Method for manufacturing aluminum nitride silicon tip and grids structure

A manufacturing method and technology of aluminum nitride, applied in chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problem of poor consistency and controllability of aluminum nitride cones, low success rate, and adhesion Inadequate problems, achieve stable electrical and thermal performance, overcome poor angle and height consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

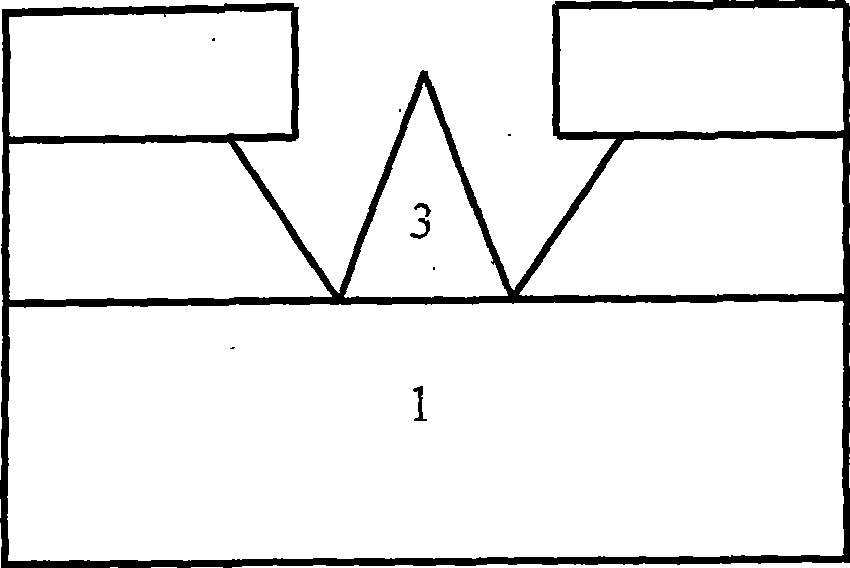

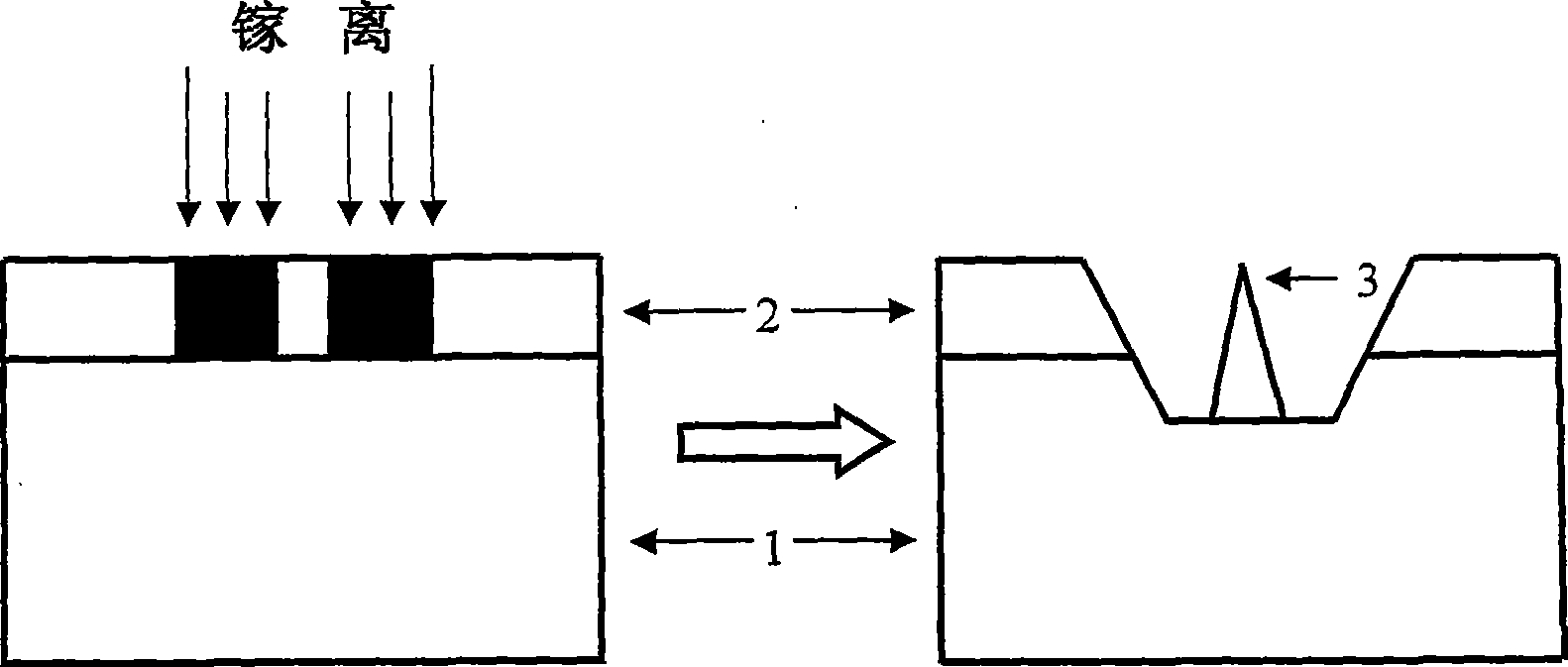

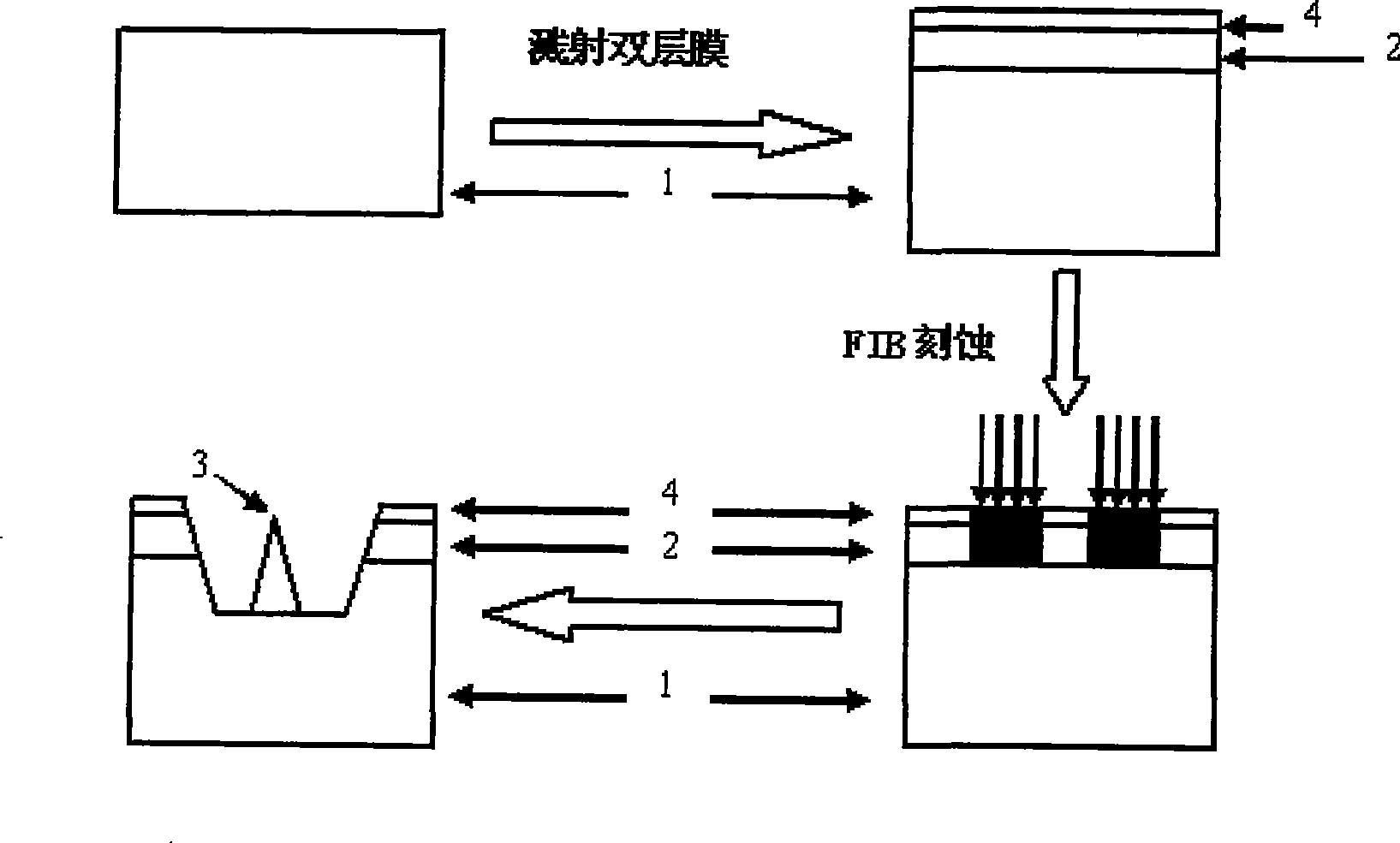

[0040] The aluminum nitride cone tip structure of this embodiment is shown in Figure 4(a); the prepared aluminum nitride cone tip has an aspect ratio of ~5, a tip curvature radius of ~150 nanometers, and a bottom diameter of ~1 micron. Its detailed process flow is as follows:

[0041] 1) Take a piece of (001) oriented monocrystalline silicon as the substrate 1, adopt a conventional semiconductor cleaning process, and ultrasonically clean it in acetone, alcohol and deionized water in sequence, and dry it with nitrogen gas after cleaning, and set it aside;

