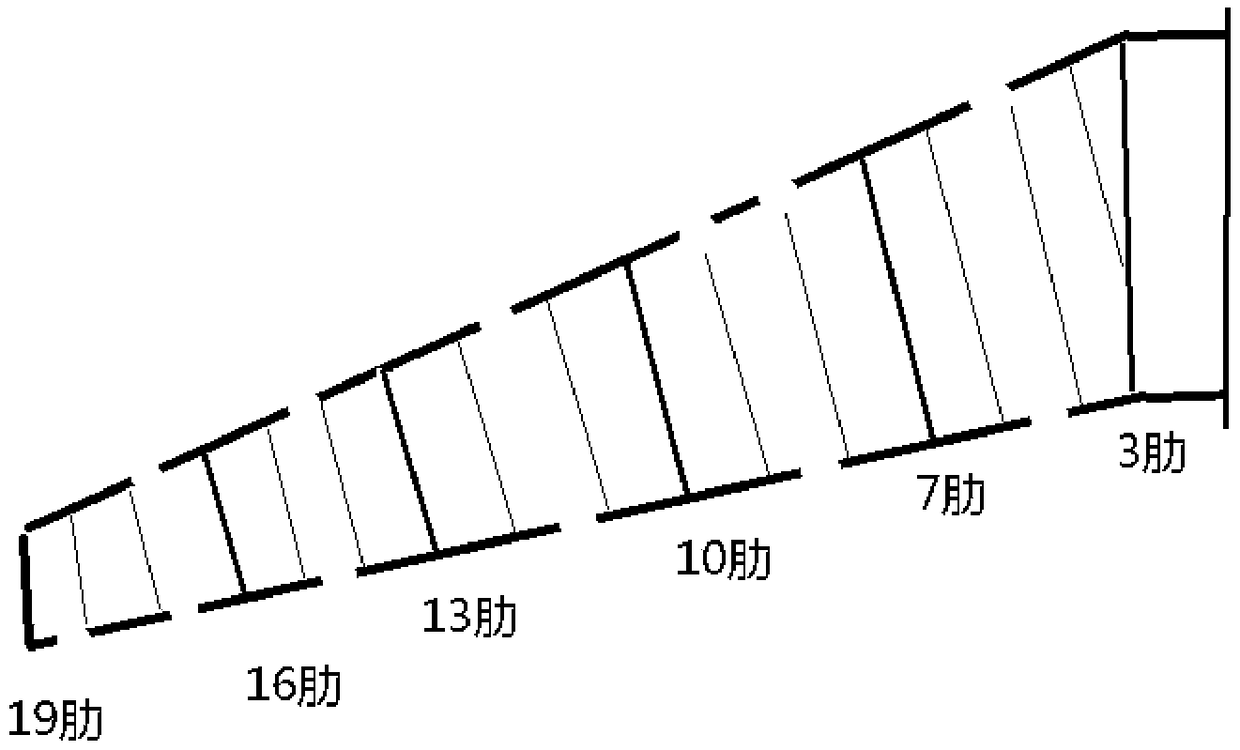

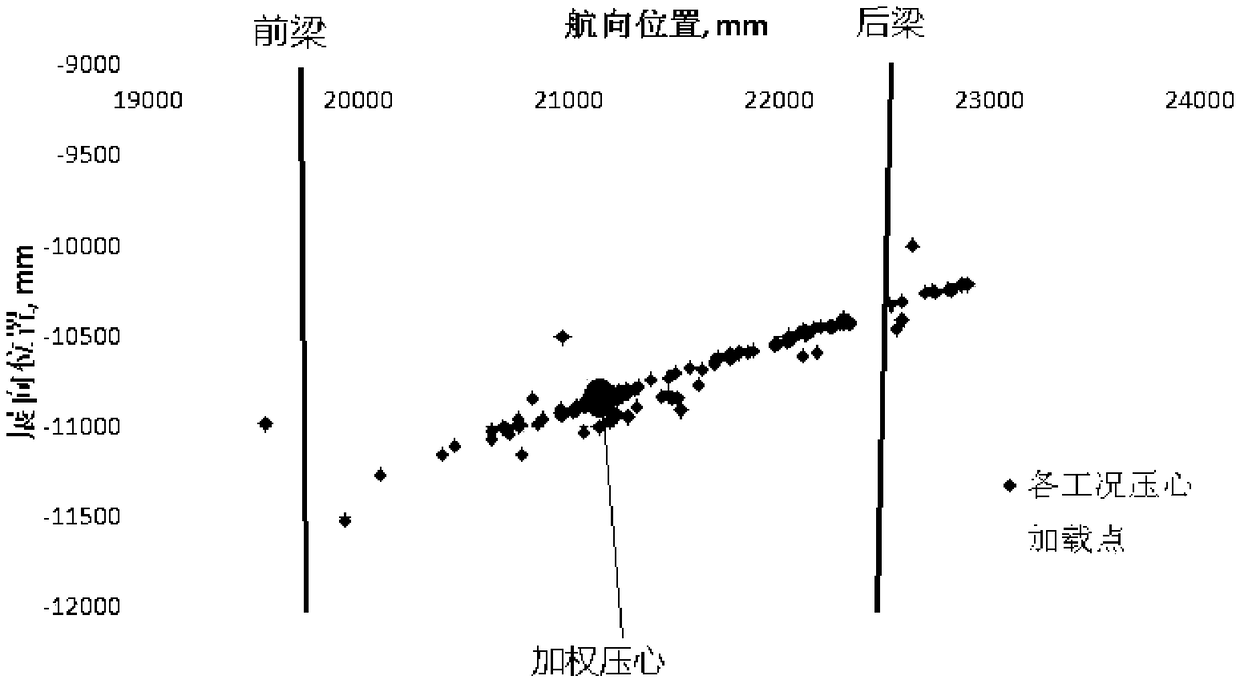

Vertical wing loading method for full scale fatigue test

InactiveCN109490116AGuaranteed accuracyEffectively control the scaleMaterial strength using repeated/pulsating forcesAviationDesign load

The invention belongs to the field of aviation fatigue test and in particular relates to a vertical wing loading method for a full scale fatigue test. The method disclosed by the invention comprises the following steps: performing weighting on a pressure core under multiple load conditions according to the damage degree, and determining the position of a loading actuator cylinder. The vertical wing loading method for the full scale fatigue test provided by the invention is obtained on premise of meeting requirements of shear force, bending moment, torque and design load conditions of each control plane of the wings, and can be widely applied to designing vertical wing loading points for the full scale fatigue test of various aircrafts.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

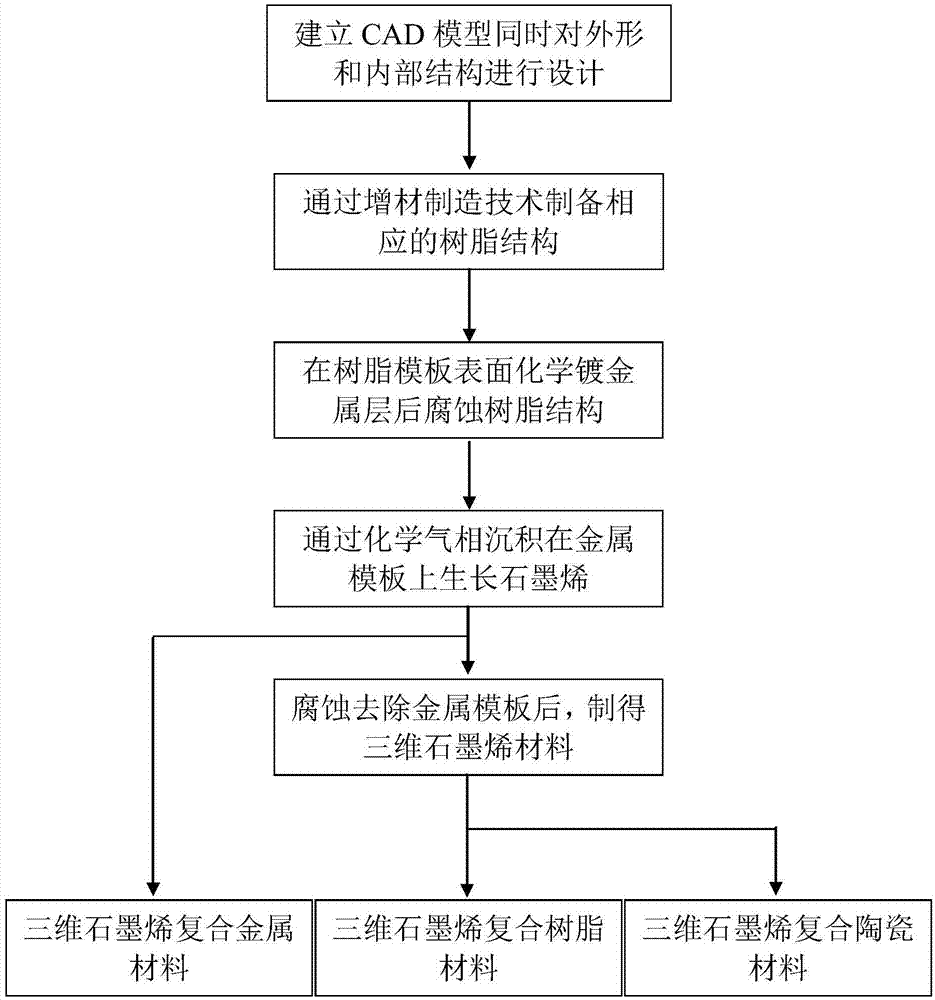

Preparation method of structure-controllable three-dimensional graphene and composite material thereof

ActiveCN107381555AOvercome uniformity issuesOvercoming controllabilityGrapheneLiquid/solution decomposition chemical coatingCvd grapheneChemical plating

The invention belongs to the field of graphene composite material preparation, and discloses a preparation method of structure-controllable three-dimensional graphene and a composite material thereof. The preparation method comprises the following steps: (a) designing and constructing a CAD model, and performing additive manufacturing to obtain a three-dimensional resin structure of a corresponding structure; (b) plating a copper or nickel metal layer on the surface of the three-dimensional resin structure obtained in step (a) by a chemical plating method, and removing a resin material to obtain a three-dimensional structural template of copper or nickel; (c) generating graphene on the three-dimensional structural metal template through a chemical vapor-phase deposition method, thereby preparing the structure-controllable three-dimensional graphene. The obtained graphene is further treated to obtain a graphene composite material. Through the preparation method, control on the structure of three-dimensional graphene can be realized, and a high-quality and multifunctional three-dimensional graphene composite material product under effective and precise control is obtained. The method is simple and convenient to operate, is short in preparation period, and is wide in adaptive range.

