Method and device for upgrading heavy oil raw materials by utilizing liquid-phase discharge in-situ hydrogenation

A liquid-phase discharge, in-situ hydrogenation technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes of applied energy, hydrocarbon oil cracking, etc. It can improve the discharge efficiency of the liquid phase, reduce the breakdown voltage and simplify the reaction device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

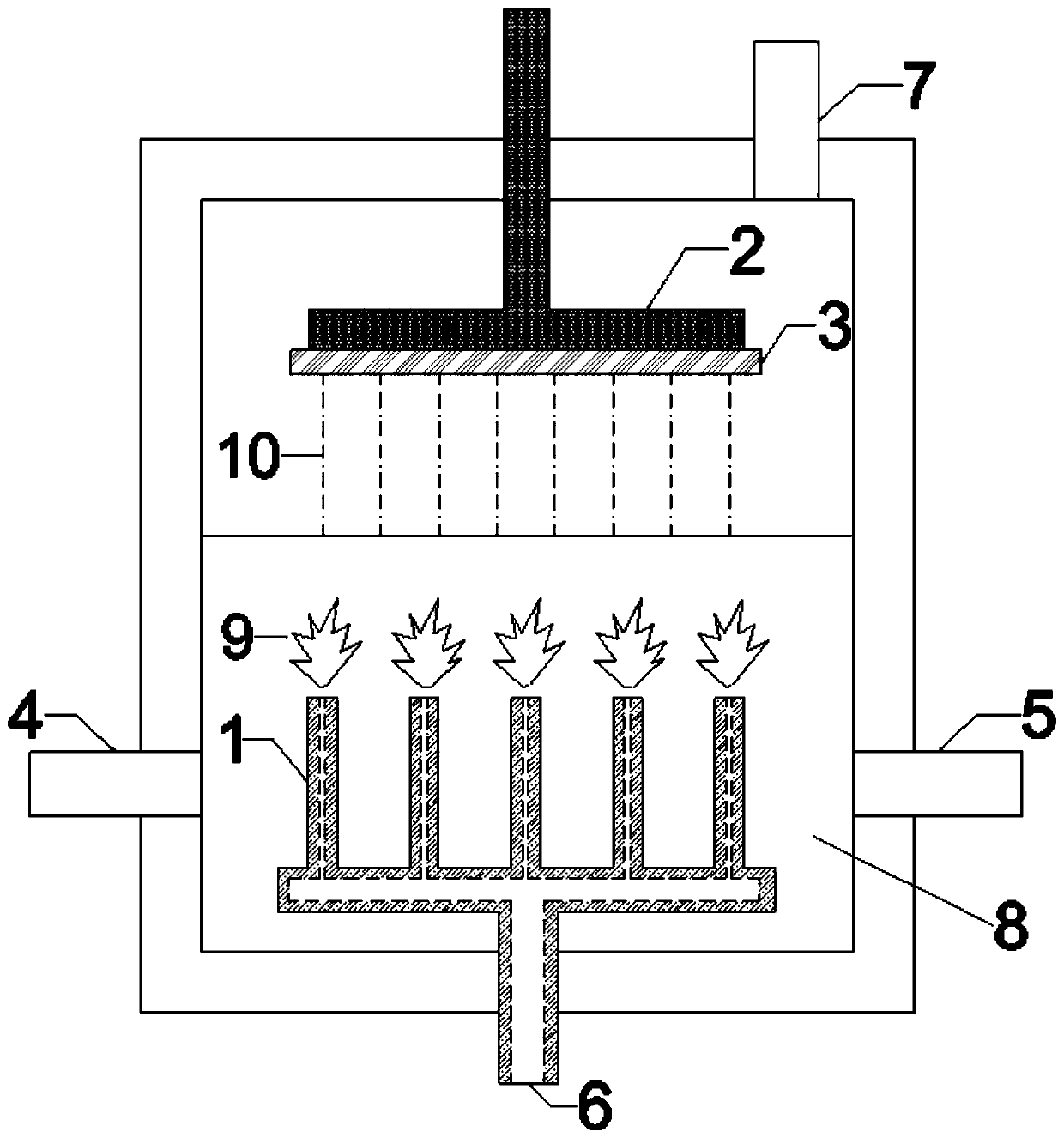

[0053] refer to figure 1 , using a corona-dielectric barrier mixed discharge device for in-situ hydrogenation and upgrading of heavy oil raw materials for reaction, including a high-voltage electrode 1, a ground electrode 2, an insulating medium layer 3, a material inlet 4, a material outlet 5, and a liquid inlet The air inlet 6 and the air outlet 7, the high-voltage electrode 1 is a multi-hollow needle electrode, and the ground electrode 2 is a plate electrode. The heavy oil raw material enters the liquid phase reactor through the feed port 4, the heavy oil raw material is immersed in the high voltage electrode 1, the hydrogen production raw material is passed into the heavy oil raw material through the hollow needle electrode, and the gaseous product after the hydrogenation and modification of the heavy oil raw material is discharged from the gas outlet 7 for collection After being collected, the modified gas product is obtained; the remaining liquid in the liquid phase reac...

