Patents

Literature

47results about How to "Realize modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

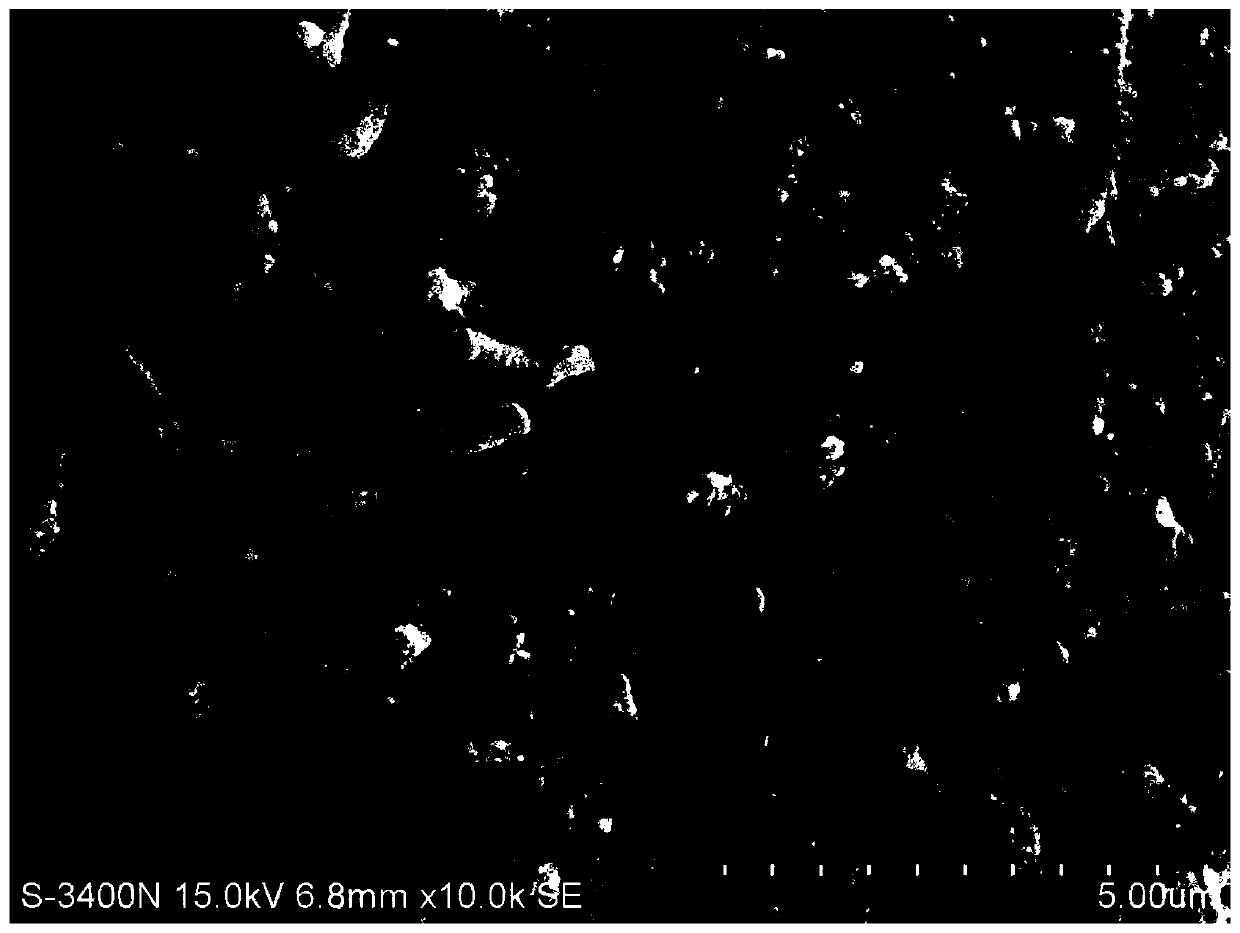

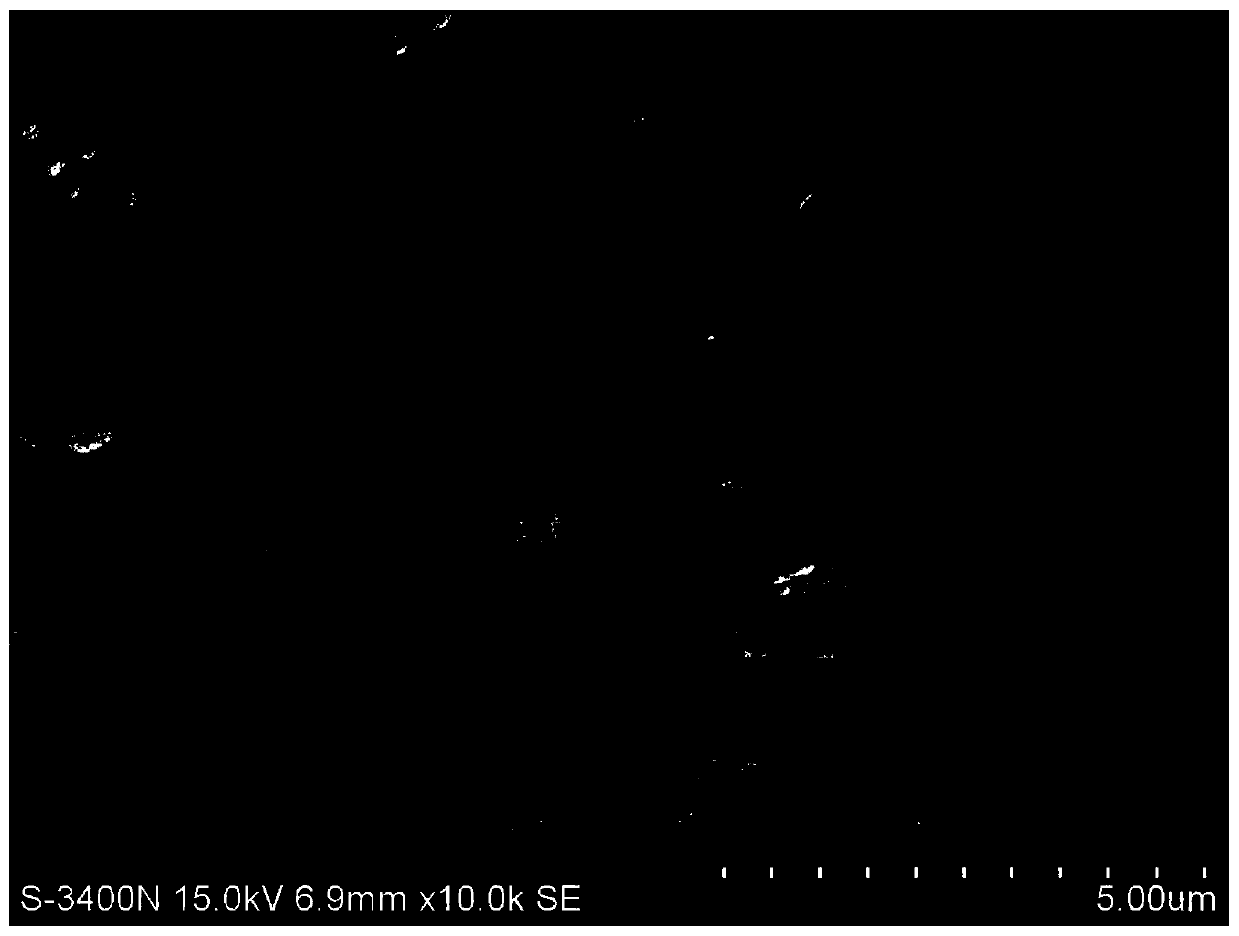

Preparation method for cellulose modification nano iron particles

ActiveCN104785793AFacilitate adaptation to in situ and heterotopic repairSimple processWater/sewage treatmentCelluloseNitrate salts

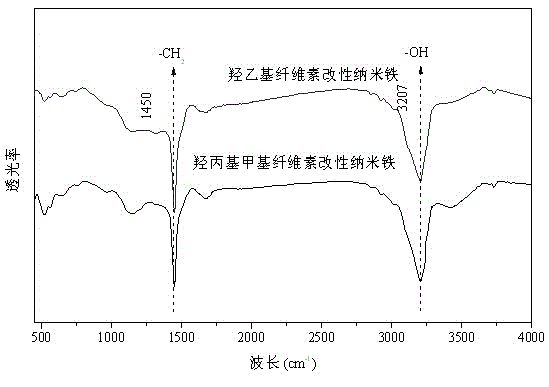

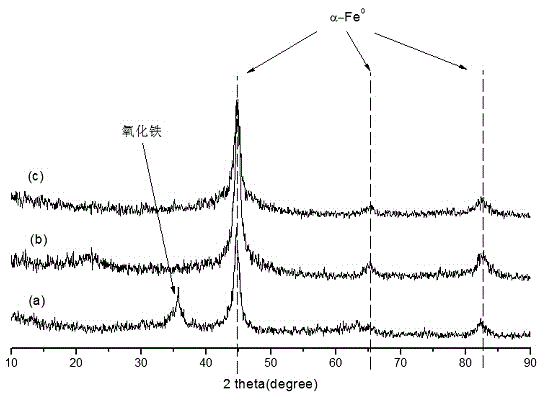

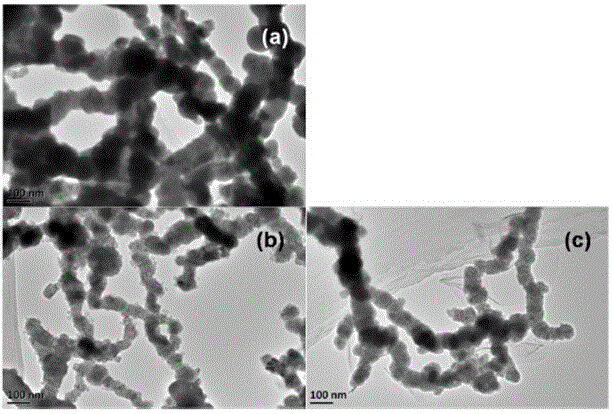

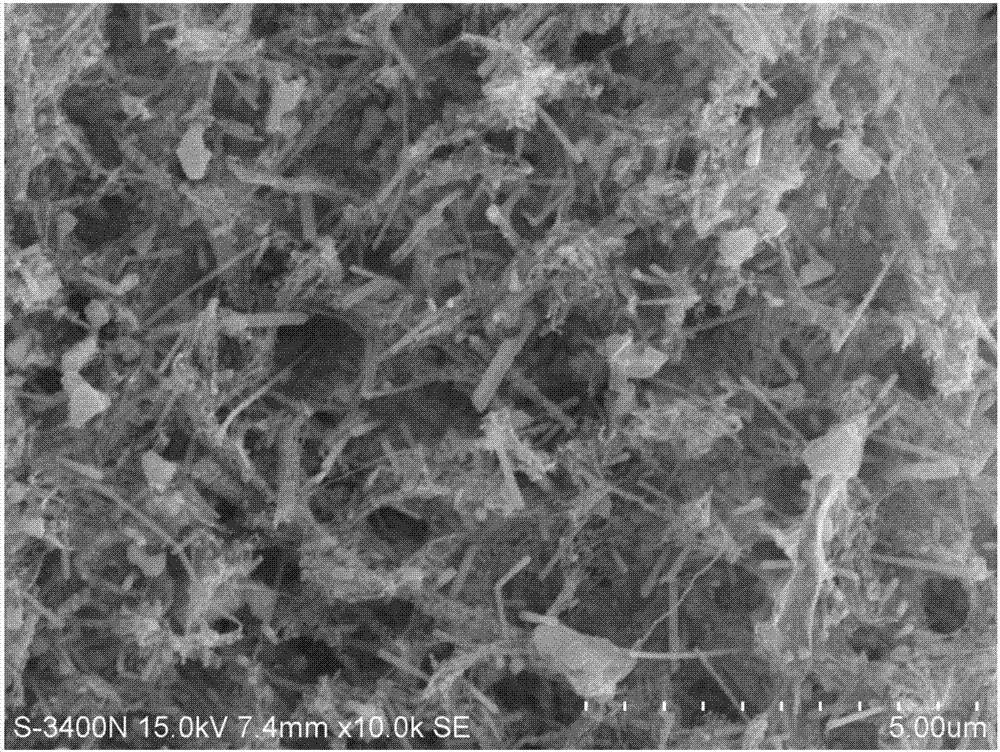

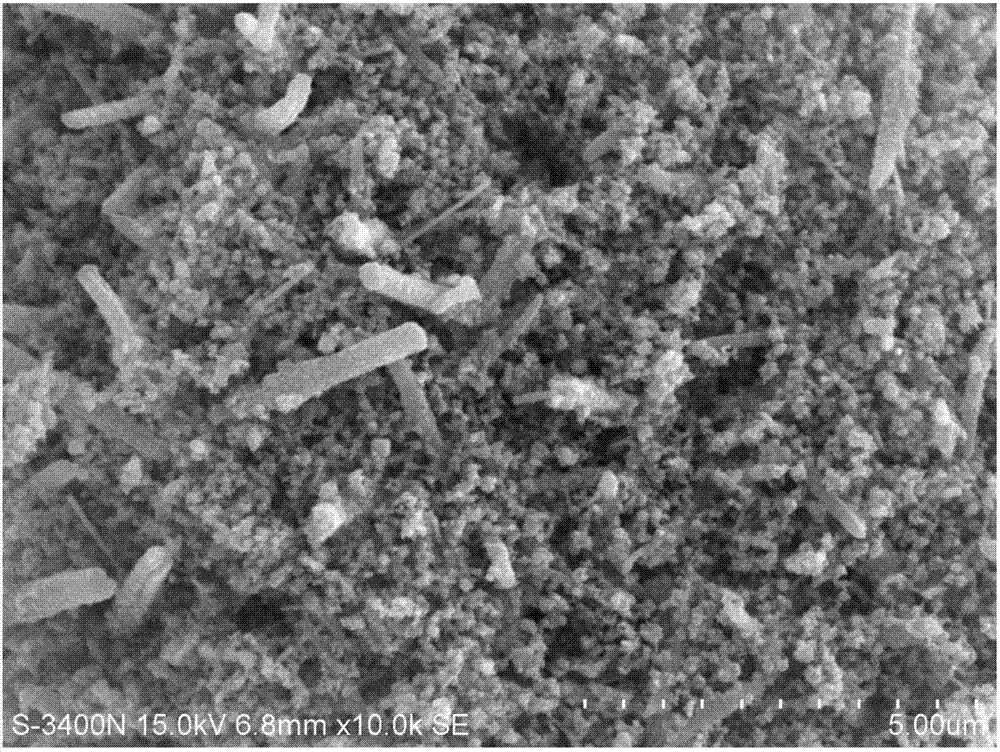

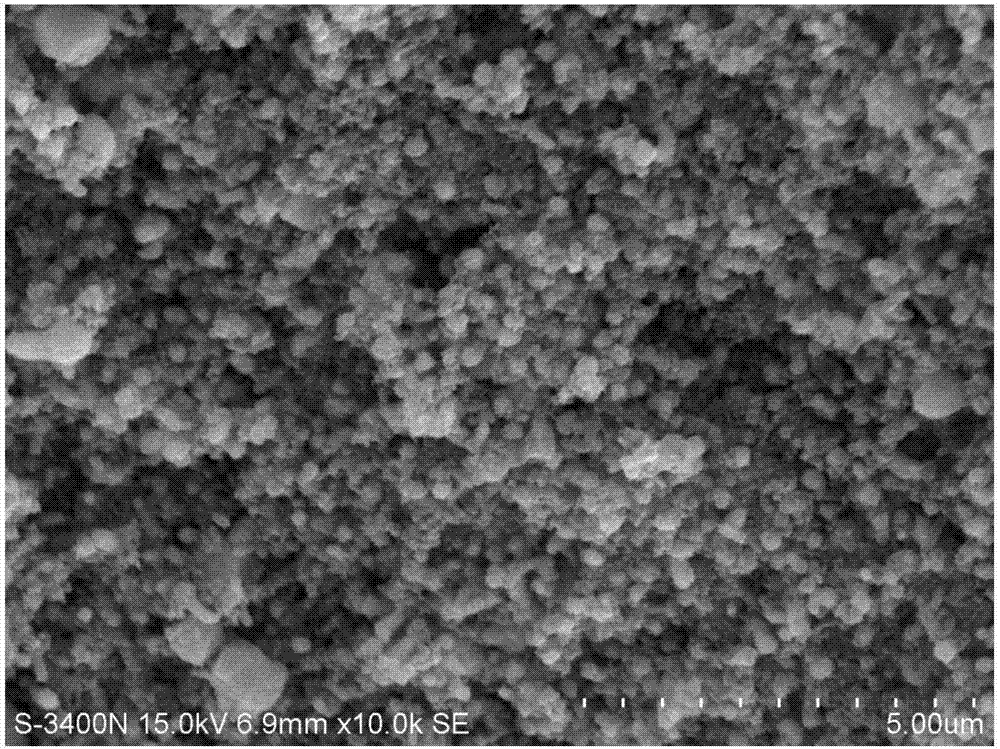

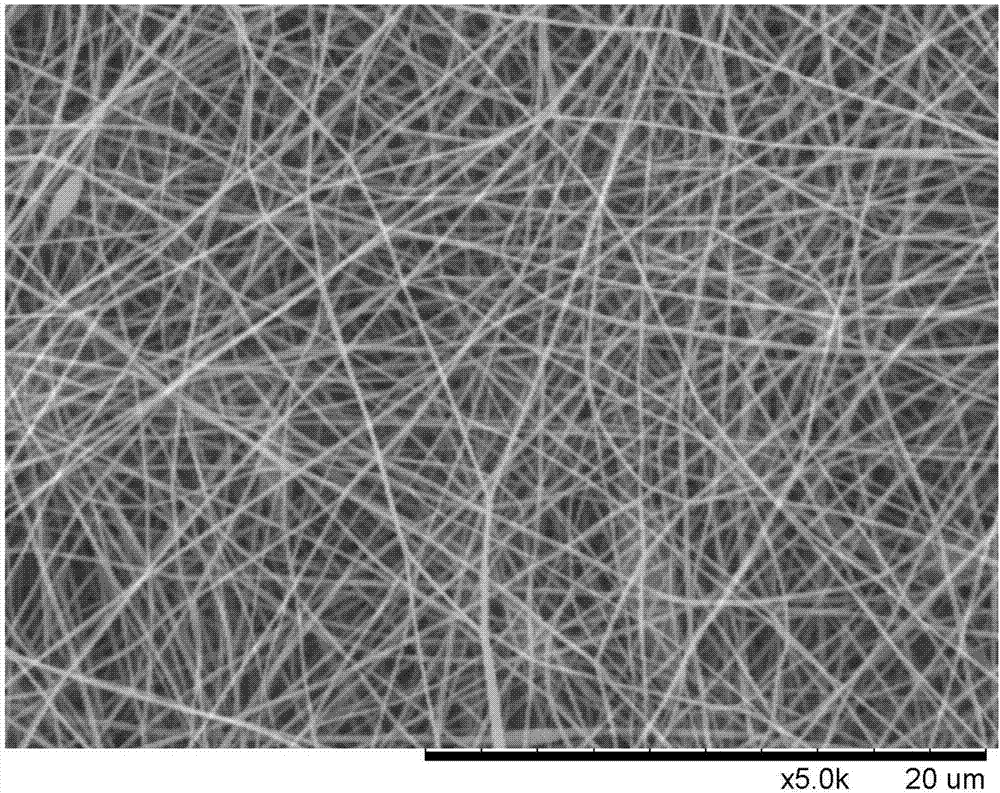

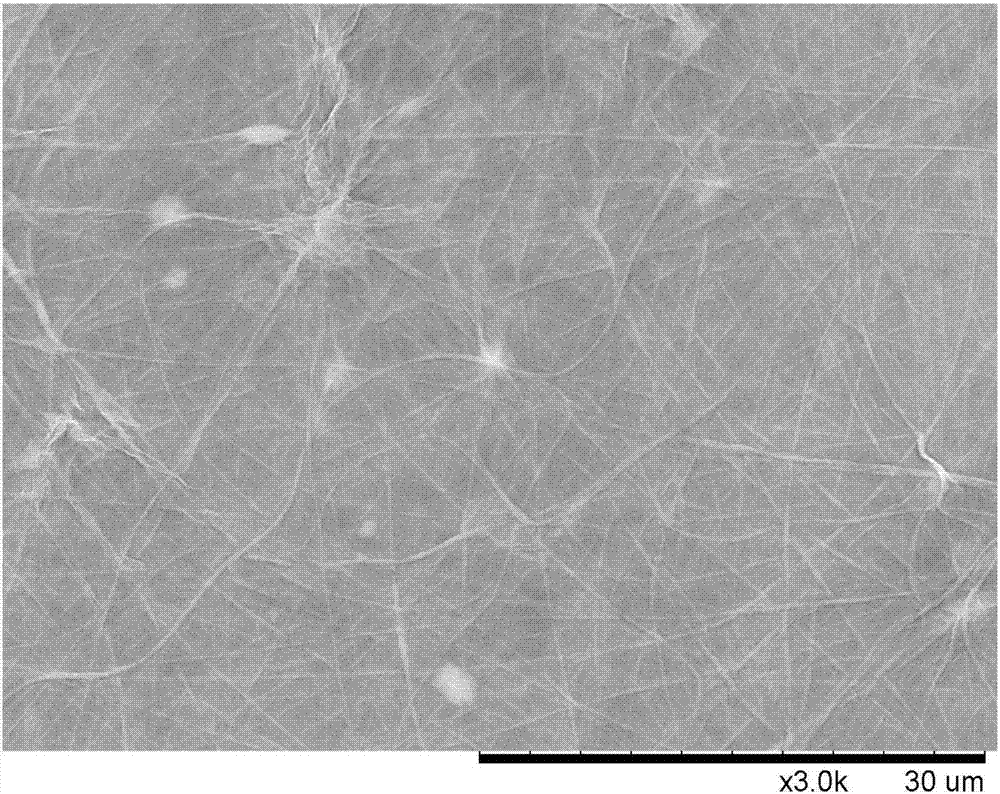

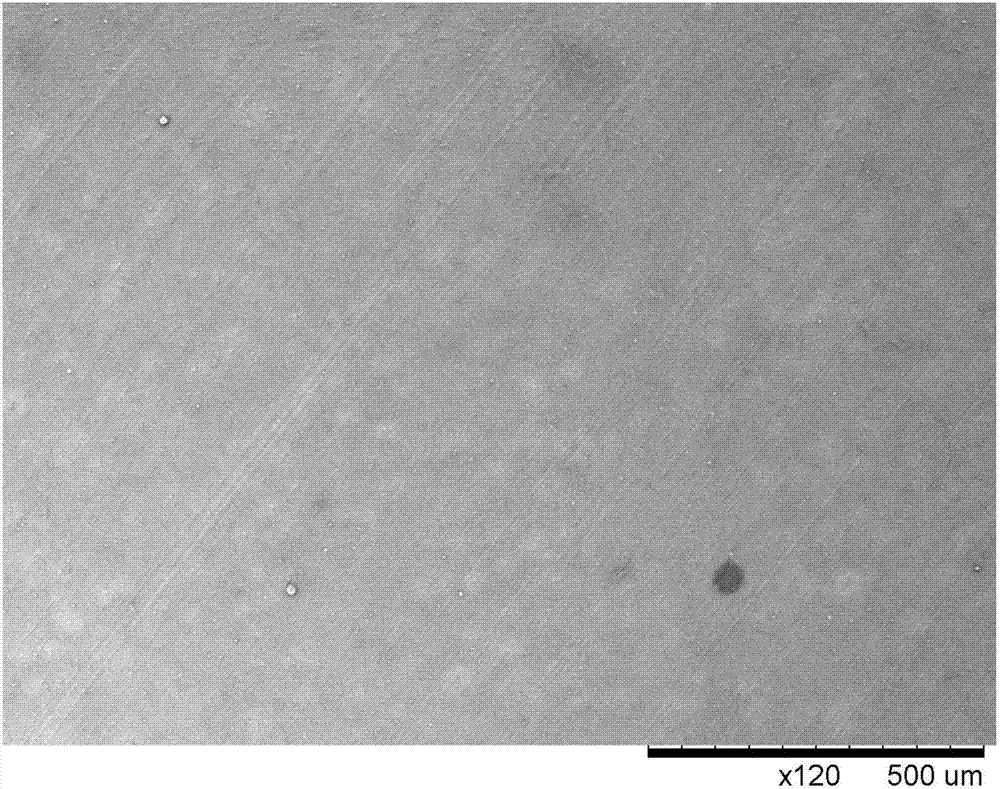

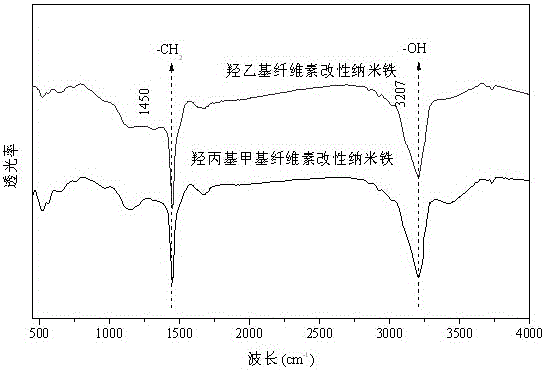

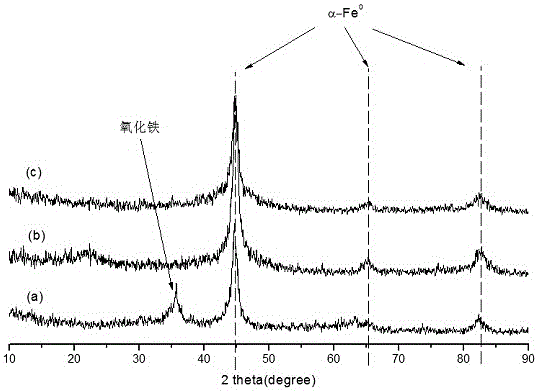

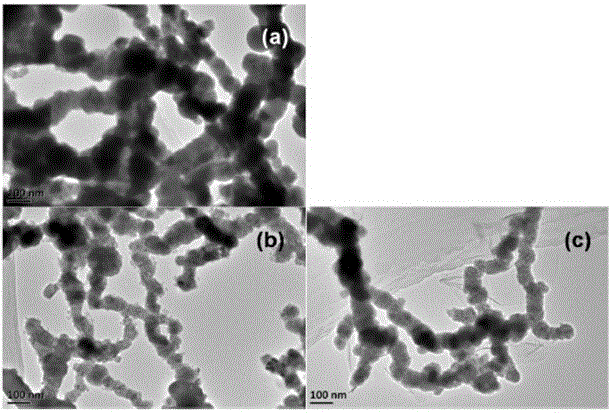

The invention discloses a preparation method for cellulose modification nano iron particles. According to the preparation method, two kinds of environment-friendly non-poisonous and innocuous cellulose are taken as dispersing agents to conduct surface modification on particles in the preparation process of the nano iron particles, and the cellulose dispersing agent modified nano iron particles are obtained. According to the preparation method for the cellulose modification nano iron particles, the process is simple and convenient, the operation is easy, the cost is low, the dispersity of the nano iron particles is good, the agglomeration of the particles in water can be reduced, and the removal efficiency of the particles to organic pollutants, dyestuff, pesticides, nitrate and heavy metal is improved.