Owner:HUAZHONG UNIV OF SCI & TECH

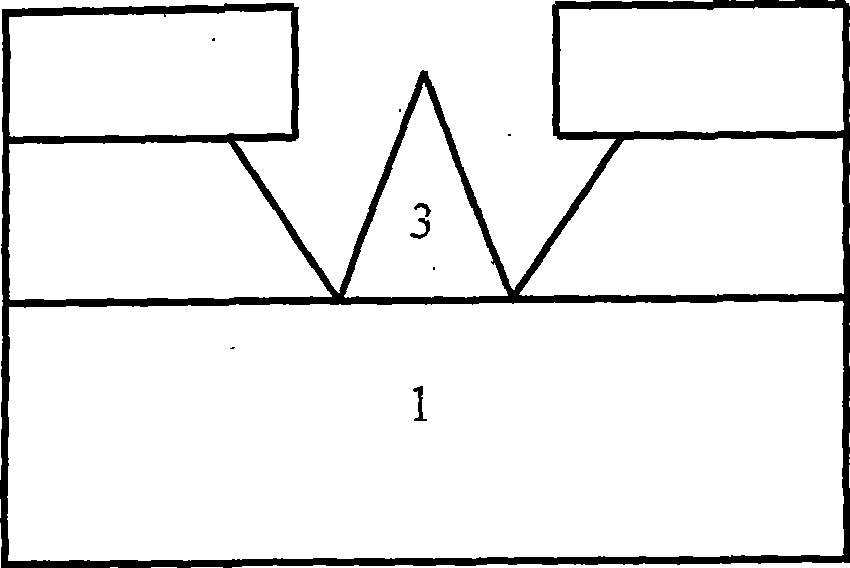

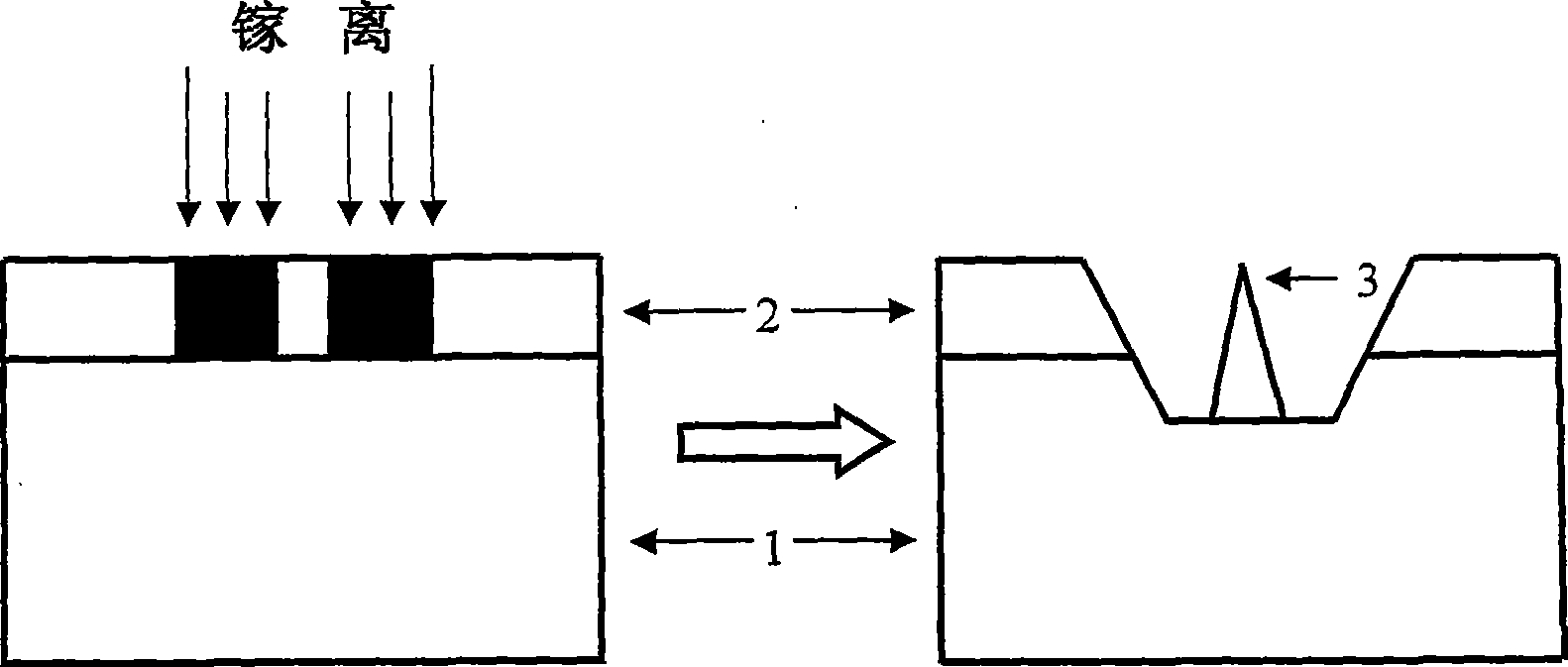

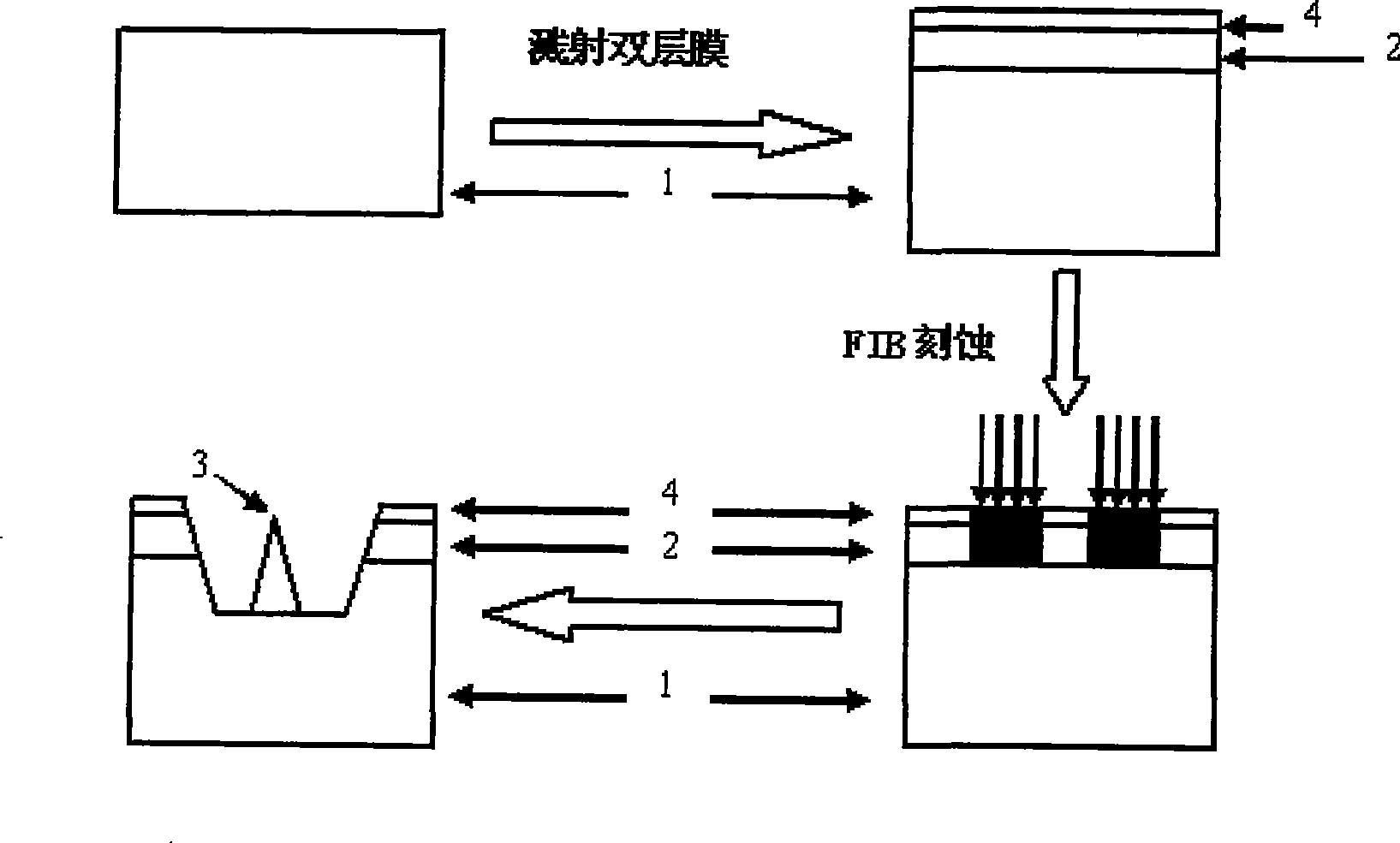

Method for manufacturing aluminum nitride silicon tip and grids structure

ActiveCN101497991APrecise control of cone densityOvercome consistencyVacuum evaporation coatingSputtering coatingEtchingRadio frequency magnetron sputtering

The invention relates to a preparation method of an aluminum nitride conical tip and a grid conical tip structure thereof. The method comprises the following steps: a layer of aluminum nitride film grows on a clean silicon substrate or a layer of gold film is then deposited on the clean silicon substrate by a radio-frequency magnetic control sputtering method; the silicon substrate is then put in a focused ion beam etching system; when the vacuum degree reaches 5.5 multiplied by 5-10mbar, a 5kV electron beam high voltage is applied to observe and position the appearance of a sample; an ion beam source is applied, and a beam current is arranged; finally, an etching pattern is arranged finally, and the focused ion beam etching is implemented to the aluminum nitride film sample according to the etching pattern to obtain the aluminum nitride conical tip 3 structure or the grid conical tip structure. The length-diameter ratio of a single cone of the aluminum nitride conical tip 3 structure is between (3-30):1, the minimum curvature radius of the tip part is less than 20 nanometer, and the diameter at the bottom is 100 nanometer to few microns. The invention can prepare the aluminum nitride conical tip and the grid conical tip structure thereof with controllable length-diameter ratio, omits a plurality of working procedures of depositing an insulating layer, photoetching, and the like which are necessary in the traditional process and has simple process and low cost.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

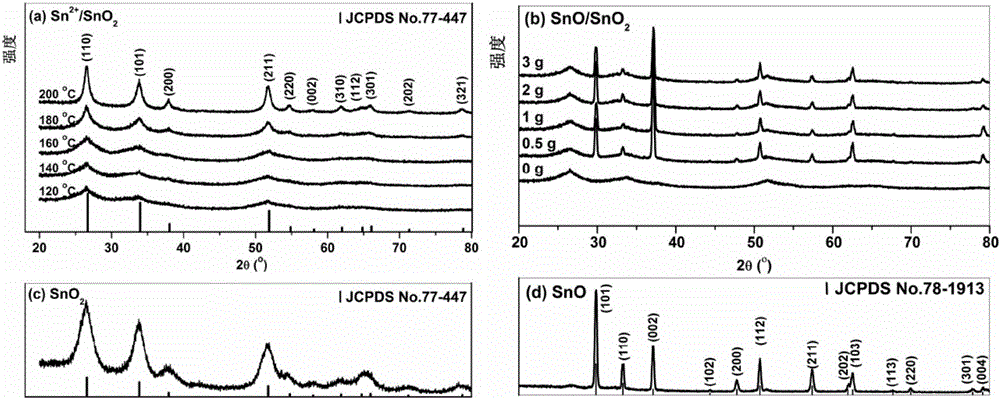

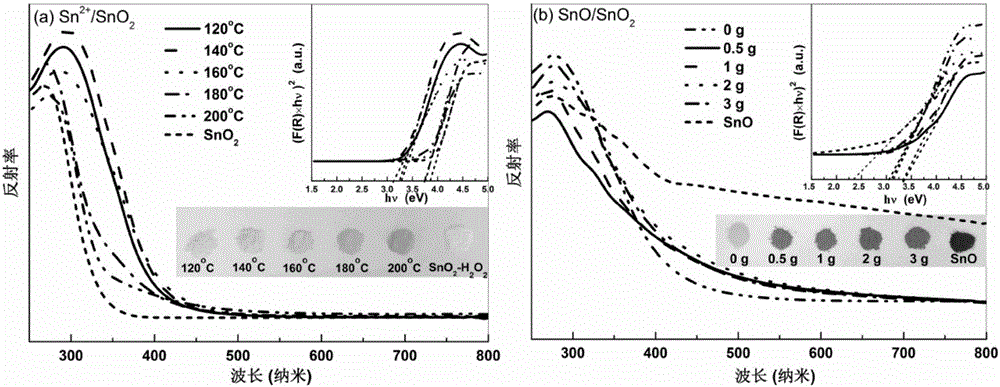

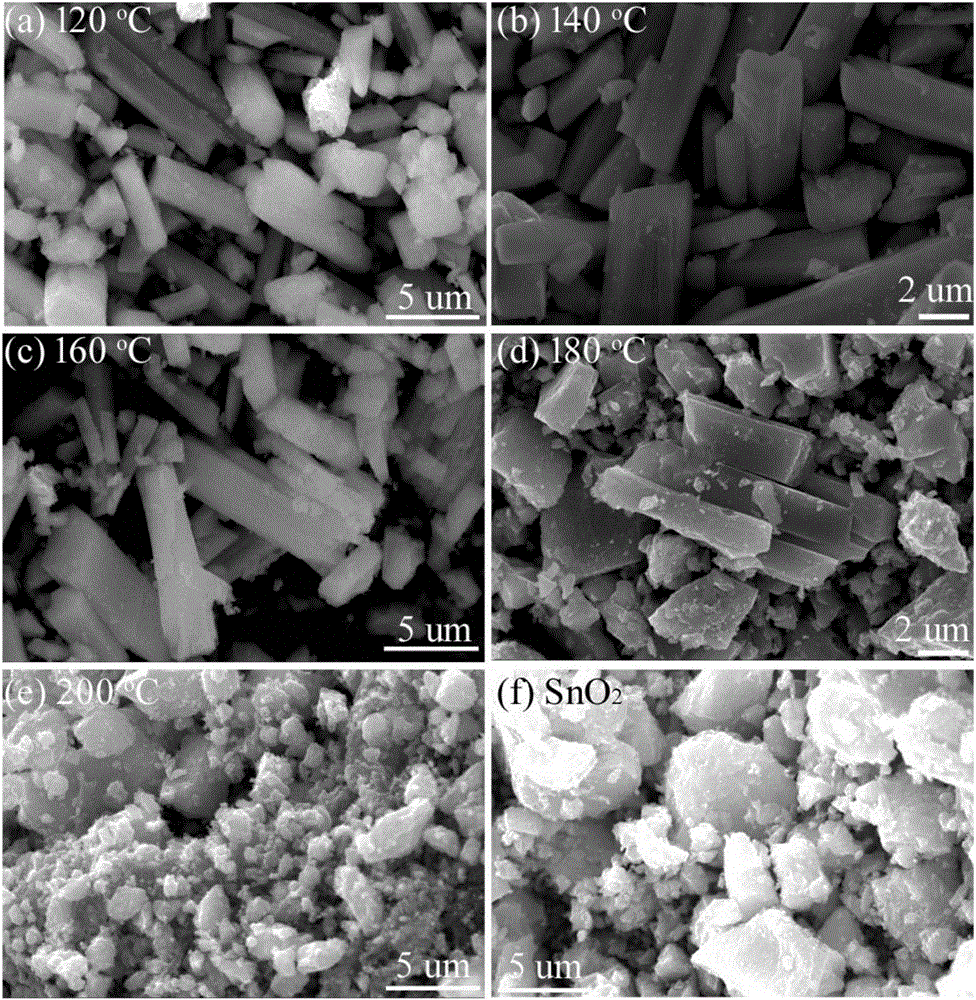

Preparation method of tin-based oxide with controllable components and photocatalytic application of tin-based oxide

ActiveCN106000384ASimple preparation processMild reaction conditionsWater/sewage treatment by irradiationWater treatment compoundsSynthesis methodsPhotocatalytic degradation

The invention discloses a preparation method of tin-based oxide with controllable components and a photocatalytic application of the tin-based oxide. The preparation method is characterized in that the tin-based oxide is prepared from stannous chloride dihydrate with one-step hydrothermal method, and samples with four different components including Sn<2+> / SnO2, SnO / SnO2, SnO or SnO2 are synthesized selectively through control of composition of a hydrothermal solution, wherein Sn<2+> / SnO2 and SnO / SnO2 show efficient photocatalytic degradation decoloration activity to methyl orange under visible light. The samples are selectively synthesized with the one-step hydrothermal method, the preparation process is simple, raw materials are cheap and available, defects of the complexity of a traditional synthesis method and uncontrollability of composition of target products are overcome, and application and popularization prospect is realized.

Owner:HUAIBEI NORMAL UNIVERSITY

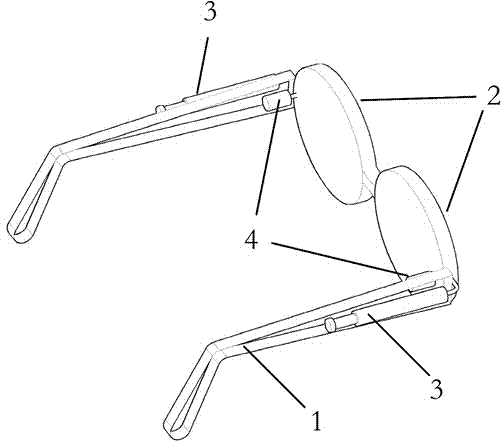

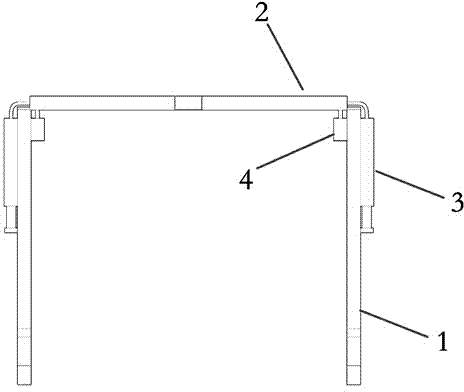

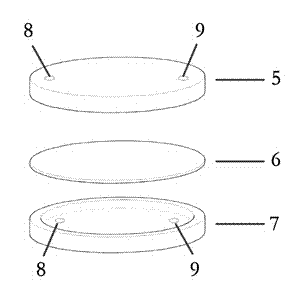

Double-layered cavity type liquid color-change glasses

ActiveCN104765162ARealize the color changing functionReduce injectionOptical partsLiquid colorEnvironmental geology

The invention provides a pair of double-layered cavity type liquid color-change glasses. The pair of double-layered cavity type liquid color-change glasses comprises a glasses frame, lenses, colorless fluid executing mechanisms, colored fluid, colorless fluid, elastic thin films, colorless fluid cavities, colored fluid cavities and elastic colored fluid storage cavities, wherein the inner part of each lens is composed of one colorless fluid cavity, one colored fluid cavity and one elastic thin film, and the colorless fluid cavity and the colored fluid cavity are separated by the elastic thin film; the colorless fluid executing mechanisms are mounted on the two sides of two glasses legs of the glasses frame; the colorless fluid is stored in the colorless fluid executing mechanisms and the colorless fluid executing mechanisms are connected with the colorless fluid cavities by pipelines; the elastic colored fluid storage cavities are mounted on the inner sides of the two glasses legs of the glasses frame; the colored fluid is stored in the elastic colored fluid storage cavities; and the elastic colored fluid storage cavities are connected with the colored fluid cavities by pipelines. According to the double-layered cavity type liquid color-change glasses, the circulating flowing of the colored fluid between the lenses and the storage cavities is controlled by the deformation of the thin films, caused by the pressure change of the colorless fluid in the cavities, so that the colors of the lenses are changed.

