Preparation method for Cu2ZnSn(S1-xSex)4 film with continuously adjustable Se/S ratio

A thin film, cu2 technology, applied in the field of Cu2ZnSn4 thin film preparation, can solve the problems of strong pollution, high film production cost, low raw material utilization rate and production efficiency, achieve high efficiency, overcome poor controllability, optimize Se/S than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

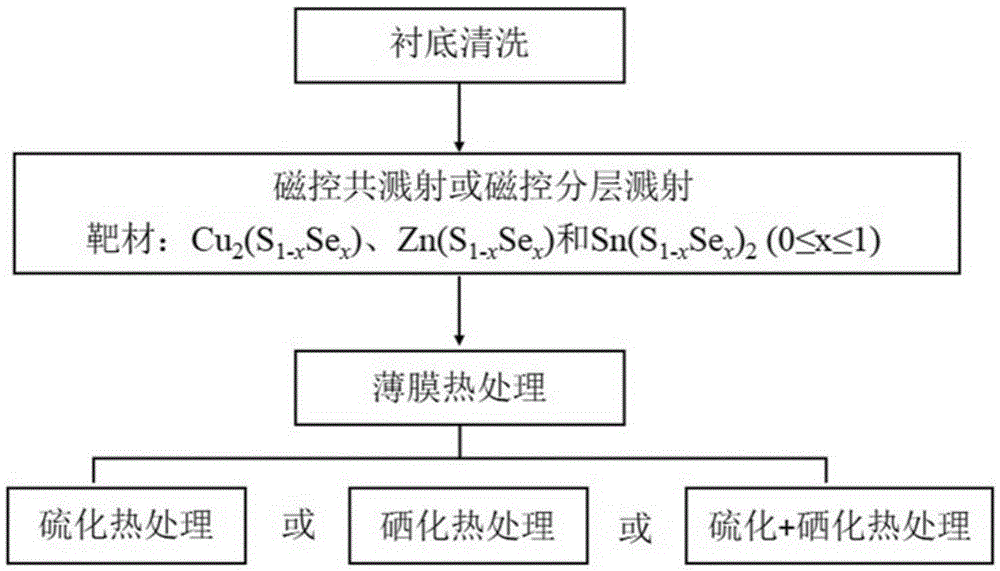

[0019] Such as figure 1 As shown, the Cu with continuously adjustable Se / S ratio of the present invention 2 ZnSn(S 1-x Se x )4 The preparation method of the thin film mainly includes three steps: 1) the substrate is cleaned; 2) with Cu 2 (S 1-x Se x ), Zn(S 1-x Se x ) and Sn(S 1-x Se x ) 2 is the target material (0≤x≤1), using magnetron sputtering to prepare Cu 2 ZnSn(S 1-x Se x ) 4 film; 3) performing heat treatment on the film, and the heat treatment atmosphere is selected from a sulfide atmosphere, a selenization atmosphere or a mixed atmosphere of a sulfide atmosphere and a selenization atmosphere.

[0020] The present invention can prepare Cu with consistent ratio of metal elements and continuously adjustable Se / S ratio 2 ZnSn(S 1-x Se x ) 4 film.

Embodiment 1

[0022] Using magnetron sputtering technology, Cu 2 S, ZnS and SnS 2 As the target material, the as-deposited film was prepared by co-sputtering, and then the crystallized Cu 2 ZnSnS 4 (x=0) film, specifically:

[0023] Step 1: Substrate Cleaning

[0024] The soda-lime glass substrate was ultrasonically cleaned with deionized water, acetone and absolute ethanol in sequence for 10 min, and the remaining ethanol on the substrate surface was blown off with a nitrogen gun.

[0025] Step 2: Thin Film Deposition

[0026] The target is Cu 2 S, ZnS and SnS 2 , the sputtering gas is Ar gas, the sputtering pressure is 0.25Pa, and the film is deposited by co-sputtering, in which Cu 2 S, ZnS and SnS 2 The targets are all radio frequency sputtering, Cu 2 S, ZnS and SnS 2 The sputtering power of the target is 65W, 85W and 27W in turn, and the sputtering time is 20min.

[0027] Step 3: Thin film heat treatment

[0028] After the film deposition is completed, the film is vulcanized...

Embodiment 2

[0030] Using magnetron sputtering technology, Cu 2 Se, ZnSe, and SnSe 2 As the target material, the deposited film was prepared by layered sputtering, and then crystallized Cu was prepared by selenization heat treatment. 2 ZnSnSe 4 (x=1) film, specifically:

[0031] Step 1: Substrate Cleaning

[0032] The soda-lime glass substrate was ultrasonically cleaned with deionized water, acetone and absolute ethanol in sequence for 10 min, and the remaining ethanol on the substrate surface was blown off with a nitrogen gun.

[0033] Step 2: Thin Film Deposition

[0034] The target is Cu 2 Se, ZnSe, and SnSe 2 , the sputtering gas is Ar gas, the sputtering pressure is 0.5Pa, and the thin film is deposited by layered sputtering. Among them, Cu 2 Se, ZnSe, and SnSe 2 The targets are all radio frequency sputtering, and the deposition sequence is ZnSe, SnSe 2 and Cu 2 Se, ZnSe, SnSe 2 and Cu 2 The sputtering power of the Se target was 80W, 30W and 50W in turn, and the sputtering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com