Owner:KUNMING UNIV OF SCI & TECH

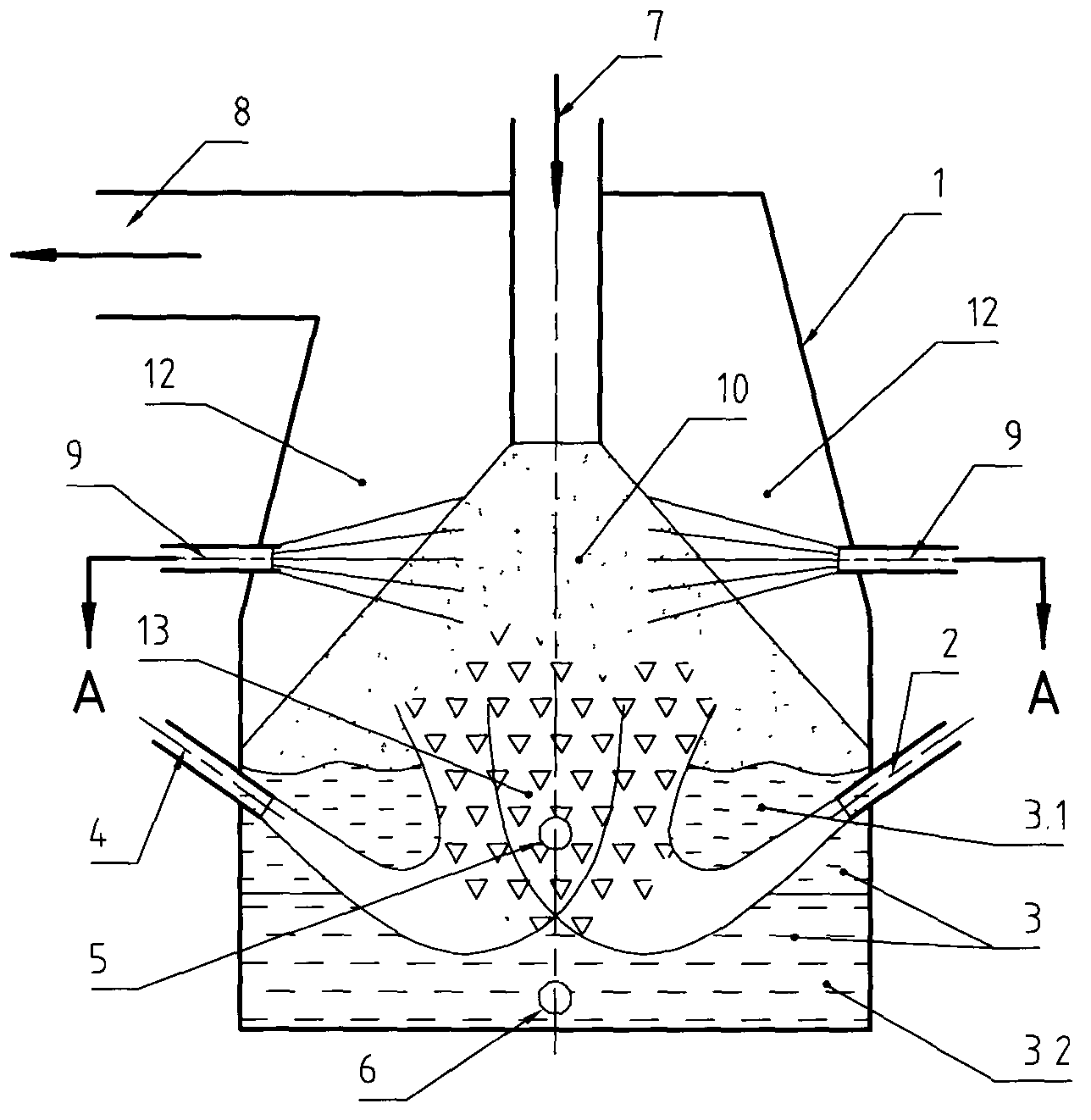

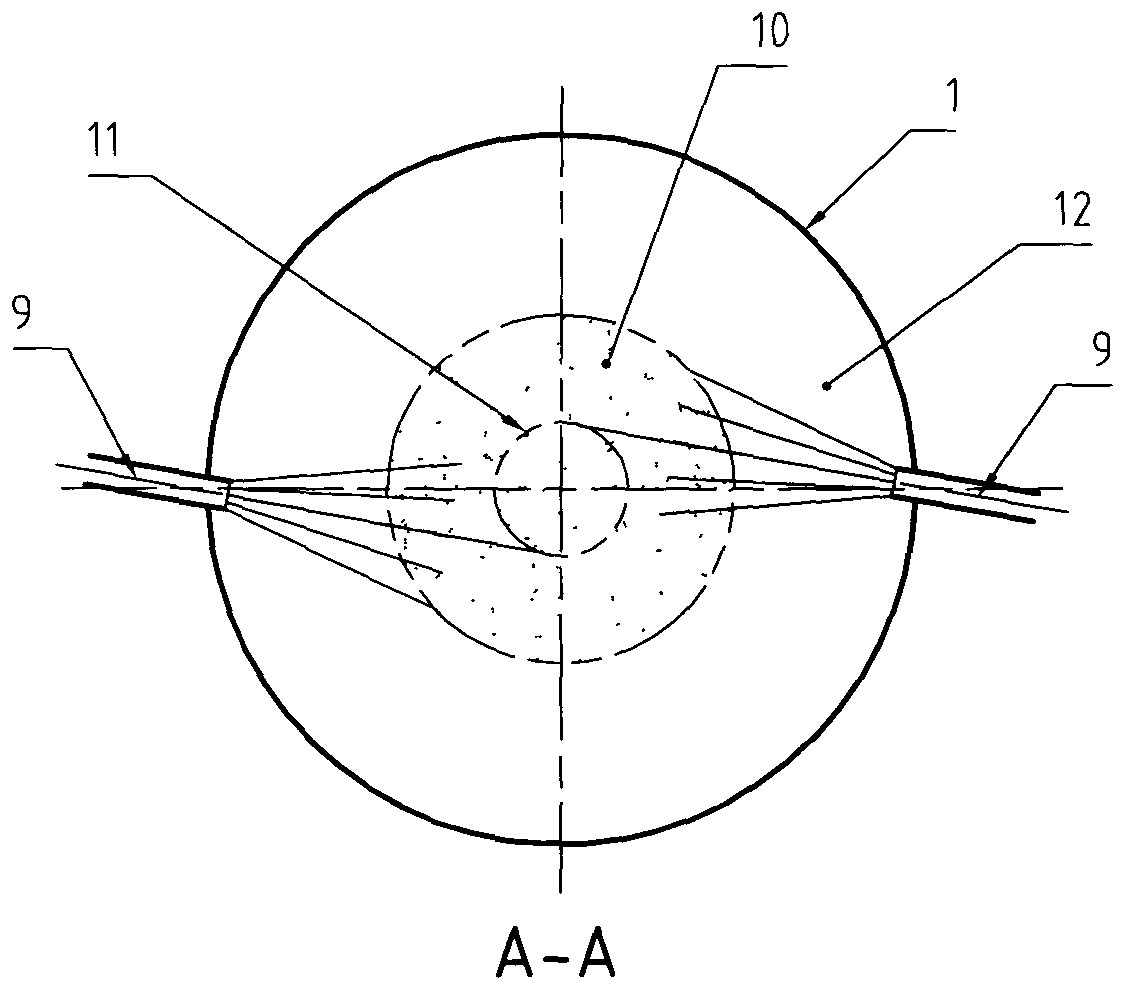

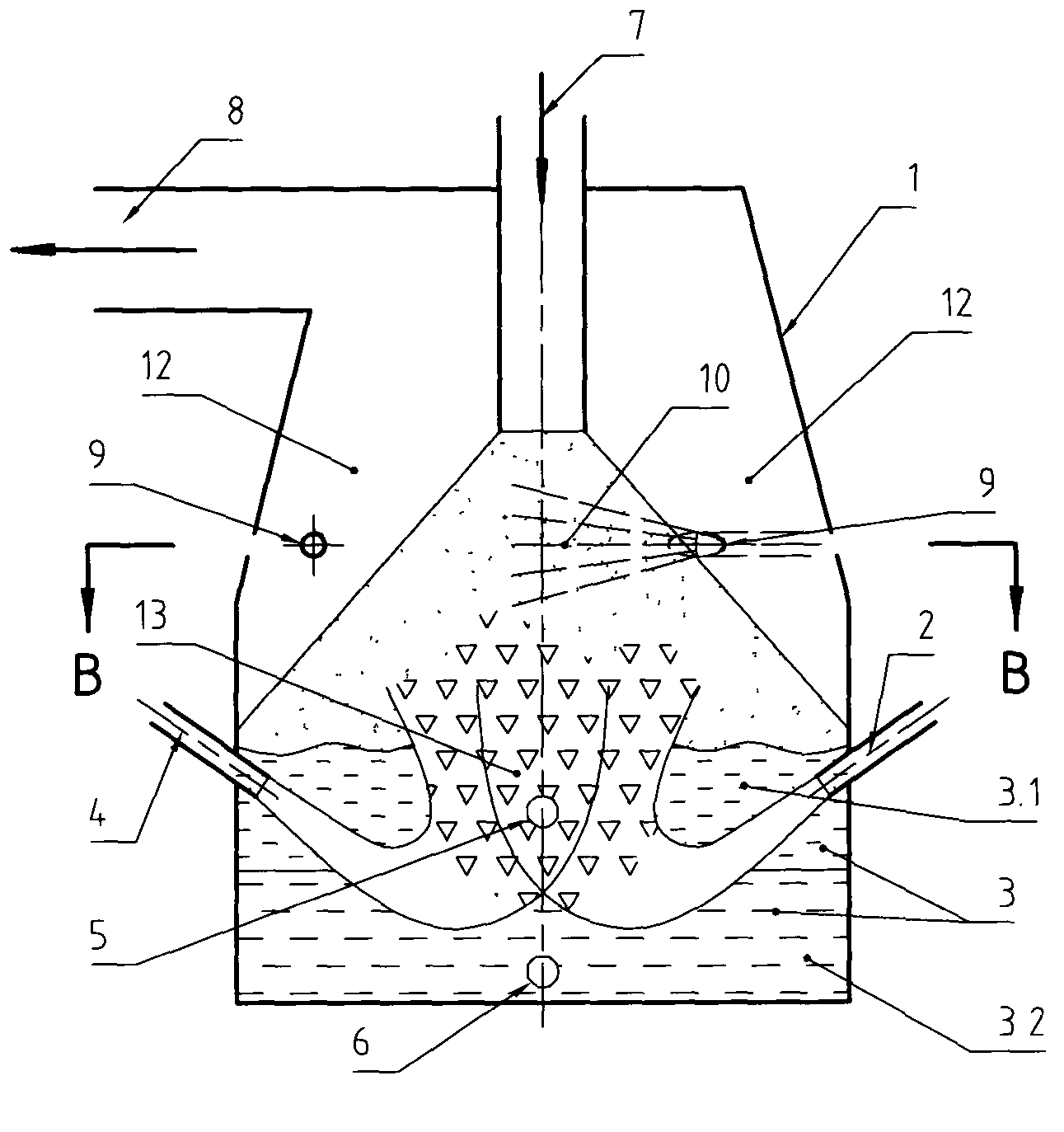

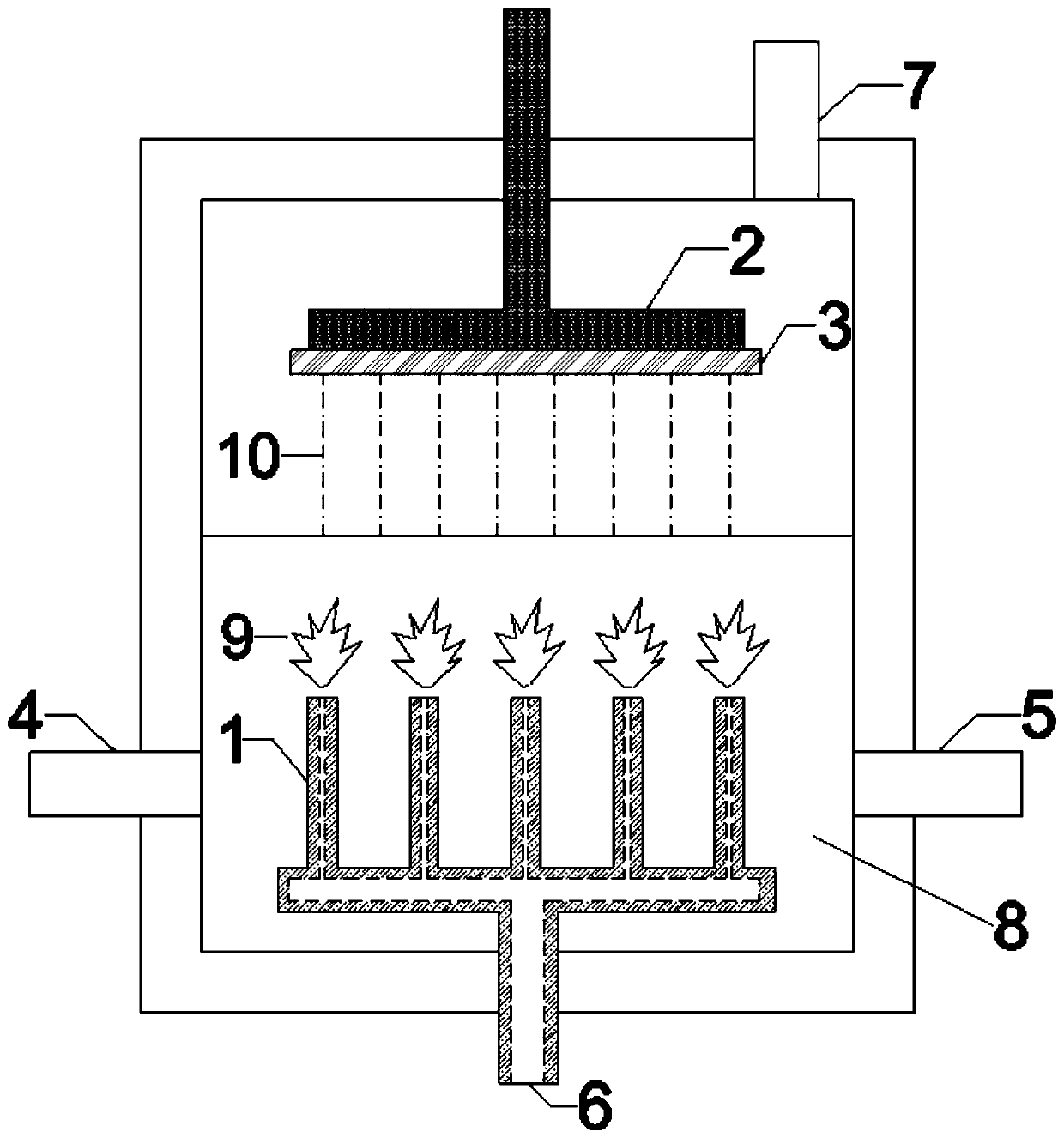

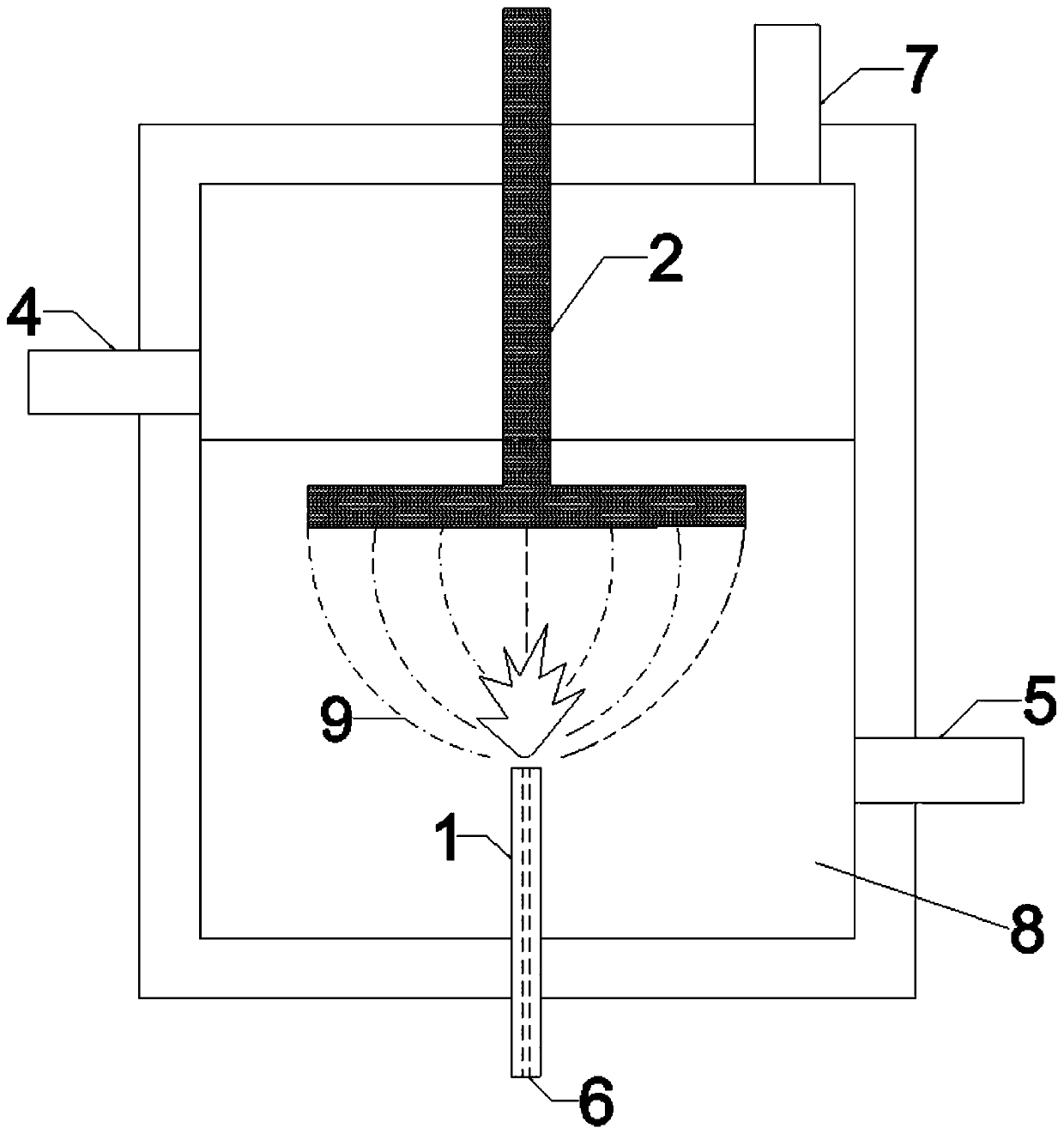

Furnace-inside modification method of furnace gas in Hismelt smelting reduction furnace and smelting reduction furnace thereof

The invention discloses a furnace-inside modification method of furnace gas in a Hismelt smelting reduction furnace and a smelting reduction furnace thereof, and belongs to the technical field of Hismelt smelting reduction. The invention aims to solve the main technical problems of improving quality of furnace gas in a Hismelt smelting reduction furnace, reducing ability, using economy, and productivity of a Hismelt smelting reduction furnace. The basic technical characteristic of the furnace-inside modification method of furnace gas in a Hismelt smelting reduction furnace and the smelting reduction furnace thereof is that: coal powder is sprayed into the space above the slag layer in a smelting reduction furnace through a nozzle. The furnace-inside modification method of furnace gas in a Hismelt smelting reduction furnace and the smelting reduction furnace thereof are suitable for a technical system of Hismelt smelting reduction.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

