Paper-based microfluidic chip and preparation method thereof

A microfluidic chip, paper-based chip technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problem of unfavorable liquid control, microstructure effects of migration speed, volatilization and pollution of flowing liquids, etc. problem, to achieve the effect of low cost, simple cross-linking and curing method, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of linear paper-based microfluidic chip

[0036] Use a computer to design a linear microfluidic channel configuration, take a single-layer paper substrate and cut out a paper-based chip that matches the linear channel configuration, and cut out a linear microfluidic channel on the paper-based chip with a laser cutting machine. For the fluidic channel, set the diameter of the microfluidic channel to 300 μm by adjusting the laser intensity (such as figure 1 shown).

[0037] Take a single-layer paper base material, cut out a paper base sheet that matches the paper-based chip with a laser cutting machine, and glue the paper base sheet to the bottom of the paper-based chip with 8146-2 optically transparent adhesive (manufactured by 3M Company in the United States) . Soak the bonded paper-based chip and paper-based sheet in polydimethylsiloxane glue, remove excess polydimethylsiloxane glue, place in an oven, and heat at 60-120°C Bake for 40 minutes t...

Embodiment 2

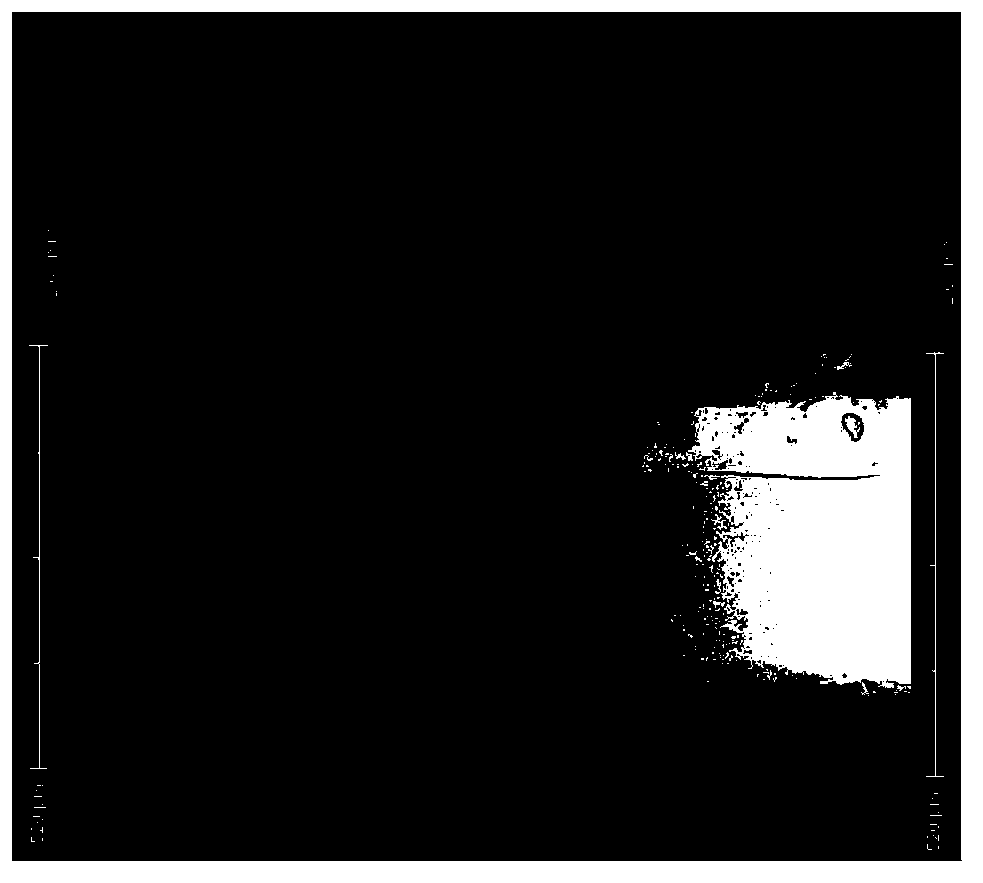

[0040] Example 2: Preparation of linear paper-based microfluidic chip

[0041] Use a computer to design a linear microfluidic channel configuration, take two layers of paper substrates and cut out paper-based chips that match the linear channel configuration, and use a laser cutting machine to hollow out the two-layer paper-based chips. Create a linear microfluidic channel, and set the diameter of the microfluidic channel to 300 μm by adjusting the laser intensity. Use 8146-2 optically transparent glue to bond two layers of paper-based chips together to form a multi-layer paper-based chip.