Owner:HARBIN INST OF TECH

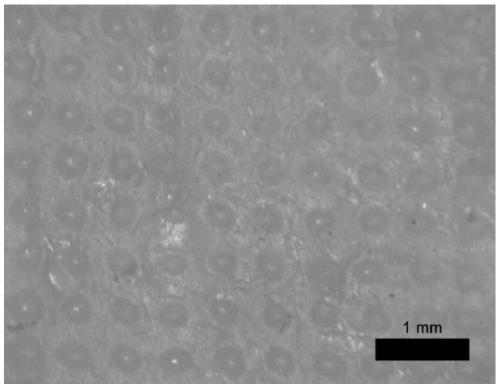

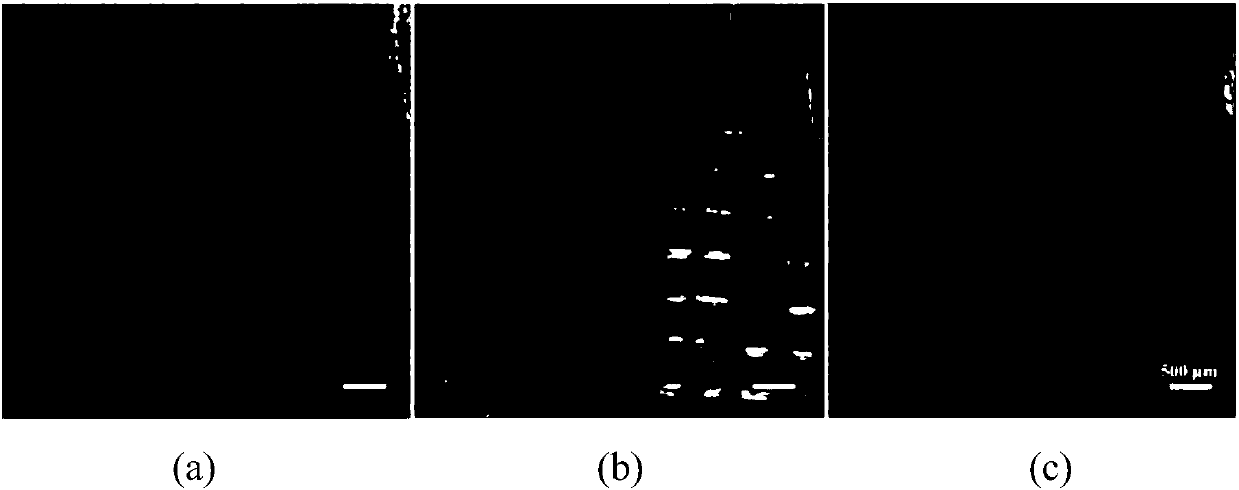

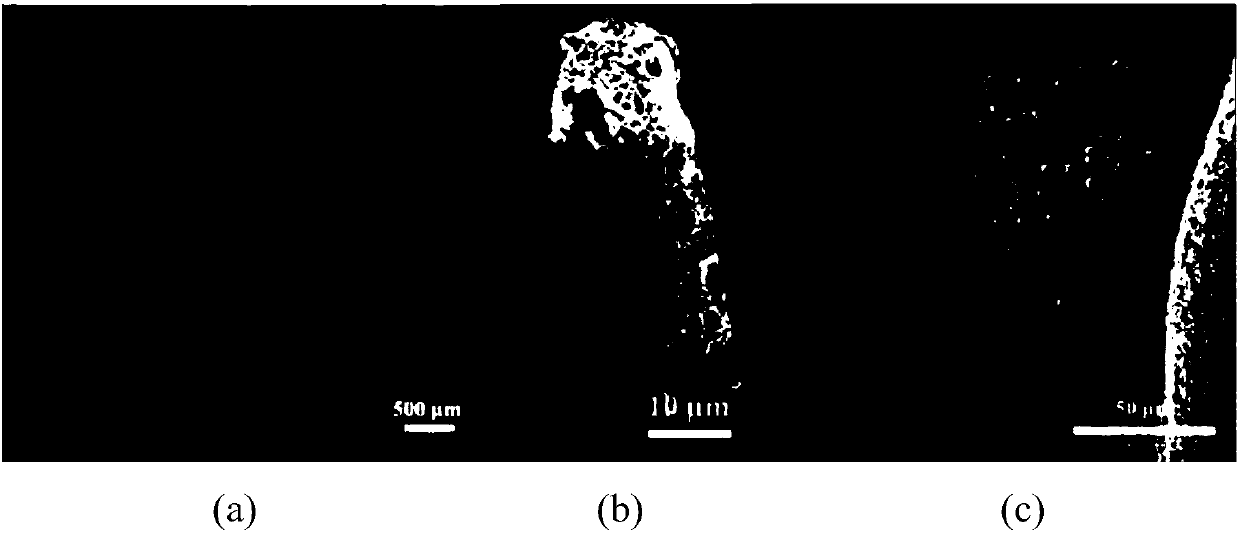

Method for preparing porous polymer microneedle based on phase separation technology and application of method

ActiveCN110115707ASmall apertureRegular hole structureMetabolism disorderMicroneedlesPolymer dissolutionPolymer science

The invention discloses a method for preparing a porous polymer microneedle based on a phase separation technology and application of the method. The method comprises the following steps that 1, a polymer is dissolved into a solvent A to obtain a polymer solution; 2, the polymer solution is put into a microneedle mould; 3, the microneedle mould is placed in a poor solvent B, so that phase separation of the polymer in the microneedle mould is facilitated; 4, the poor solvent B is removed, and then the porous polymer microneedle can be obtained. Through the simple and mild phase separation technology, the porous polymer microneedles can be prepared on a large scale, and therefore, the technical problems can be solved that the preparation process of the porous polymer microneedle is complicated, the conditions are harsh, the technology is tedious, the price is high, the pore structure, the size and the distribution are difficult to control, and it is difficult for large-scale production and application. The prepared porous polymer microneedle can be used for interstitial fluid extraction and transdermal drug delivery.

Owner:武汉楚颜生物科技有限公司

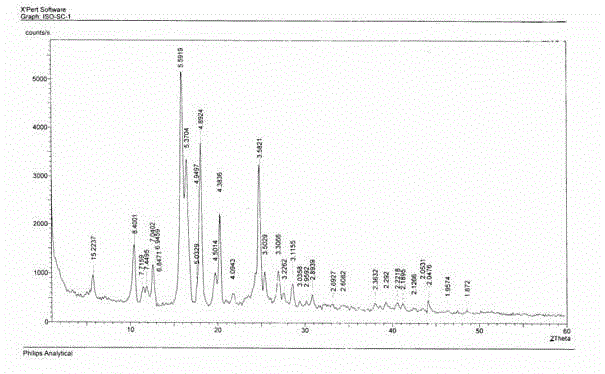

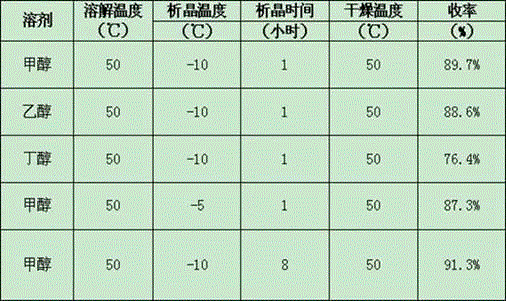

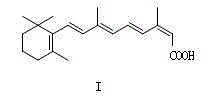

Novel crystal form of isotretinoin as well as preparation method and application thereof

InactiveCN104447459AImprove stabilityHave storageOrganic chemistryHydroxy compound active ingredientsAlcoholPhysical chemistry

The invention relates to the field of medicinal chemistry, in particular to a crystal form preparation process and application of isotretinoin. A crystal form A takes positions 2theta of diffraction peaks as spectrogram feature parameters, wherein the positions 2theta sequentially comprise 5.8+ / -0.2, 10.52+ / -0.2, 11.46+ / -0.2, 11.87+ / -0.2, 12.56+ / -0.2, 15.83+ / -0.2, 16.49+ / -0.2, 18.11+ / -0.2, 19.70+ / -0.2, 20.24+ / -0.2, 21.68+ / -0.2, 24.83+ / -0.2, 25.40+ / -0.2, 26.94+ / -0.2, 28.62+ / -0.2, and 30.87+ / -0.2. A specific preparation method comprises the steps that an isotretinoin raw material is dissolved with organic alcohol to obtain an isotretinoin organic alcohol solution, crystallization is conducted with a temperature differential method, solid-liquid separation is conducted, a solid is dried and then the crystal form A is obtained; the crystal form A is put under light in air and the stability of the crystal form A is obviously better than that of a raw material medicine.

Owner:CHONGQING HUAPONT PHARMA

Chinese medicine cataplasm matrix and preparing technique thereof

InactiveCN1528270AHigh drug loadingGood curative effectAerosol deliveryOintment deliveryMedicineHypersensitive response

The present invention relates to a Chinese medicine emplastrum matrix which can be added into Chinese medicine extract and its preparation technique. Said matrix is made up by mixing polyacrylic acid, glycerine, triethanolamine, magnesium hydroxide, polyvinylpyrrolidone, azone and water. Said matrix has large medicine-carrying quantity, unique slowly-releasing process, strong transdermal effect, good breathing property and good affinity with various medicines and skin. Said invented matrix is suitable for making Chinese medicine emplastrum, and is an ideal transdermal administration transferring platform.

Owner:XIAN CHIHO PHARMA

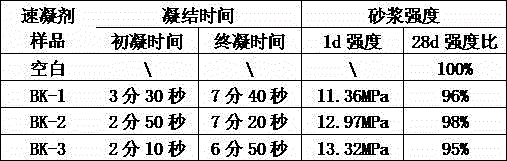

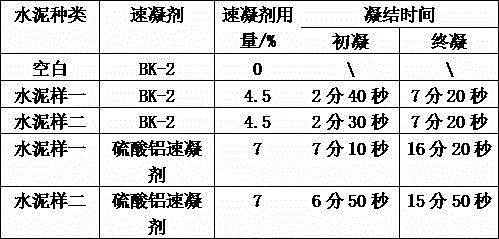

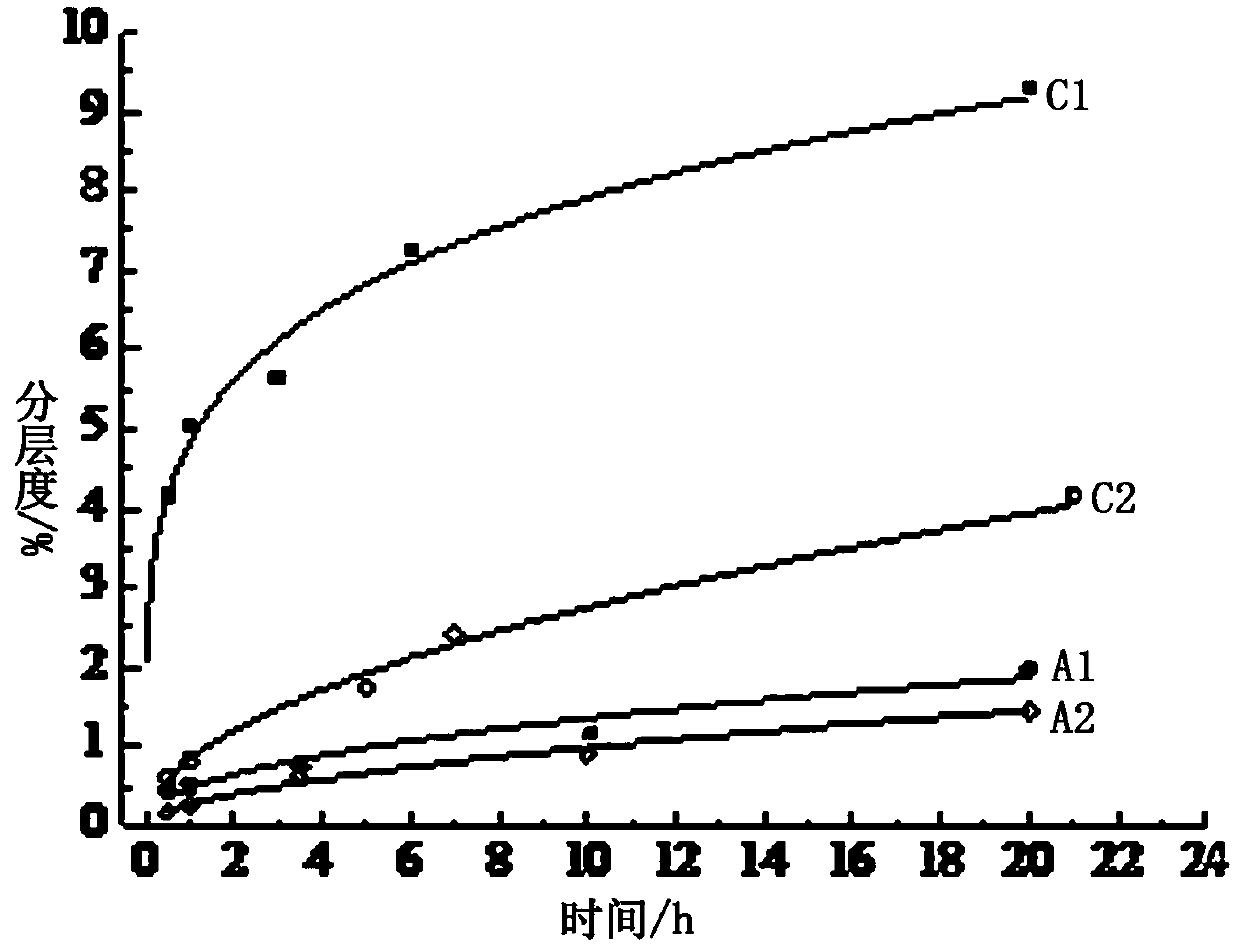

Non-corrosive liquid setting accelerator used in coal mine paste filling, and preparation method thereof

InactiveCN104909601AFreely Adjust MobilityThere is no phenomenon of precipitation and stratificationTime rangeAluminium sulfate

The invention relates to a non-corrosive liquid setting accelerator used in coal mine paste filling, and a preparation method thereof. The invention relates to a liquid setting accelerator and the preparation method thereof. The paste filling non-corrosive liquid setting accelerator has a pH value of 3-5 and a density of 1.4g / cm<3>, and is weakly acidic. A paste filling material with the setting accelerator can maintain fluidity with the time range of 15-45min, and has strength higher than 0.1MPa after 2h. The storage period of the setting accelerator is 6 months. The paste setting accelerator is composed of sodium aluminate, sodium carbonate, aluminum sulfate, alkanolamine and a plasticizer. The preparation process of the setting accelerator comprises sodium aluminate modification, modified sodium aluminate and aluminum sulfate reaction, and alkanolamine substance and plasticizer introduction. With the setting accelerator, problems of excessively short setting time, uncontrollable flow time, high corrosivity and poor storage stability of a common setting accelerator used in coal mine waste filling mining application are overcome; paste filling efficiency is greatly improved; and the filling technology is more mature. The setting accelerator assists in promoting the development of the coal mine waste filling mining technology to a certain extent.

Owner:XUZHOU CUMT BACKFILL TECH

Continuous glass steel pipeline manufacturing method and prepared glass steel pipeline

The invention discloses a glass steel pipeline and a continuous manufacturing method thereof. The method comprises the following steps: (1) wrapping a chopped strand mat on the surface of a core rod, using a first resin composition to fully penetrate the chopped strand mat, and then weaving glass fibers on the surface of the chopped strand mat so as to form a leakage-proof layer; (2) winding glass fibers around the leakage-proof layer obtained in the step (1), then impregnating the glass fibers in a second resin composition, and repeating the soaking operation for several times so as to obtain a semi-finished product; (3) heating, curing, and moulding the semi-finished product obtained in the step (2), and finally demoulding so as to obtain the glass steel pipeline. The glass steel pipeline has the advantages of high strength, and good pressure resistance, and is capable of effectively preventing the leakage, and moreover the manufacturing method is more environment-friendly.