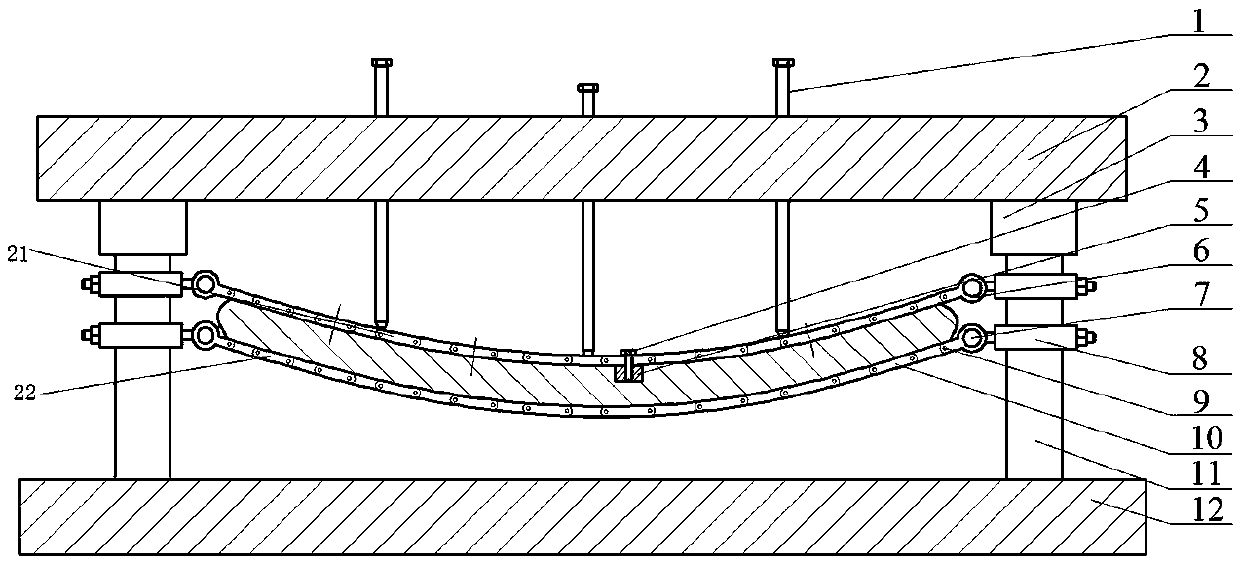

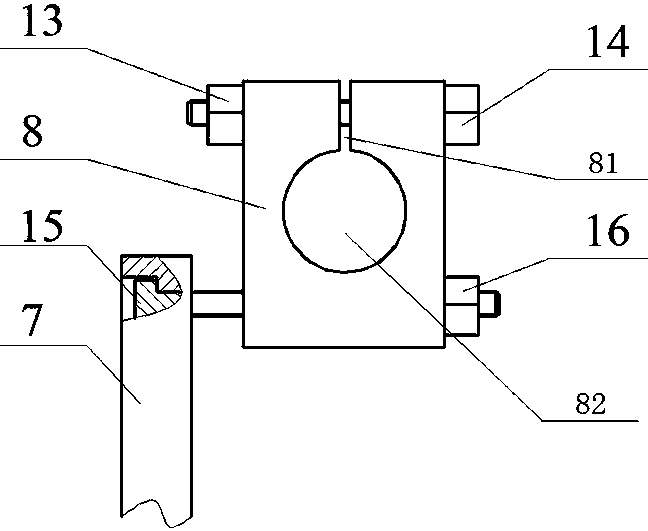

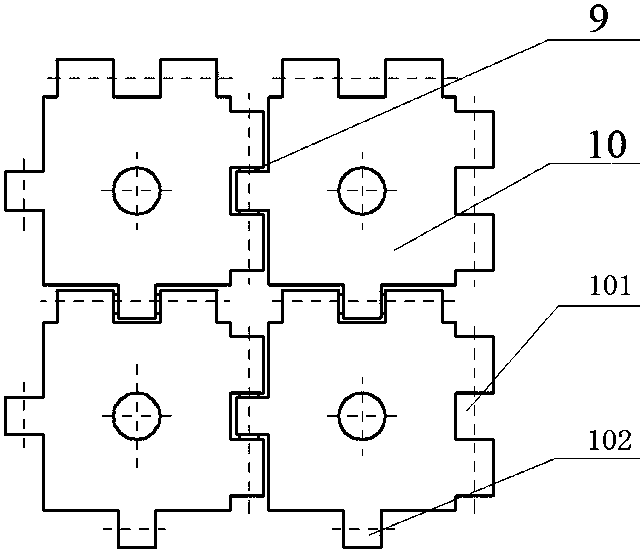

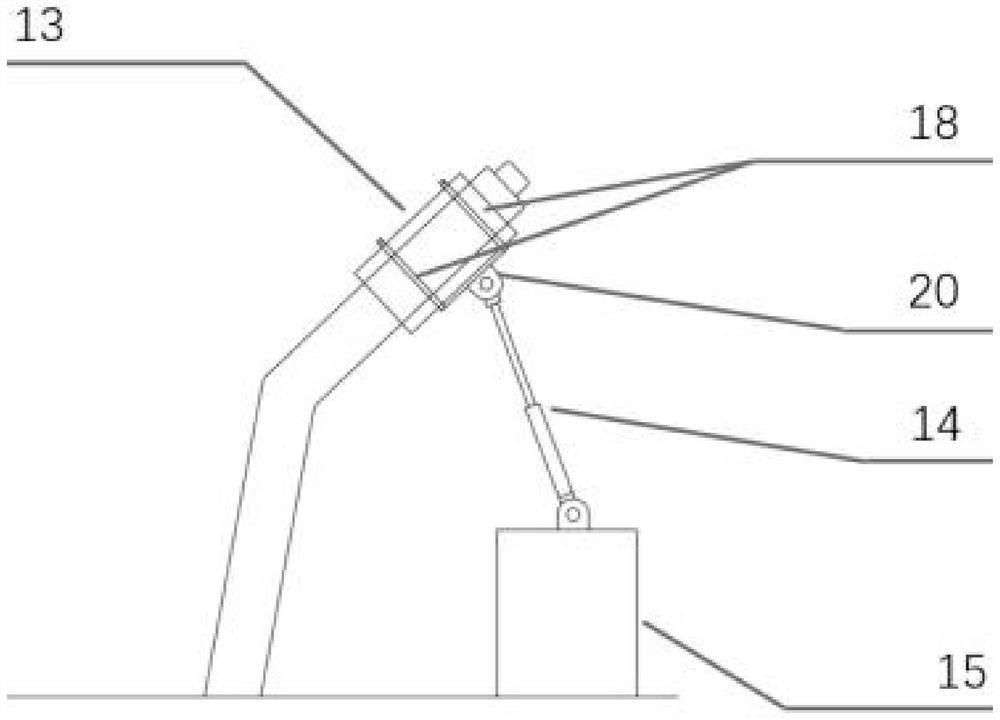

Combined type mechanical loading creep age forming device

The invention discloses a combined type mechanical loading creep age forming device which comprises an upper die plate, loading bolts, a male die and a female die. Two sides of the upper die plate aresupported through multiple stand columns; the multiple loading bolts are arranged on the upper die plate; the lower ends of the loading bolts contact the top surface of the male die; the male die andthe female die are formed by hinging multiple bidirectional shaped plate connecting units; and two sides of the male die and the female die are connected with the stand columns on two sides of the upper die plate. The combined type mechanical loading creep age forming device provided by the invention can flexibly adjust the shapes and the sizes of the curved surfaces of the male die and the female die so as to be suitable for parts with complicated-curvature curved surfaces and conventional single-curvature parts, and suitable for forming small-sized parts and large-sized parts. The combinedtype mechanical loading creep age forming device provided by the invention can be used for correcting a piece to be formed deformed due to resilience, and is simple in structure, low in production cost, and not only suitable for small-batch scientific research tests but also suitable for industrial production.

Owner:HUNAN UNIV OF SCI & TECH

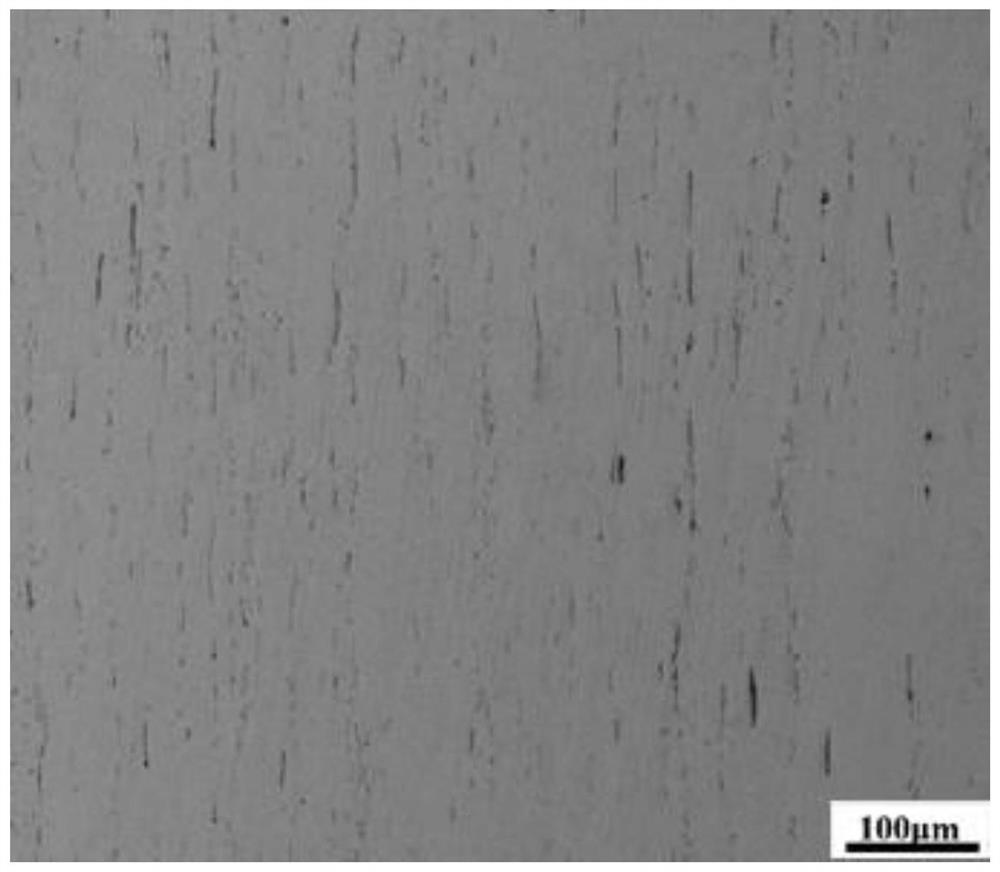

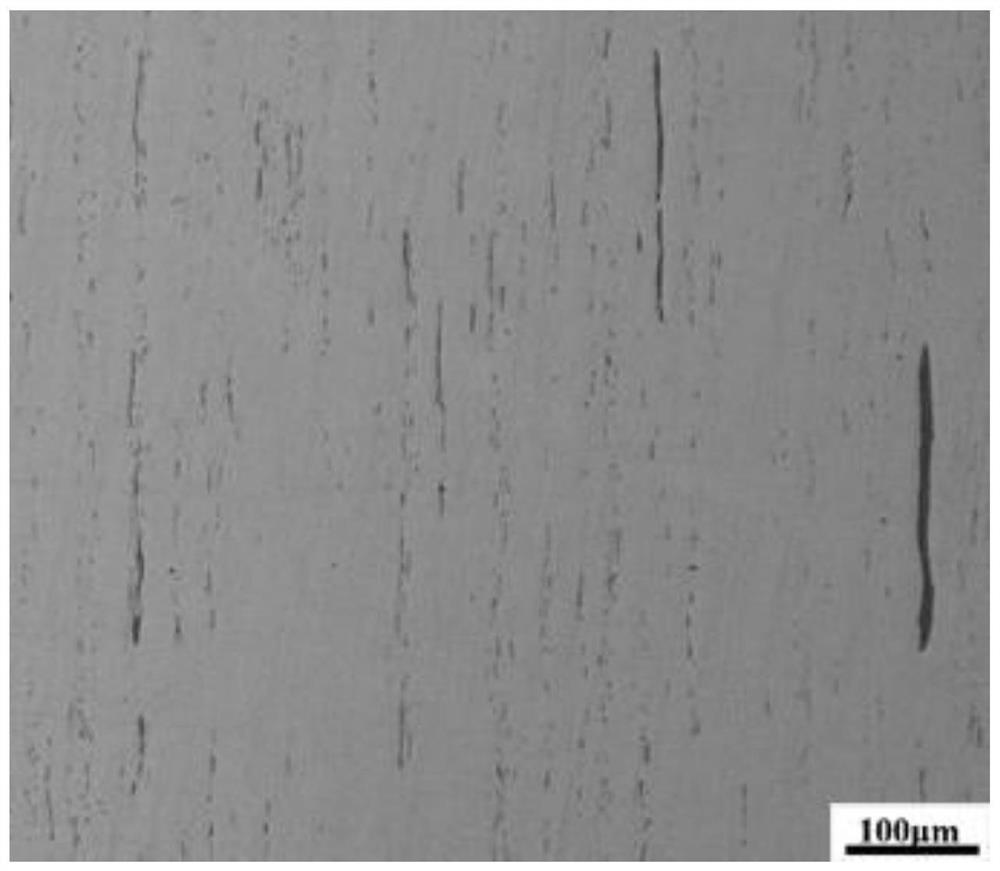

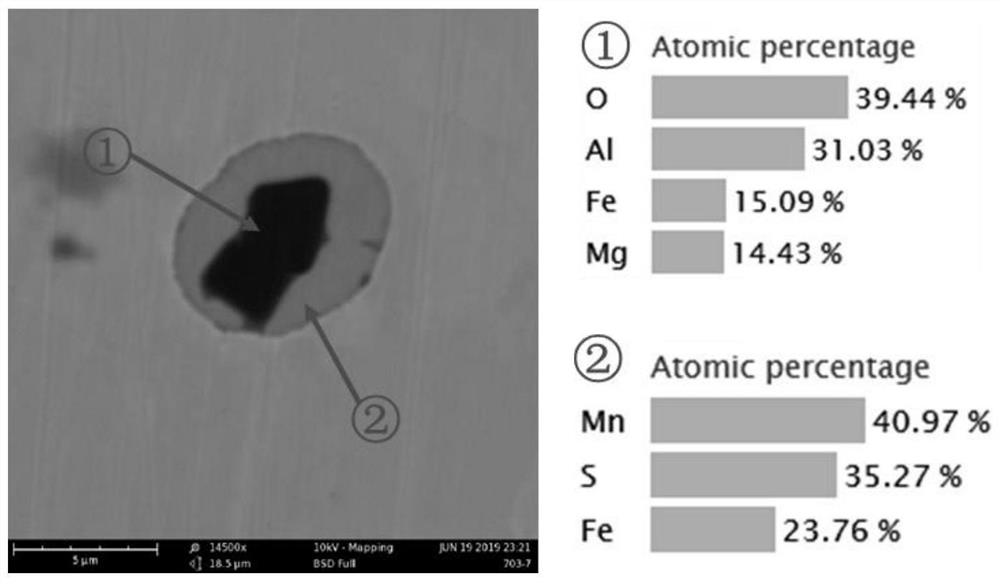

Preparation method of magnesium-based high-sulfur free-cutting steel

PendingCN112063916AEasy to shapeImprove chip breaking abilityManufacturing convertersProcess efficiency improvementMachinabilityContinuous casting

The invention discloses a preparation method of magnesium-based high-sulfur free-cutting steel. The magnesium-based high-sulfur free-cutting steel comprises the following chemical components in percentage by mass: 0.05-0.50% of C, less than or equal to 0.40% of Si, 1.0-1.7% of Mn, less than or equal to 0.08% of P, 0.15-0.35% of S, 0.0003-0.0020% of Mg, less than 0.0030% of O and the balance of iron and inevitable impurities. A production process comprises the steps of converter or electric furnace smelting, LF refining, continuous casting and rolling, magnesium-containing cored wires are addedat the final stage of refining, the degree of superheat is controlled before wire feeding, the total oxygen content is not higher than 30 ppm, and an intermittent feeding method is adopted. The wirefeeding process is stable, violent splashing is avoided, and the yield of the magnesium element is higher. The product prepared by the preparation method has excellent cutting performance and remarkably improved cutting breaking performance and the abrasion resistance of cutters. The cost of each ton of steel is increased by not more than 10 yuan, and the price advantage is obvious.

Owner:SHANGHAI UNIV

Method for regulating valence state of metal in carbonized metal-organic framework material through alkaline N

ActiveCN107876093AEfficient CatalysisIncrease reaction rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationCavitationHigh energy

The invention discloses a method for regulating the valence state of metal in a carbonized metal-organic framework material through alkaline N. Firstly, 5wt.%-10wt.% of an alkaline N source are addedto a copper acetate solution, an N group and Cu in the solution are coordinated by use of ultrasonic field radiation at the frequency of 500-1,000 W, a trimesic acid solution is dropwise added to thesolution, the reaction is sustained for 1-3 h, and an N-modified N-MOF precursor material is obtained; the N-MOF precursor material is put in a high-temperature tube furnace, heated to 600-800 DEG C in the N atmosphere and kept for 4-6 h, and a CN-MOF catalyst with Cu / CuOx / C(x<1) is obtained. The alkalinity coefficient (pKb) of the alkaline N source is in the range of 3-9, alkaline N and copper elements are bonded under the high-energy cavitation action produced by ultrasonic, so that the valence state of metal in a metal oxide produced after carbonization is regulated, and finally, the activity of the obtained catalyst is improved and the service life of the catalyst is prolonged.

Owner:GUANGXI UNIV

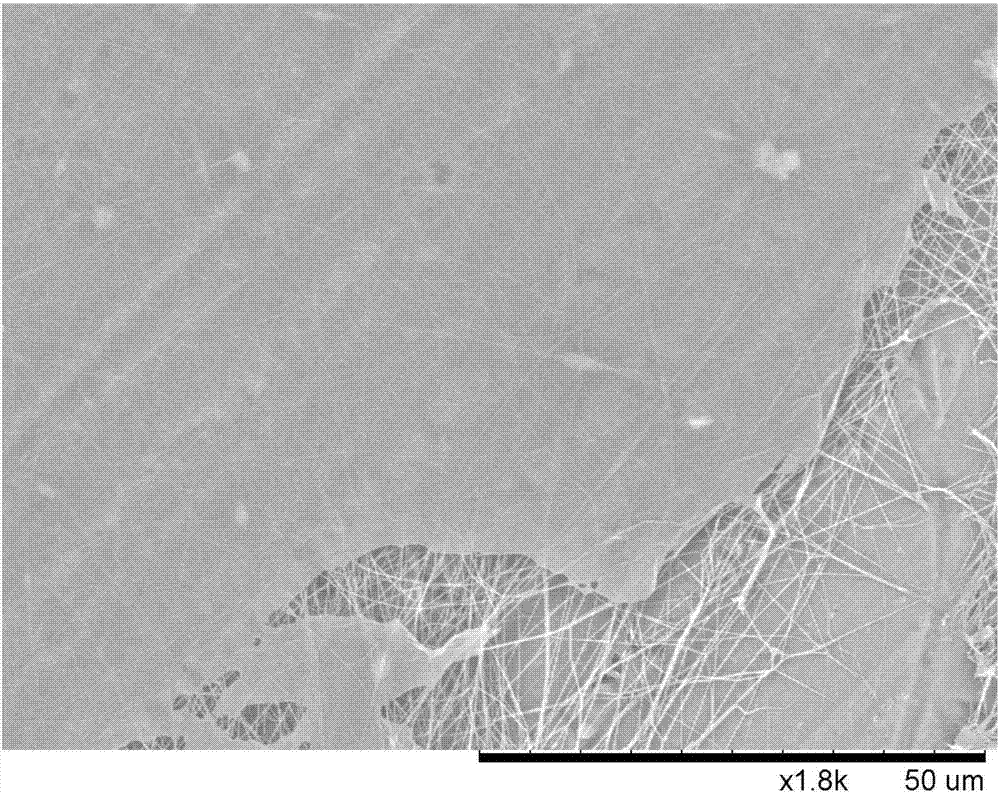

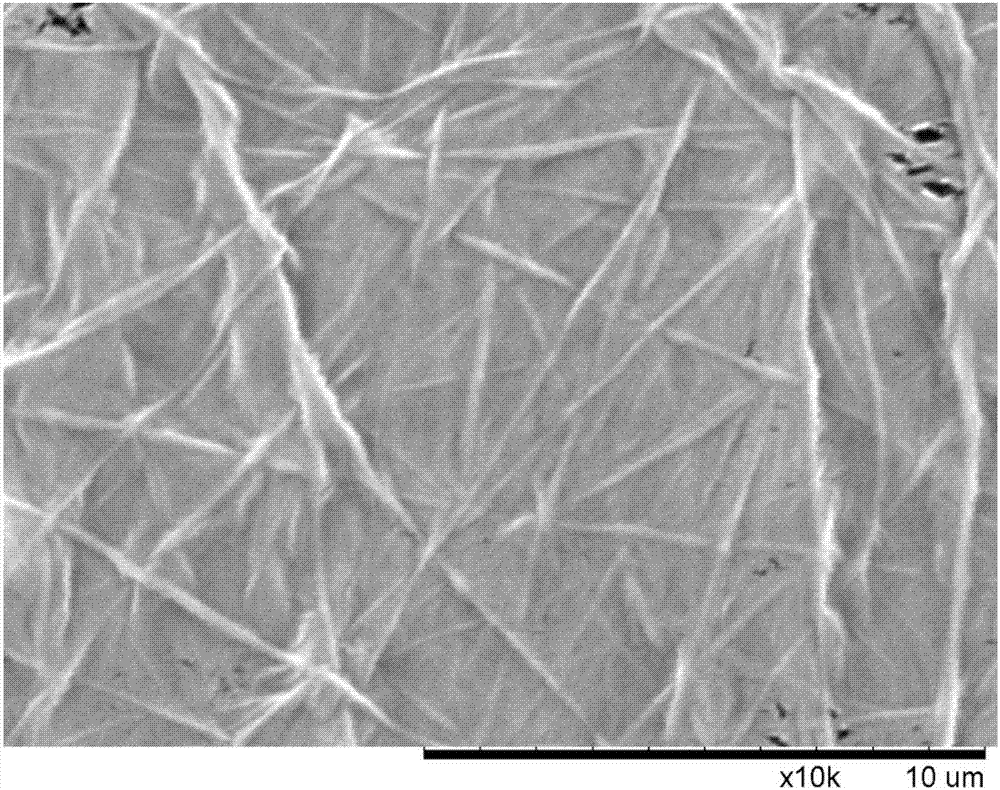

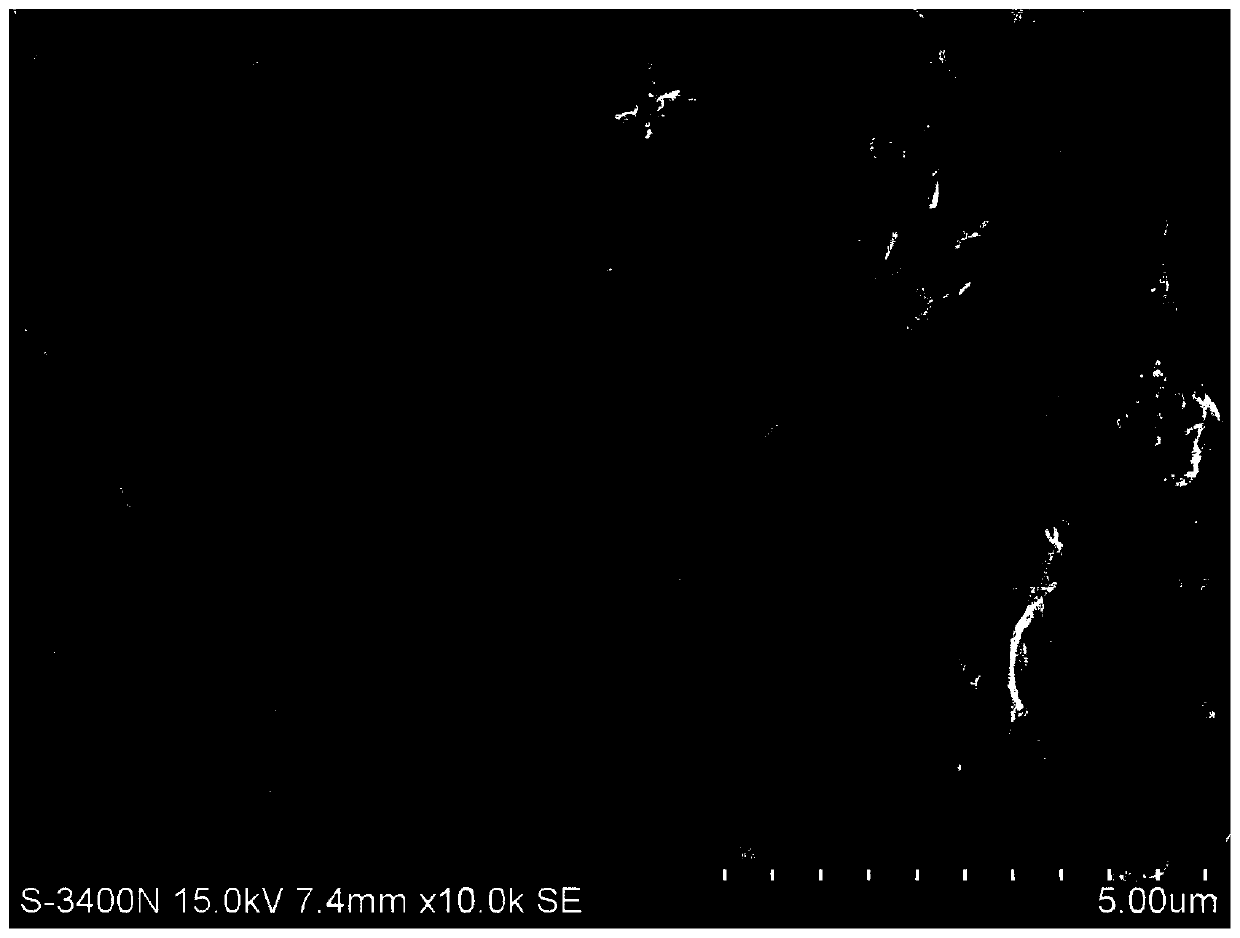

Method for preparing graphene oxide monolayer modified polyacrylonitrile nanofiber membrane

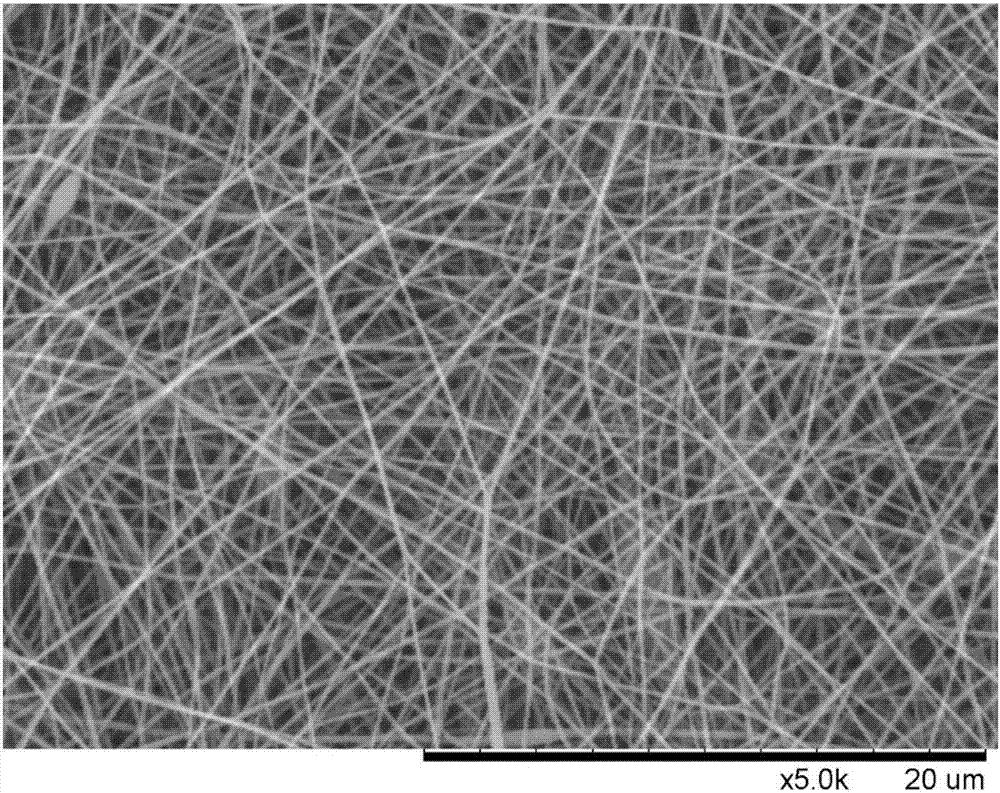

InactiveCN107059248AReduce areaSimple methodFibre treatmentNon-woven fabricsElectrospinningNanofiber

The invention relates to a method for preparing a graphene oxide monolayer modified polyacrylonitrile nanofiber membrane. The method comprises the following steps: (1) preparing a polyacrylonitrile spinning solution, and performing electrostatic spinning to obtain a polyacrylonitrile nanofiber membrane; (2) preparing a graphene oxide spreading solution, then spreading the graphene oxide spreading solution on the surface of water to obtain monolayer graphene oxide, and compressing a sliding barrier to obtain a graphene oxide thin film; and (3) transferring the graphene oxide thin film on the surface of water onto the polyacrylonitrile nanofiber membrane through a film drawing machine to obtain the graphene oxide monolayer modified polyacrylonitrile nanofiber membrane. According to the method, molecular level regulation and control, arrangement, assembly and modification of graphene oxide on the surface of polyacrylonitrile are realized, molecular levels on the surfaces of polyacrylonitrile nanofibers are modified, and the method can be widely applied to the fields of textiles, biological medicines, functional materials, water treatment and the like, and has a very high practical value and potential value. The method is simple to operate and mild in condition, and the preparation process is nontoxic and pollution-free.

