Temperature controllable polishing tool

A technology of polishing tools and polishing heads, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of demanding processing environment temperature, difficult to ensure the convergence efficiency of processing surface shape accuracy, etc., to overcome the uncontrollable temperature , improve the convergence efficiency of surface shape accuracy, and improve the effect of machining surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

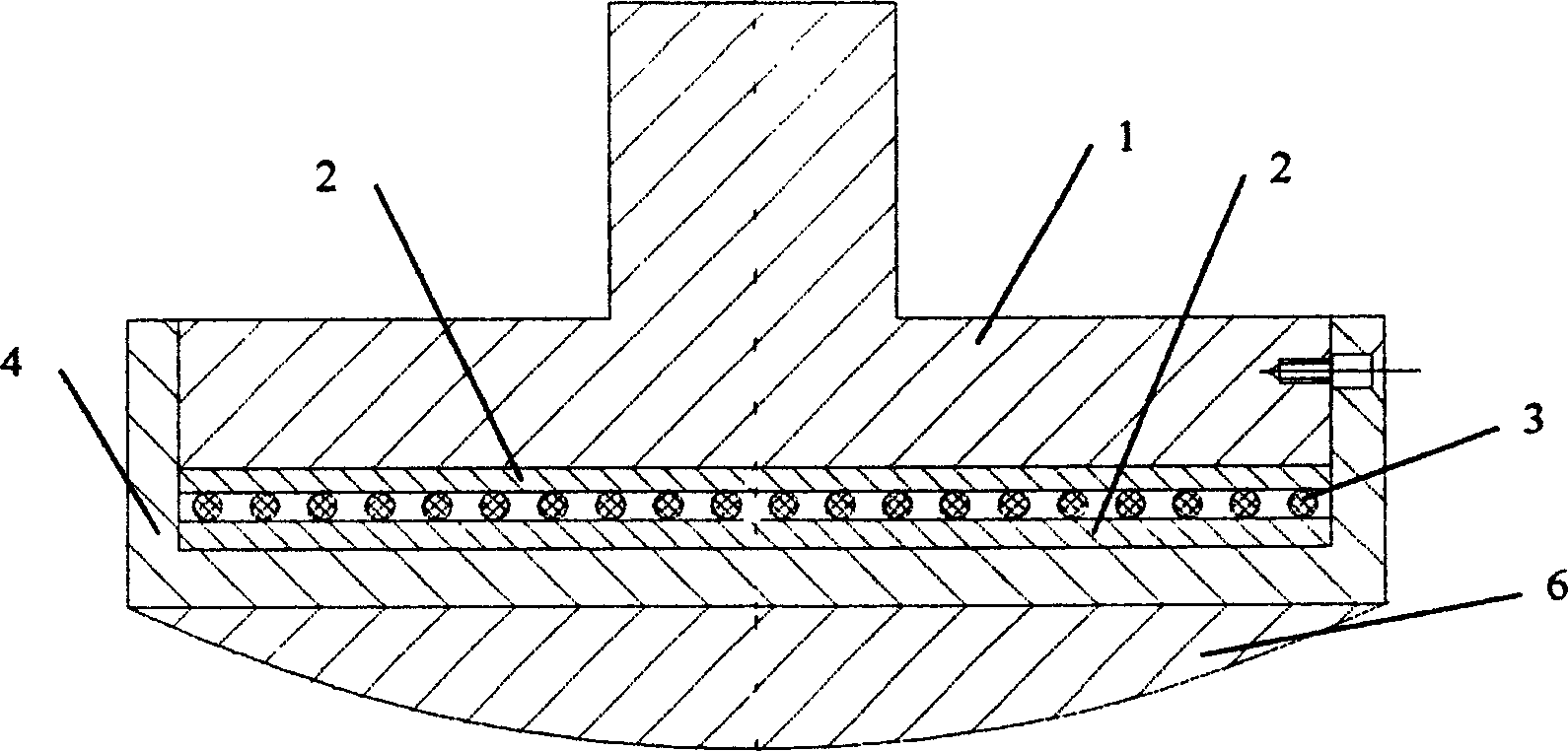

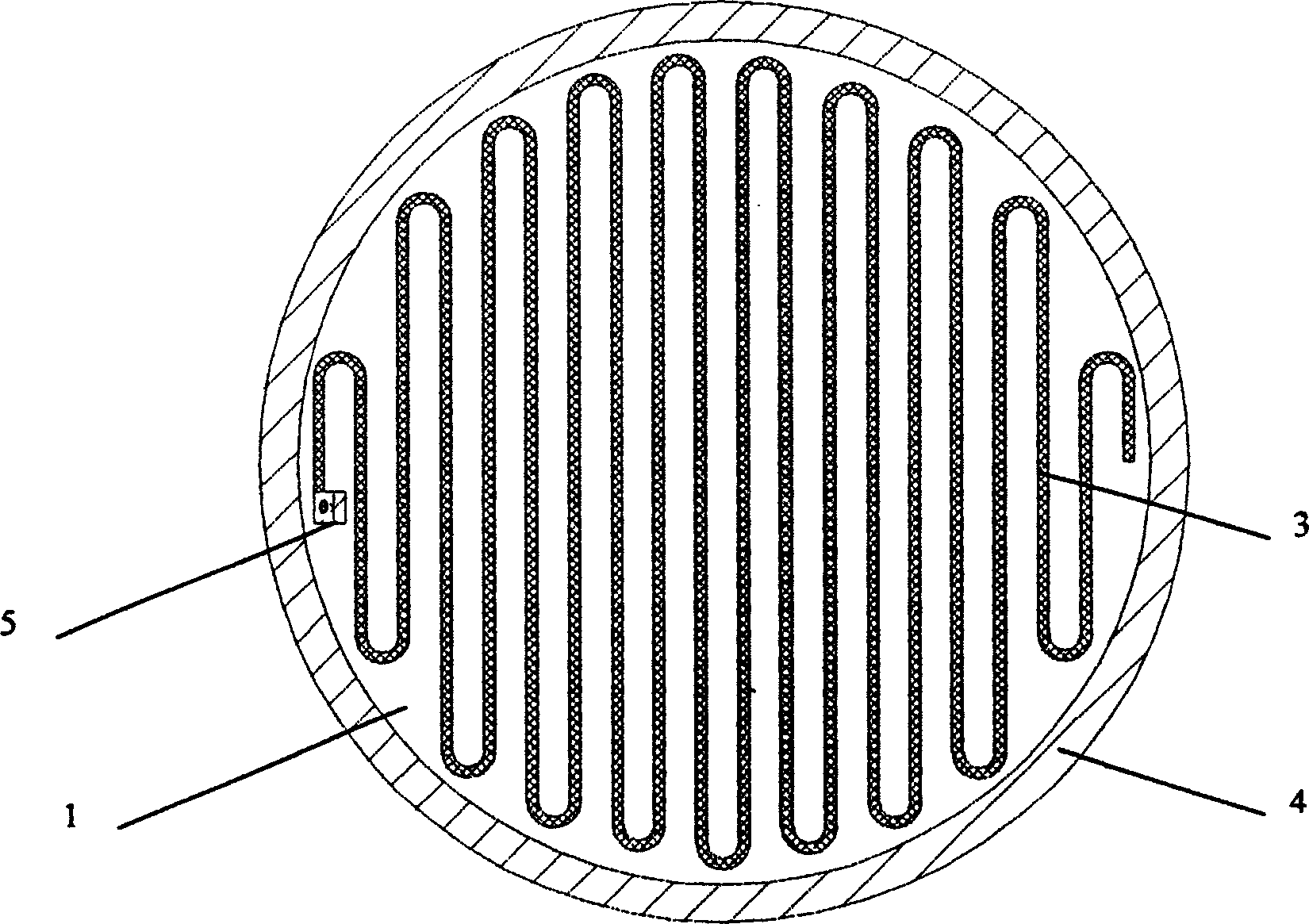