Owner:ZHEJIANG ZHONGYI GLASS FIBER REINFORCED PLASTIC

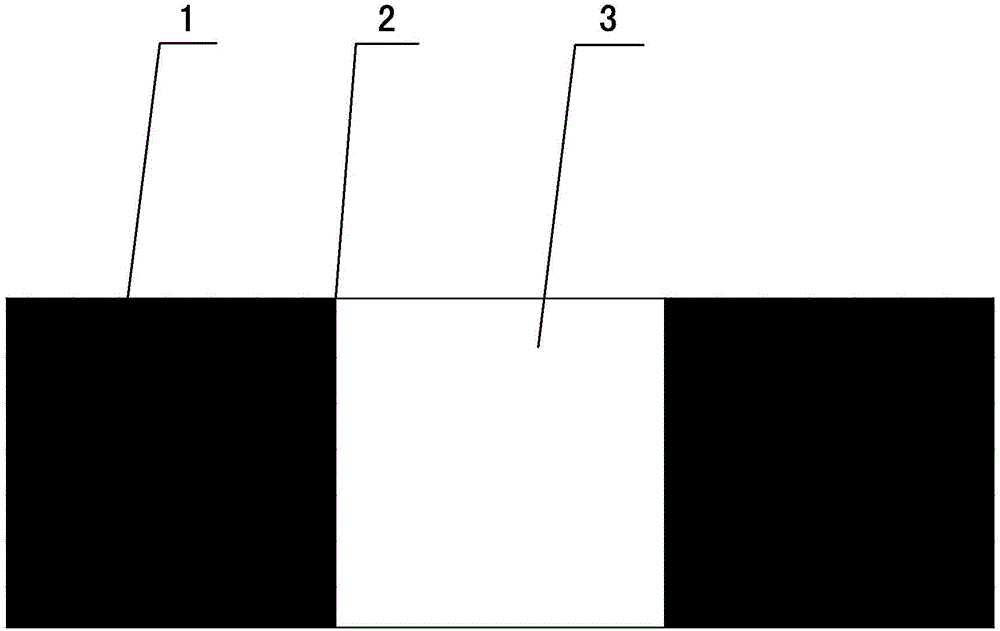

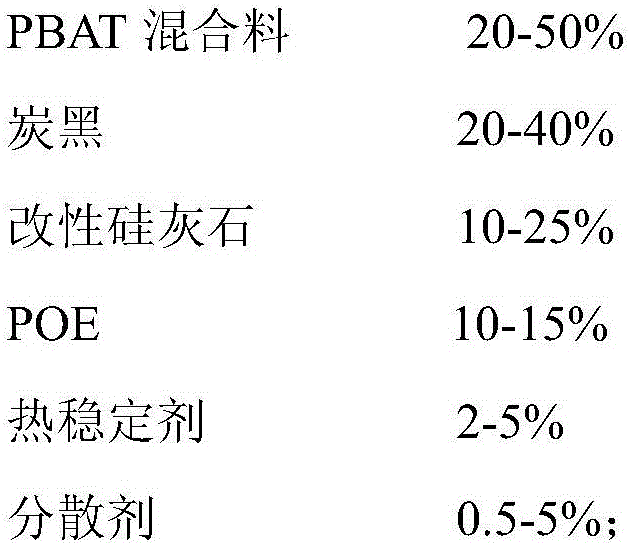

Striped full-biodegradable mulching film and preparation method thereof

ActiveCN106280289AOvercoming processabilityOvercome mechanical propertiesCultivating equipmentsFlat articlesMasterbatchMoisture

The invention belongs to the technical field of mulching film preparation and particularly relates to a striped full-biodegradable mulching film and a preparation method thereof. The striped full-biodegradable mulching film is composed of black stripes and white stripes alternating with each other, the black stripes are made from degraded black masterbatch, an anti-blocking agent and a degradable base, and the white stripes are made from a degradable base, a photo-stabilizer, and a lubricant. The serial problems that the original full-biodegradable film is difficult to process and plasticize, has poor mechanical properties and is uncontrollable in degradation cycle are overcome; in addition, the preparation process is combined with white and black film preparation process, the full-biodegradable film is produced based on stripes, and at the premise of each of the black and white stripes being controllably degradable, the black stripes automatically remove weeds, hold temperature and hold soil moisture and the white stripes are highly light-permeable and can hold moisture, temperature and soil moisture.

Owner:SHANDONG QINGTIAN PLASTIC IND

Detection method and device for number of impact times of impact type fastening tool

ActiveCN105818088APrecise control of output torqueAccurate and controllable output torqueSpannersElectrical measurementsEngineering plasticImpact wrench

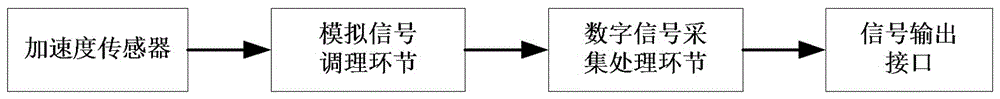

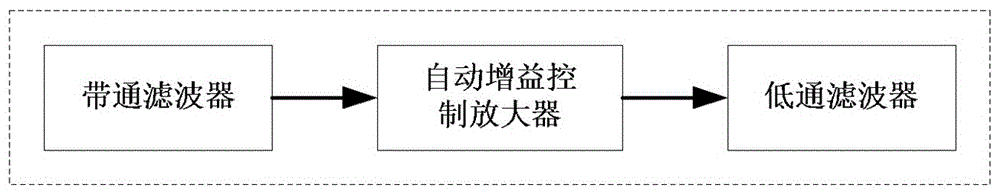

The invention relates to a detection method for the number of impact times for torque control over an impact type fastening tool. According to the detection method for the number of the impact times of the impact type fastening tool, an acceleration sensor is installed in a vibration sensitive position of the impact type fastening tool, vibration waveform signals which contain various interference elements in the working process and sensed by the acceleration sensor are detected and subjected to filtering and amplifying treatment; and the treated vibration waveform signals are sent to a digital signal acquisition and processing link through an A / D converter to be subjected to vibration waveform frequency and continuity real-time distinguishing, redundant interference pulses are removed, complete pulse wave data are formed, the real-time number of pulses is obtained, and a signal of the number of the impact times corresponding to the number of the pulses is output. According to a detection device for the number of the impact times for achieving the detection method for the number of the impact times, a number of times of impact detection and processing circuit is arranged in a metal shell or an engineering plastic shell, a signal of the number of times of impact output by the number of times of impact detection and processing circuit is connected with a universal torque controller through a signal cable, and the output torque of an impact wrench can be controlled precisely.

Owner:郑州时享电子技术有限公司

Method for preparing sulphurous acid by using sulfur as raw material

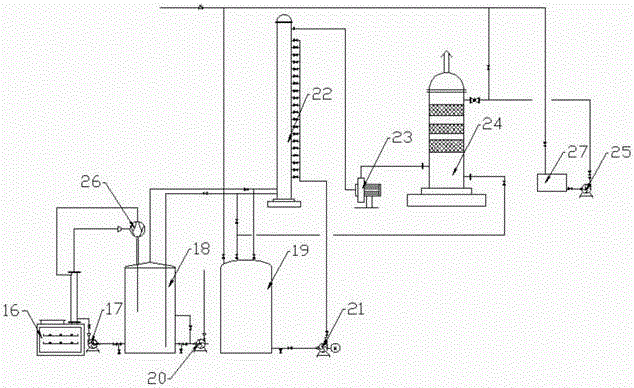

ActiveCN106629627AOvercome uncontrollableOvercoming controllabilitySulfur-dioxide/sulfurous-acidCombustionSulfur utilization

The invention belongs to the field of chemical engineering, particularly relates to a method for preparing sulphurous acid by using sulfur as a raw material, and also relates to application of a sulphurous acid product produced by the method. The method comprises the following steps that a furnace door of a combustion furnace is opened; solid sulfur is put into combustion discs; then, partial solid sulfur is fed into a dissolving box through a feeding opening formed in the upper part of the combustion furnace; meanwhile, water is added into an acid storage tank; an injection pump, a fan and an air door of the combustion furnace are opened; sulfur dioxide gas generated during sulfur combustion is exhausted through an air outlet, is subjected to temperature reduction and cooling in a position of a smoke pipe connected with the air outlet and is then absorbed by an ejector; absorption tower and tail gas absorption tower process water valves are regulated; an anticorrosion pump is started to spray process water into a tail gas absorption tower. After a sulphurous acid production system provided by the invention is used, the sulfur treatment quantity is effectively increased, and is increased to 250kg / h from the sulfur treatment quantity of 100 to 150kg / h of ordinary equipment, so that the sulfur utilization rate is improved to 99.5 percent from about 70 percent; the SO2 content of tail gas is smaller than or equal to 5mg / Nm<3>.

Owner:SHANDONG XIWANG SUGAR

Medium-temperature transmutation stained paper and preparation method thereof and ceramic provided with medium-temperature transmutation stained paper

ActiveCN106676973ASimple production processOvercoming controllabilitySpecial visual effect coatingsCoatings with pigmentsSesquioxidePrinting ink

The invention relates to the technical field of ceramic products, and in particular relates to medium-temperature transmutation stained paper and a preparation method thereof and a ceramic provided with the medium-temperature transmutation stained paper. The medium-temperature transmutation stained paper comprises stained paper bottom, and a printing material layer and a cover layer which are successively arranged on the stained paper bottom, wherein the printing material layer is proportioned by 15-35% printing ink and the balance of a dry power raw material; the dry power comprises kaolin, feldspar, quartz, iron sesquioxide, titanium dioxide, stannic oxide and pigments. The medium-temperature transmutation stained paper is used for decorating a ceramic utensil. The medium-temperature transmutation stained paper achieves a transmutation effect through the stained paper and can solve the technical problem that the conventional transmutation effect cannot be controlled and quantitative production cannot be performed. In addition, a production process for producing and preparing the ceramic product with the medium-temperature transmutation stained paper is simple. Through detection, no lead and cadmium are dissolved out, so that the medium-temperature transmutation stained paper is safe to use and attractive in appearance and has a unique artistic effect.

Owner:福建省德化云水窑陶瓷有限公司

Temperature controllable polishing tool

A temp controllable polishing tool with circular plate shape features that the miniature temp controlling relay and heater are arranged in the insulating layer between heat-transfer base plate and the substrate of polishing head, and the polishing layer is adhered on the external surface of heat-transfer base plate. The surface shape of said polishing layer is same as the surface to be polished.

Owner:TSINGHUA UNIV

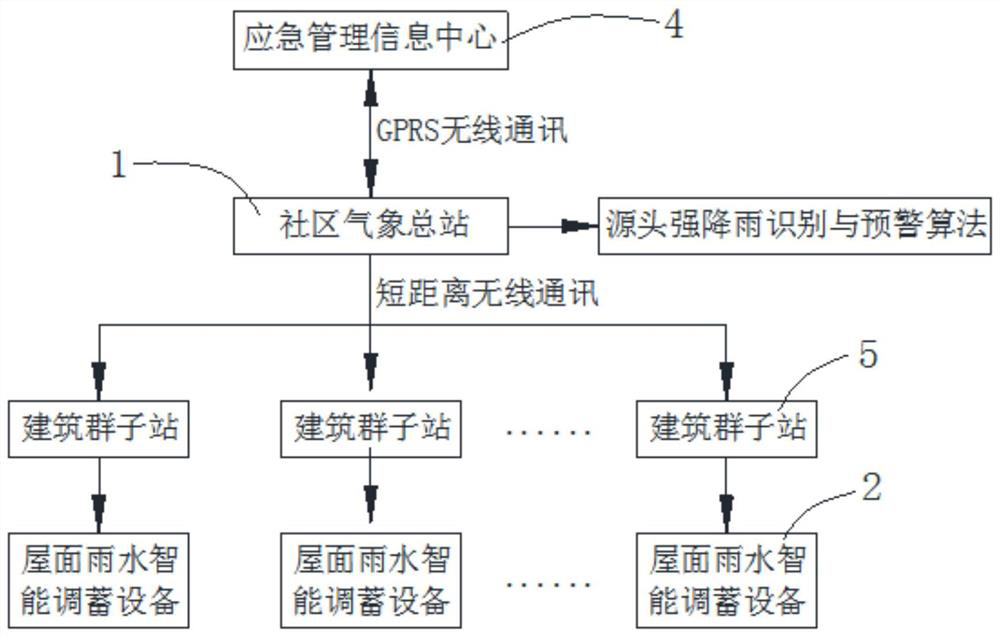

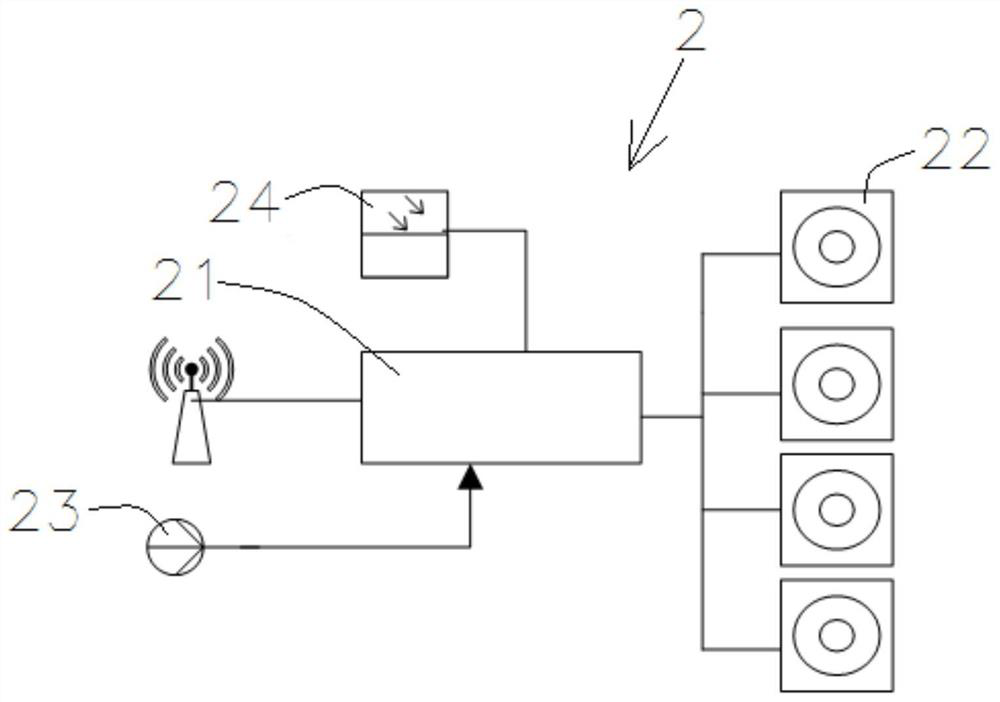

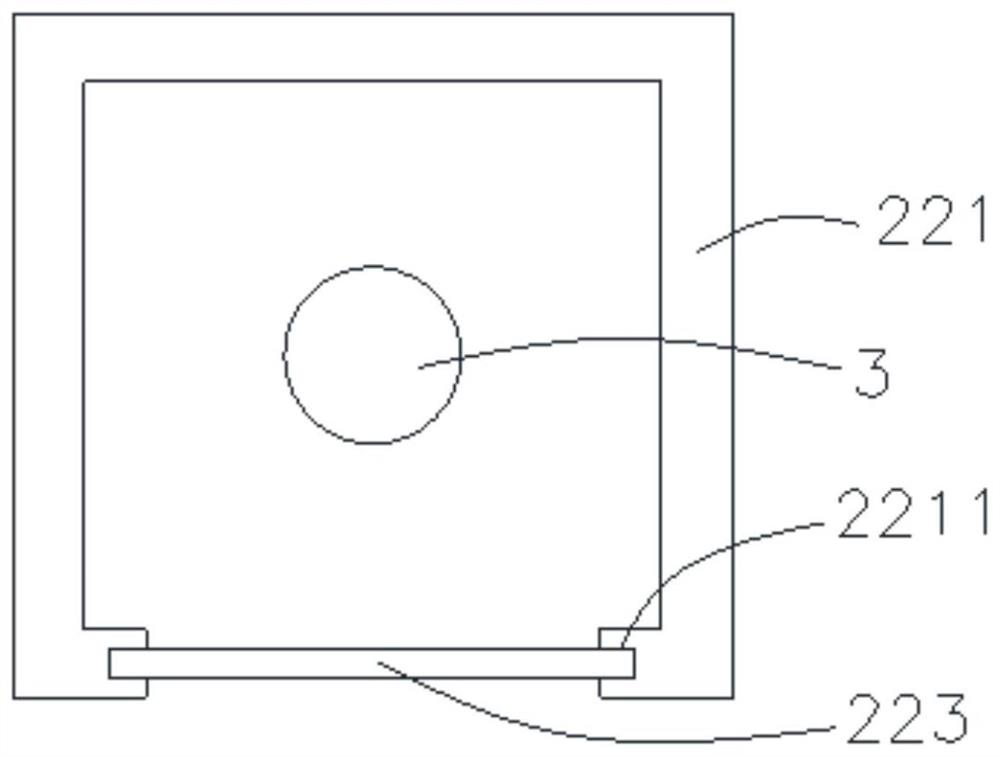

Early warning and control method and device for short-time heavy rainfall community source

ActiveCN112904455AOvercome the defect of insufficient weather forecast accuracyReduce the impact of peak discharge loadsRainfall/precipitation gaugesComplex mathematical operationsWater storageAtmospheric sciences

The invention particularly relates to an early warning and control method for a short-time heavy rainfall community source. The method comprises the steps that S1 a community weather master station monitors the rainfall intensity in real time through a tipping bucket rain gauge, the sampling time is recorded as delta T, the collected total rainfall amount is recorded as V, and the rainfall intensity is recorded as P, and then according to a source heavy rainfall recognition and early warning algorithm, P = V / delta T; S2 the community weather master station compares the rainfall intensity P with a set early warning threshold value K, if P is greater than K, it is judged that heavy rainfall occurs once in a short time, otherwise, it is judged that no heavy rainfall exists in the short time; and S3 a roof rainwater intelligent regulation and storage device regulates and controls the water storage capacity of the roof by controlling the rainwater discharge amount of a roof water outlet, and when the roof rainwater intelligent regulation and storage device receives a heavy rainfall signal, the roof water outlet is closed by the roof rainwater intelligent regulation and storage device; and when the roof rainwater intelligent regulation and storage device receives a short-time heavy rainfall-free signal, the roof rainwater intelligent regulation and storage device opens the roof water outlet.

