Preparation method of structure-controllable three-dimensional graphene and composite material thereof

A graphene composite, graphene technology, applied in graphene, metal material coating process, liquid chemical plating and other directions, can solve the problem that the pore characteristic graphene sheet orientation cannot be effectively controlled, and the graphene sheet orientation cannot be realized. control, poor surface quality of metal templates, etc., to overcome the uneven distribution of graphene, short preparation cycle, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

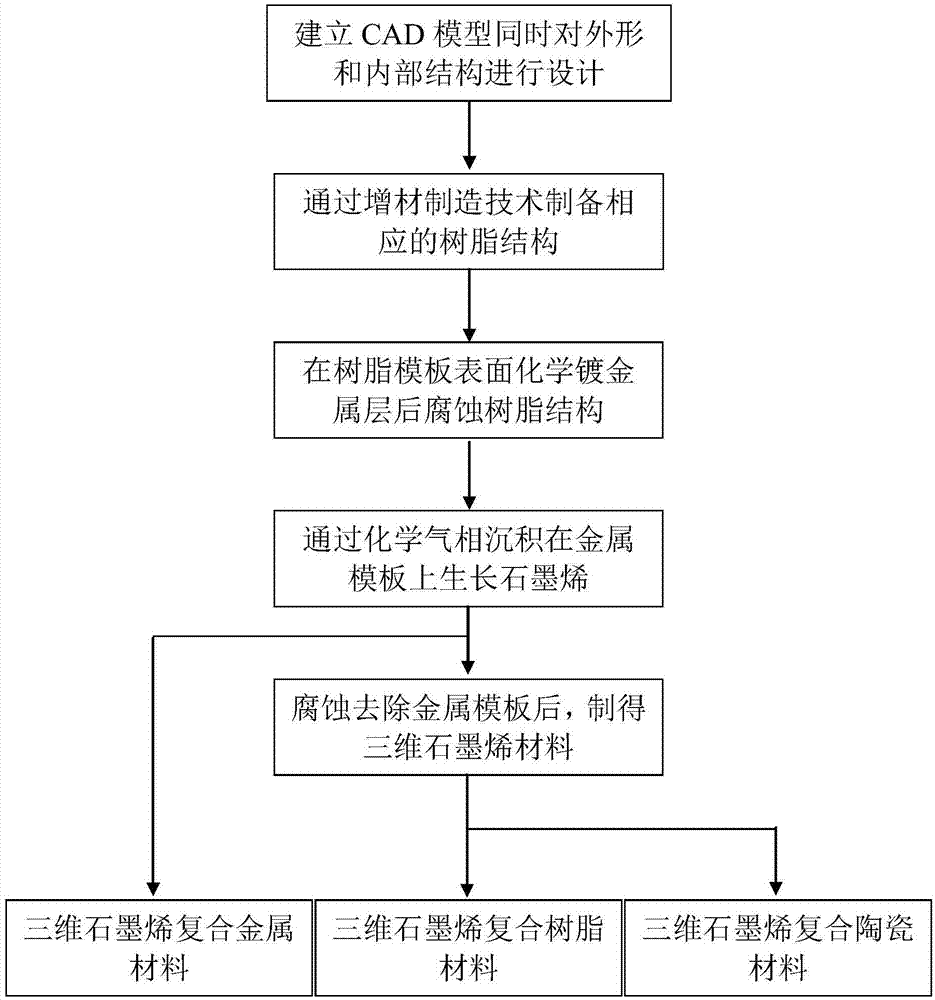

Method used

Image

Examples

preparation example Construction

[0042] (6) the preparation of three-dimensional graphene composite metal material, the metal structure that the surface that step (4) makes has graphene is long as composite additive material, adopts the method for casting, hot isostatic pressing to make metal fill template space, make Obtain three-dimensional graphene composite metal material;

[0043] The filling metal in step (6) is copper or nickel; the proportion of three-dimensional graphene in the composite material is 0.01-10wt%.

[0044] (7) The three-dimensional graphene with the resin support layer is used for injection molding and solvent evaporation to make the resin material fill the template gap to obtain a three-dimensional graphene composite resin material; the three-dimensional graphene with the resin support layer is filled with ceramic slurry Material, colloidal molding method, so that the ceramic material fills the gap, and then use organic solvent corrosion or heat treatment to remove the resin support la...

Embodiment 1

[0049] (1) Use CAD software to establish a three-dimensional porous unit body with a unit size of 0.1mm. The unit body array is designed as a periodic porous structure with a porosity of 30% and an orderly arrangement. The external size of the model is 50mm×50mm ×10mm.

[0050] (2) The resin structure of the constructed CAD model was prepared by light-curing additive manufacturing technology.

[0051] (3) After cleaning, roughening, neutralizing, sensitizing, and activating the prepared resin structure, adopt an electroless copper plating process to plate a copper metal layer on the surface of the resin structure. The electroless copper plating solution uses copper sulfate as copper salt, and formaldehyde As a reducing agent, the thickness of the plated metal copper layer is 1 μm. Soak the prepared resin structure coated with the metal layer in acetone, take it out after the resin structure is completely dissolved, and then wash and dry it.

[0052] (4) Put the metal templat...

Embodiment 2

[0055] (1) Using CAD software, a three-dimensional porous unit body with a unit size of 10mm is correspondingly established. The unit body array is designed as a periodic porous structure with a porosity of 99% and an orderly arrangement. The external size of the model is 100mm×100mm× 100mm.

[0056] (2) The resin structure of the constructed CAD model was prepared by fused deposition additive manufacturing technology.

[0057] (3) After cleaning, coarsening, neutralizing, sensitizing and activating the prepared resin structure, adopt the electroless nickel plating process to plate a copper metal layer on the surface of the resin structure. The electroless nickel plating solution adopts nickel sulfate as nickel salt, sub Sodium phosphate is used as a reducing agent, and the thickness of the metal nickel layer plated is 50 μm. The prepared resin structure coated with the metal layer was heat-treated at 900° C. for 3 hours under a nitrogen protective atmosphere to decompose and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com