Asymmetric nanopore composite film and preparation method and application thereof

A technology of nano-channels and composite membranes, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low synthesis yield of block copolymer membranes, poor control ability of etching technology, complicated preparation process, etc. Achieving the effects of abundant raw materials, low prices and overcoming complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

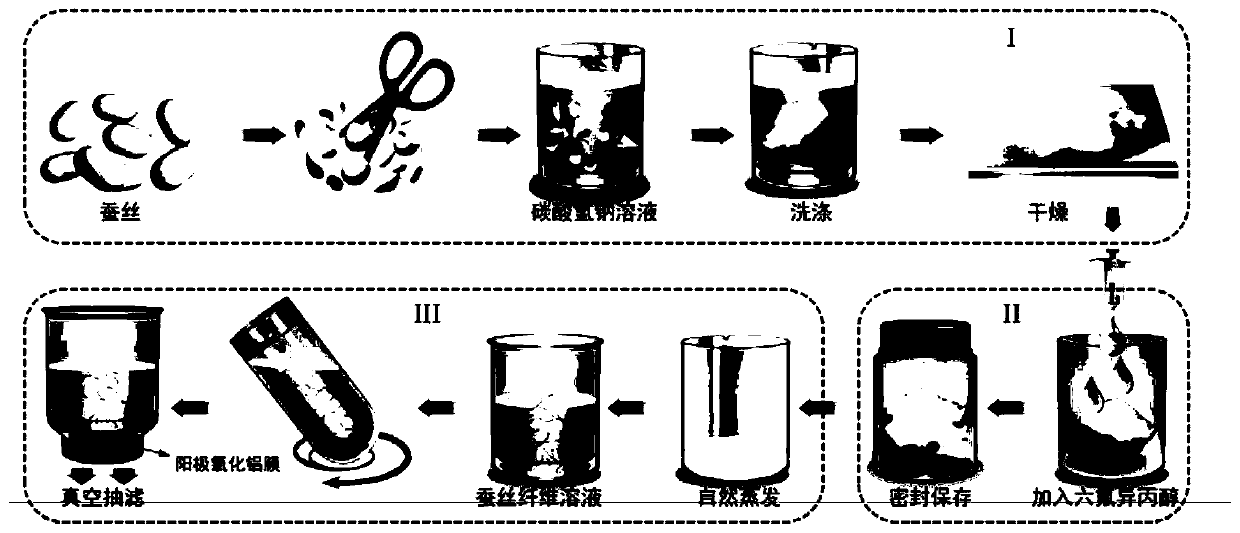

[0045] The silk shells used in the preparation process of the composite membrane provided by the present invention are purchased commercially, which is not limited in the present invention. Here, the present invention provides a preparation method of the above-mentioned silk nanofibers, comprising the following steps:

[0046] (1) silk degumming treatment: 1 part of silk is added to 400 parts of sodium bicarbonate solution with a mass fraction of 0.5%, boiled for 1h, washed with cold water to neutrality, and dried to obtain degummed silk fibers;

[0047] (2) Preparation of silk microfibers: infiltrate 1 part of degummed silk fiber into 30 parts of hexafluoroisopropanol solution, keep it in a constant temperature and airtight manner at 60°C for 24 hours, and let the hexafluoroisopropanol evaporate naturally for 5 hours at normal temperature and pressure to obtain silk microfibers;

[0048] (3) prepare silk nanofiber solution: dissolve 1 part of silk microfiber in 400 parts of wa...

Embodiment 1

[0062] Preparation of Asymmetric Nanoporous Composite Membranes

[0063] like figure 1 As shown, the preparation of the asymmetric nanoporous composite membrane includes the following steps:

[0064] (1) Cut the cocoon into nail-sized pieces, add 1 part of silk into 400 parts of sodium bicarbonate solution with a mass fraction of 0.5%, boil for 1 hour, then wash with cold distilled water until it is neutral, then squeeze the silk to dry, then spread On a piece of clean aluminum foil, let the silk dry overnight at room temperature to obtain degummed silk fibers.

[0065] (2) Then 1 part of degummed silk fiber was soaked into 30 parts of hexafluoroisopropanol solution, fully stirred, and then kept in a constant temperature and airtight at 60 ° C for 24 hours, then moved into a fume hood, and let it be kept under normal temperature and pressure. Hexafluoroisopropanol was naturally evaporated for 5h to obtain silk microfibrils. (3) Dissolve 1 part of silk microfibers in 400 par...

Embodiment 2-5

[0067] Preparation of composite membranes with different silk membrane thicknesses

[0068] Compared with Example 1, by changing the consumption of the silk fiber solution in step (4), it can be obtained that the pore size of the anodic aluminum oxide film is 80-100 nm, the pore size of the silk film is 15-25 nm, and the thickness of the silk film is 5 μm and 15 μm respectively. , 40 μm and 80 μm asymmetric nanoporous composite membranes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com