Owner:CHANGZHOU INST OF TECH

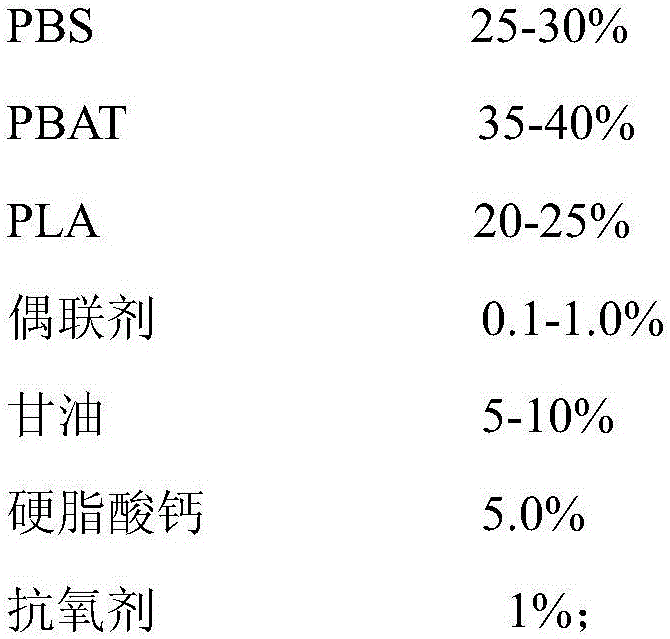

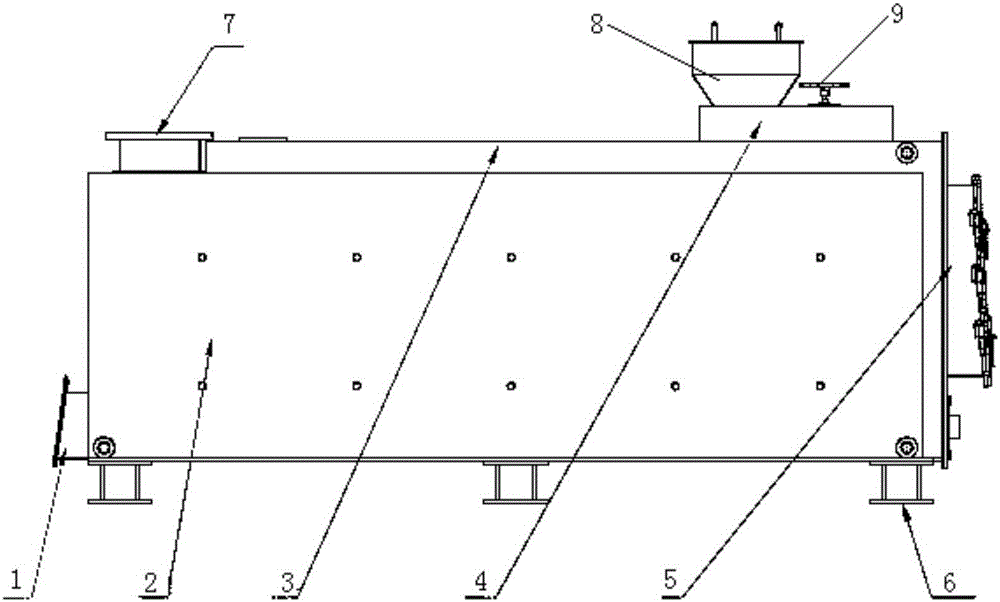

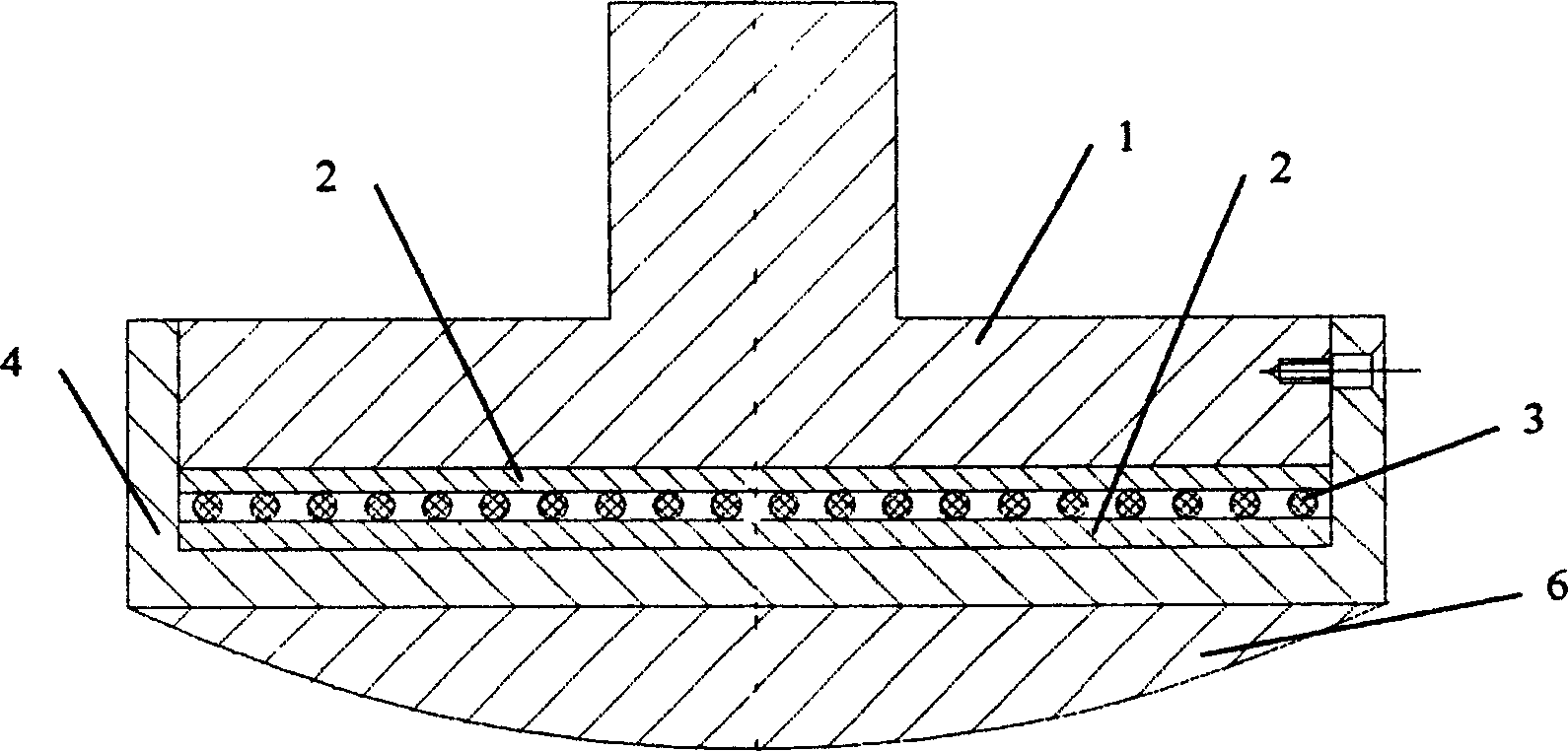

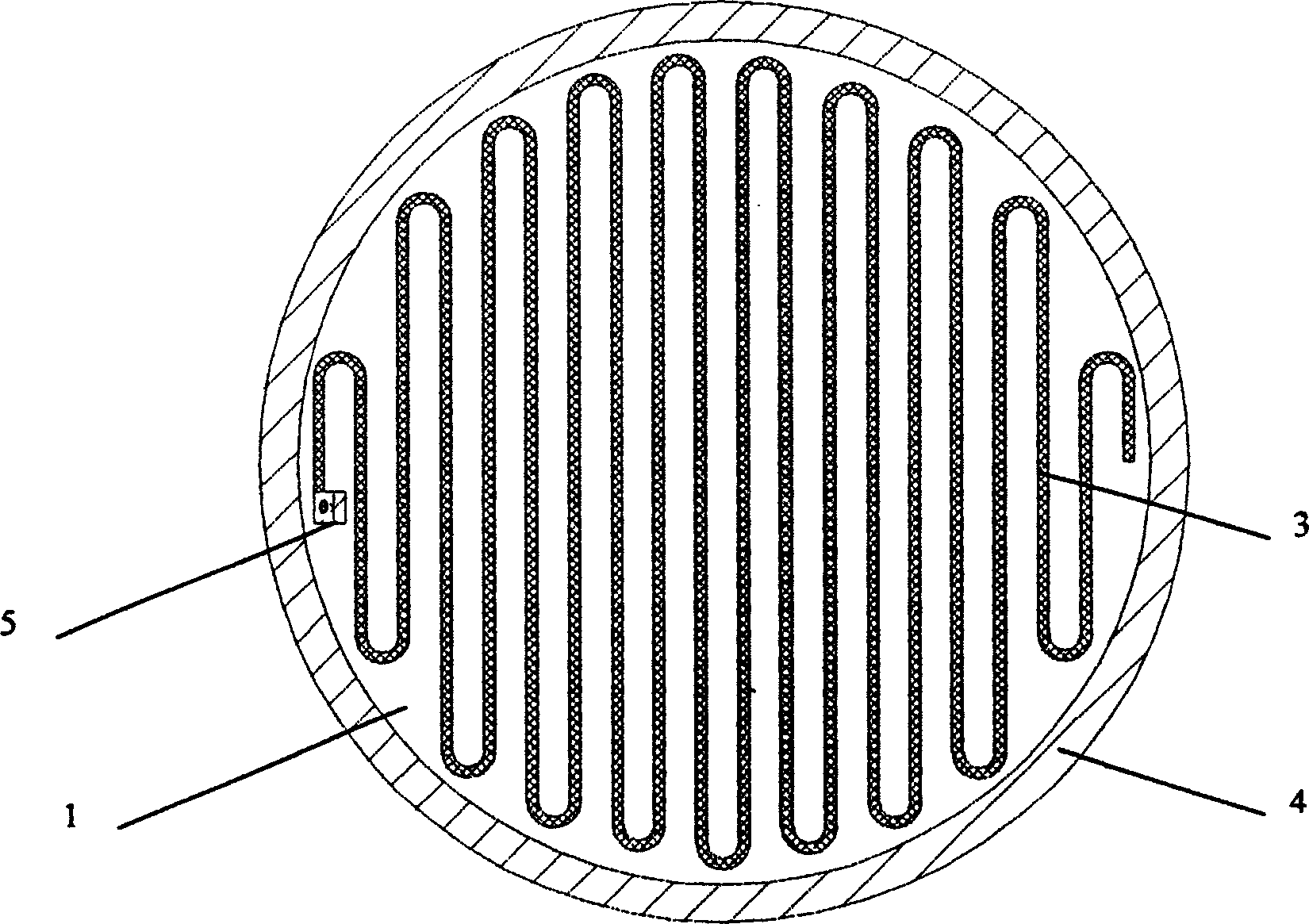

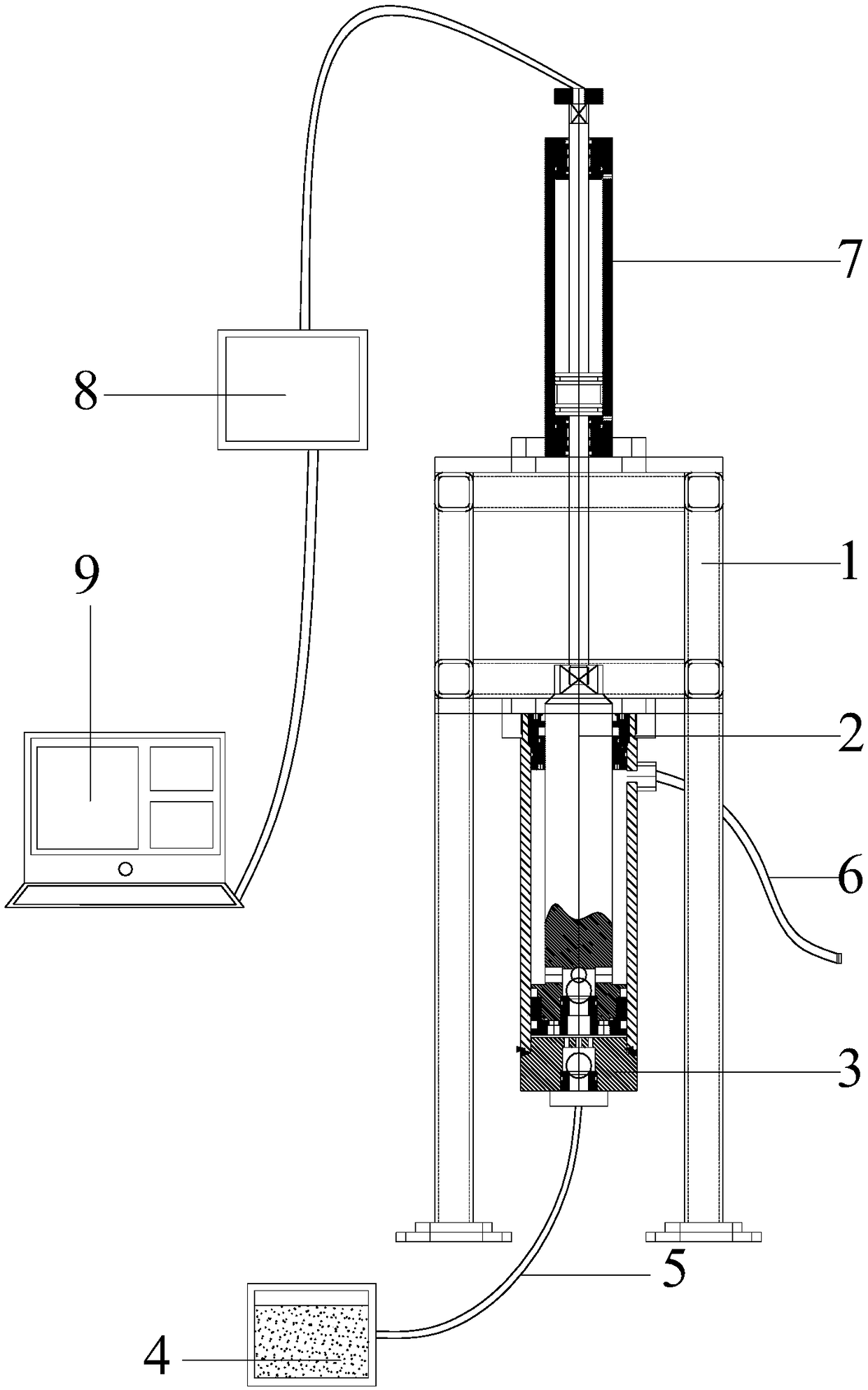

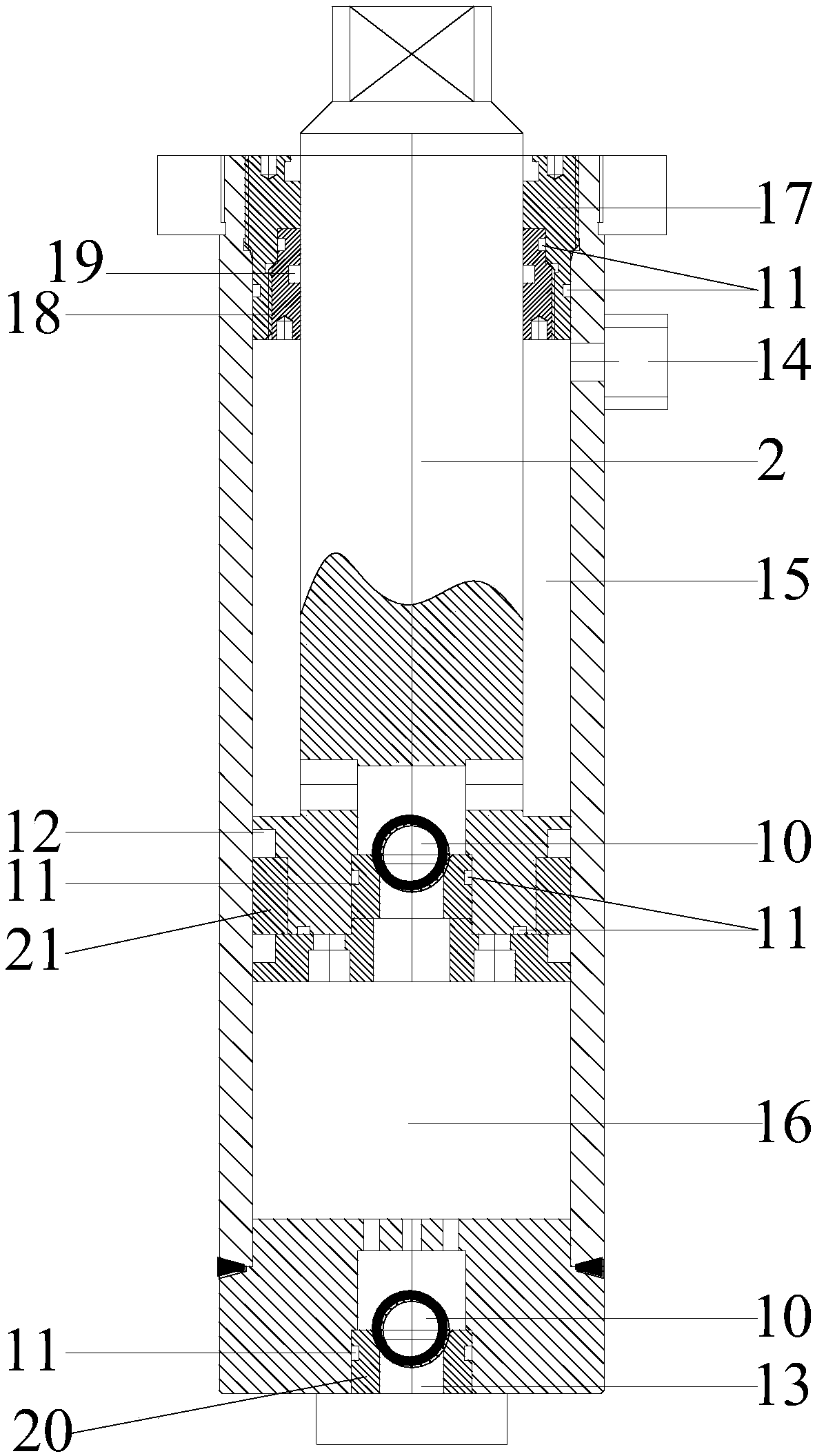

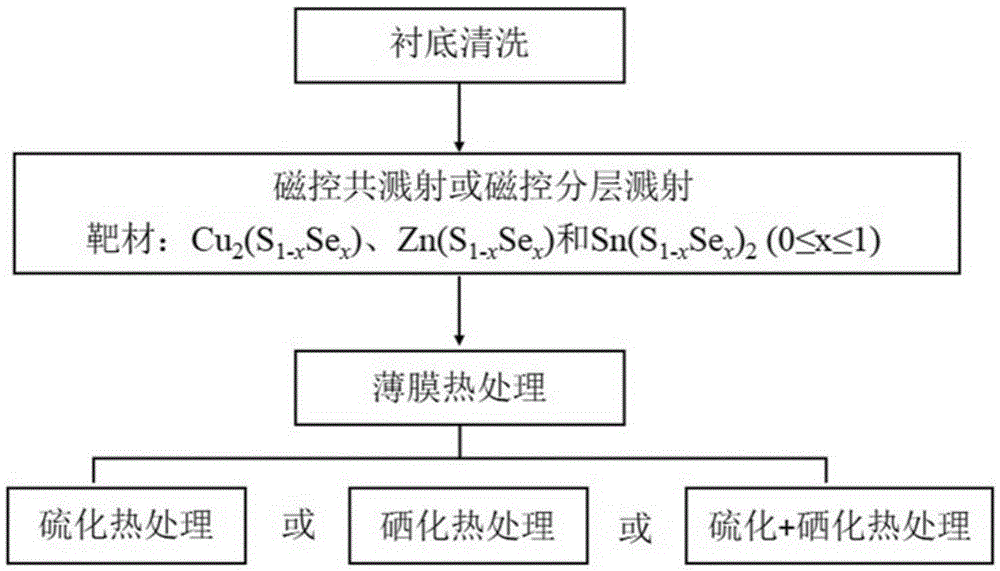

Intelligent non-pulse grouting pump for indoor model test and using method of intelligent non-pulse grouting pump

PendingCN108386331AOvercome stabilityOvercoming controllabilityPump controlPiston pumpsReciprocating motionControl system

The embodiment of the invention provides an intelligent non-pulse grouting pump for an indoor model test and a using method of the intelligent non-pulse grouting pump. The grouting pump comprises a pump body, a piston rod, a pumping system, a slurry storage tank, a slurry conveying pipe, a slurry discharging pipe, a hydraulic system and a PLC control system. The using method comprises the steps that the PLC control system sets the grouting pressure or the grouting speed, transmits signals to the hydraulic system and adjusts and propels an oil cylinder to control the reciprocating motion of thepiston; when the piston moves upwards, a steel ball in the upper part seals a rod cavity, the size is reduced, and grouting is realized; and when the piston moves downwards, a steel ball in the lowerpart seals a rodless cavity, the size is reduced, and grouting is realized. According to the intelligent non-pulse grouting pump for the indoor model test and the using method