[0042] Take a single-layer paper base material, cut out a paper base sheet that matches the multilayer paper-based chip with a laser cutting machine, and glue the paper base sheet to the bottom of the multi-layer paper-based chip with 8146-2 optically transparent glue. Soak the bonded multi-layer paper-based chip and paper-based sheet in polydimethylsiloxane glue, remove excess polydimeth...

Embodiment 3

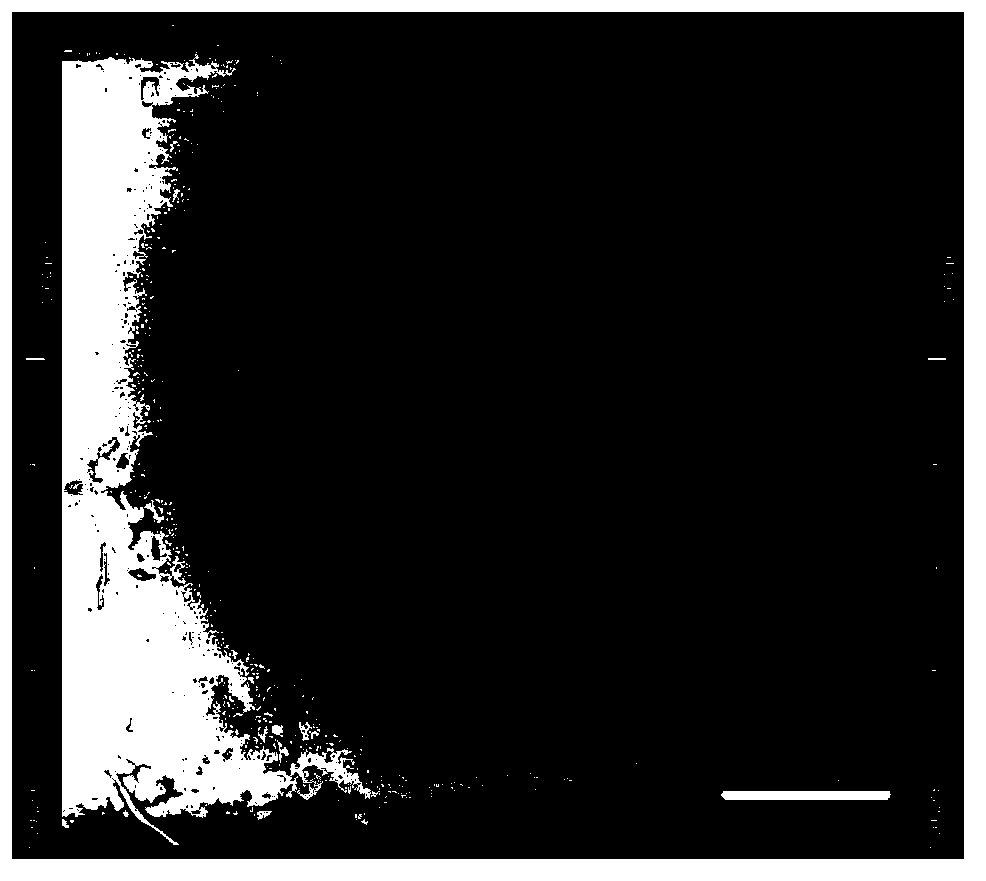

[0046] Example 3: Preparation of linear three-dimensional paper-based microfluidic chip

[0047] Take the linear paper-based microfluidic chip prepared in Example 1 or Example 2, and fold it to form a linear three-dimensional paper-based microfluidic chip (such as image 3 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com