Owner:DONGHUA UNIV

Catalyst for photocatalytic hydrogen production, and preparation method and application thereof

ActiveCN109201115ARealize modificationImprove shunt efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionAir atmosphereArgon atmosphere

The invention discloses a catalyst for photocatalytic hydrogen production, and a preparation method and application thereof. The catalyst uses HKUST-1 as a precursor and is prepared by rapidly treating a sample through thermal decomposition in an argon atmosphere and an air atmosphere successively. The preparation method comprises the following steps: preparing HKUST-1 at first; and then heating the prepared HKUST-1 in the argon atmosphere to 300-500 DEG C, then maintaining the temperature, and carrying out a heating reaction in the air atmosphere for 0.5-2 h. A method for decomposing water toproduce hydrogen by using the catalyst for photocatalytic hydrogen production comprises the following steps: dispersing the photocatalyst in a mixed solution of water and a sacrificial reagent at first; removing air in a reaction system; and carrying out a reaction under visible light for 4-8 h, wherein the wavelength of the visible light ranges from 420 to 700 nm. The catalyst for photocatalytichydrogen production in the invention can generate hydrogen under the conditions of normal temperature, normal pressure and visible light, and has the characteristics of high catalytic activity and good hydrogen production stability; the raw materials of the catalyst are widely available and low in price; and the preparation method is simple in process and suitable for large-scale production.

Owner:YANCHENG INST OF TECH

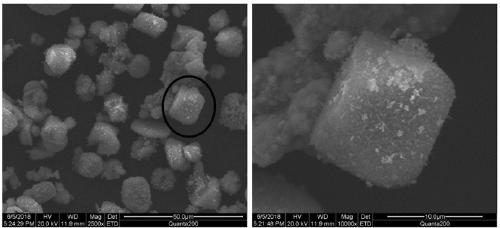

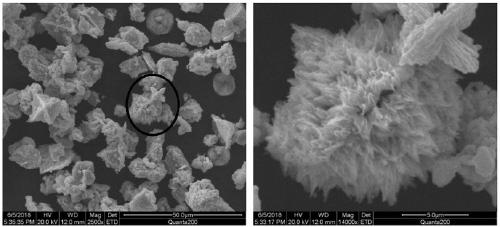

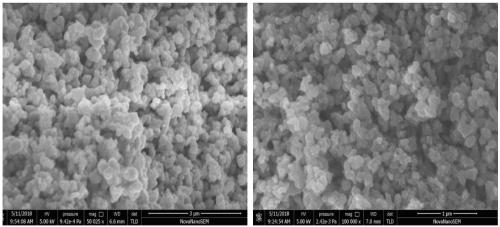

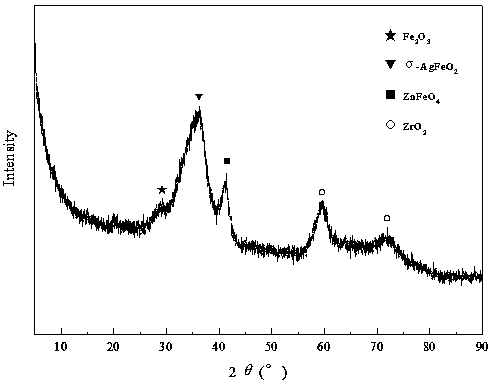

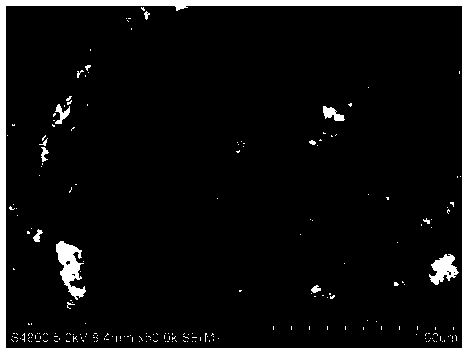

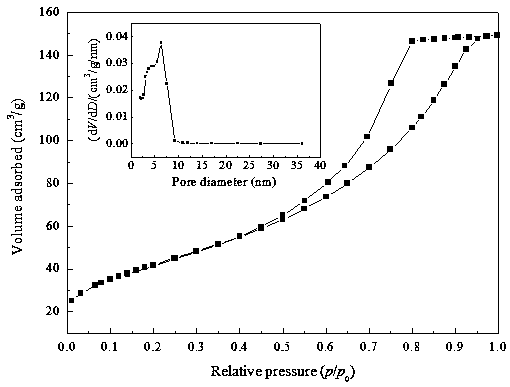

Active mixed metal oxide loading silver modifying iron-based metallic oxide arsenic removal micro-nano adsorbent and preparation method thereof

InactiveCN108295805ALarge specific surface areaHigh removal rateOther chemical processesWater contaminantsArsenic pollutionSorbent

The invention belongs to the technical field of nanometer materials, particularly relates to active mixed metal oxide loading silver modifying iron-based metallic oxide arsenic removal micro-nano adsorbent and a preparation method thereof. Mixed metallic salt solution is prepared from iron-based metal salt solution, silver salt solution, zinc salt solution and zircon salt solution; hydrothermal reaction is carried out; after the reaction and natural cooling, under the circumstance of magnetic stirring, precipitator solution is dropped in the mixed metallic salt solution until the pH value of the mixed metallic salt solution is eight; after the dropping is finished, high speed centrifugation is carried out to obtain precipitate; washing and centrifugal separation are carried out again untilthe pH value of supernatant liquid of the mixed metallic salt solution is neutral; finally, drying roasting treatment are carried out to obtain the arsenic removal adsorption materials. The adsorbenthas the pore structure characteristics that the pore is larger than the superficial area, and mesoporous and macropore are 'mixed', the adsorbent has the advantages that the removal rate is high, theadsorption capacity is high, the use amount is less, the adsorption rate is quick and the secondary pollution can not occur. The adsorbent can be applied to the deep treatment of low concentration arsenic pollution in underground water and surface water and industrial wastewater containing low-concentration arsenic.

Owner:FUZHOU UNIV

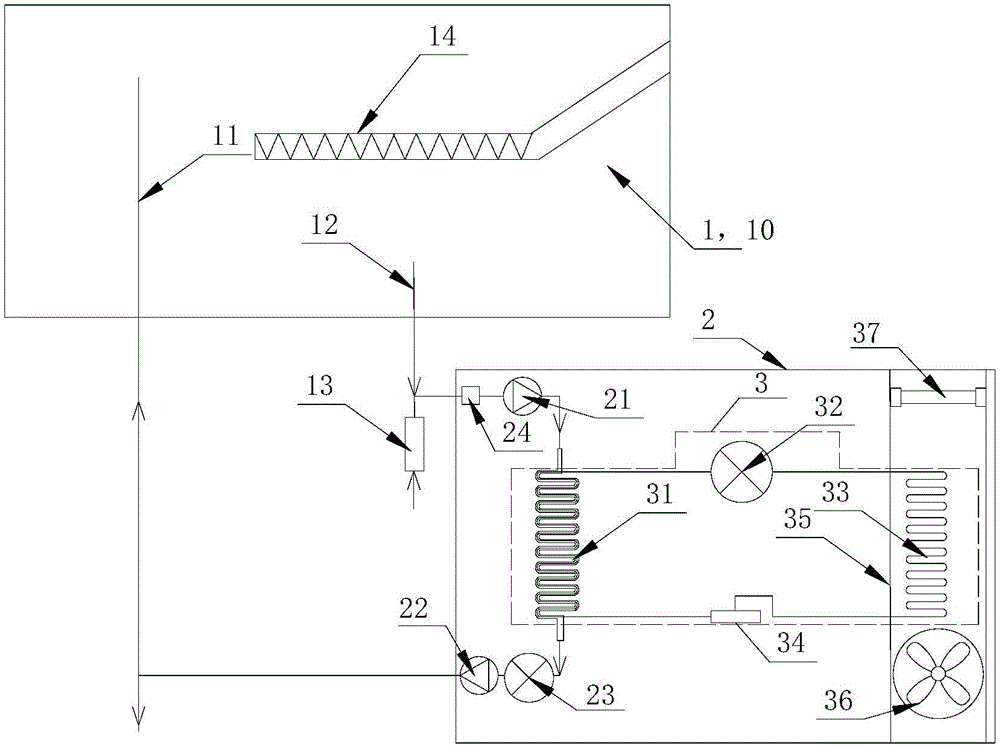

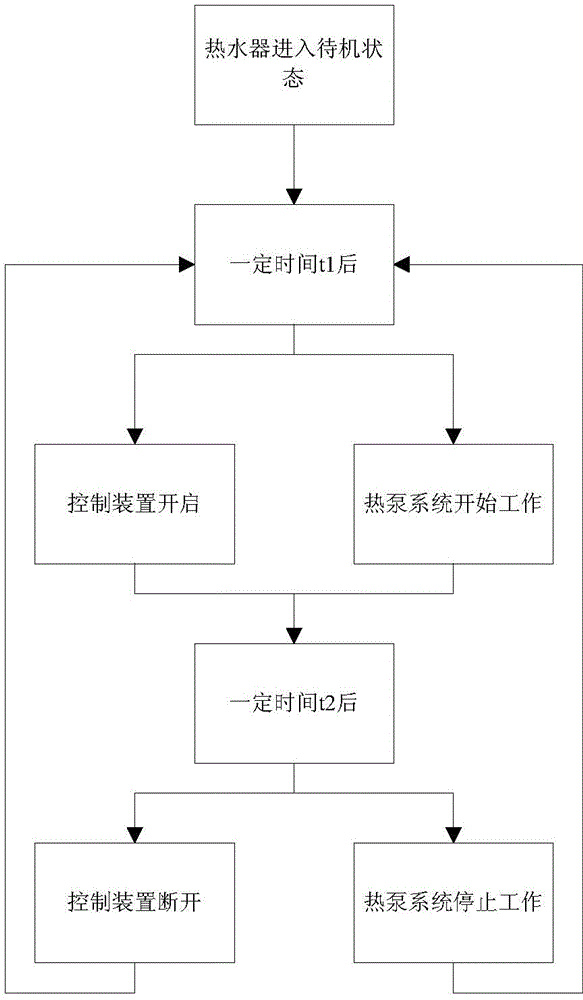

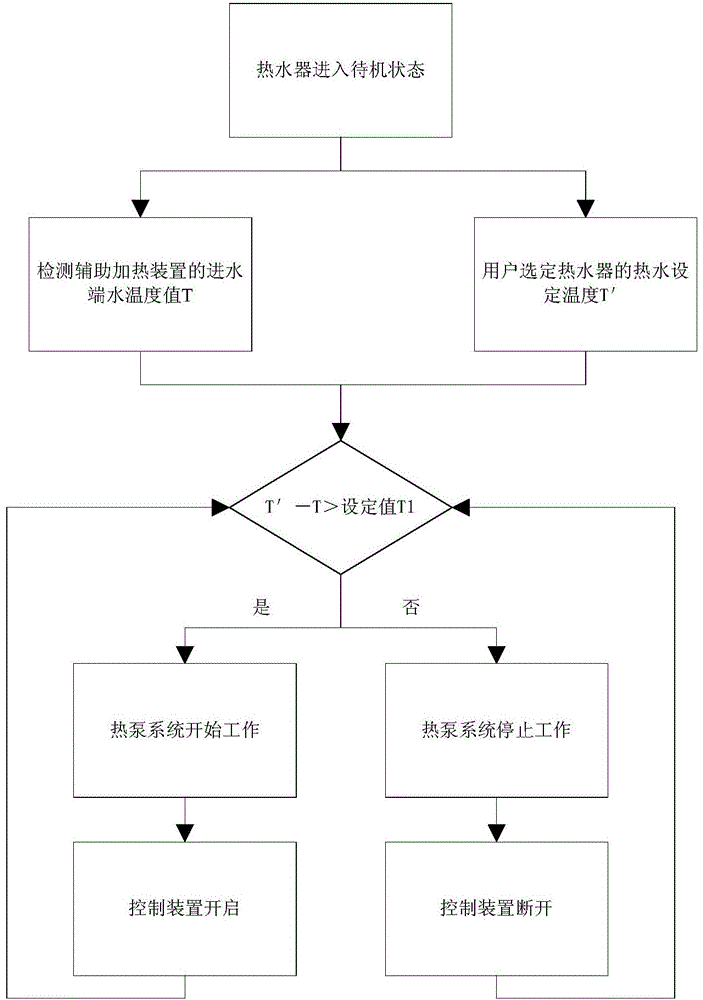

Auxiliary heat pump device of water heater and control method

The invention relates to an auxiliary heat pump device of a water heater and a control method. The heat pump device comprises a heat pump system. The heat pump system comprises a condenser, a compressor, an evaporator, an expansion valve and an air supply device, wherein the condenser is provided with a water inlet end communicating with a water inlet pipe of the water heater, and a water outlet end communicating with a water outlet pipe of the water heater, so that circulating water flow between the water heater and the condenser is formed, and the purpose of auxiliary heating of the circulating water flow through heat in air by the heat pump system is achieved. More specifically, the evaporator is arranged close to the position where a user uses hot water of the water heater, so that the evaporator collects waste heat, diffused to the environment, of the hot water of the water heater and transfers the collected waste heat through refrigerants, heat exchange between the circulating water flow flowing through the condenser and the refrigerants flowing through the condenser is achieved, and auxiliary heating treatment of water in the water heater through the heat pump system is achieved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

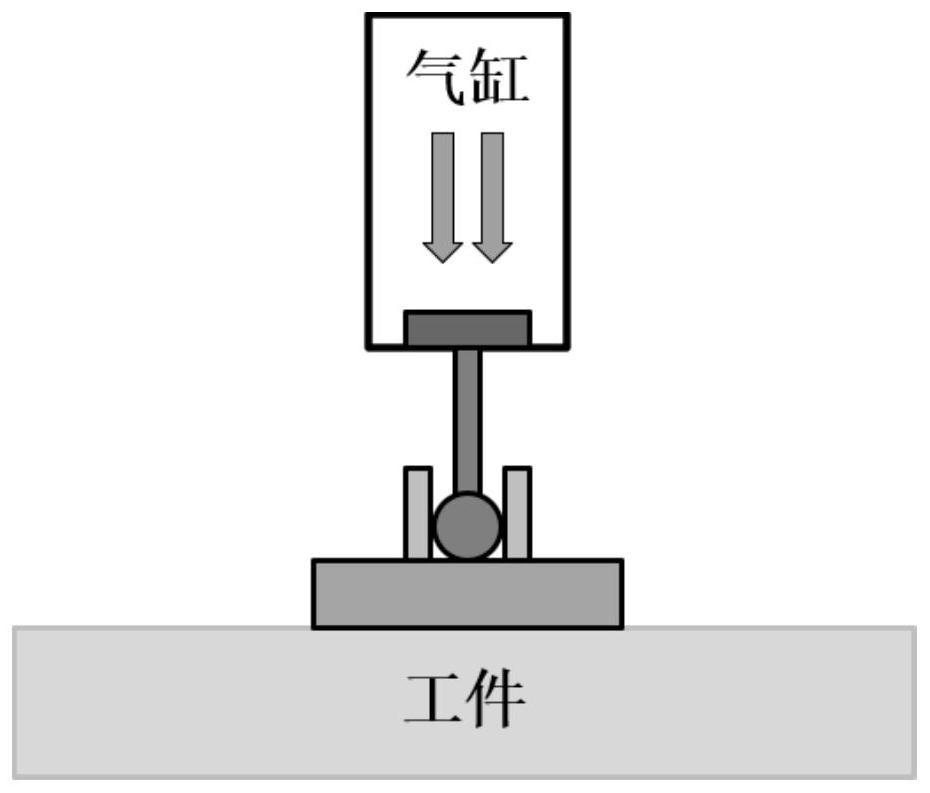

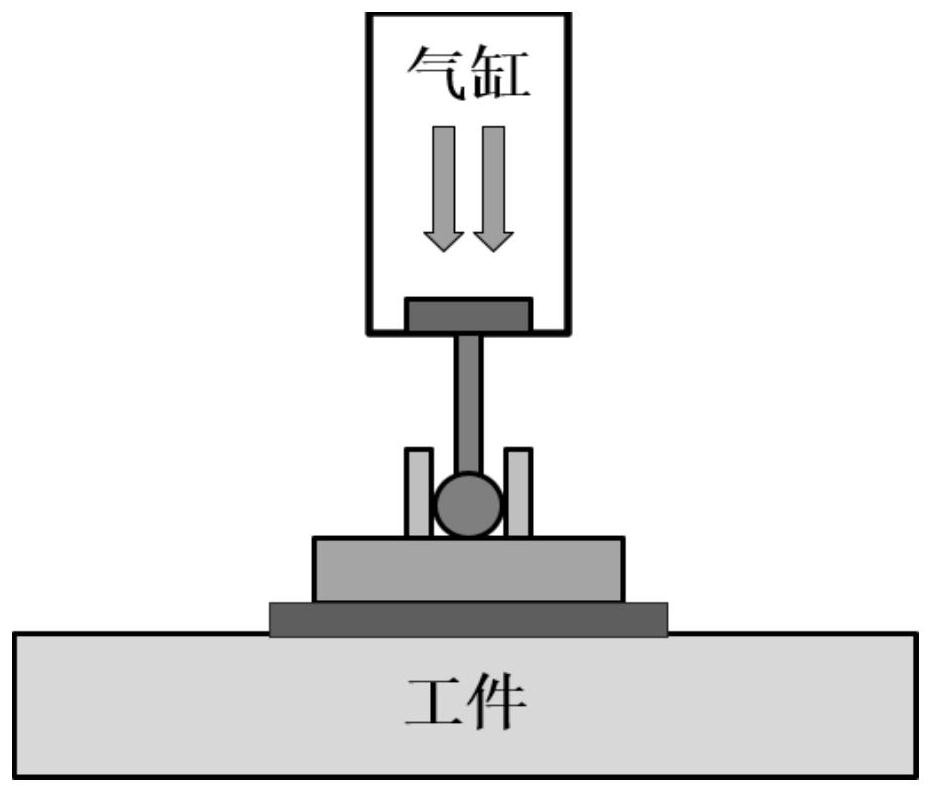

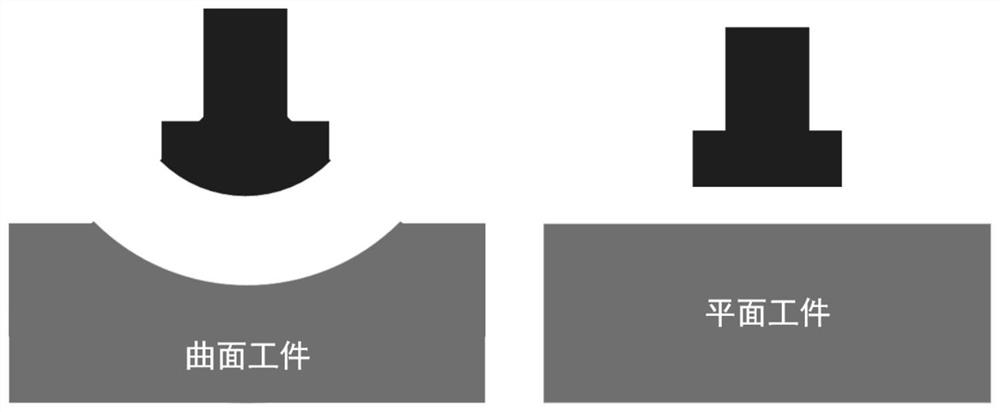

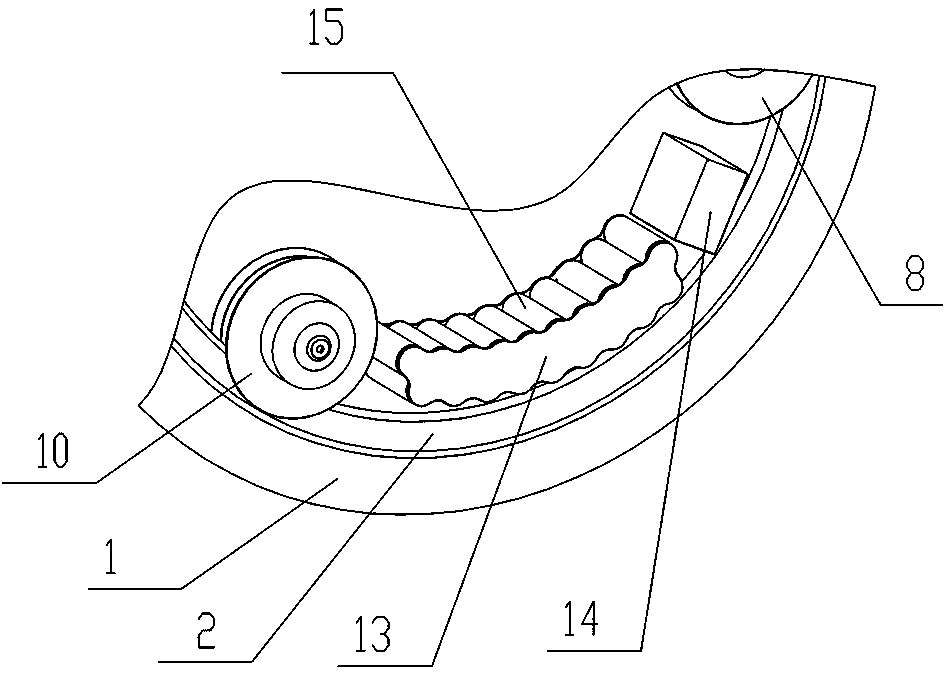

CCOS shear thickening polishing method

ActiveCN112658812AAchieve polishRealize modificationOptical surface grinding machinesPolishing compositions with abrasivesPolishingChanging equipment

