Detection method and device for number of impact times of impact type fastening tool

A technology for fastening tools and detection devices, applied to measuring devices, manufacturing tools, measuring electrical variables, etc., to achieve cost reduction, low power consumption, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] see Figure 1 to Figure 5 , the impact detection method of the impact fastening tool of the present invention, the realization method is as follows:

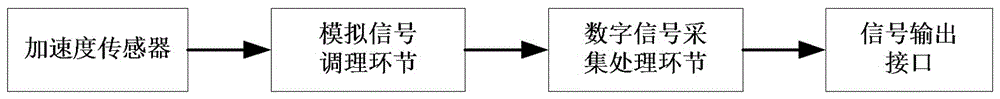

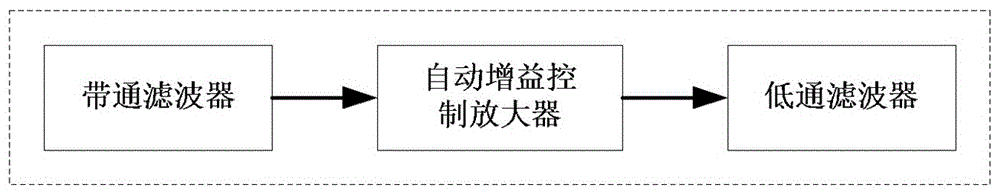

[0039] The acceleration sensor is installed on the vibration-sensitive part of the impact fastening tool frame to detect the vibration signal sensed by the acceleration sensor during the working process; through the analog signal conditioning link, the acceleration sensor senses various interference components and the amplitude is positive to the impact intensity The relevant vibration waveform signals are filtered and amplified, and the obtained vibration waveform signals are converted into digital waveform signals through the A / D converter in the digital signal acquisition and processing link, and the vibration waveform frequency and continuity of the digital waveform signals are judged in real time. Remove redundant interference pulses to form complete pulse wave data, obtain real-time pulse numbers, and output shock n...

Embodiment 2

[0041] see Figure 5 , Figure 6 , Figure 7 , Figure 8 , the impact number detection method of the impact fastening tool in this embodiment is different from Embodiment 1 in that it further discloses the specific implementation steps for the digital signal acquisition and processing link to process the vibration waveform signal in real time and output the impact number signal:

[0042] 1) Storage step—store the frequency m of the shock pulse wave in the data storage unit 上限 、m 下限 and the amplitude characteristic parameter k of the pulse wave, which are used to filter out the interference pulse in real time in the digital signal acquisition and processing link;

[0043] 2) Reading step—read the signal output mode of the number of impacts from the selection switch, determine the type of output signal and the number of simultaneous output channels, and set the initial value of the number of impacts at the same time;

[0044] 3) Acquisition step—convert the vibration analog...

Embodiment 3

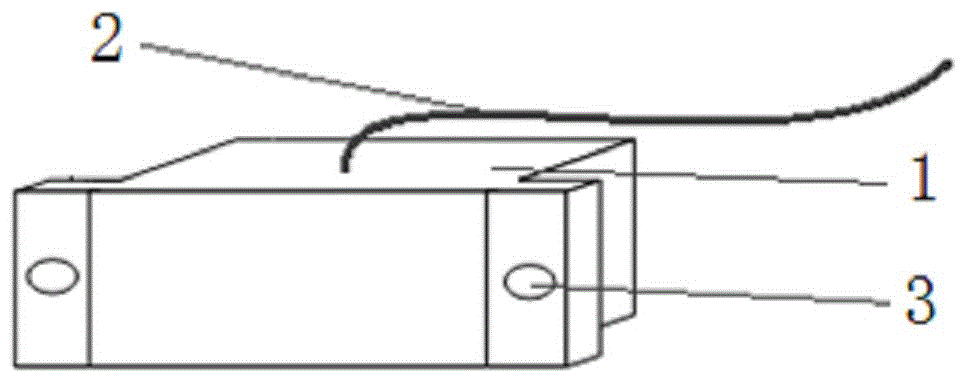

[0048] see figure 1 , figure 2 , the present embodiment is an impact frequency detection device for realizing the impact frequency detection method as described above, including a metal or engineering plastic shell 1 and an impact frequency detection processing circuit arranged inside the shell 1, and the impact frequency detection processing circuit The output impact frequency signal is connected to the universal torque controller through the signal cable 2, so as to realize the accurate controllability of the output torque of the impact wrench. The impact frequency detection and processing circuit includes an acceleration sensor, an analog signal conditioning link, a digital signal acquisition and processing link and a signal output Interface; the output vibration waveform signal of the acceleration sensor is connected to the analog signal conditioning link, and the analog signal conditioning link filters and amplifies the input vibration waveform signal, and then accesses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com