[0042] 2) On the silicon substrate 1 obtained by cleaning in step 1), put it into a radio frequency magnetron sputtering system, and grow a layer of aluminum nitride film 2 by radio frequency magnetron sputtering method, and the growth conditions are as follows: nitrogen / argon The mixing ratio is 17.5:10.2, the growth temperature is 700oC, the sputtering pressure is 15mTorr, the sputtering incident power is 100W, the reflect...

Embodiment 2

[0045] The aluminum nitride cone tip structure of this embodiment is shown in FIG. 4( b ); the prepared aluminum nitride cone tip has an aspect ratio of ~8, a tip curvature radius of ~50 nm, and a bottom diameter of ~0.6 μm. Its detailed process flow is as follows:

[0046] 1) Take a piece of (001) oriented single crystal silicon as the substrate 1, adopt a conventional semiconductor cleaning process, ultrasonically clean it in acetone, alcohol and deionized water in sequence, and then dry it with nitrogen;

[0047] 2) On the silicon substrate 1 obtained by cleaning in step 1), put it into a radio frequency magnetron sputtering system, and grow a layer of aluminum nitride film 2 by radio frequency magnetron sputtering method, and the growth conditions are as follows: nitrogen / argon The mixing ratio is 17.5:10.2, the growth temperature is 700 degrees Celsius, the sputtering pressure is 15mTorr, the sputtering incident power is 100W, the reflected power is 0.5W, the sputtering t...

Embodiment 3

[0050] The aluminum nitride cone tip structure of this embodiment is shown in FIG. 4( c ): the aluminum nitride cone tip 3 has an aspect ratio of ~16, a tip curvature radius of about 20 nm, and a bottom diameter of ~0.4 μm. The specific preparation steps are as follows:

[0051] 1) Take a piece of (001) oriented single crystal silicon as the substrate 1, adopt a conventional semiconductor cleaning process, ultrasonically clean it in acetone, alcohol and deionized aqueous solution in sequence, and then dry it with nitrogen;

[0052] 2) On the silicon substrate 1 obtained by cleaning in step 1), a layer of aluminum nitride film 2 is grown by radio frequency magnetron sputtering method, and the growth conditions are as follows: the ratio of nitrogen / argon gas mixture is 17.5:10.2, the growth temperature The temperature is 700oC, the sputtering pressure is 15mTorr, the sputtering incident power is 100W, the reflected power is 0.5W, the sputtering time is 3 hours, and the (002)-ori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com