The invention discloses a CCOS shear thickening polishing method. A shear thickening polishing solution is led in for thickening in the process of machining a workpiece by adopting a polishing disk in a CCOS process, so as to improve the flatness and the surface shape precision of CCOS machining. The method has the capacity of modifying the surface of a low-precision workpiece, a medium-precision workpiece and a high-precision workpiece, it is not necessary to apply all machining equipment, various errors caused by equipment replacement are avoided, the surface of the workpiece can be modified, and meanwhile, the flatness and the surface shape precision of the surface of the workpiece can be improved. The method has the advantages that a device is simple, easy to build and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

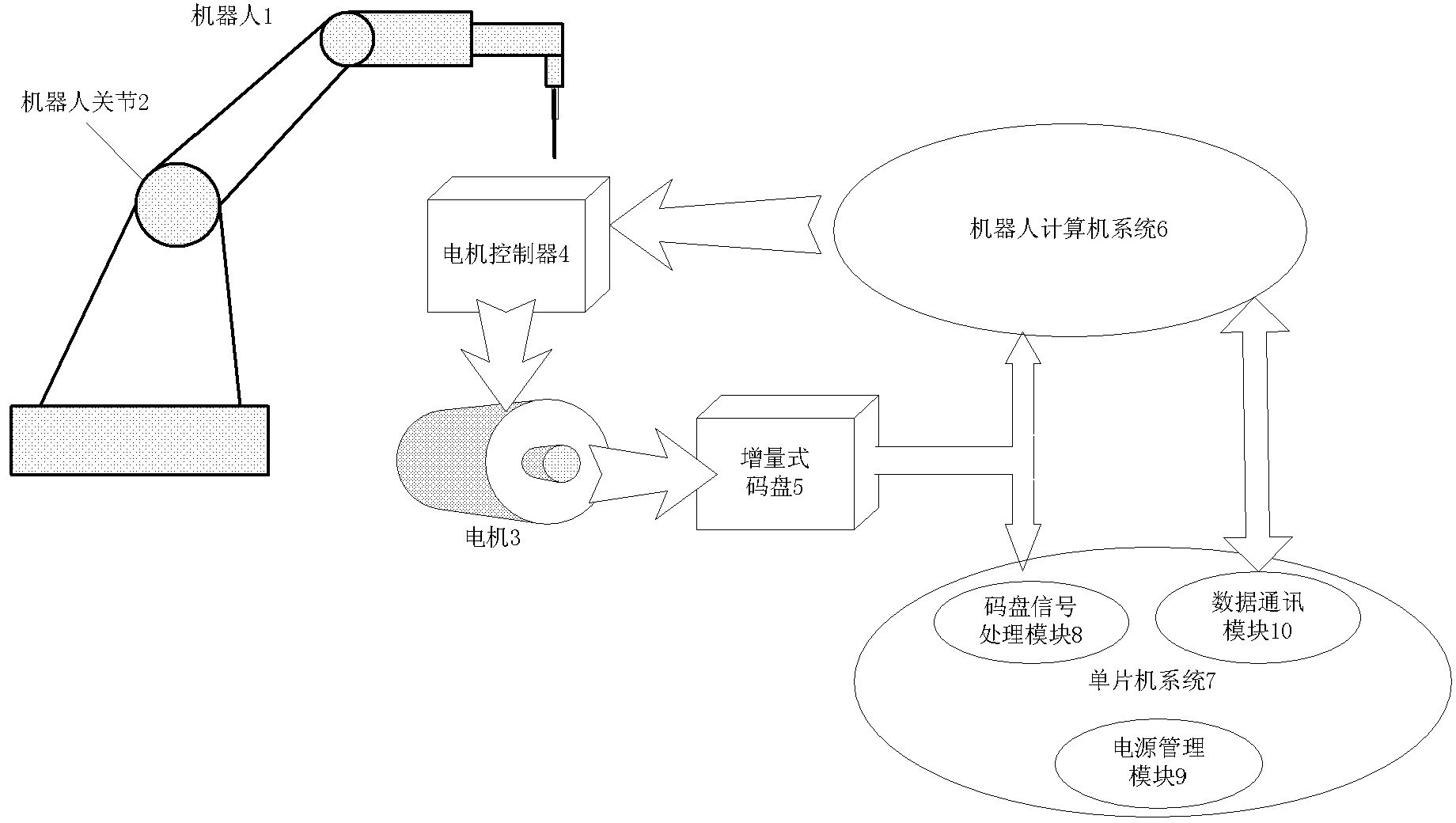

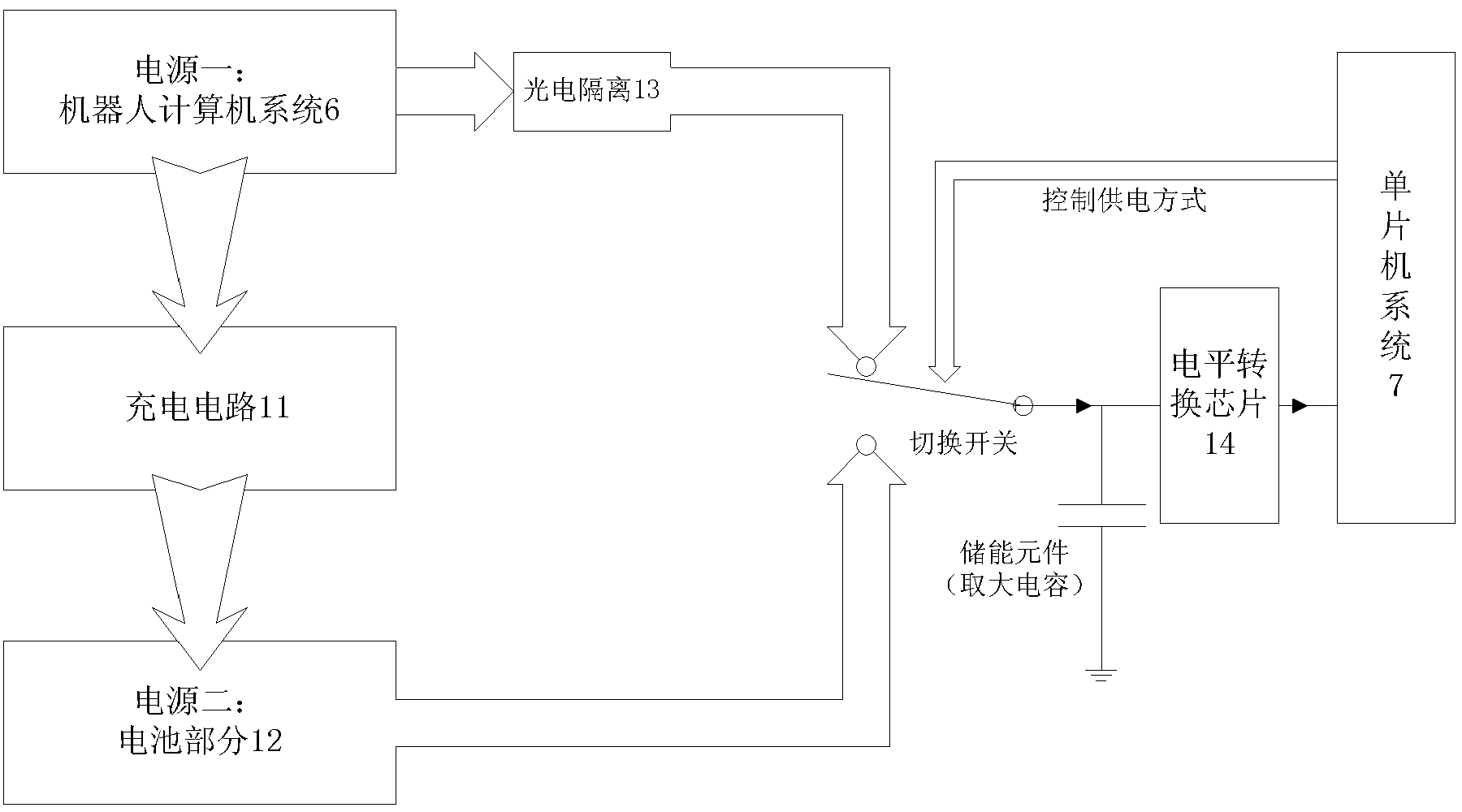

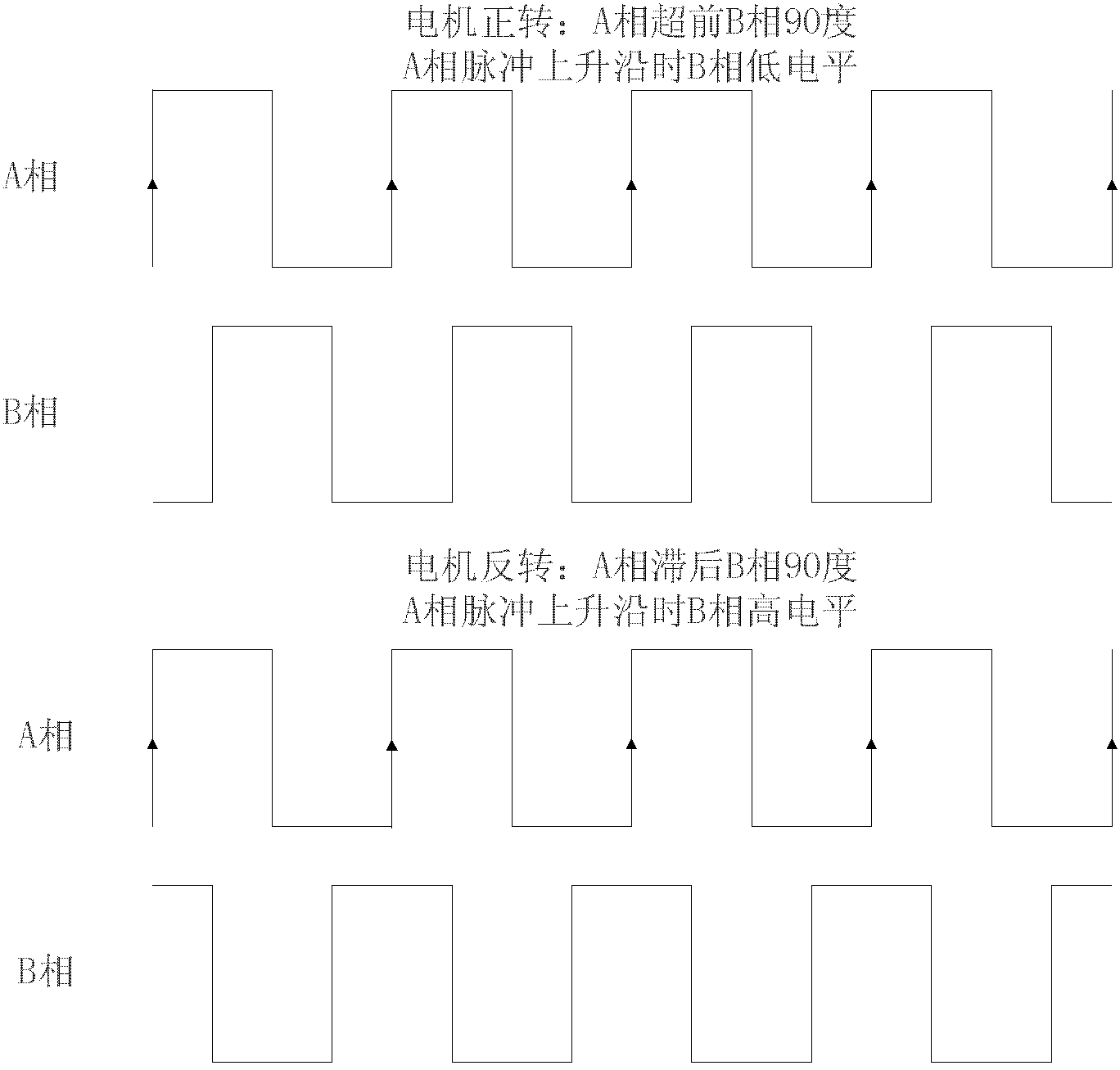

System and method for improving performance of incremental code disc

ActiveCN103240743ARealize the absolute counting functionFunction increaseProgramme-controlled manipulatorMicrocontrollerRobotic systems

The invention discloses a system and a method for improving performance of an incremental code disc. A single-chip microcomputer system is added on the basis of a robot computer system to achieve performance improvement. The robot computer system is used for controlling operation of a robot and detecting current position information of a robot joint through the incremental code disc. The robot computer system sends the current position information of the robot joint to the single-chip microcomputer system when the robot finishes working and receives the current position information of the robot joint from the single-chip microcomputer system when the robot starts working. The single-chip microcomputer system is used for detecting pulse information sent by the incremental code disc after receiving the current position information of the robot joint sent by the robot computer system and updating the current position information of the robot joint according to the pulse information. By means of the system, a current position of a motor can be obtained correctly at any time, absolute counting of the incremental code disc is achieved, and the requirements of producers for low cost and high performance of a robot system are met.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

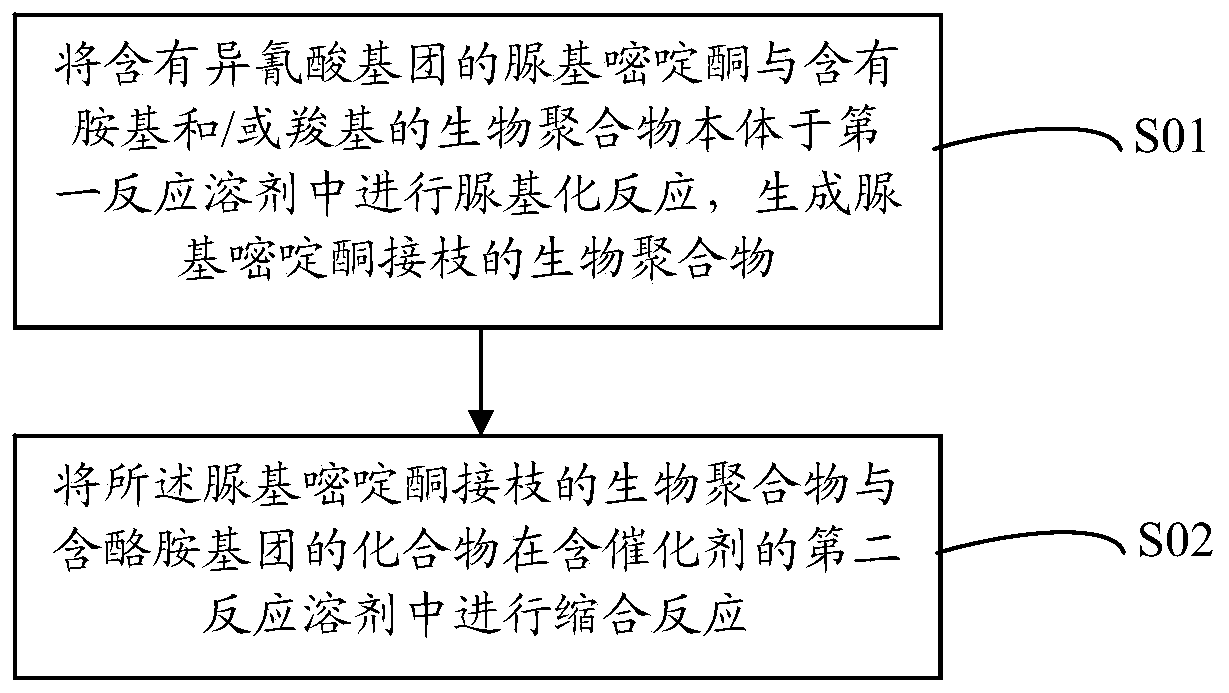

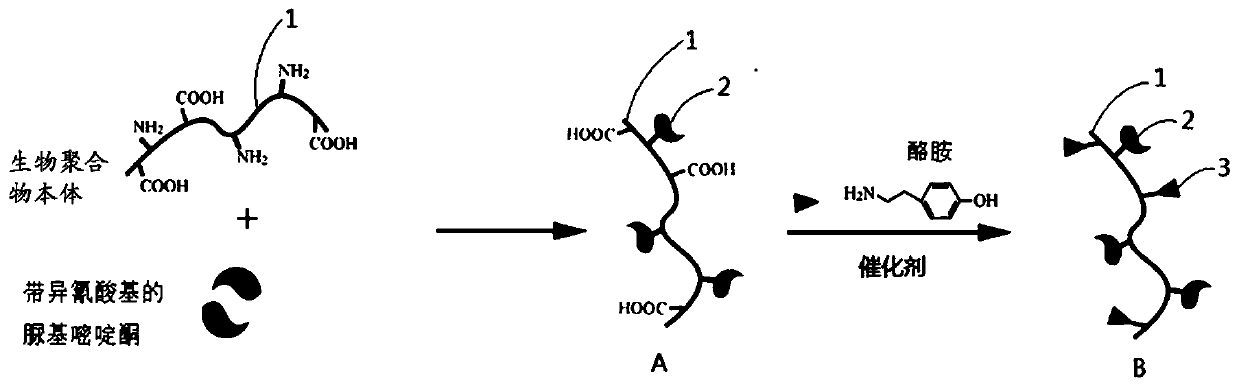

Modified biopolymer and use thereof in 3D printing

InactiveCN110483804AHigh viscosityGood compatibilityAdditive manufacturing apparatusCell culture supports/coatingCross-linkComponent Load

The invention discloses a modified biopolymer, a preparation method of the modified biopolymer, modified biopolymer bio-ink and application thereof. The modified biopolymer comprises a biopolymer mainchain, and a ureido pyrimidinone group and a tyramine group are grafted on the biopolymer main chain. The modified biopolymer bio-ink comprises a solvent and a modified biopolymer dissolved in the solvent, and further comprises a biological functional component loaded by the modified biopolymer, with the modified biopolymer in the bio-ink being the modified biopolymer provided by the invention. The modified biopolymer has good viscosity, has the characteristic that the viscosity is adjustable along with the temperature, and also has the characteristic that self-solidification is directly carried out at room temperature, and gel formed by solidification has good mechanical properties. The modified biopolymer bio-ink has good viscosity and biocompatibility, is especially suitable for 3D printing, can be used for direct printing of a biological scaffold, and avoids additional addition of components harmful to biological components such as a cross-linking agent and the like.