Embodiment 2

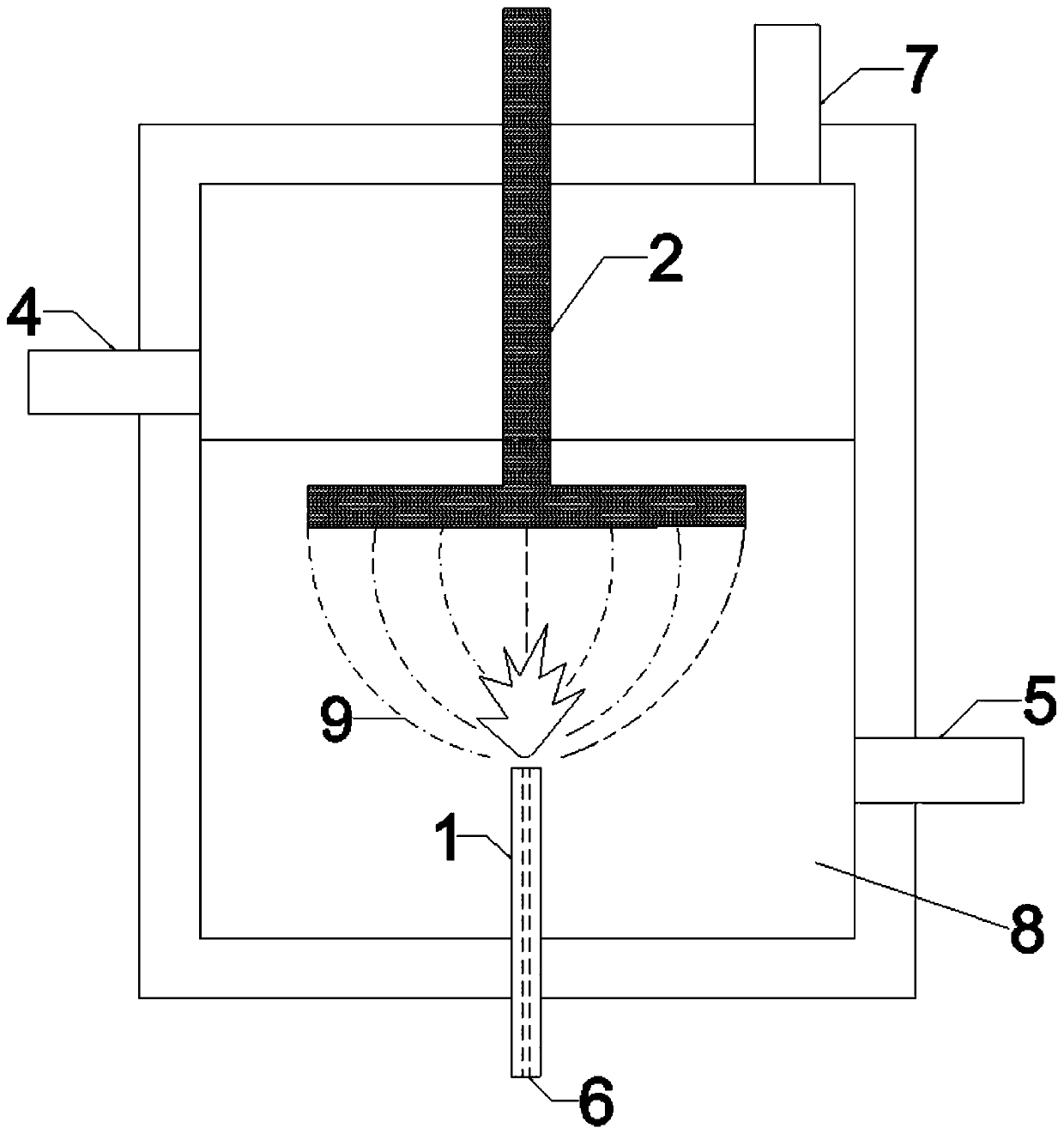

[0057] refer to figure 2 , the liquid phase reactor includes a high-voltage electrode 1, a ground electrode 2, a feed port 4, a discharge port 5, a liquid inlet port 6, and a gas outlet port 7. The high-voltage electrode 1 is a single hollow needle electrode, and the ground electrode 2 is a plate electrode. . The heavy oil raw material enters the liquid-phase reactor through the feed inlet 4, and the hydrogen-producing raw material is passed into the heavy oil raw material through the hollow needle electrode. The final gaseous product; the remaining liquid in the liquid phase reactor is discharged and collected through the discharge port 5 to obtain a liquid product after hydrogenation and upgrading of the heavy oil raw material. Both the high-voltage electrode 1 and the ground electrode 2 are immersed in the liquid-phase heavy oil to form corona discharge, critical spark discharge, complete spark discharge, arc discharge and other forms.

[0058] The heavy hydrocarbons of n-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com