Catalyst for photocatalytic hydrogen production, and preparation method and application thereof

A catalyst and photocatalysis technology, applied in the direction of physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, chemical instruments and methods, etc., can solve problems such as poor photostability and easy photocorrosion, and achieve Large hydrogen production, improved stability, carrier splitting efficiency, and high hydrogen evolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

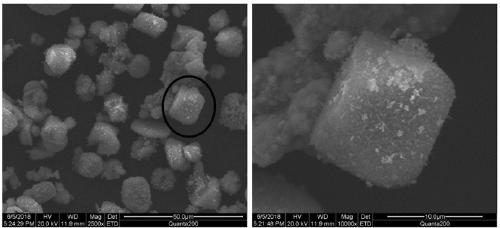

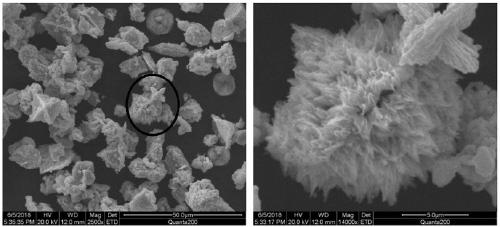

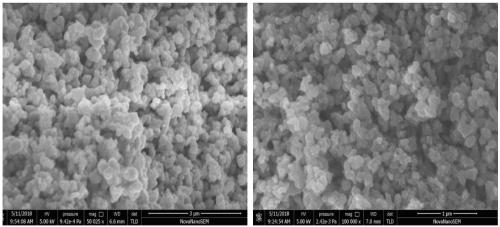

Image

Examples

Embodiment 1

[0040] (1) Synthesis of HKUST-1

[0041] 0.436g Cu(NO 3 ) 2 ·3H 2 O and 0.210g 1,3,5-benzenetricarboxylic acid are added in the mixed solvent (volume ratio is 1:1) of 12mL water / ethanol, stirred and reacted for 15 minutes, then the reaction solution is packed in the stainless steel reactor of 25mL, in The reaction was heated at 180° C. for 12 hours, and then naturally cooled to room temperature. The resulting cyan-blue precipitate HKUST-1 was separated by centrifugation, washed four times with deionized water, DMF and ethanol, respectively, and dried overnight at 65 °C.

[0042] (2) Preparation of catalyst

[0043] Firstly, HKUST-1 was exposed to argon atmosphere at 5°C min -1 The heating rate was increased to 300°C, 350°C, 400°C, 450°C and 500°C to heat it, then the argon flow was turned off, and HKUST-1 was exposed to the air, and kept under the corresponding heating temperature conditions for 1 hour respectively. The photocatalysts synthesized by heating at 300 °C, 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com