Furnace-inside modification method of furnace gas in Hismelt smelting reduction furnace and smelting reduction furnace thereof

A reduction furnace and furnace gas technology, applied in the field of Hismelt smelting reduction, can solve the problems of low calorific value of the pre-reduction tail gas, reduce the productivity of the reduction furnace, and be difficult to use economically, so as to achieve economical and high-efficiency utilization, and improve the reduction capacity. , Improve the effect of pre-reduction degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

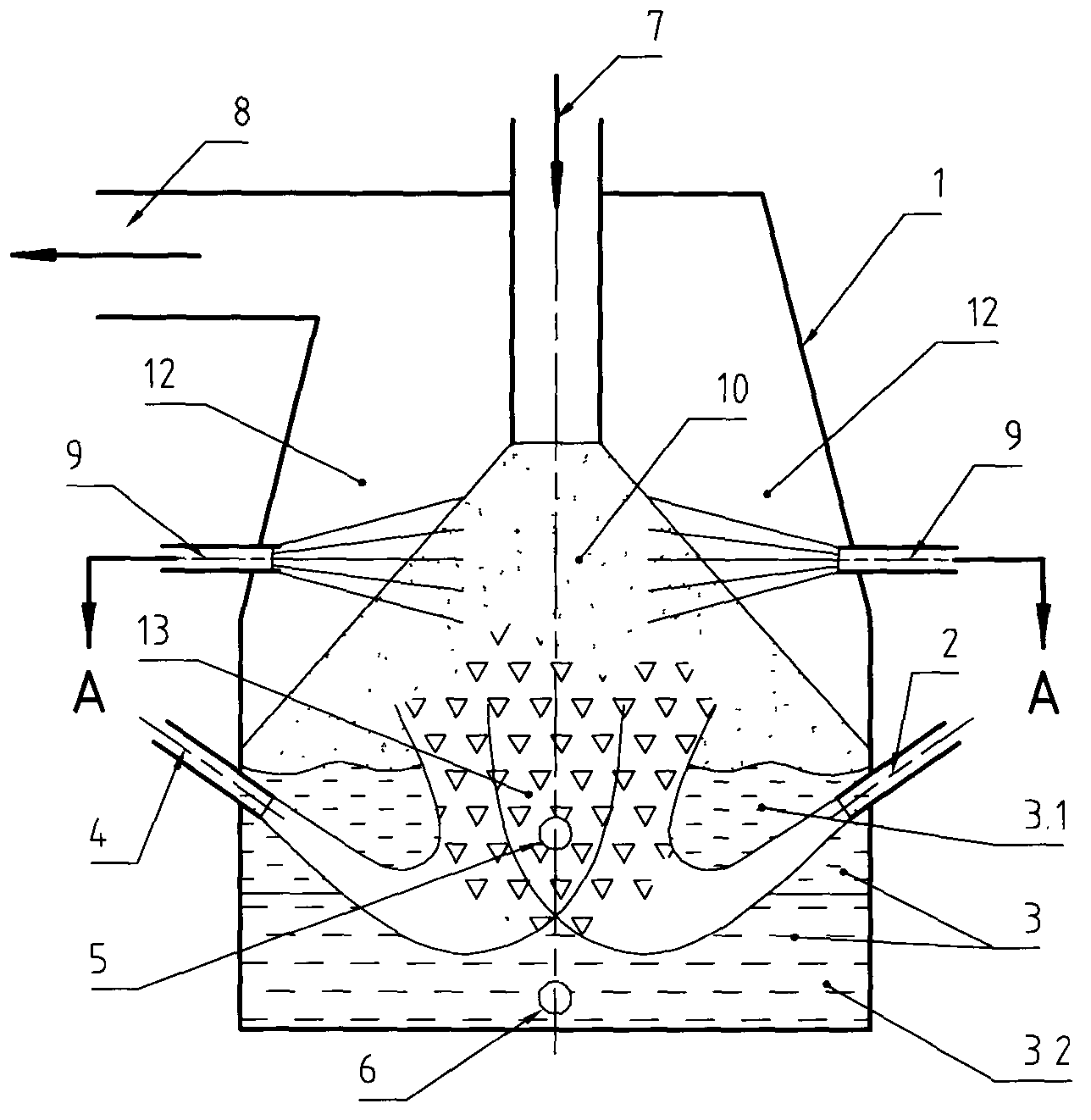

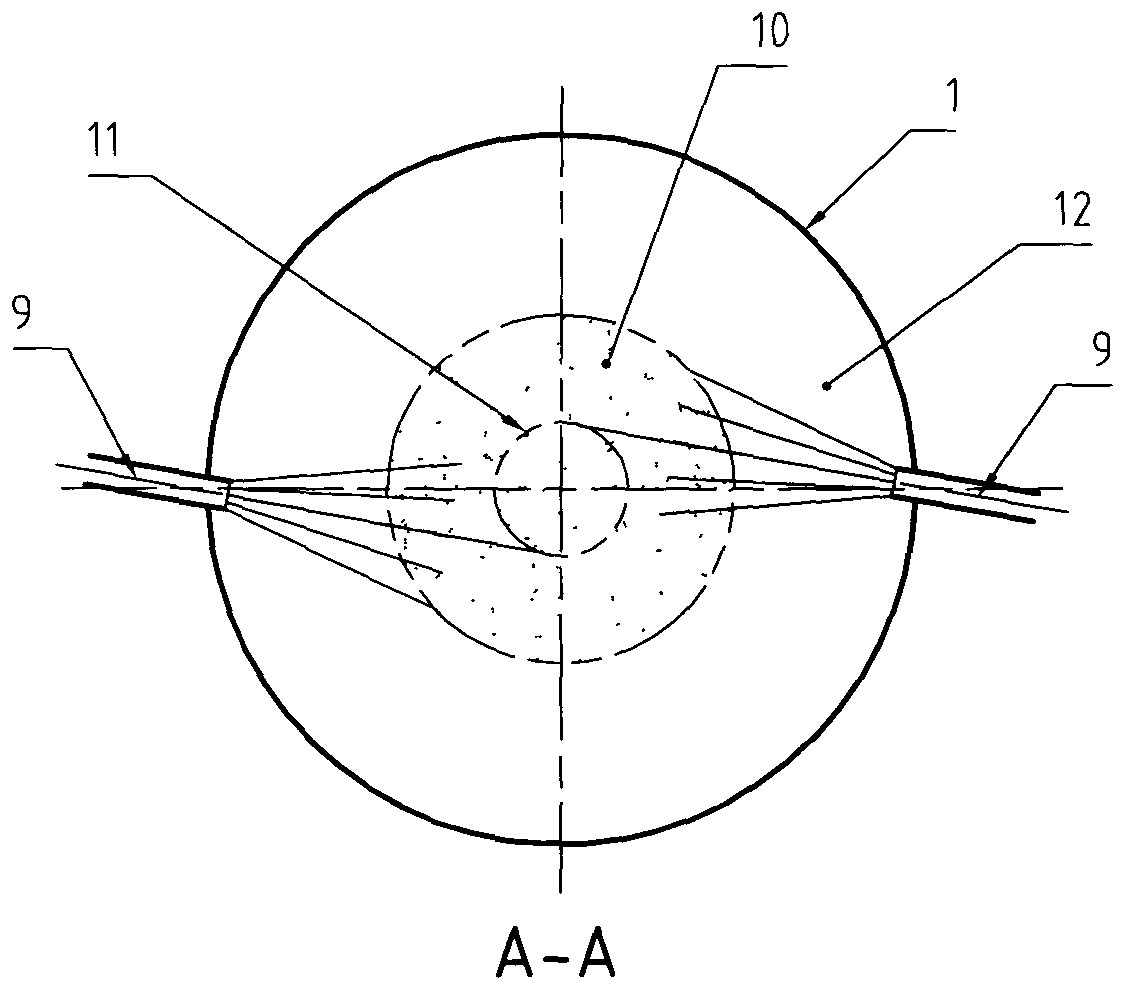

[0028] Example 1, such as figure 1 with figure 2 shown.

[0029] exist figure 1 with figure 2 Among them, 1 represents the furnace shell and cooling wall of the smelting reduction furnace. 2 indicates the entrance of coal for smelting, which sprays coal into the molten pool 3 by blowing, and vigorously stirs the molten pool 3; in the molten pool 3, it includes the violently stirred slag layer 3.1 and molten iron Layer 3.2.4 is the entrance of the iron-containing raw material, which also sprays the iron-containing raw material into the molten pool 3 by means of blowing, and vigorously stirs the molten pool 3. 5 represents the slag outlet. 6 represents the tap hole. 7 represents the entrance of combustion-supporting gas. 8 represents the outlet of furnace gas. 9 denotes a spray gun for spraying pulverized coal into the space above the slag layer in the smelting reduction furnace. 10 represents the approximate range of the secondary combustion zone in the smelting redu...