of the intelligent non-pulse grouting pump, high-flow, high-pressure and high-precision grouting requirements can be met, quantitative control and monitoring can be effectively realized on the grouting amount and the grouting speed, and meanwhile, during the reciprocating motion, the same grouting amount is achieved at the same grouting speed, so that the guarantee is provided for achieving accurate control; and the test data are easy to collect, so that the grouting pump can be widely applied to the indoor model test.

Owner:BEIJING JIAOTONG UNIV

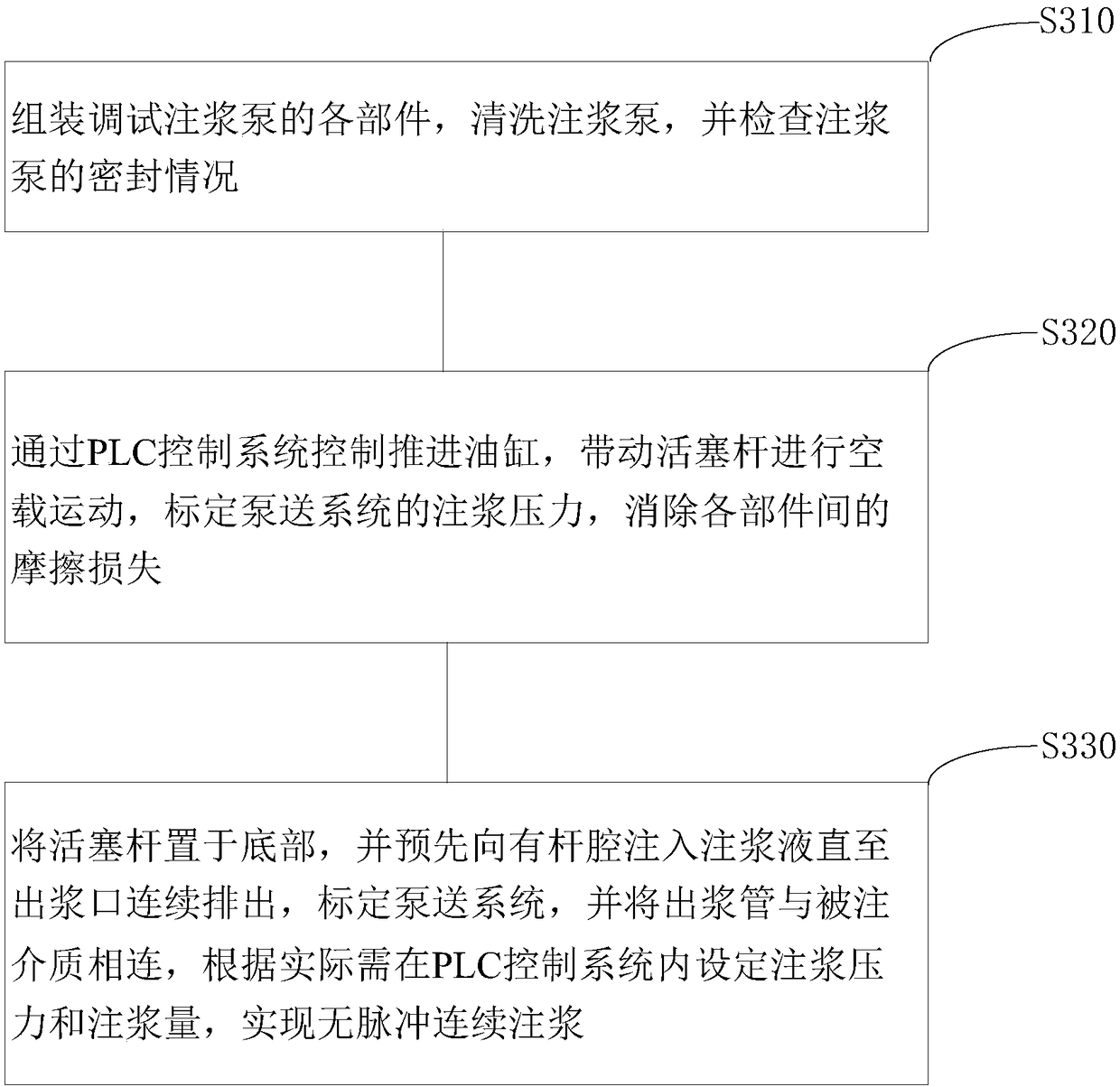

Preparation method for Cu2ZnSn(S1-xSex)4 film with continuously adjustable Se/S ratio

InactiveCN106637107ASe doping achievedOvercoming controllabilityVacuum evaporation coatingSputtering coatingMetalHeat treated

The invention discloses a preparation method for a Cu2ZnSn(S1-xSex)4 film with a continuously adjustable Se / S ratio, wherein x is not less than 0 and not greater than 1. The method comprises the following steps: 1) cleaning a substrate; 2) taking Cu2(S1-xSex), Zn(S1-xSex) and Sn(S1-xSex)2 as target materials, and preparing an as-deposited film through a magnetron sputtering technology; and 3) carrying out heat treatment on the film to obtain a crystallized Cu2ZnSn(S1-xSex)4 film. The Cu2ZnSn(S1-xSex)4 film with the same metal element ratio and the continuously adjustable Se / S ratio can be obtained through the preparation method disclosed by the invention.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

