Double-layered cavity type liquid color-change glasses

A technology of color-changing glasses and cavity, applied in glasses/goggles, optics, instruments, etc., can solve the problems of cumbersome production process, large flow resistance and high cost, and achieve the effect of reducing cost, strong controllability and reducing residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

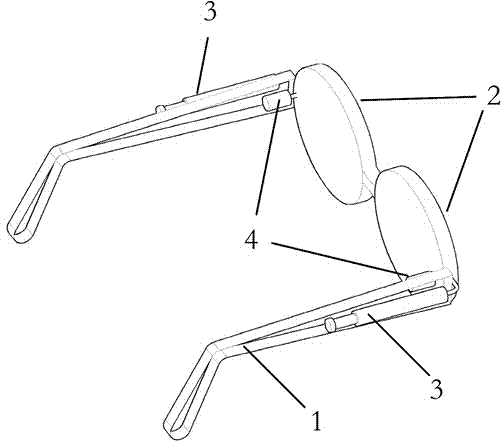

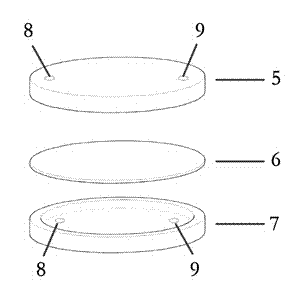

[0024] Specific implementation mode one: combine figure 1 and image 3 Explain that the color-changing glasses include a frame 1, two lenses 2, two colorless fluid (liquid / gas) actuators 3, two elastic colored fluid storage chambers 4, colorless fluid chambers 5, elastic films 6 and colored The fluid chamber 7 is composed. Two lenses 2 are arranged in the frame 1, two colorless fluid actuators 3 are installed on the outside of the two temples of the frame 3, and two colored fluid storage chambers 4 are installed on the inside of the two temples. The colorless fluid actuator 3 is two manual pistons, the cavity is filled with colorless fluid (liquid / gas), and the elastic colored fluid storage chamber 4 stores colored fluid. The inside of the lens 2 is composed of a colorless fluid chamber 5, a colored fluid chamber 7 and an elastic film 6, and the three parts are assembled together to form an eyeglass. The colorless fluid actuator 3 is connected to the colorless fluid chamber...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 Note that the depth of the colorless fluid chamber 5 is 1-2 mm, and the depth of the colored fluid chamber 7 is 0.05-1 mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

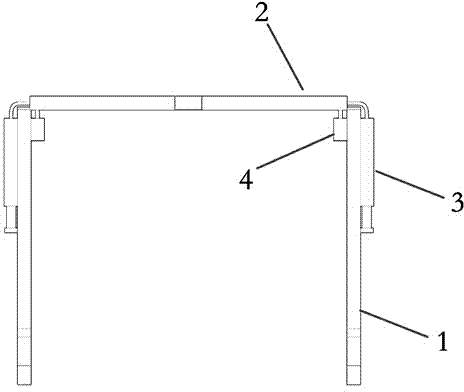

[0026] Specific implementation mode three: combination figure 2 Explain that the colorless fluid actuator 3 is two diaphragm chambers, which are installed on the two corners of the mirror frame 1 . The diaphragm cavity is connected with the colorless fluid cavity 5 in the lens 2 . When the diaphragm is pressed, the colorless fluid in the diaphragm chamber is pushed into the colorless fluid chamber 5 on the lens 2 . Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com