High-strength full-degradable lignin-based super absorbent resin and preparation method thereof

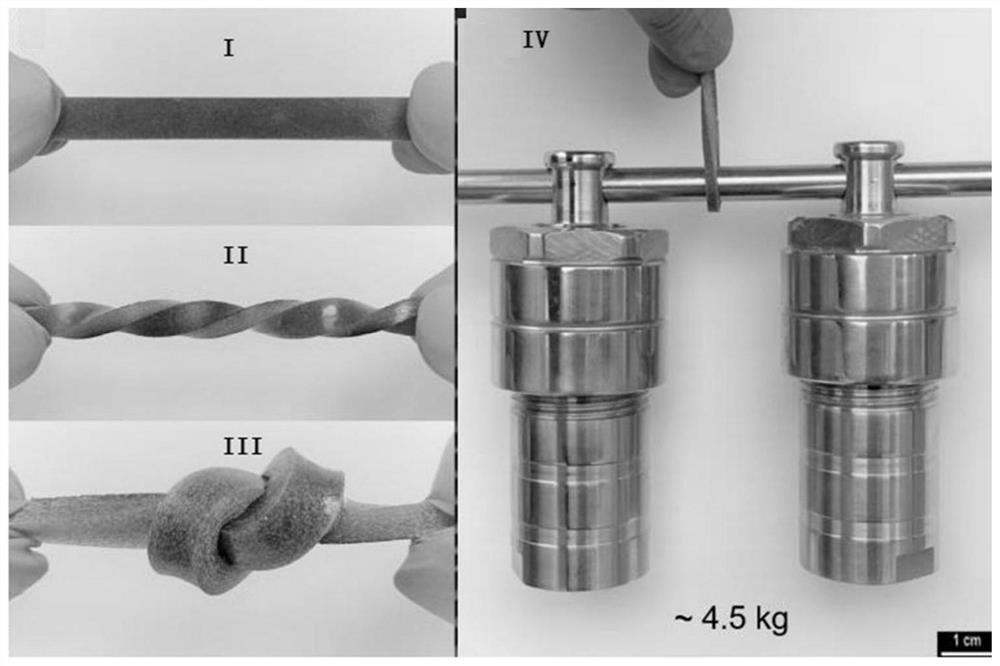

A super absorbent resin, lignin-based technology, applied in the field of high-strength fully degradable lignin-based super absorbent resin and its preparation, can solve the problems of poor mechanical strength, low degradability, high gel strength, etc. The effect of low cost, high toughness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

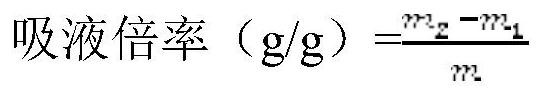

Examples

Embodiment 1

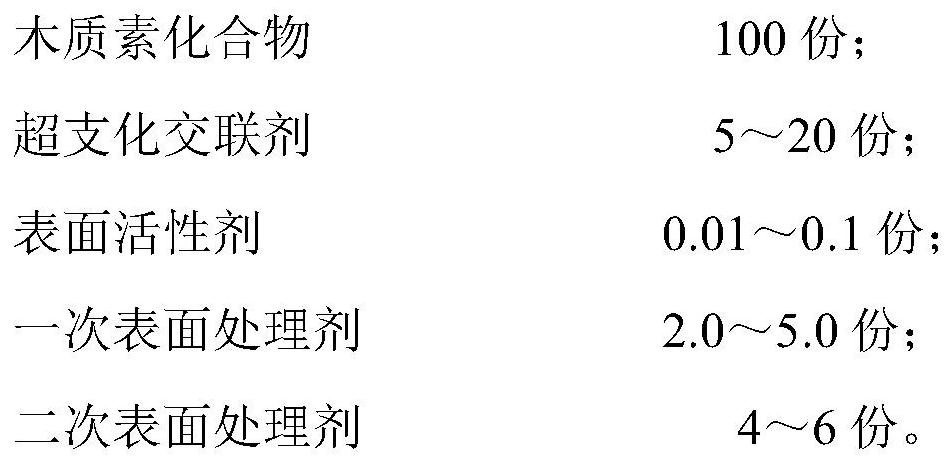

[0049] A polyether-structured aldehyde-terminated hyperbranched crosslinking agent, used to prepare high-strength fully degradable lignin-based superabsorbent resin gel or resin, prepared through the following process:

[0050] (1) Add trimethylolpropane (10mmol), sodium methoxide (10mmol), and methanol (20mL) to a round-bottomed flask, heat and boil to reflux for 2 hours, and remove methanol under reduced pressure to obtain white sodium pentaerythritol powder;

[0051] (2) Add glycidyl alcohol (0.6mol) in the flask of step (1), heat to 110 DEG C under stirring, cationic ring-opening polymerization takes place, obtain glycidyl alcohol hyperbranched prepolymer;

[0052] (3) Add glyoxylic acid (0.5mol) and methanesulfonic acid (0.2g) into the flask of step (2), heat to 90°C, stir for 6 hours, cool down, add carbon tetrachloride for extraction, and depressurize the oil phase The aldehyde-terminated hyperbranched crosslinker is obtained after removing carbon tetrachloride.

[005...

Embodiment 2

[0060] A carboxyl-terminated hyperbranched crosslinking agent with a polyether structure, used to prepare high-strength fully degradable lignin-based superabsorbent resin gel or resin, prepared through the following process:

[0061] (1) Add pentaerythritol (10mmol), sodium methoxide (10mmol), methanol (20mL) into the round bottom flask, heat and boil under reflux for 2h, and remove methanol under reduced pressure to obtain white sodium pentaerythritol powder;

[0062] (2) Add glycidyl alcohol (0.5mol) into the flask, heat to 100°C under stirring, cationic ring-opening polymerization takes place, and obtain glycidol hyperbranched prepolymer;

[0063] (3) Add oxalic acid (0.5mol) methanesulfonic acid (0.2g) into the flask, heat to 60°C, stir for 12 hours, cool down, add carbon tetrachloride for extraction, and remove tetrachloride from the oil phase under reduced pressure After carbon, a carboxyl-terminated hyperbranched crosslinker is obtained.

[0064] A high-strength fully ...

Embodiment 3

[0071] An epoxy-terminated hyperbranched cross-linking agent with a polyether structure, used for the preparation of high-strength fully degradable lignin-based superabsorbent resin gel or resin, prepared through the following process:

[0072] (1) Add pentaerythritol (10mmol), sodium methoxide (10mmol), methanol (20mL) into the round bottom flask, heat and boil under reflux for 2h, and remove methanol under reduced pressure to obtain white sodium pentaerythritol powder;

[0073] (2) Glycidyl alcohol (0.5mol) is added into the flask, heated to 90°C under stirring, cationic ring-opening polymerization occurs, and a glycidol hyperbranched prepolymer is obtained;

[0074] (3) Add epichlorohydrin (0.5mol), tetrabutylammonium bromide (0.2g) into the flask, and add sodium hydroxide solution (0.1mol / L, 100mL) to adjust the alkaline environment, and heat to 70°C , stirring and reacting for 10 hours, cooling, adding carbon tetrachloride for extraction, removing carbon tetrachloride fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com