Owner:SHENZHEN INST OF ADVANCED TECH

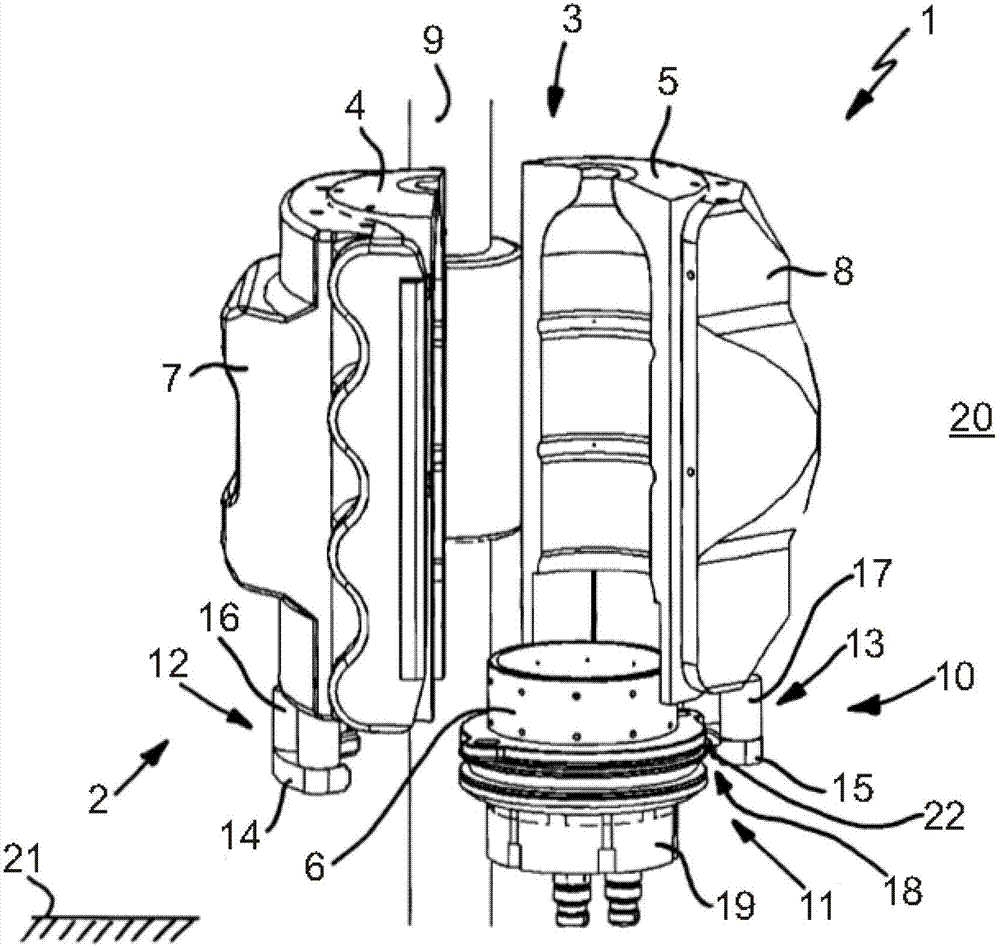

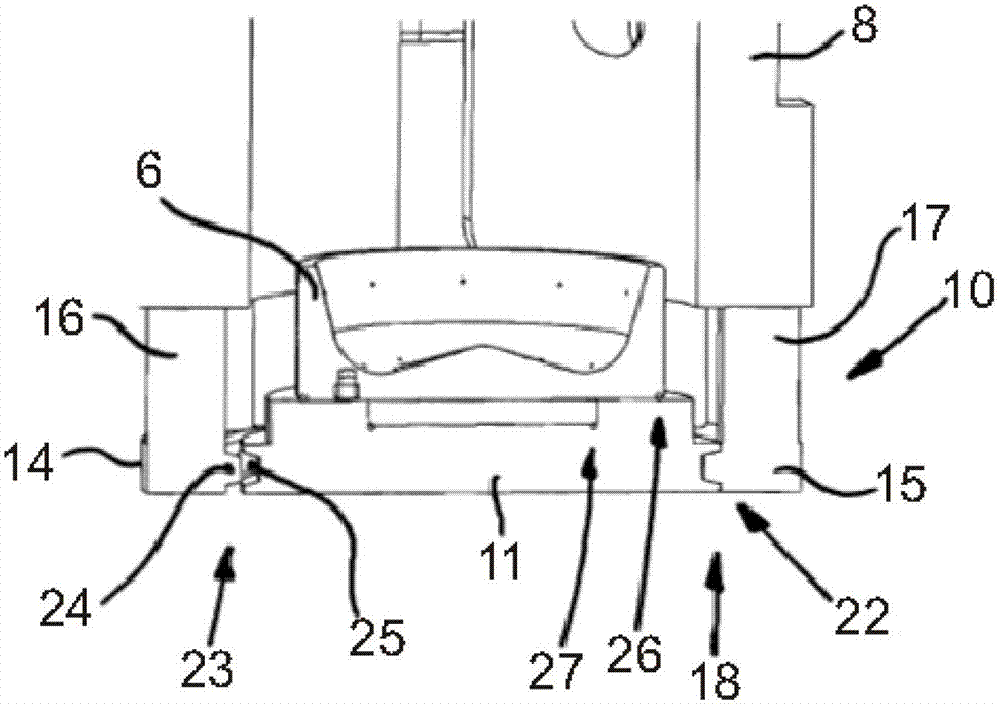

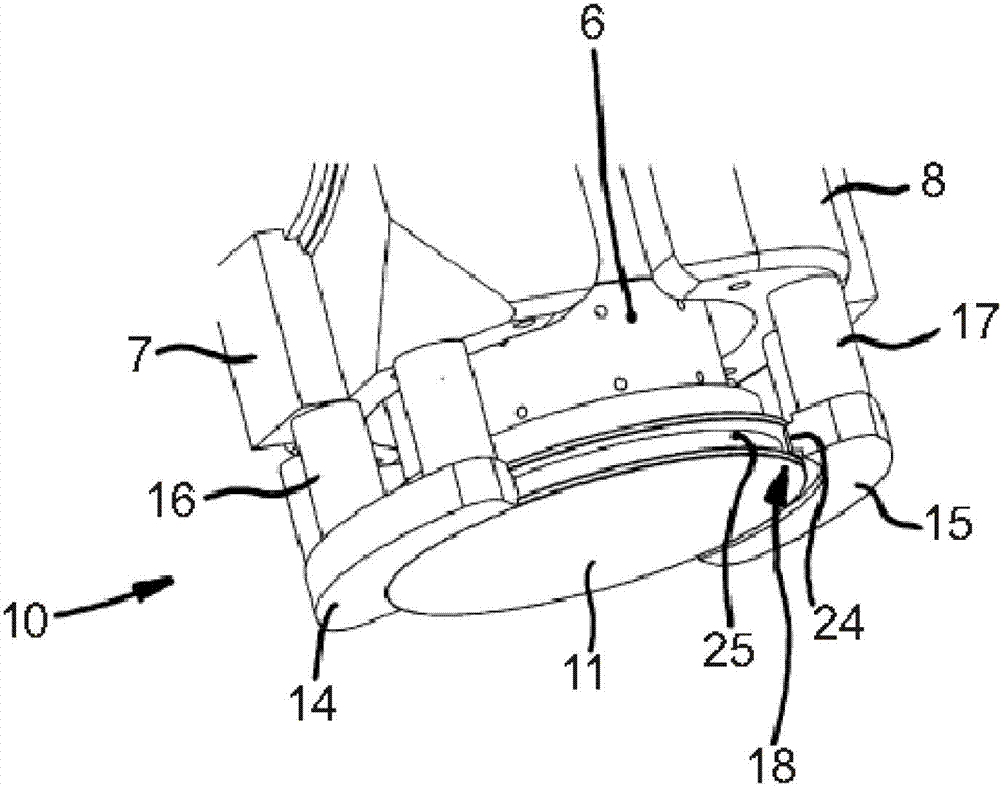

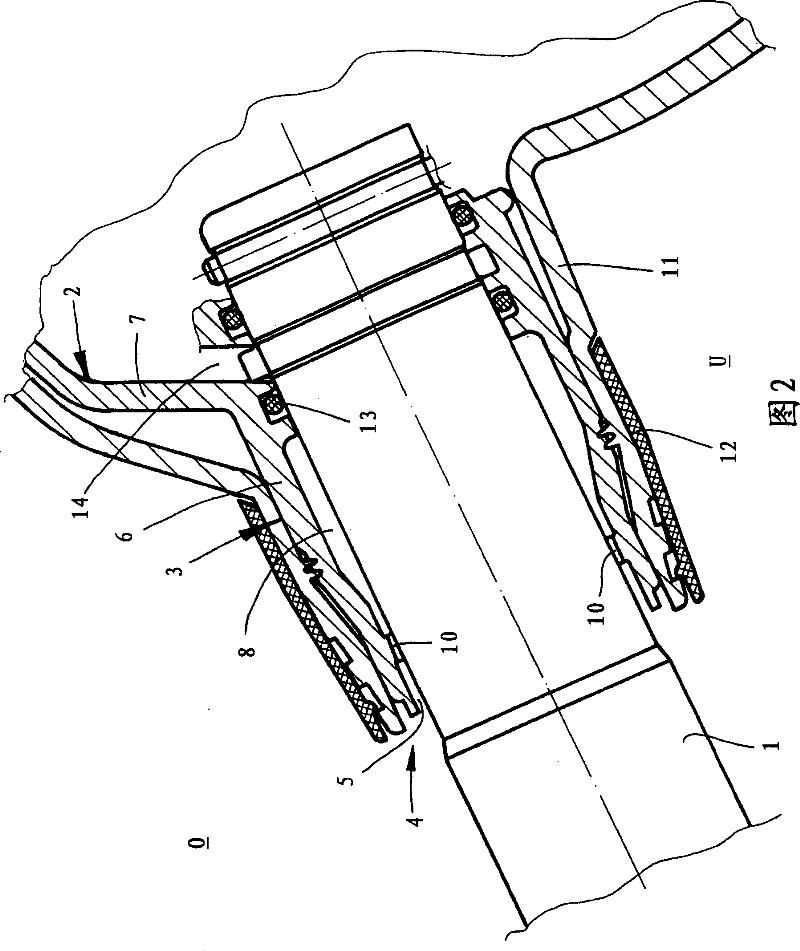

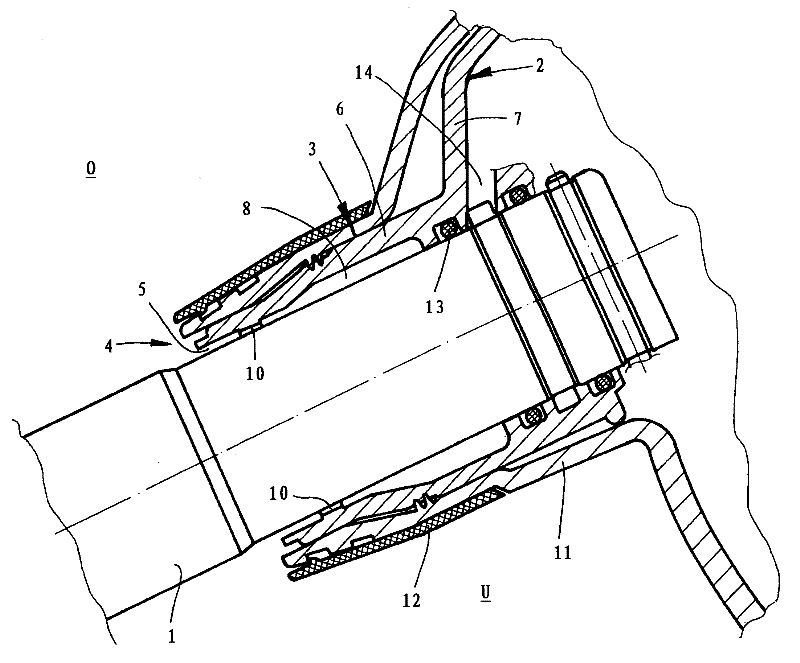

Stretch-blow molding apparatus and equipment of plastic material perform and application of ceramic member

InactiveCN102806655AGood sliding propertiesImprove the stabilityLoad modified fastenersBoltsBlow moldingEngineering

The invention relates to apparatus (1) which perform stretching and blow molding on a plastic material perform to form a plastic material container. The apparatus (1) has a bearing assembly (2) used for bearing a blow-molding die (3) comprising at least two housing components (4, 5) and a base component (6), and has a base component clamping assembly comprising a base component accommodating mechanism (11; 111) and used for holding a holding assembly (12, 13 and 14, 15; 114, 115 respectively) of the base component accommodating mechanism (11; 111), wherein the base component accommodating mechanism (11; 111) can be clamped to the holding assembly (12, 13 and 14, 15; 114, 115 respectively) via a forced interlocking fastening part (18; 118), and the forced interlocking fastening part (18; 118) has a forced interlocking area (22) made of ceramic materials.

Owner:KRONES AG

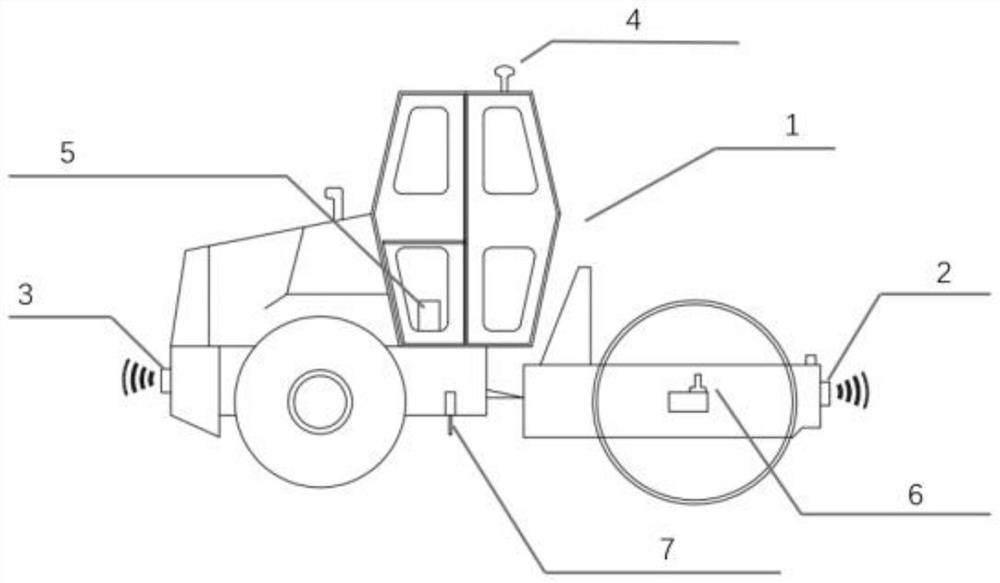

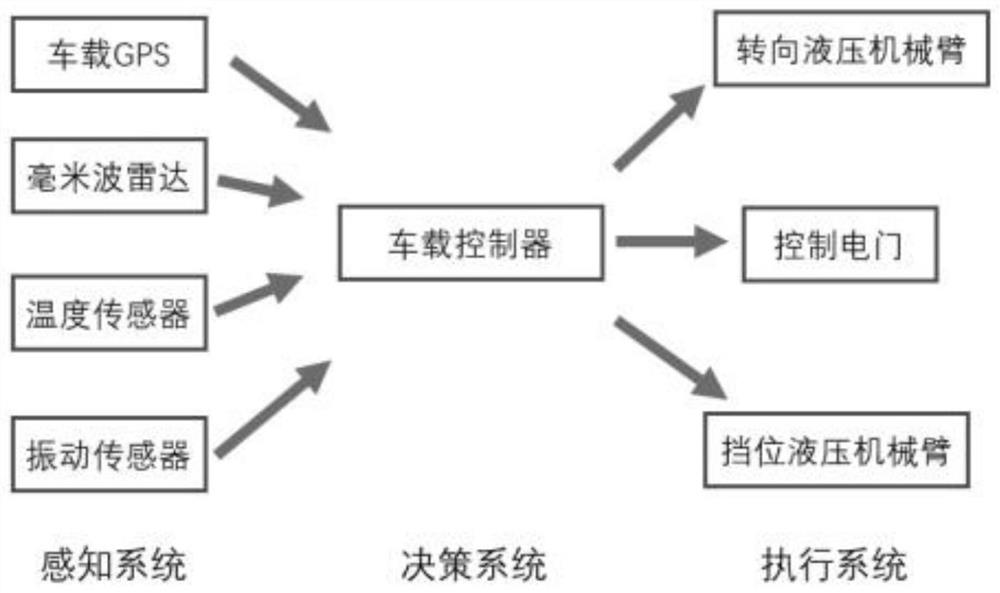

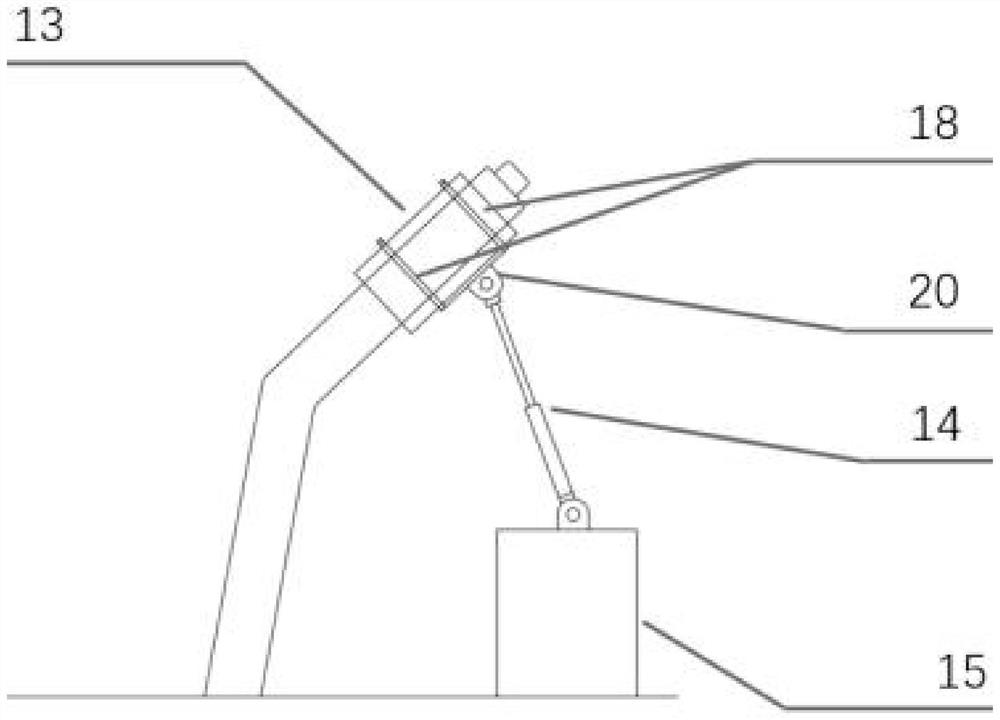

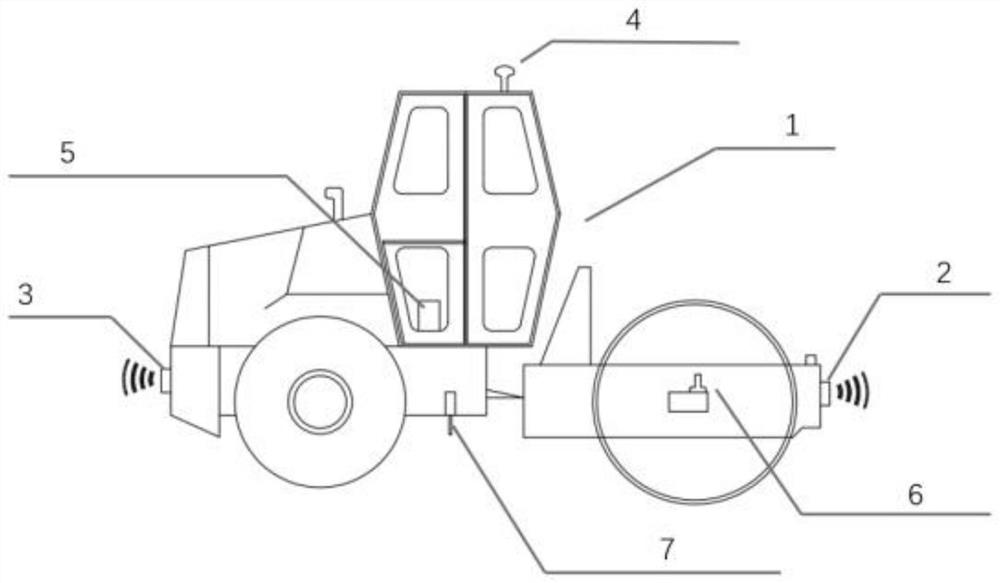

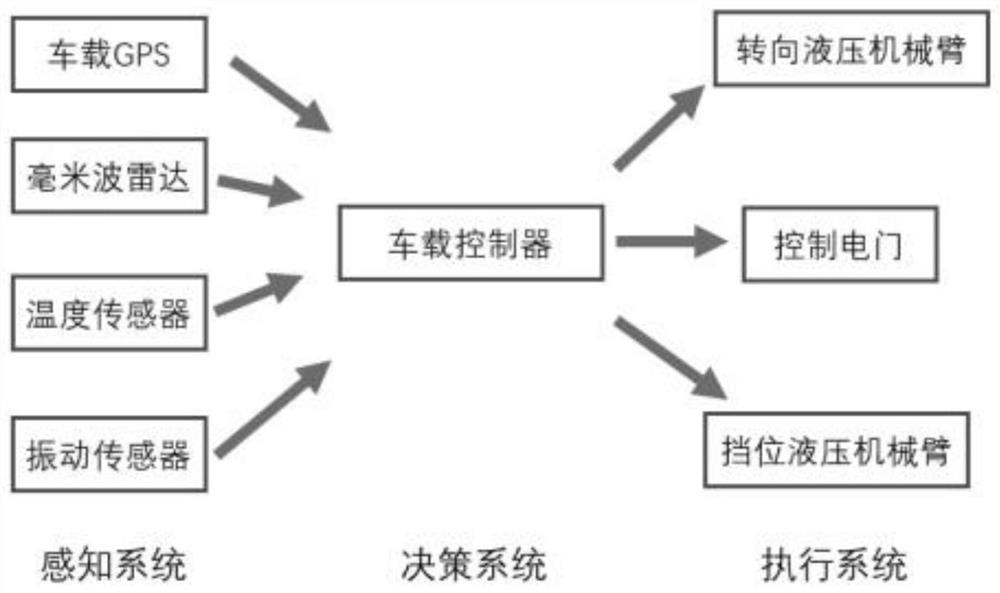

External hanging type road roller unmanned auxiliary driving system

ActiveCN113512924ARealize modificationReduce workloadRoads maintainenceElectric/fluid circuitDriver/operatorVibration control

The invention relates to an external hanging type road roller unmanned auxiliary driving system, according to the auxiliary driving system, a manned road roller is modified, a vehicle-mounted GPS, a millimeter wave radar, a vibration sensor and a temperature sensor are arranged on the road roller, and the output ends of the temperature sensor, the vehicle-mounted GPS and the vibration sensor are connected with a vehicle-mounted data box; the vehicle-mounted data box is connected with an auxiliary controller; a steering wheel of the cab is connected with the steering hydraulic mechanical arm through a first transition part, and the gear position of the cab is connected with the gear hydraulic mechanical arm through a second transition part. the vehicle-mounted data box and the auxiliary controller are loaded in the case, and the auxiliary controller is electrically connected with the control switch, the steering hydraulic mechanical arm, the gear hydraulic mechanical arm, the front millimeter-wave radar and the rear millimeter-wave radar at the same time; and the control switch is connected in parallel with a vibration switch of the vibration control circuit of the manned road roller. Aiming at unmanned quick modification of a common road roller driven by a driver, unmanned driving of the common road roller is realized.

Owner:HEBEI UNIV OF TECH

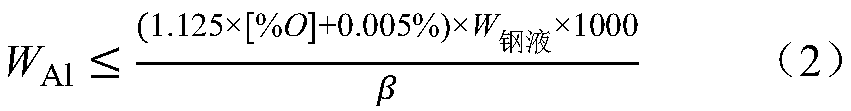

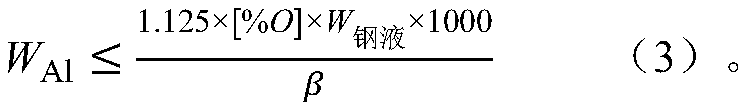

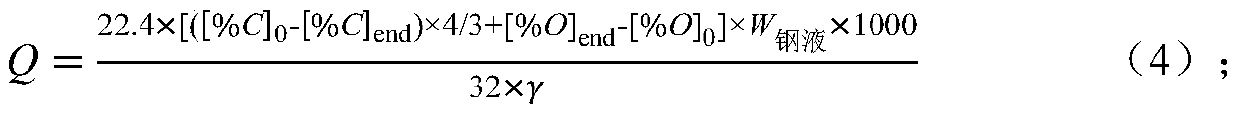

Temperature and cleanliness controlling method for production of steel liquid of low-carbon steel and ultra-low carbon steel

The invention discloses a temperature and cleanliness controlling method for production of steel liquid of low-carbon steel and ultra-low carbon steel, and belongs to the field of steel and iron metallurgy. The method disclosed by the invention comprises the following steps: adding aluminum products such as aluminum granules, aluminum ingots and aluminum alloys into the steel liquid in a steel ladle or in a tapping process before tapping of a converter so as to ensure that the aluminum products react with oxygen in the steel liquid and heat is released, and thus the temperature of molten steelis increased; simultaneously reducing oxidizability of furnace residues; controlling the added aluminum to ensure that the total aluminum products react with the oxygen in the tapping steel liquid and the aluminum content in the tapping steel liquid is less than 50*10<-6>; and basically floating and removing generated Al2O3 before entering into RH refining. When RH refining is performed and the vacuum degree of a vacuum tank is less than 20-50kPa, forced oxygen blowing and decarbonization can be carried out by adopting a top lance, so that the RH decarbonization efficiency is ensured; and meanwhile, after control of the decarbonization is finished, the oxygen content is less than 400x10<-6>, so that the phenomenon that the molten steel is higher in cleanliness after RH refining is performed is ensured. According to the method disclosed by the invention, the temperature of the steel liquid can be increased, the problem of insufficient temperature in RH decarbonization and refining processes in steel plants is solved, and meanwhile, the oxygen blowing amount for RH refining forced decarbonization can be controlled more accurately, the terminal oxygen content for RH decarbonization is controlled and reduced, and the cleanliness of the steel liquid is improved.

Owner:UNIV OF SCI & TECH BEIJING

Method and device for upgrading heavy oil raw materials by utilizing liquid-phase discharge in-situ hydrogenation

PendingCN110317636AImprove discharge efficiencyImprove light weight rateHydrocarbon oil crackingEnergy based chemical/physical/physico-chemical processesReduction rateCombustion

The invention discloses a method and device for upgrading heavy oil raw materials by utilizing liquid-phase discharge in-situ hydrogenation. The method comprises the steps that discharge is directly performed in a liquid, liquid-phase discharge hydrogen production is combined with liquid-phase discharge hydrogenation for upgrading heavy oil, a hydrogen production raw material is added into the heavy oil raw materials in a high electric field region of a reactor, liquid-phase high-pressure discharge plasma is utilized to simultaneously decompose the hydrogen production raw material and heavy oil molecules in different regions, active hydrogen free radicals are generated from the hydrogen production raw material in a plasma strong field region to rapidly react with the heavy oil molecules cracked by liquid-phase discharge, correspondingly hydrogen production, cracking of the heavy oil raw materials and in-situ hydrogenation are simultaneously carried out, and therefore the weight reduction of heavy oil is realized. The method has the advantages that in-situ hydrogen production and hydrogenation are realized, the reaction efficiency is high, and the weight reduction rate is effectively increased. Meanwhile, the device can be directly used for fuel oil modification in online application, and liquid and gas products generated by the device can be used as fuels for combustion withoutseparation.

Owner:DALIAN MARITIME UNIVERSITY

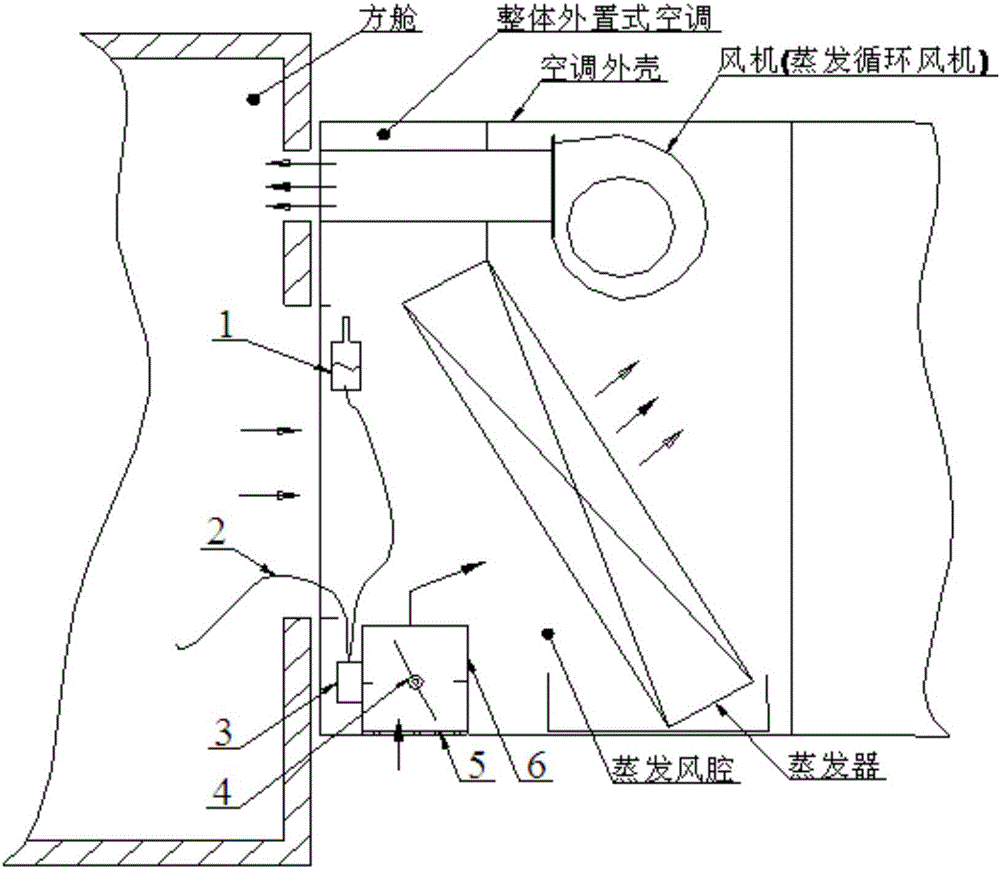

Device for automatically realizing fresh air replacement for integral external air conditioner

InactiveCN105890096ADangers of lack of fresh air to breatheEasy to controlSpace heating and ventilation safety systemsLighting and heating apparatusElectricityHigh concentration

The invention discloses a device for automatically realizing fresh air replacement for an integral external air conditioner. The device comprises a square cabin and the integral external air conditioner, wherein a carbon dioxide sensor is arranged at an air return opening of the integral external air conditioner; a ventilation air valve assembly is arranged in an evaporation air cavity of the integral external air conditioner; an air inlet of the ventilation air valve assembly is led to an external environment, and the ventilation air valve assembly comprises an air valve mechanism and a driving mechanism for driving the air valve mechanism to work; the carbon dioxide sensor and the driving mechanism are electrically connected with a control panel of the integral external air conditioner respectively through signal cables. By detection of the concentration of carbon dioxide in the square cabin or a room, fresh air replacement is automatically and intelligently realized, so that fresh air can be automatically supplemented into the square cabin; therefore, potential safety hazards caused by extremely high concentration of the carbon dioxide in the closed square cabin where a worker stays for a long time are avoided.

