Brake-energy recycling system for electric vehicle

A braking energy recovery and electric vehicle technology, applied in the direction of brakes, braking transmission devices, control devices, etc., can solve the problems of insufficient stability of the technology and high initial energy requirements, and achieve simple and easy layout, effective and stable transmission, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

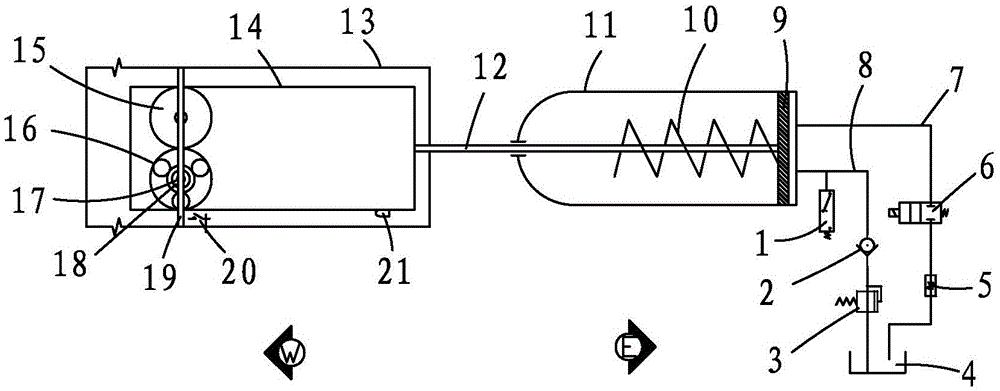

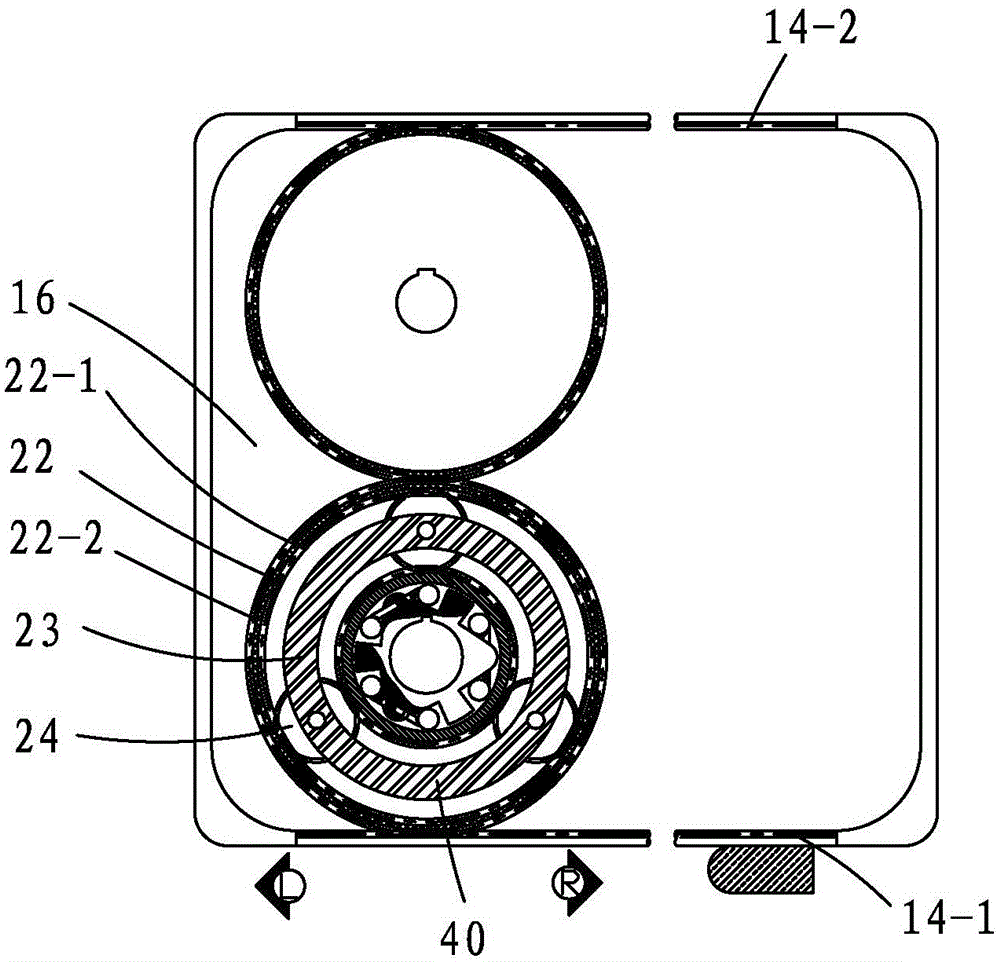

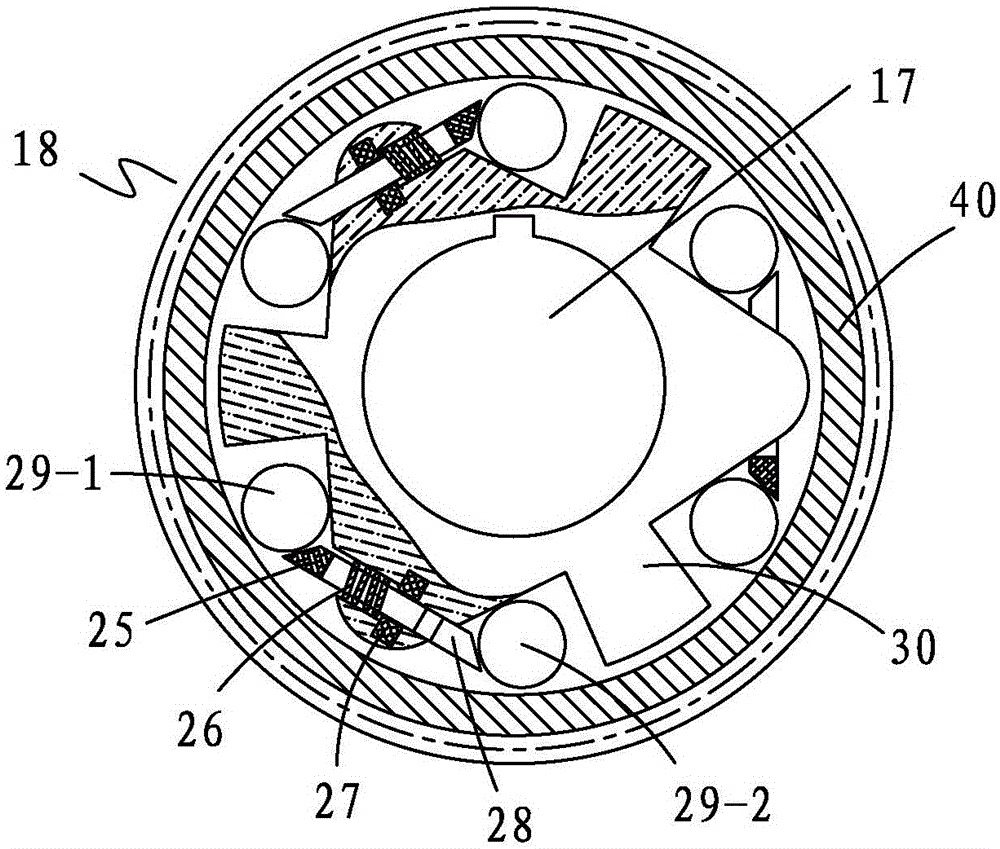

[0028] A kind of specific implementation mode of the present invention is as follows:

[0029] Such as Figures 1 to 5 As shown, its connection mode is: the two-way overrunning clutch 18 is connected with the drive shaft 17 of the vehicle drive wheel through a flat key, and the two-way overrunning clutch 18 is connected to the inner hole of the sun gear 40 of the planetary gear mechanism 16, and the sun gear 17 of the planetary gear mechanism 16 The wheel 40 is connected to the planetary gear 24 and then connected to the ring gear 22 internal teeth 22-1, and the ring gear internal teeth 22-1 and the ring gear external teeth 22-2 of the planetary gear mechanism 16 are respectively fixed on the inner ring of the ring gear 22 and the outer ring, the upper side of the ring gear outer teeth 22-2 is connected to the auxiliary gear 15 outer teeth, and the other lower side is connected to the lower rack 14-1 of the double rack frame 14, and the auxiliary gear 15 outer teeth are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com