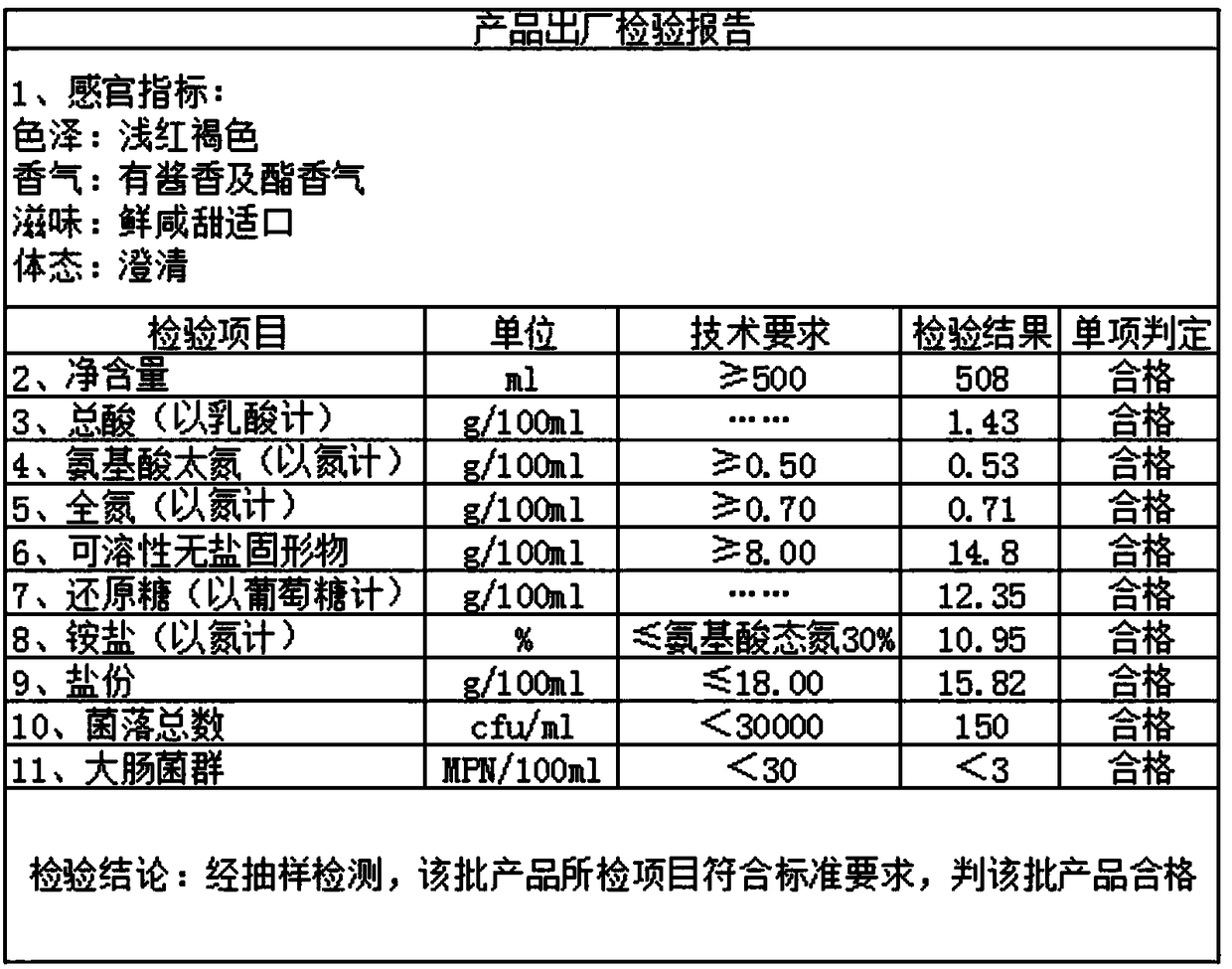

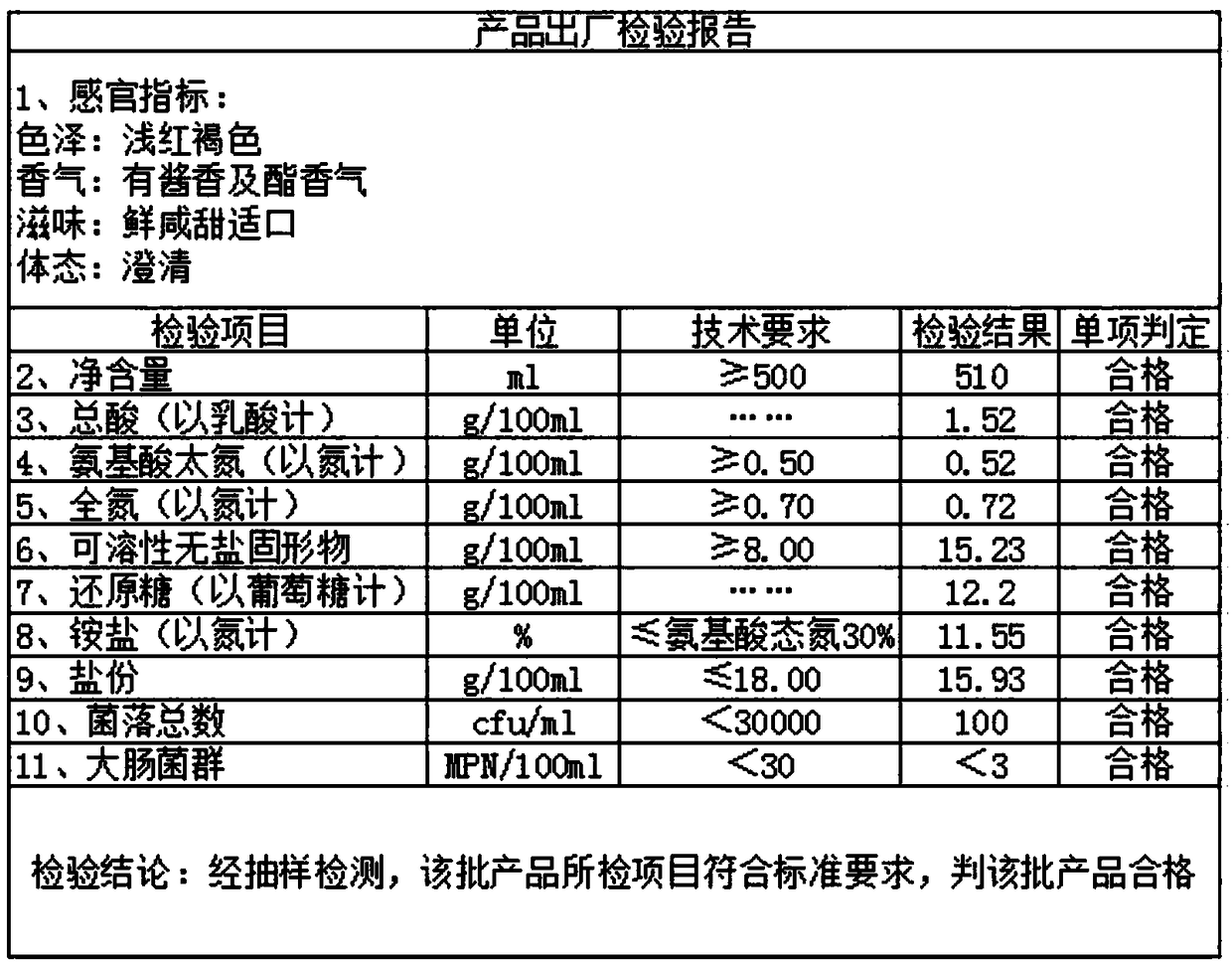

Making method of pale-soup soy sauce

The invention discloses a making method of a pale-soup soy sauce. The making method comprises the following steps of performing dry-steaming on non-GMO defatted soybeans and wheat flour, then performing steaming with steam, performing moistening, mixing the moistened soybeans and the moistened wheat flour with fried oatmeal, through working procedures of making koji, making mellow wine and the like, adding strains of a certain proportion for fermentation, after the fermentation period is finished, performing pressing to obtain juice, performing sterilizing and blending, and then performing filtering to obtain finished products. According to the making method disclosed by the invention, the production efficiency of the pale-soup soy sauce can be improved, the pale-soup soy sauce has high quality and nutrient components, and can improve the sweetness and the mellow mouth feel of dishes, and the working procedures are mature and controllable.

Owner:江苏恒顺沭阳调味品有限公司

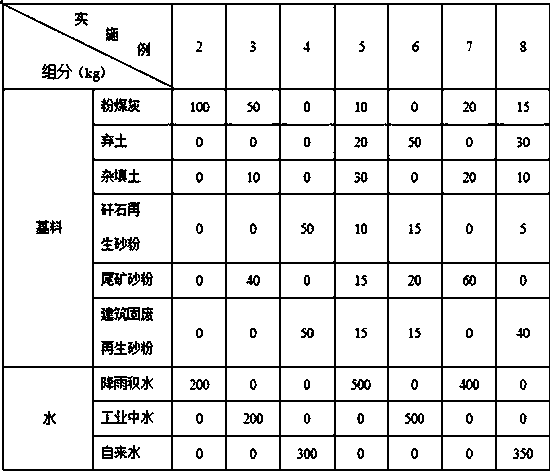

Quick-setting slurry for fire extinguishing and cooling of gangue dump as well as preparation method and application of the quick-setting slurry

ActiveCN111228708AIncrease moisture contentGood suspensionDust removalFire preventionFluid phaseProcess engineering

The invention discloses quick-setting slurry for fire extinguishing and cooling of a gangue dump as well as a preparation method and application of the quick-setting slurry. The invention belongs to the technical field of geological disaster prevention. Raw materials for preparing effective components of the quick-setting slurry comprise the following components: water, a base material, a strong suspension complexing agent, a solid phase flow state regulator and a liquid phase flow state regulator; and high-water-content strong suspension slurry is turned into jelly semisolid which cannot flowin a certain period of time. The preparation method comprises the following steps: mixing the base material and the solid phase flow state regulator, adding the strong suspension complexing agent andthe water, mixing, finally adding the liquid phase flow state regulator, stirring, mixing, starting a pump, and infusing the mixture into a gangue dump. The quick-setting slurry disclosed by the invention has the advantages of high water content, no separation of a solid phase and a liquid phase, good suspension property and capability of forming colloidal slurry within preset time; the defects that pure water and traditional slurry are low in water content and high in flowing speed are overcome, the slurry can cover and adhere to a target body to achieve the synergistic effect of cooling, oxygen insulation and suffocation, the slurry is suitable for fire extinguishing and cooling of all gangue dumps, and the preparation method is used for preparing the quick-setting slurry.

Owner:XIJING UNIV

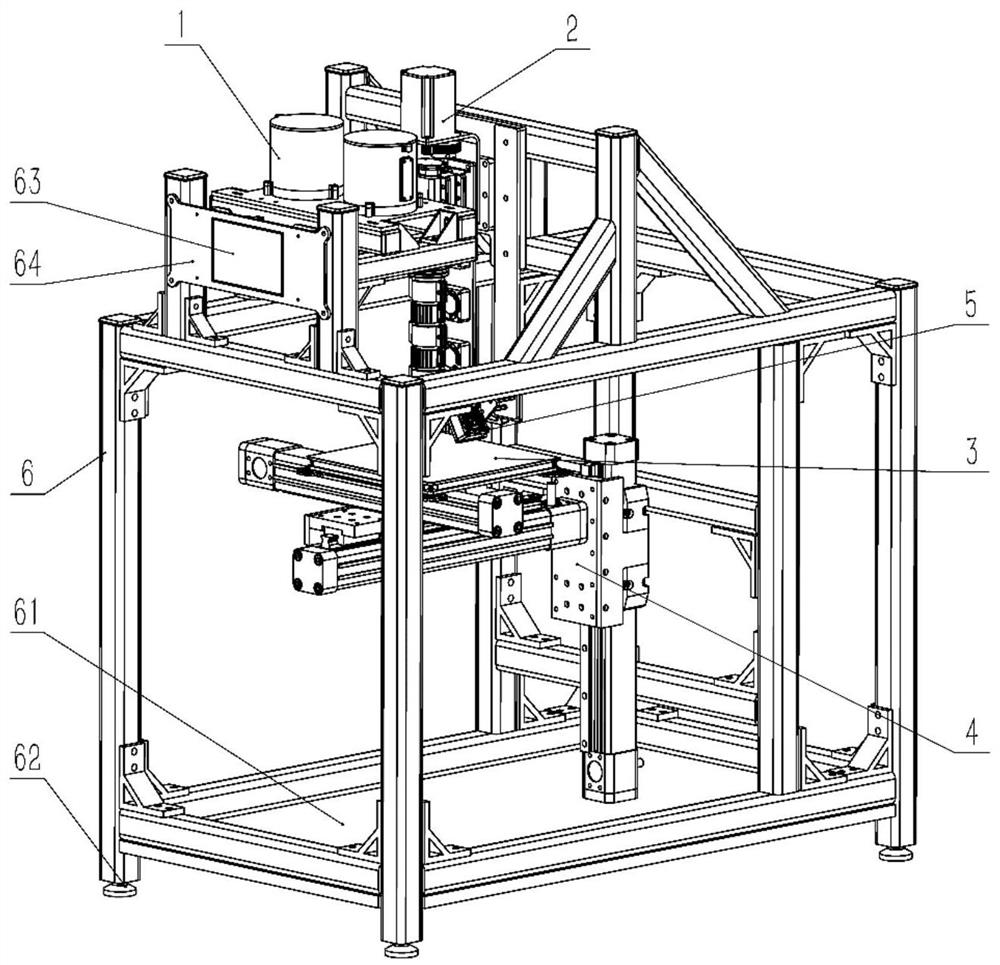

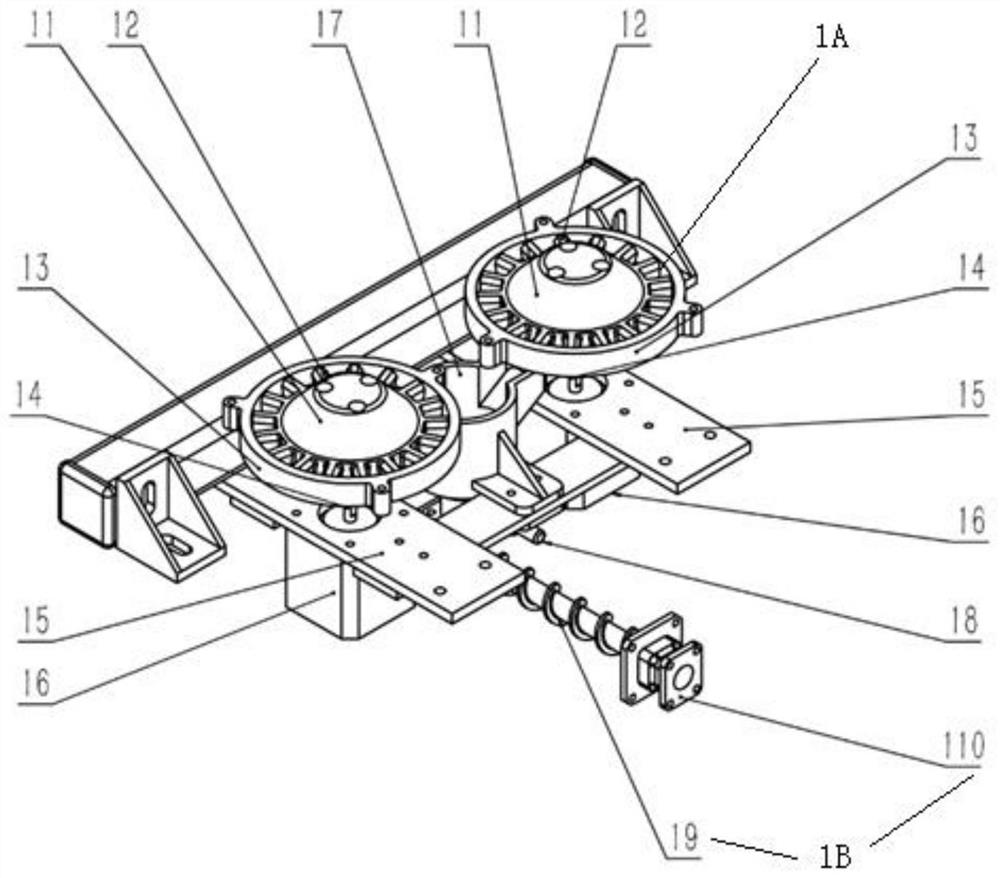

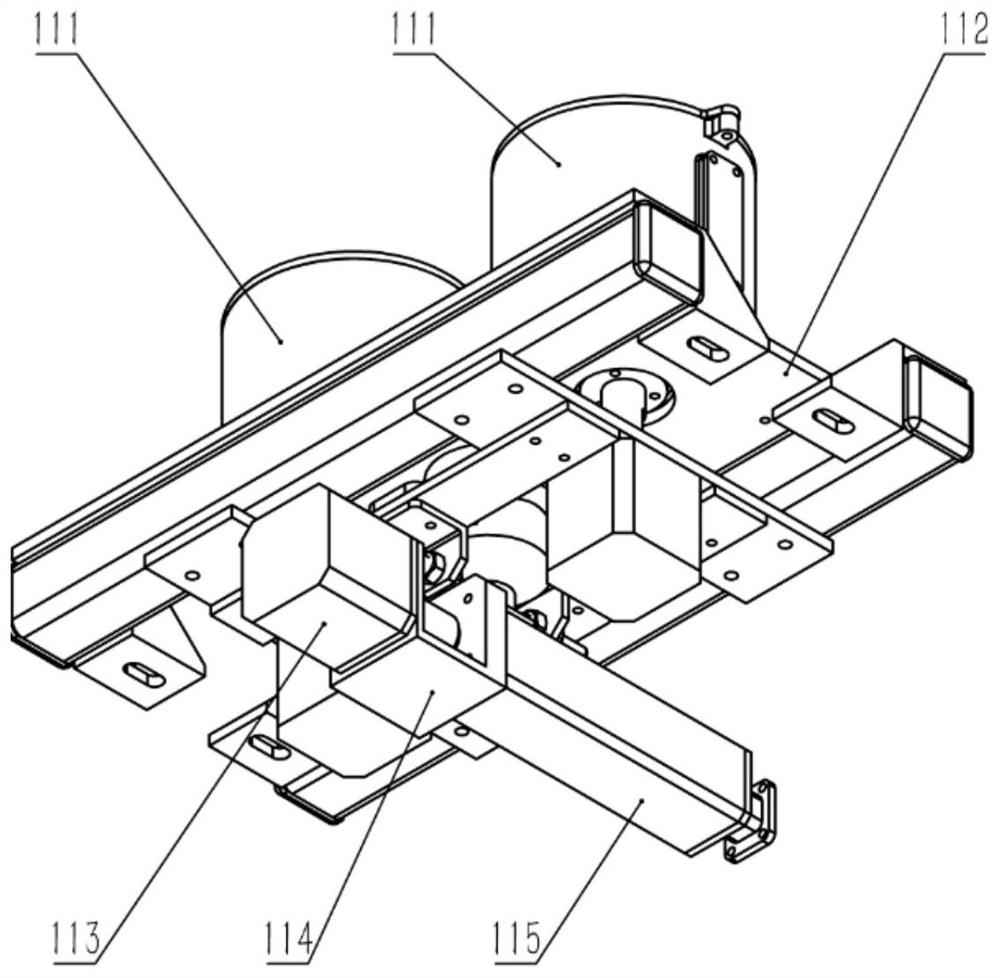

Melt extrusion device, 3D printer, 3D printer control method and application

PendingCN112406099AIncreased distribution and mixing capabilitiesAvoid complex processManufacturing heating elementsManufacturing material handlingComputer printingManufactured material