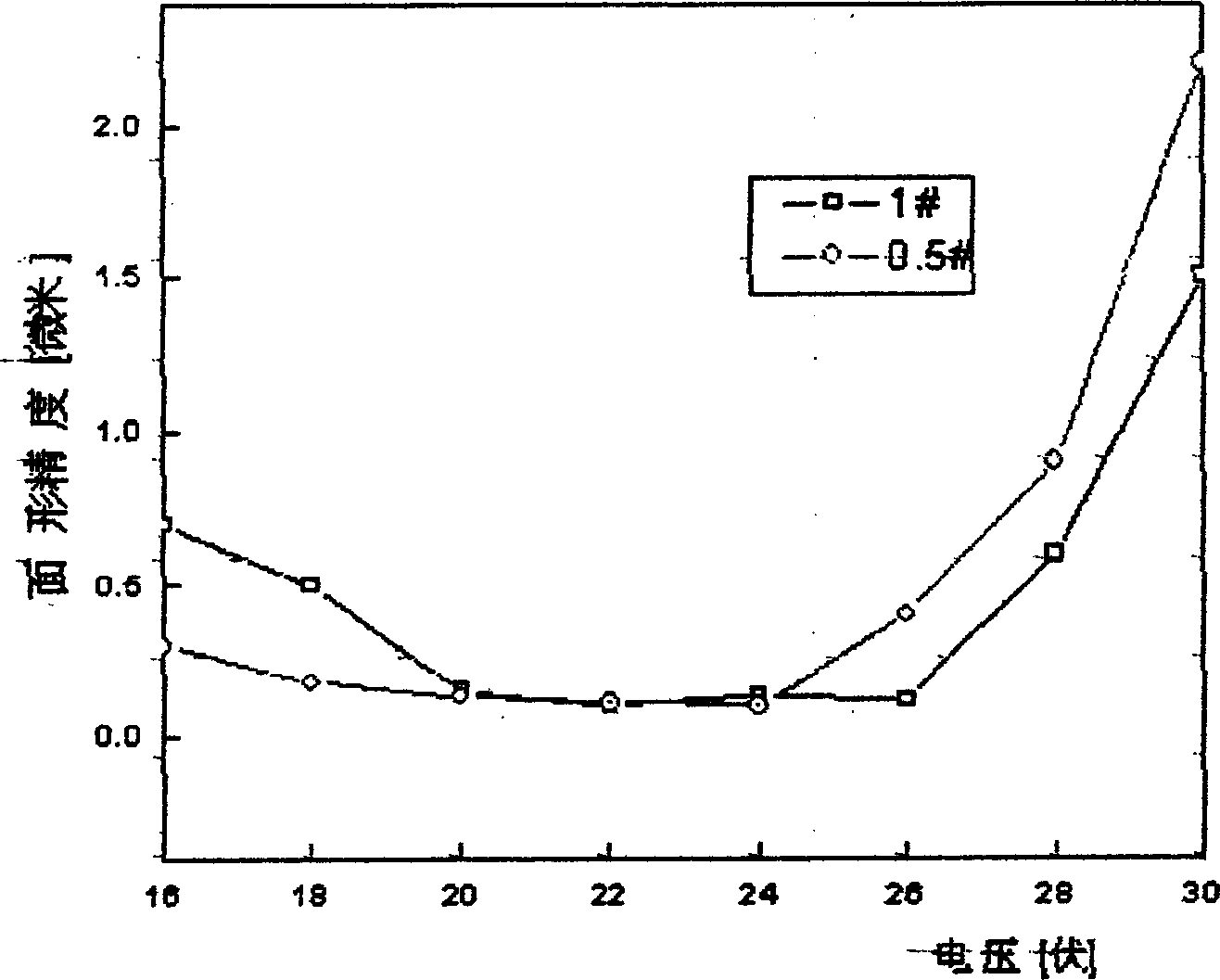

[0013] The invention provides a temperature-controllable polishing tool. figure 1 The polishing tool shown is disc-shaped, and is threadedly connected between its heat transfer substrate 4 and the polishing head base 1, and the insulating layer 2 is tiled on the lower surface of the polishing head base 1 and the inner surface of the heat transfer substrate 4 respectively, and An internal space is formed, and the miniature temperature control relay 5 and the heater 3 are installed therebetween. The heater can be a resistance wire or an electrothermal ceramic. on (such as figure 2 shown). The miniature temperature control relay 5 is fixed on the insulating layer 2 laid on the inner surface of the heat transfer substrate 4 by means of screws, its input end is welded and connected with the positive pole of the power supply, and its output end is welded with one end of the resistance wire 3; the other end of the resistance wire 3 It is welded and connected with the negative elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com