Owner:合肥天鹅制冷科技有限公司

Method for preparing anthracene and phenanthrene through co-carbonization of hydrogenated anthracene oil and refined asphalt

PendingCN111718232AReduce equipment investmentSimple processHydrocarbon purification/separationHydrocarbonsChemistryCarbonization

The invention relates to a method for preparing anthracene and phenanthrene through co-carbonization of hydrogenated anthracene oil and refined asphalt. According to the method, the hydrogenated anthracene oil serving as a hydrogen donor and refined asphalt are subjected to co-carbonization, hydrogen transfer occurs and product separation is performed to obtain a mixture of which the main components are anthracene and phenanthrene, and crystallization is performed to finally obtain refined anthracene and refined phenanthrene. Compared with the prior art, the method has the beneficial effects that the process has the advantages of low equipment investment, simple process and low energy consumption. A mixture with anthracene and phenanthrene as main components can be easily obtained, and therefined anthracene and refined phenanthrene as components can be simply and efficiently extracted through crystallization separation. According to the process, while anthracene and phenanthrene are obtained, organic or inorganic heteroatoms are promoted to be converted into gas to escape, asphalt modification can be synchronously achieved, and coking substances are reduced. Raw materials can be fully utilized, energy is saved, emission is reduced, and investment treatment by-products do not need to be increased.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

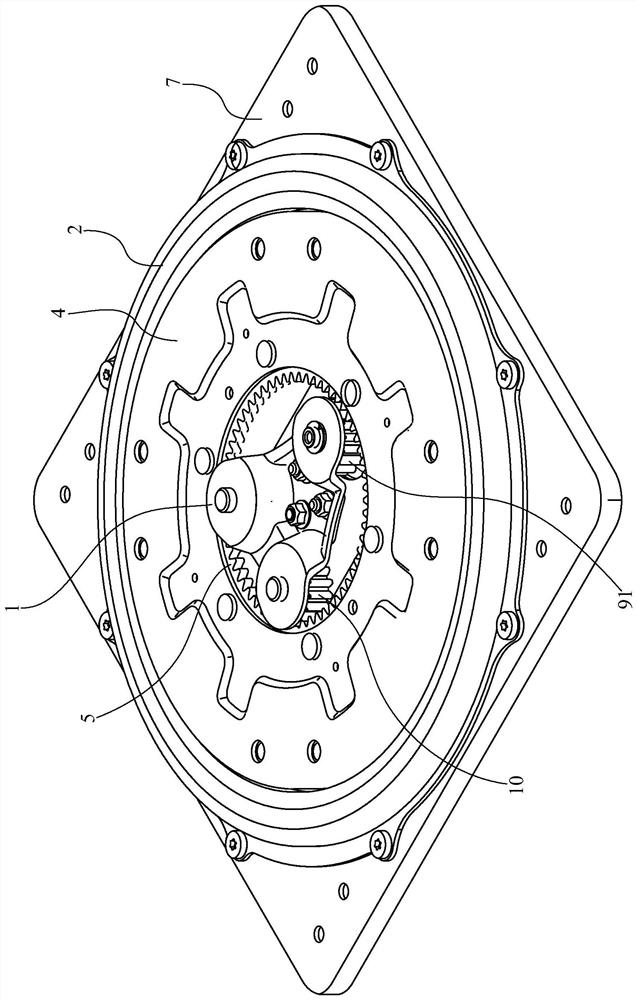

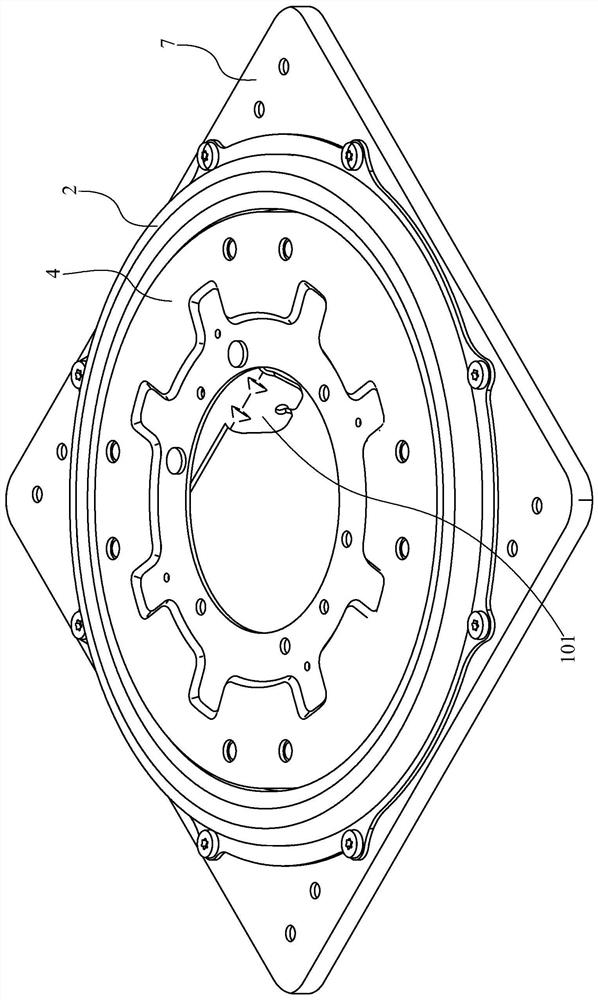

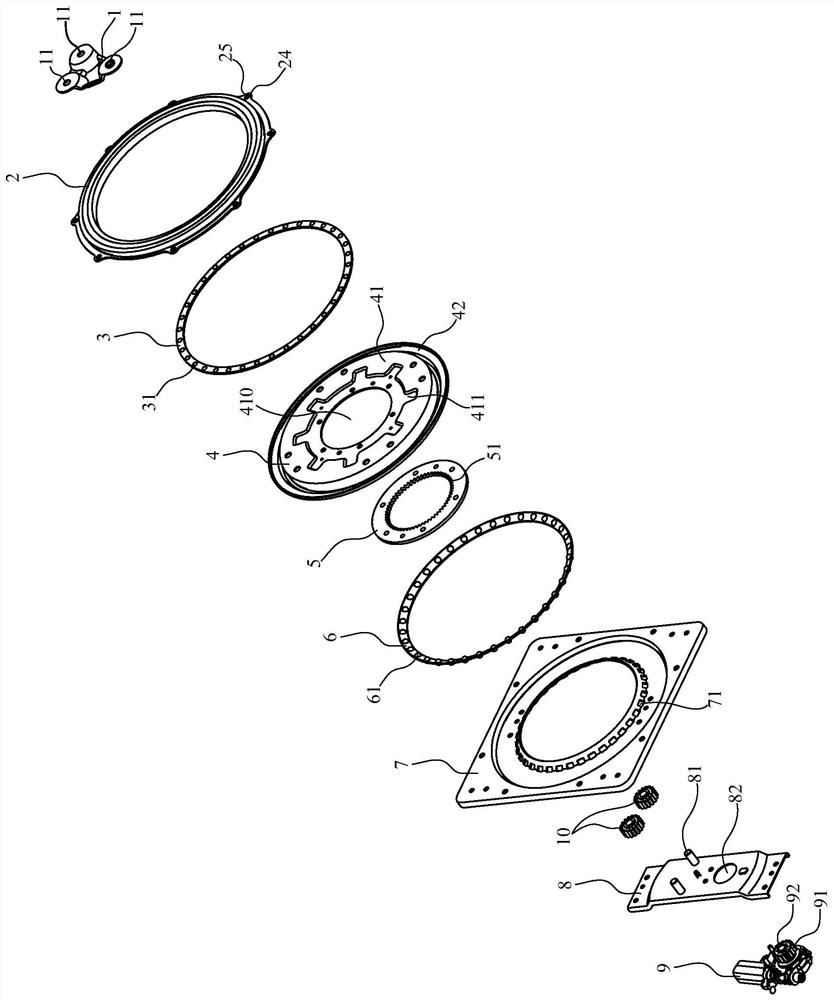

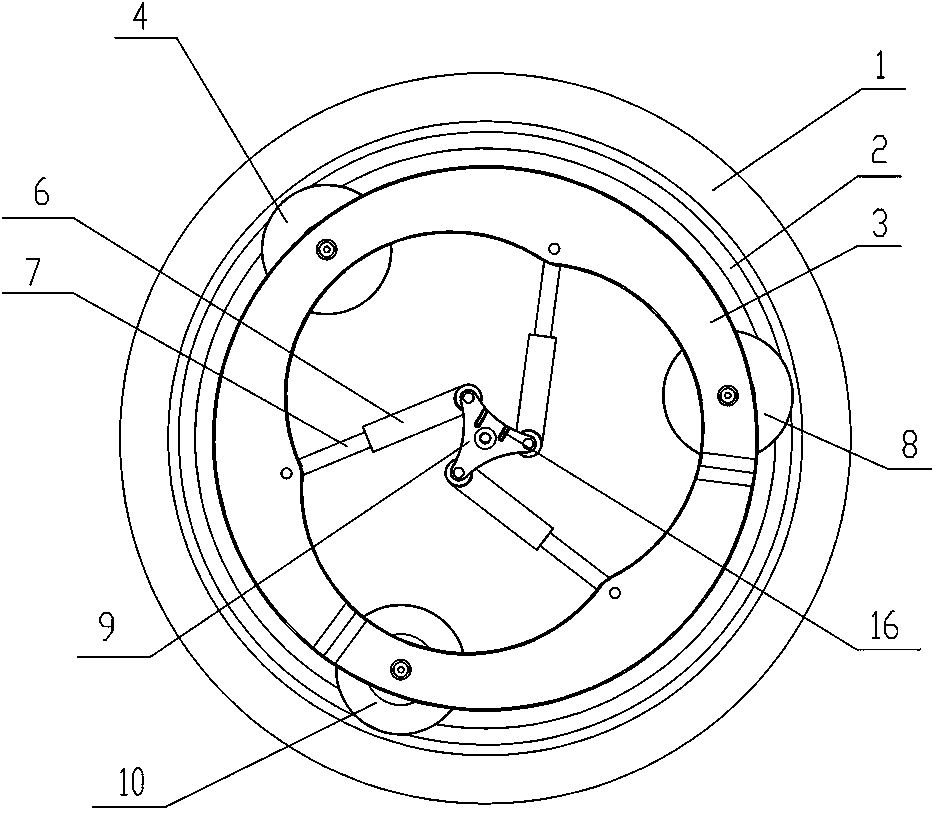

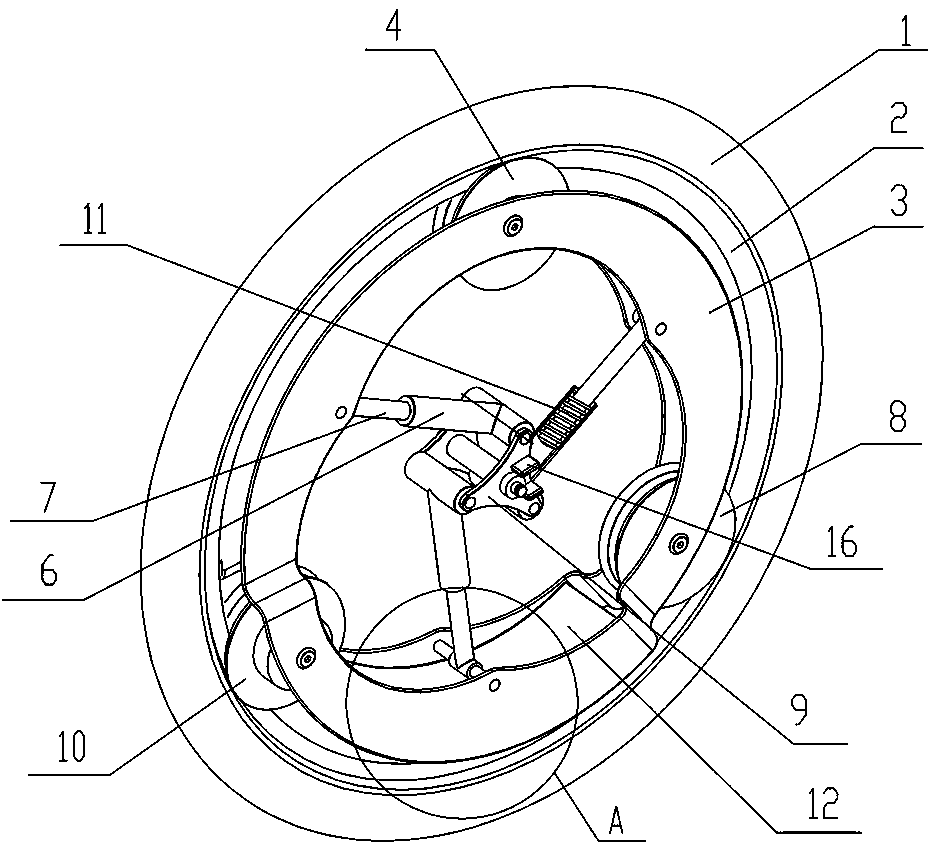

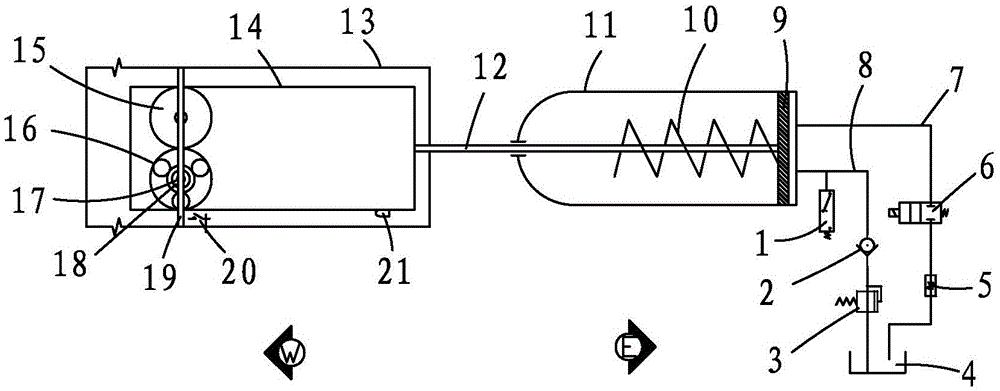

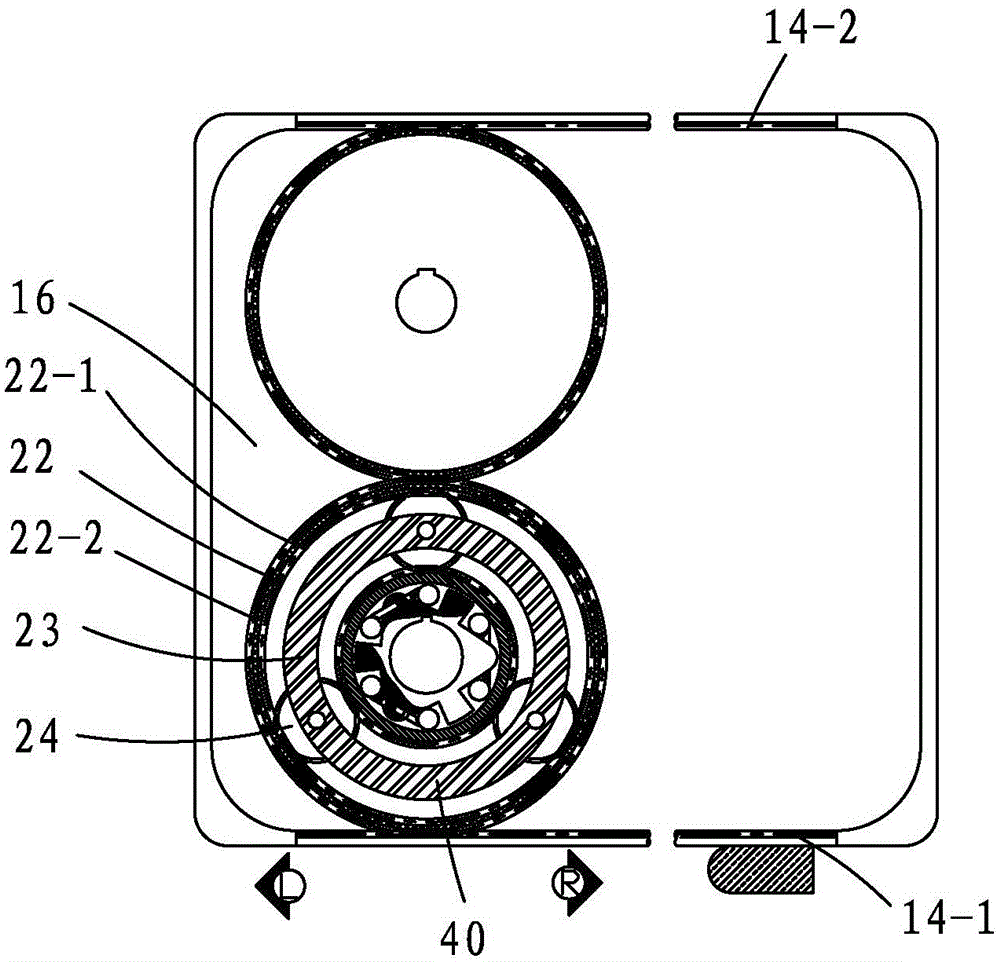

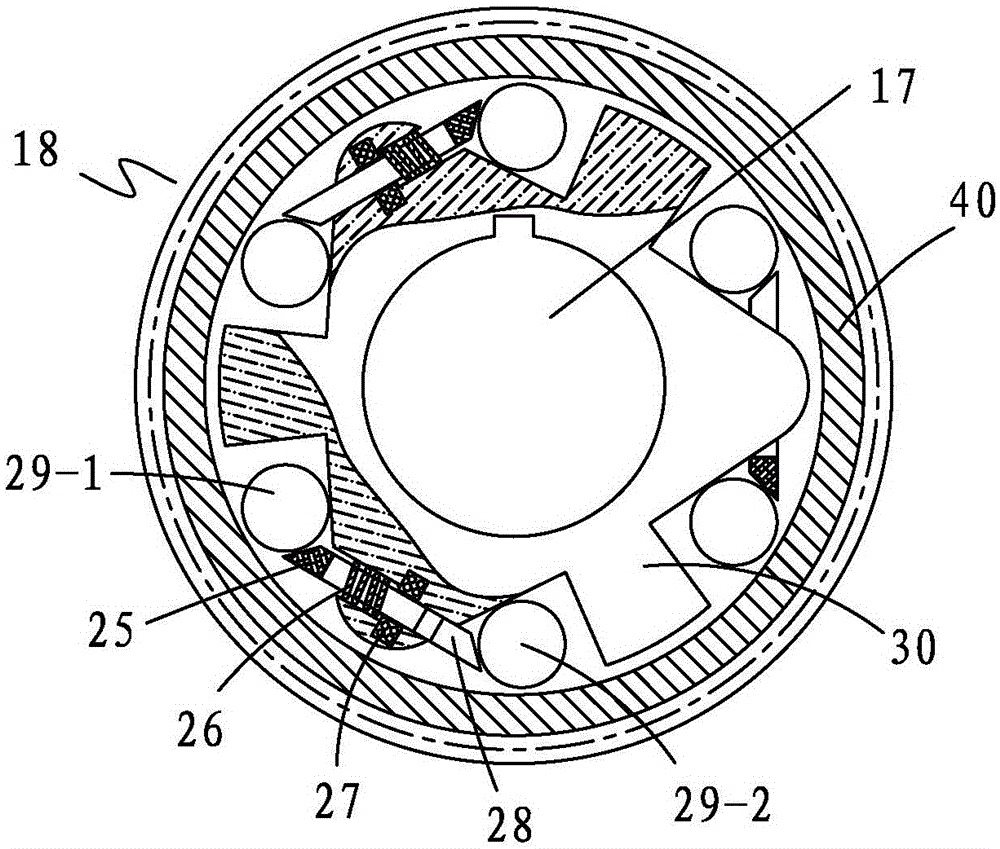

Manual and electric integrated rotating disc for automobile seat and rotating method of manual and electric integrated rotating disc

ActiveCN113895322ARealize modificationGood versatility with manual and electricMovable seatsCar seatEngineering

The invention relates to a manual and electric integrated rotating disc for an automobile seat and a rotating method of the manual and electric integrated rotating disc. The integrated rotating disc comprises a chassis, a rotating disc body, a pressing disc, an upper holder and a lower holder and further comprises one of an electric driving device and a manual driving device, the pressing disc is fixedly connected with the chassis, and the pressing disc is used for pressing the rotating disc body on the chassis; the rotating disc body and the chassis are in rotating fit through the lower holder, and the rotating disc body and the pressing disc are in rotating fit through the upper holder; and the electric driving device or the manual driving device is connected with the chassis and the rotating disc body and is used for driving the rotating disc body to rotate relative to the chassis. When the integrated rotating disc is used as an electric rotating disc, an electric driving device is selected to be installed, when the integrated rotating disc is used as a manual rotating disc, a manual driving device is selected to be installed, the manual and electric universality is good, and modification between manual operation and electric operation can be achieved through slight modification.