Embodiment 2

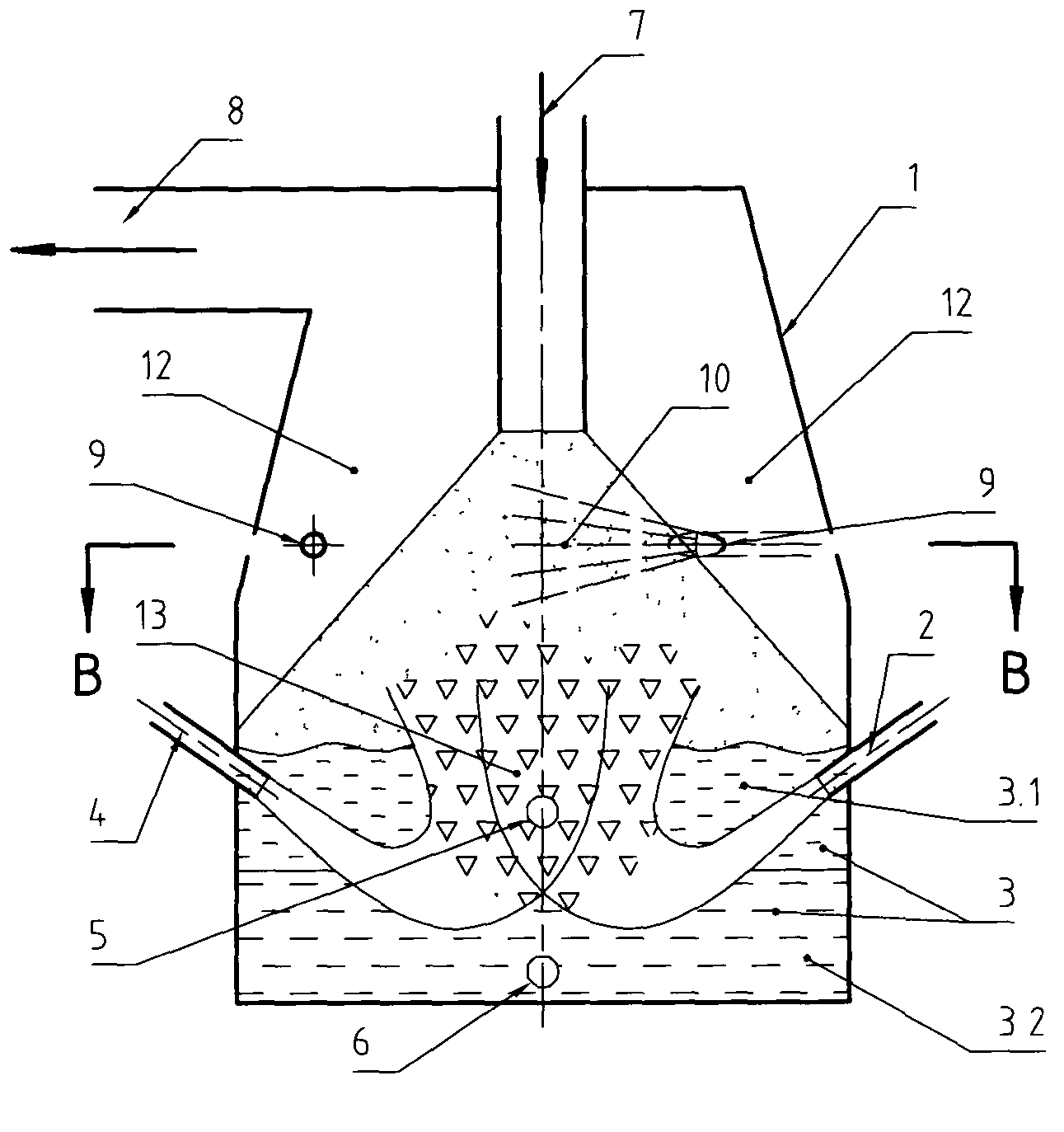

[0032] Example 2, such as image 3 with Figure 4 shown.

[0033] This embodiment has been changed on the basis of Embodiment 1: the spray gun 9 is moved up moderately, so that the pulverized coal spray gun 9 faces the non-combustion zone 12 of the furnace gas, and the size of the base circle 11 is adjusted, as a pulverized coal The standard of the spray gun 9 tangential configuration; at the same time, the quantity of the spray gun 9 is increased from 2 to 4 and so on. In fact, there may be more or less options for selecting the number of spray guns, so details will not be repeated here.

[0034] For the rest, refer to the relevant description of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com