The invention discloses a melt extrusion device, a 3D printer, a 3D printer control method and application. The melt extrusion device is used for melt extrusion of raw materials of the 3D printer, themelt extrusion device comprises a screw assembly and a spray head assembly connected with the screw assembly, the screw assembly comprises a shell and at least two screws arranged in the shell, threads of the adjacent screws are meshed with each other, the raw materials are evenly mixed and melted through homodromous rotation of the screws, and the molten raw materials are extruded through the spray head assembly. According to the melt extrusion device, the 3D printer, the 3D printer control method and application, the at least two screws are meshed with each other and rotate in the same direction, the raw materials are gradually molten under rotary shearing of the screws, the shearing rate and shearing stress of a melt at the meshed position are large, good back mixing is generated, andthe distribution mixing capacity of the multiple raw materials is greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

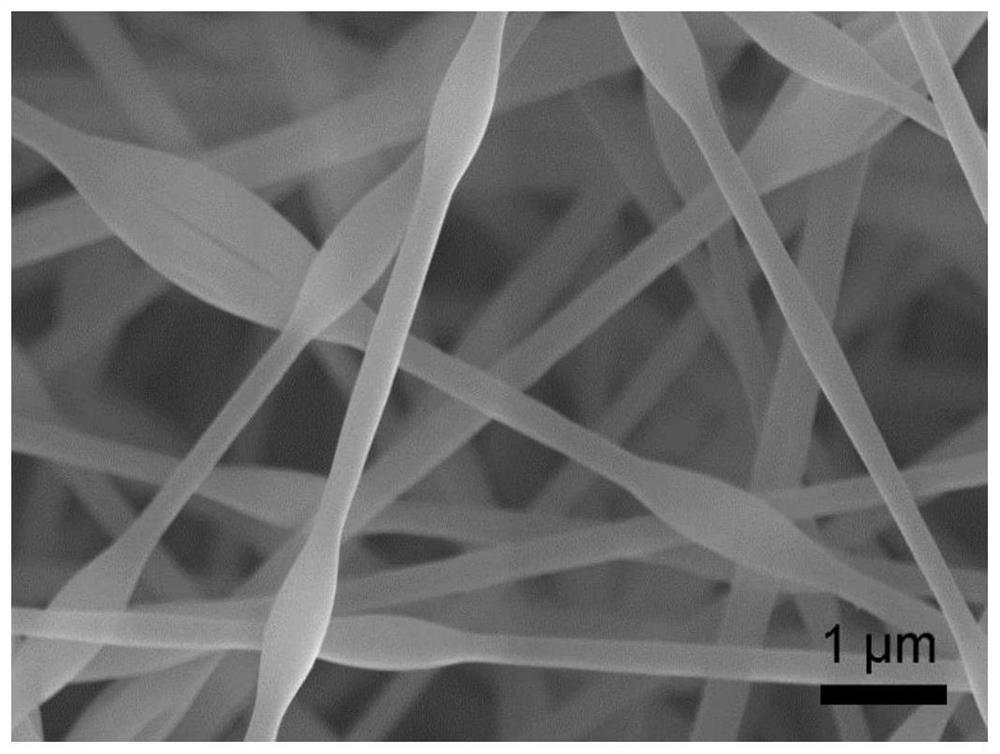

Preparation method of fusiform silicon dioxide composite fiber

PendingCN114016157AFlat surfaceSmooth compositionElectro-spinningConjugated synthetic polymer artificial filamentsFiberPolymer dissolution

The invention discloses a preparation method of a fusiform silicon dioxide composite fiber, and belongs to the field of preparation of micro-nano composite materials. A polymer and a silicon dioxide precursor are used as main raw materials, and the fusiform silicon dioxide composite fiber is prepared through a sol-gel combined electrostatic spinning technology. The method comprises the following steps: firstly, dissolving a polymer in a proper solvent to prepare a viscous solution; fully hydrolyzing the silicon dioxide precursor under an acidic condition to form clear silicon dioxide sol; mixing the sol with a polymer solution, and continuously stirring to obtain a uniform mixed solution; and preparing the obtained mixed solution into the fusiform composite fiber which is smooth in surface, uniform in bead size, high in dispersity and good in hydrophilicity by adopting an electrostatic spinning technology. The method has the advantages of simple process, good repeatability, low energy consumption and low cost, and effectively avoids the agglomeration problem of inorganic nanoparticles in the composite fiber obtained by the traditional mechanical mixing method. The composite fiber can be used as a medicine carrier, a filtering or adsorbing material in environmental treatment, a tissue engineering scaffold and the like.

Owner:CHINA UNIV OF MINING & TECH

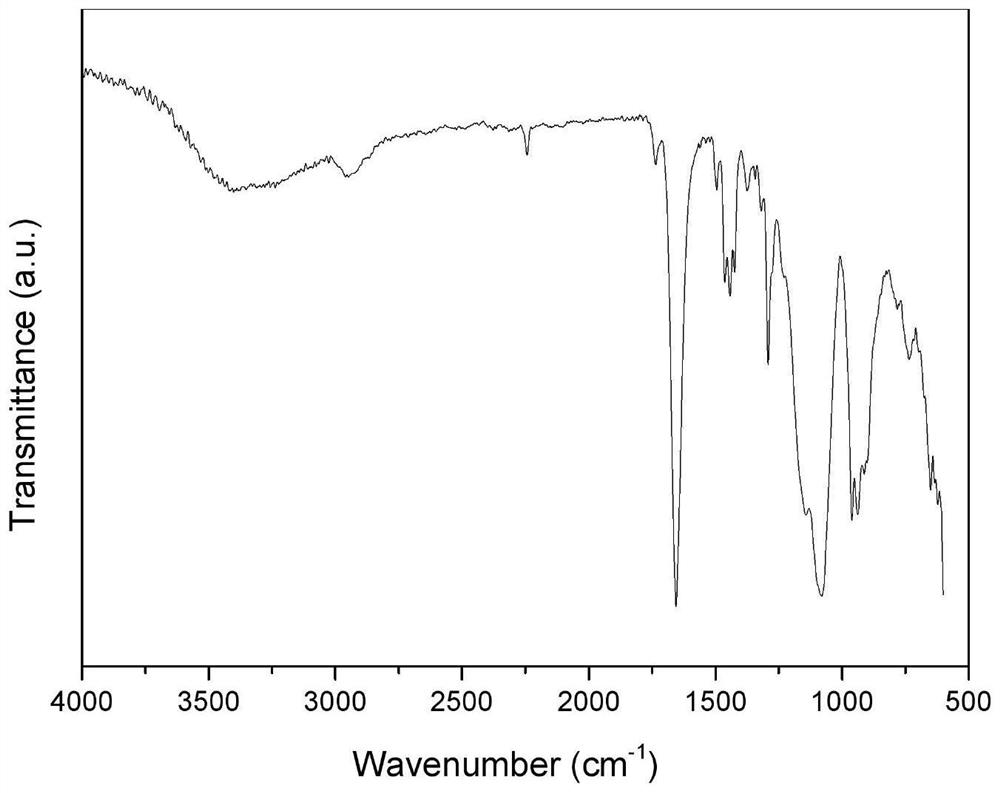

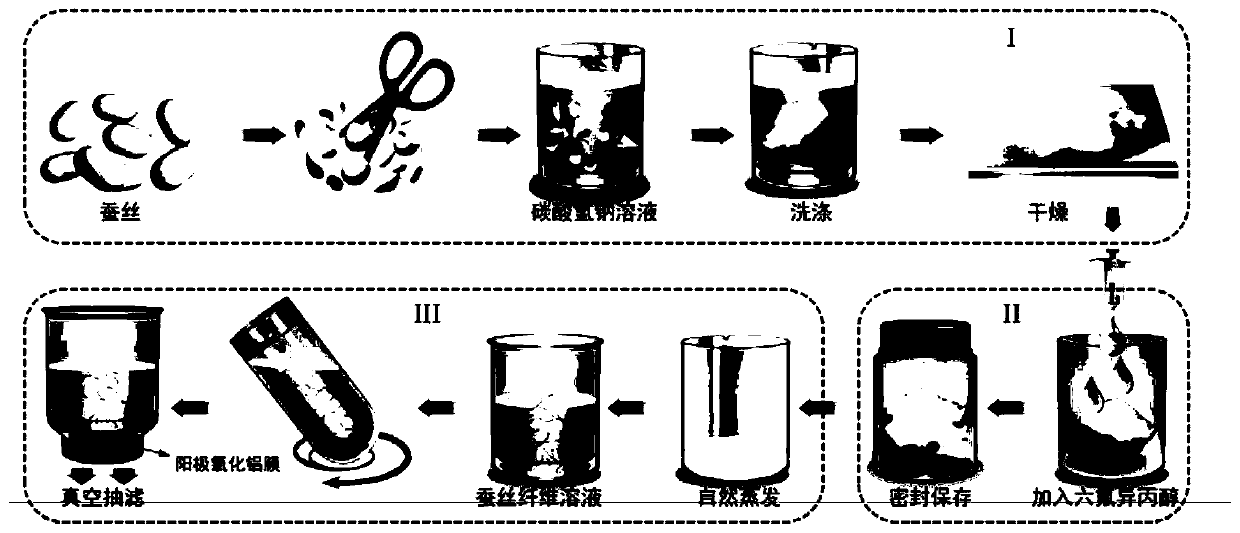

Asymmetric nanopore composite film and preparation method and application thereof

ActiveCN109847594AImprove performanceAbundant raw materialsMaterial nanotechnologySemi-permeable membranesComposite filmMesoporous material

The invention discloses an asymmetric nanopore composite film based on mesoporous-macroporous materials and a preparation method and application thereof. The composite film comprises a silk film layerof a mesoporous structure and a film material of a macroporous structure, wherein the asymmetric nanopore is formed through communication of a part of mesopores in the silk film of a mesoporous structure with a part of macropores in the film material of a macroporous structure. The silk film is adopted as a mesoporous material for the first time, and is used for preparing the asymmetric nanoporecomposite film, and the silk film has stable performance, abundant raw materials, low price, mild preparation conditions and simple operation; in addition, the prepared asymmetric nanopore composite film can be used as a salt difference battery diaphragm in a salt difference power generation system, and has the advantages of long-time current output, application of a wide pH range, stable performance, high conversion efficiency and a wide application range.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

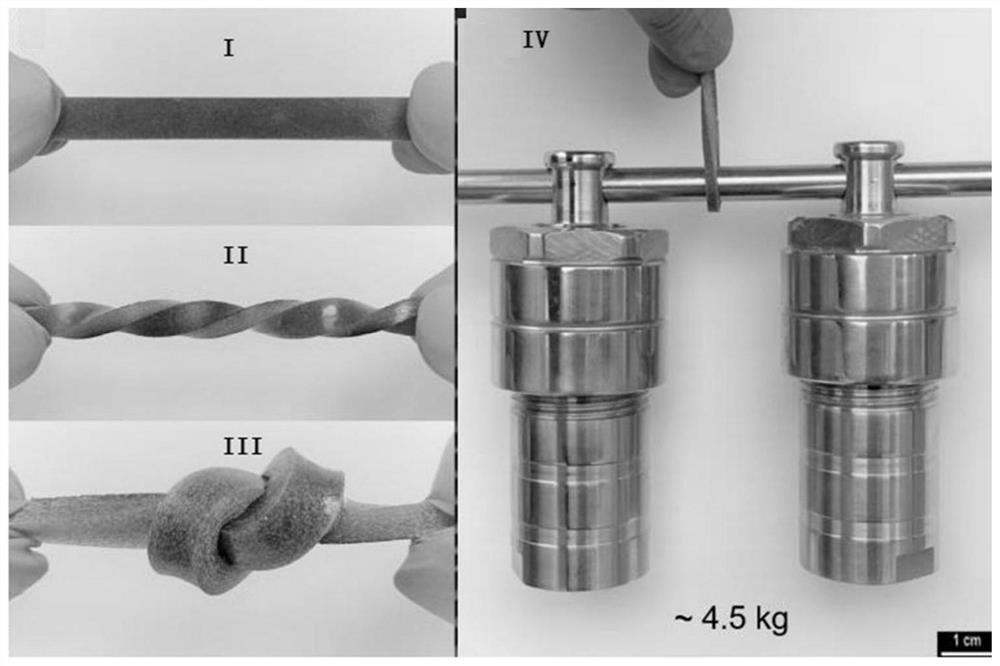

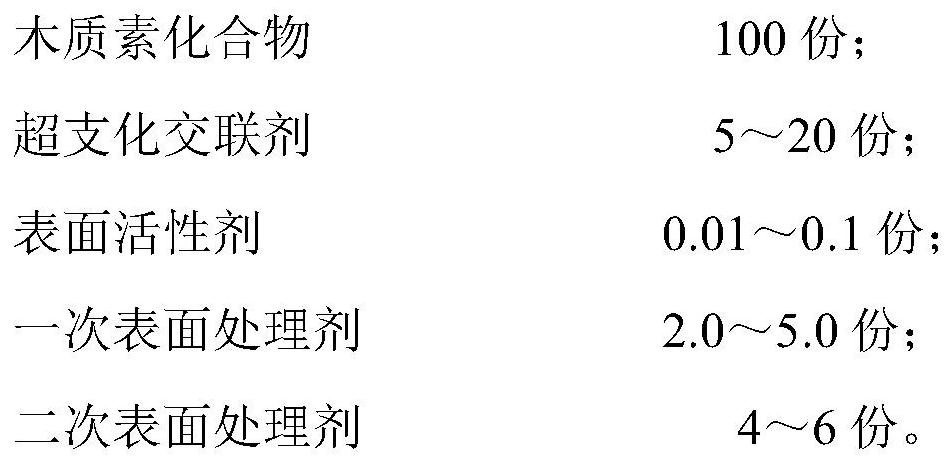

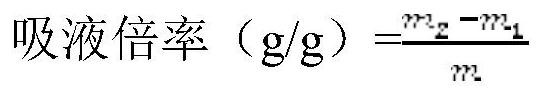

High-strength full-degradable lignin-based super absorbent resin and preparation method thereof

The invention relates to the technical field of super absorbent resin, and discloses high-strength full-degradable lignin-based super absorbent resin in order to solve the problems that super absorbent resin is low in degradability, poor in mechanical strength after absorbing water and the like. The lignin-based super absorbent resin is prepared from the following components, by weight: 100 partsof a lignin compound, 5-20 parts of a hyperbranched cross-linking agent, 0.01-0.1 part of a surfactant, 2.0-5.0 parts of a primary surface treating agent and 4-6 parts of a secondary surface treatingagent. The hyperbranched cross-linking agent is an aldehyde end group hyperbranched cross-linking agent with a polyether structure as a main chain, a carboxyl end group hyperbranched cross-linking agent, an amino end group hyperbranched cross-linking agent and an epoxy end group hyperbranched cross-linking agent. The resin prepared in the invention has a high swelling rate in pure water and normalsaline, still has high toughness and strength after absorbing water, has excellent degradation performance, and has a 90-day degradation rate of over 80% and a 270-day degradation rate of over 95% under the experimental conditions of simulating the bottom of a refuse landfill.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com