Active mixed metal oxide loading silver modifying iron-based metallic oxide arsenic removal micro-nano adsorbent and preparation method thereof

A composite metal and oxide technology, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problems of insufficient load firmness, complicated preparation process, and unenvironmental protection of the process, and achieve infinite adsorption rate The effects of secondary pollution, simple process, and fast adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

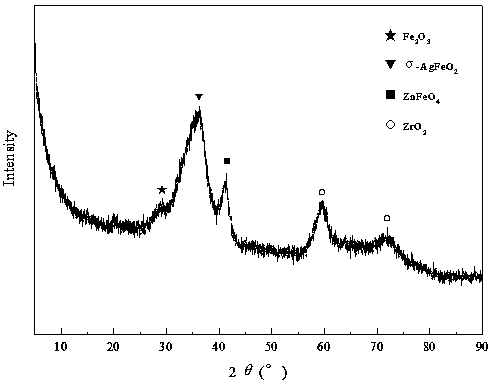

[0034] 1.0 M AgNO 3 solution, 1.0 M Fe(NO 3 ) 3 solution, 1.0 M Zn(NO 3 ) 2 solution and 0.25 M Zr(NO 3 ) 4 The solution is in a certain ratio of substances ( n (Ag) / n (Fe) / n (Zn) / n (Zr)= 0.1:0.2:0.5:1) to prepare mixed metal salt solution. Then, hydrothermal reaction was carried out at 150 °C for 6 h. After natural cooling, 5 Vol% NH was added dropwise under magnetic stirring 3 ·H 2 The pH value of O solution is 7.5~8.5. After the dropwise addition, the precipitate was separated by high-speed centrifugation at a speed of 4000 rpm and a centrifugation time of 8 min. Then, it was repeatedly washed with deionized water and centrifuged until the pH value of the supernatant was neutral. Finally, dry at 110 °C for 12 h, heat up to 300 °C at a rate of 3.3 °C / min and calcinate at this temperature for 3.0 h in a still air atmosphere, and cool naturally with the furnace to prepare the adsorbent material. The removal rate and adsorption capacity of arsenic in water wer...

Embodiment 2

[0040] 1.0 M AgNO 3 solution, 1.0 M Fe(NO 3 ) 3 solution, 1.0 M Zn(NO 3 ) 2 solution and 0.25 M Zr(NO 3 ) 4 The solution is in a certain ratio of substances ( n (Ag) / n (Fe) / n (Zn) / n (Zr)= 0.2:0.4:0.5:1) to prepare mixed metal salt solution. Then, hydrothermal reaction was carried out at 150 °C for 6 h. After natural cooling, 5 Vol% NH was added dropwise under magnetic stirring 3 ·H 2 The pH value of O solution is 7.5~8.5. After the dropwise addition, the precipitate was separated by high-speed centrifugation at a speed of 4000 rpm and a centrifugation time of 8 min. Then, it was repeatedly washed with deionized water and centrifuged until the pH value of the supernatant was neutral. Finally, dry at 110 °C for 12 h, heat up to 300 °C at a rate of 3.3 °C / min and calcinate at this temperature for 3.0 h in a still air atmosphere, and cool naturally with the furnace to prepare the adsorbent material. The removal rate and adsorption capacity of arsenic in water wer...

Embodiment 3

[0045] 1.0 M AgNO 3 solution, 1.0 M Fe(NO 3 ) 3 solution, 1.0 M Zn(NO 3 ) 2 solution and 0.25 M Zr(NO 3 ) 4 The solution is in a certain ratio of substances ( n (Ag) / n (Fe) / n (Zn) / n (Zr)= 0.4:0.4:0.5:1) to prepare mixed metal salt solution. Then, hydrothermal reaction was carried out at 150 °C for 6 h. After natural cooling, 5 Vol% NH was added dropwise under magnetic stirring 3 ·H 2 The pH value of O solution is 7.5~8.5. After the dropwise addition, the precipitate was separated by high-speed centrifugation at a speed of 4000 rpm and a centrifugation time of 8 min. Then, it was repeatedly washed with deionized water and centrifuged until the pH value of the supernatant was neutral. Finally, dry at 110 °C for 12 h, heat up to 300 °C at a rate of 3.3 °C / min and calcinate at this temperature for 3.0 h in a still air atmosphere, and cool naturally with the furnace to prepare the adsorbent material. The removal rate and adsorption capacity of arsenic in water wer...

PUM

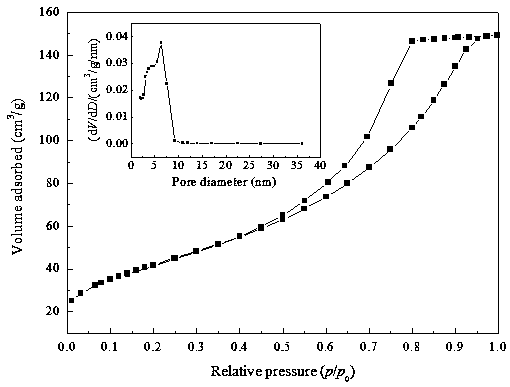

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com