Owner:ZHEJIANG LONGSHENG AUTO PARTS TECH CO LTD

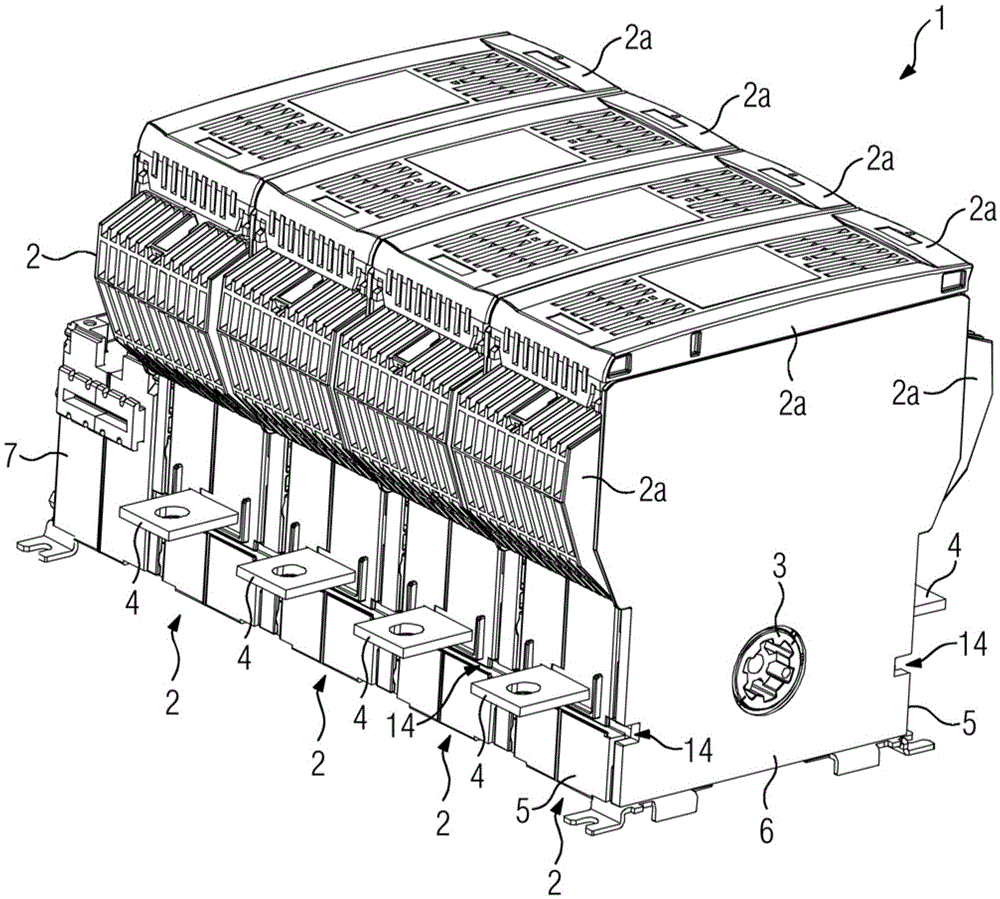

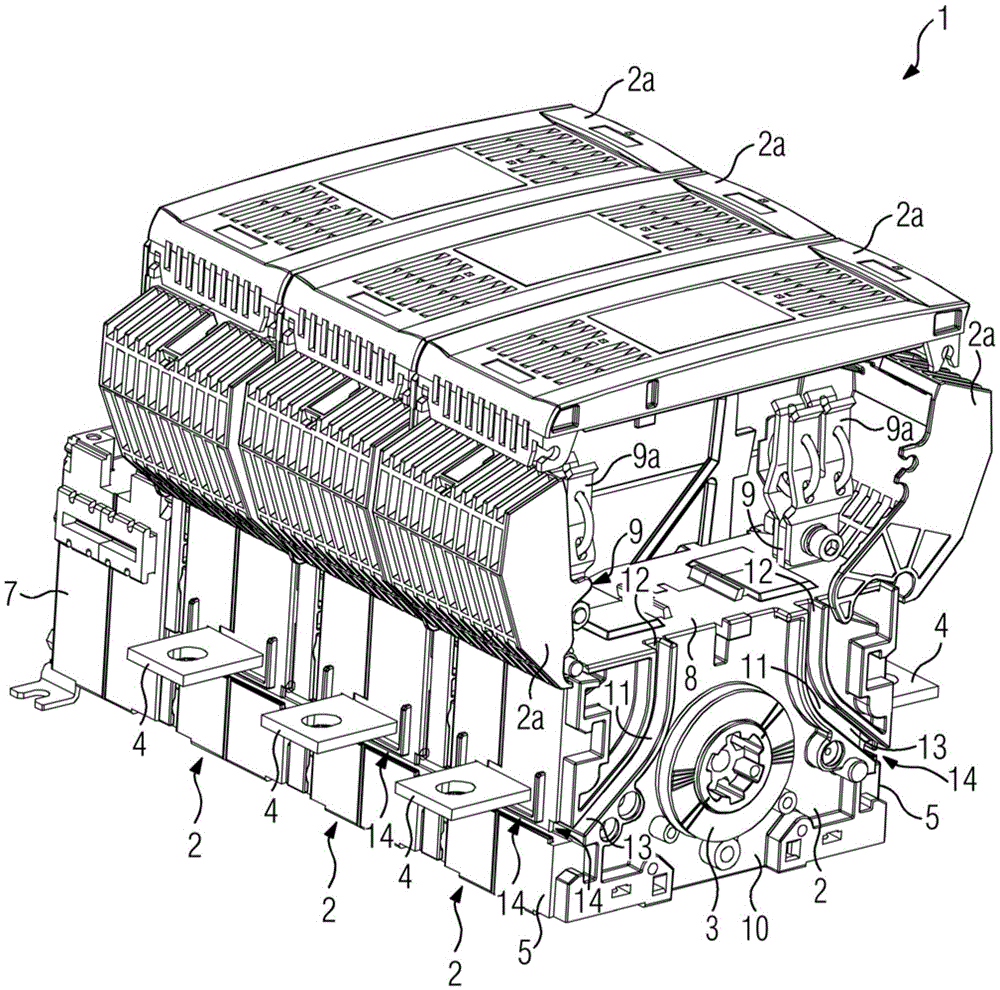

Multipole switch formed from multiple pole housings

ActiveCN105990046ARealize modificationAvoid contactProtective switch detailsElectric switchesEngineeringElectrical and Electronics engineering

The present invention relates to a multipole switch (1) having a plurality of pole housings (2) arranged laterally side by side, the switch comprising a switching shaft (3) for separating switching contacts arranged in the pole housings (2); two first terminal elements (4) which are respectively led outwards on two opposite first side surfaces (5) through the pole housings (2); and two second terminal elements (9) which are respectively led outwards on one of two opposite second side surfaces (8) through the pole housings (2) and contact there with contacts of an electric fuse. To implement refitting of electric wires so as to monitor the fuse, prevent contact with charged components and maintain a necessary dielectric distance, an electric wire channel (11) open at two end portions (12, 13) is arranged on a side wall (10) of each pole housing (2), wherein one end portion (12) is arranged in a region of the terminal element (9), the other end portion (13) is crossed with one of the two first side surfaces (5), and electric wires which can be connected to the contacts of the fuse can be led outwards through the electric wire channel (11).

Owner:SIEMENS AG

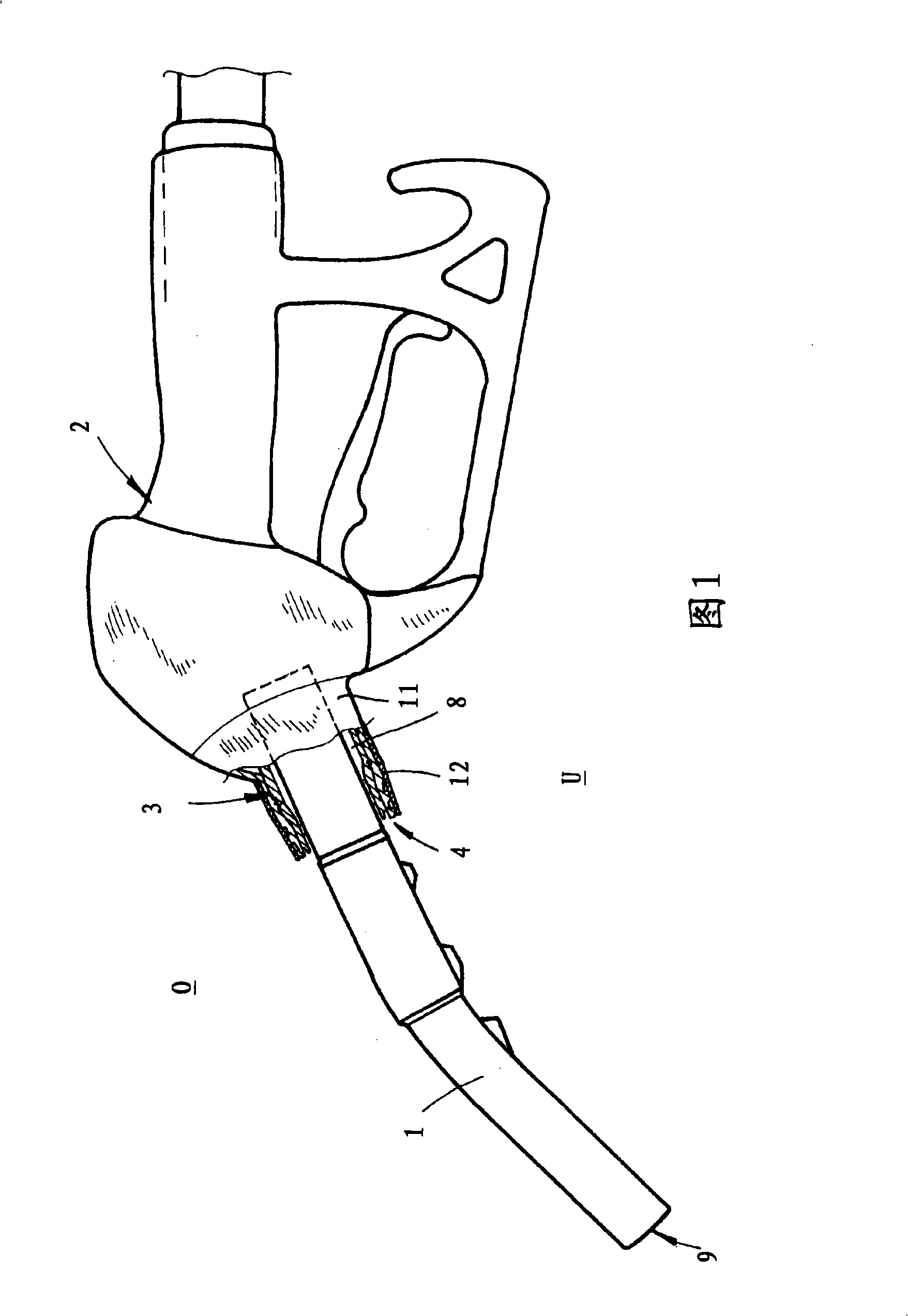

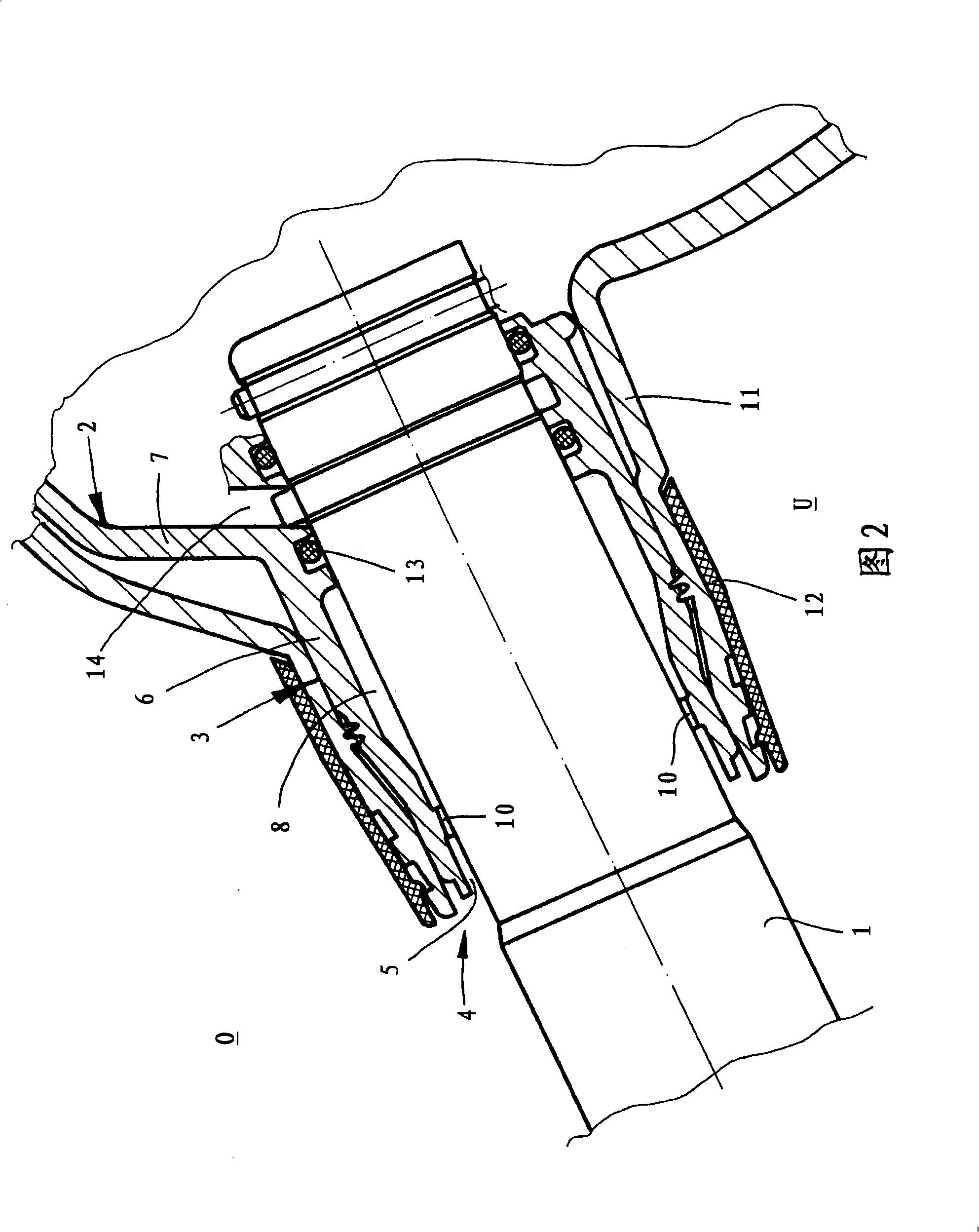

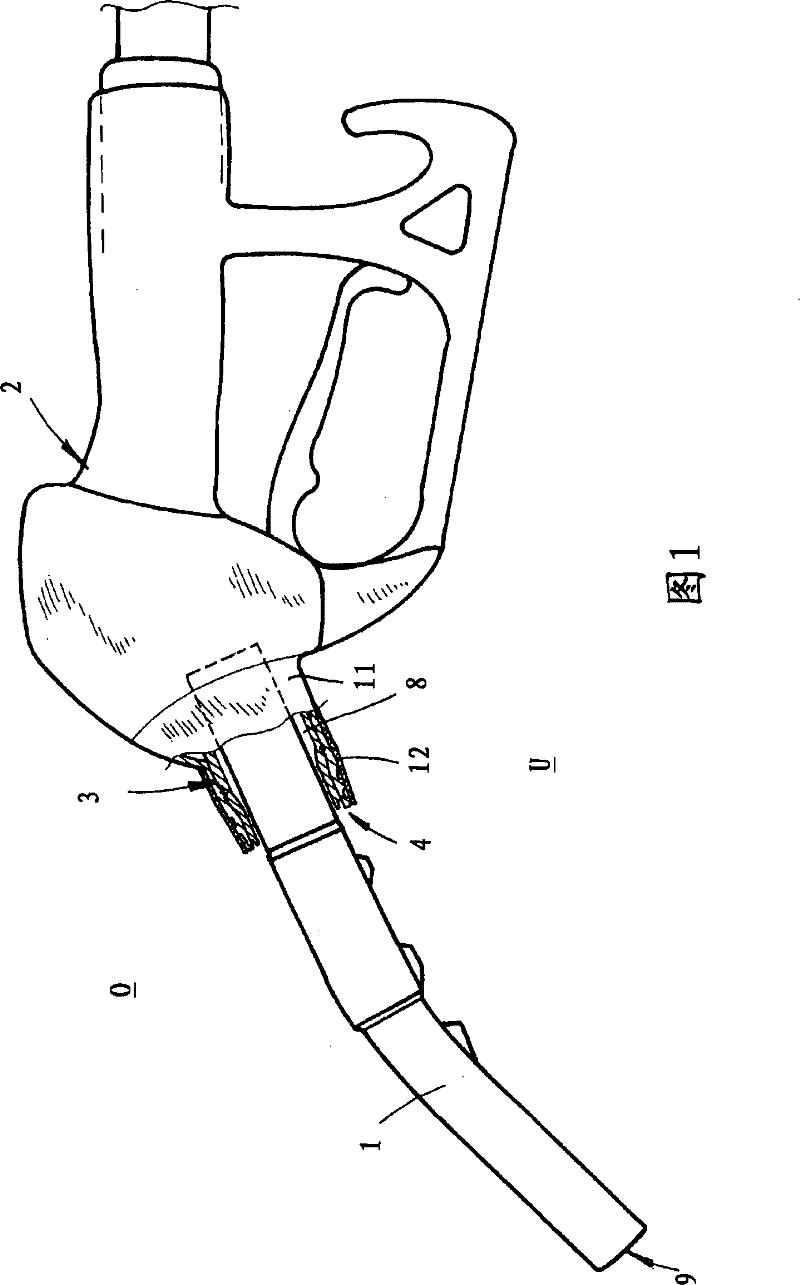

Automatic fuel nozzle

ActiveCN101353150ASimple and effortless replacementRealize modificationWork holdersLiquid transferring devicesAutomatic balancing valvesPetroleum engineering

The invention relates to an automatic oiling valve of fuel output tube of oil station column for supplying diesel fuel, comprising an oiling tube, a casing with casing connection tube and a circumfluence oil drop collector with a circumfluence groove, wherein the oiling tube is embedded into the casing connection tube, the circumfluence oil drop collector is assembled into the casing connection tube, and the circumfluence groove of the circumfluence oil drop collector is connected to one holding cavity of the circumfluence groove in the casing connection tube or casing.

Owner:凯.埃勒斯 +2

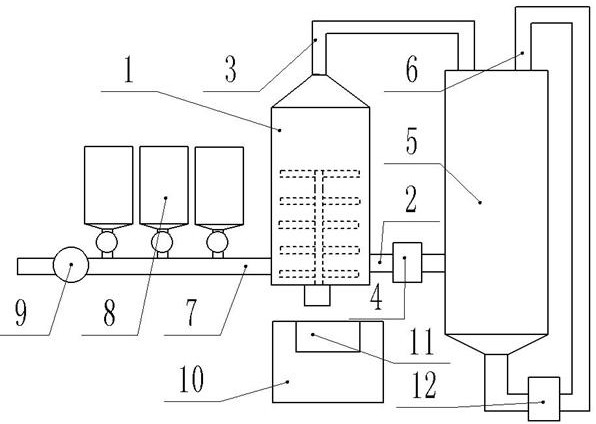

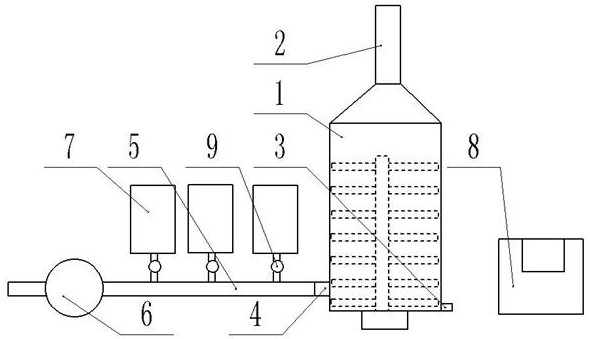

Silicon carbide micro-powder grinding system and using method thereof

The invention discloses a silicon carbide micro-powder grinding system and a using method thereof, and belongs to the technical field of smashing machinery. The silicon carbide micro-powder grinding system comprises a storage box, a feeding pipe is arranged on the side wall of the lower end of the storage box, and a first feeding pump is installed on the feeding pipe; the feeding pipe is connected with a grinding mechanism, and a discharging pipe is arranged between the upper end of the grinding mechanism and the upper end of the storage box for connection; the lower end of the grinding mechanism is connected with an air inlet pipe, a fan is installed on the air inlet pipe, a plurality of medium storage tanks are installed on the air inlet pipe between the fan and the grinding mechanism in parallel, and the different medium storage tanks are used for storing silicon carbide media with different particle sizes; and a control box is arranged on one side of the grinding mechanism, the control box is connected with a control panel, and the control box is electrically connected with the first feeding pump, the grinding mechanism and the fan.

Owner:潍坊凯华碳化硅微粉有限公司

Preparation method for anti-ultraviolet polyacrylonitrile nanofiber membrane

The invention relates to a preparation method for an anti-ultraviolet polyacrylonitrile nanofiber membrane. The preparation method comprises the following steps of: (1) preparing a polyacrylonitrile spinning solution, and performing electrostatic spinning to obtain the polyacrylonitrile nanofiber membrane; (2) preparing a graphene oxide spreading solution; spreading the graphene oxide spreading solution on a water surface to obtain single-molecular-layer graphene oxide; and performing compression obstacle-slip to obtain a graphene oxide film; (3) utilizing a LB technology, and transferring the graphene oxide film on a water surface onto the polyacrylonitrile nanofiber membrane through a membrane drawing machine; and (4) preparing the anti-ultraviolet polyacrylonitrile nanofiber membrane through the LB technology. The preparation method is simple to operate, is gentle in reaction condition, is non-poisonous and pollution-free, can be widely applied to the fields such as biological medicines, environmental friendliness and cosmetics, and has a very good practical value and potential value.

Owner:DONGHUA UNIV

Preparation method of cellulose-modified modified nano-iron particles

ActiveCN104785793BFacilitate adaptation to in situ and heterotopic repairSimple processWater/sewage treatmentNitrateNanoscale iron particles

The invention discloses a method for modifying nano iron particles on the surface of cellulose. The invention uses two kinds of environment-friendly, non-toxic, harmless cellulose as dispersants, and in the preparation process of the nano iron particles, the surface of the particles is surface-treated. Modified and modified, the prepared cellulose dispersant modified nano iron particles. The process of the invention is simple and easy to operate, low in cost, and has good dispersibility of the nano-iron particles, which can reduce the agglomeration of the particles in water and improve the removal efficiency of the particles to organic pollutants, dyes, pesticides, nitrates and heavy metals.

Owner:KUNMING UNIV OF SCI & TECH

Electric power assisted wheel

The invention discloses an electric power assisted wheel which comprises a wheel body. The wheel body comprises a tire, a rim and side plates, the inner side of the tire closely fits the rim, and gears are distributed on the inner periphery of the rim. The side plates are distributed on two inner sides of the rim, the inner periphery of each side plate is in a three-petal flower shape while the outer periphery of each side plate is circular, a first fixed pulley, a second fixed pulley and a brushless motor are connected between the two side plates through bolts, and tooth structures meshed with the gears on the inner periphery of the rim are uniformly distributed in grooves of the first fixed pulley, the second fixed pulley and the brushless motor. A battery storage cavity with a cover isformed between the two side plates between the second fixed pulley and the brushless motor, and a damping device is arranged in each side plate and comprises a damping rod, a damping rod outer sleeveand a connection plate, a rotating shaft at the upper end of each damping rod outer sleeve is connected with a connection plate, and two parallel retaining plates are vertically arranged on each connection plate. The electric power assisted wheel has advantages of quickness in mounting, convenience, flexibility and wide suitability.

Owner:KAIFENG UNIV

Silicon carbide micro-powder grinding device and using method thereof

The invention discloses a silicon carbide micro-powder grinding device and a using method thereof, and belongs to the technical field of silicon carbide micro-powder production. The silicon carbide micro-powder grinding device comprises a grinding tank, a stirring shaft is installed in the grinding tank, a plurality of evenly-distributed stirring blades are installed on the stirring shaft, one end of the stirring shaft penetrates through the grinding tank to be connected with a driving motor, and a material port for feeding and discharging materials is formed in the upper portion of the grinding tank; a discharging port is formed in the bottom of the grinding tank, a feeding port is formed in the position, close to the discharging port, of the side wall of the grinding tank, the feeding port is connected with a material channel pipe, and a fan used for screening silicon carbide micro-powder is installed on the material channel pipe; a plurality of medium storage tanks are connected to the portion, between the fan and the grinding tank, of the material channel pipe in parallel, and silicon carbide media with different particle sizes are stored in the different medium storage tanks; and a control box is installed on one side of the grinding tank, and a control panel is installed on the control box.

Owner:潍坊凯华碳化硅微粉有限公司

An unmanned auxiliary driving system for an external road roller

ActiveCN113512924BRealize modificationReduce workloadRoads maintainenceElectric/fluid circuitDriver/operatorVibration control

The present invention is an unmanned assisted driving system for an external road roller. The output terminals of the sensors are all connected to the on-board data box; the on-board data box is connected to the auxiliary controller; the steering wheel of the cab is connected to the steering hydraulic mechanical arm through the first transition part, and the gear position of the cab is connected to the gear hydraulic pressure arm through the second transition part. Mechanical arm; the chassis is equipped with a vehicle-mounted data box and an auxiliary controller, and the auxiliary controller is electrically connected to the control switch, the steering hydraulic mechanical arm, the gear hydraulic mechanical arm, and the front and rear millimeter-wave radars; the control switch is connected in parallel On the vibration switch of the vibration control circuit of the manned road roller. Aiming at the unmanned shortcut modification of the ordinary road roller driven by the driver, the unmanned driving of the ordinary road roller is realized.

Owner:HEBEI UNIV OF TECH

A method for basic n regulation of metal valence in carbide metal organic frameworks

ActiveCN107876093BEfficient CatalysisIncrease reaction rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPtru catalystMetal-organic framework

The invention discloses a method for regulating the valence state of metals in carbonized metal-organic framework materials with basic N. First add 5~10wt.% alkaline nitrogen source into the copper acetate solution, use 500~1000W frequency ultrasonic field radiation to coordinate the N group with Cu in the solution, and then add the trimesic acid solution dropwise to continue the reaction. 1 to 3 hours to obtain the nitrogen-modified N‑MOF precursor material; then place the N‑MOF in a high-temperature tube furnace, heat it to 600 to 800°C in a nitrogen atmosphere and keep it for 4 to 6 hours to obtain Cu / CuO x / C(x<1) component is the main CN‑MOF catalyst. The basic nitrogen source used in the present invention has a basicity coefficient (pKb) in the range of 3 to 9. The high-energy cavitation generated by ultrasound is used to bond the basic nitrogen and copper elements, thereby regulating the metal in the metal oxide generated after carbonization. valence state, ultimately improving the activity and service life of the resulting catalyst.

Owner:GUANGXI UNIV

Brake-energy recycling system for electric vehicle

InactiveCN104999908ASmooth transmissionRealize collection and storageBraking action transmissionControl devicesGear wheelMechanical energy

The invention provides a brake-energy recycling system for an electric vehicle. The brake-energy recycling system comprises a planetary gear mechanism, an energy storage mechanism, a double-rack frame, a gear fixing rack and an auxiliary gear, wherein a two-way overrunning clutch is arranged in the planetary gear mechanism; one end part of the double-rack frame is connected to the energy storage mechanism; the planetary gear mechanism is meshed with the auxiliary gear; a lower rack and an upper rack are arranged in the double-rack frame; the upper rack is meshed with the auxiliary gear; the lower rack is meshed with the planetary gear mechanism; the gear fixing rack is used for fixing the planetary gear mechanism and the auxiliary gear to the electric vehicle, so that the mechanical energy can be sufficiently recycled.

Owner:FUJIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com