Method for preparing graphene oxide monolayer modified polyacrylonitrile nanofiber membrane

A nanofiber membrane, polyacrylonitrile technology, applied in fiber processing, textiles and papermaking, non-woven fabrics and other directions, can solve the problems of low graft density of graphene oxide, unguaranteed fiber bonding strength, difficult to promote production and application, etc. Achieve the effect of good practical value and potential value, mild experimental conditions, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of polyacrylonitrile nanofiber membrane comprises the steps:

[0027] Step 1: Accurately weigh 0.4g of polyacrylonitrile powder, dissolve it in 5ml of DMF and magnetically stir in a constant temperature water bath at 60°C for 12h to obtain a transparent and homogeneous spinning solution of 0.08g / ml.

[0028] Step 2: Adjust the spinning parameters as positive voltage 7v, negative voltage -8v, spinning speed 0.5ml / h, and spinning distance 18cm.

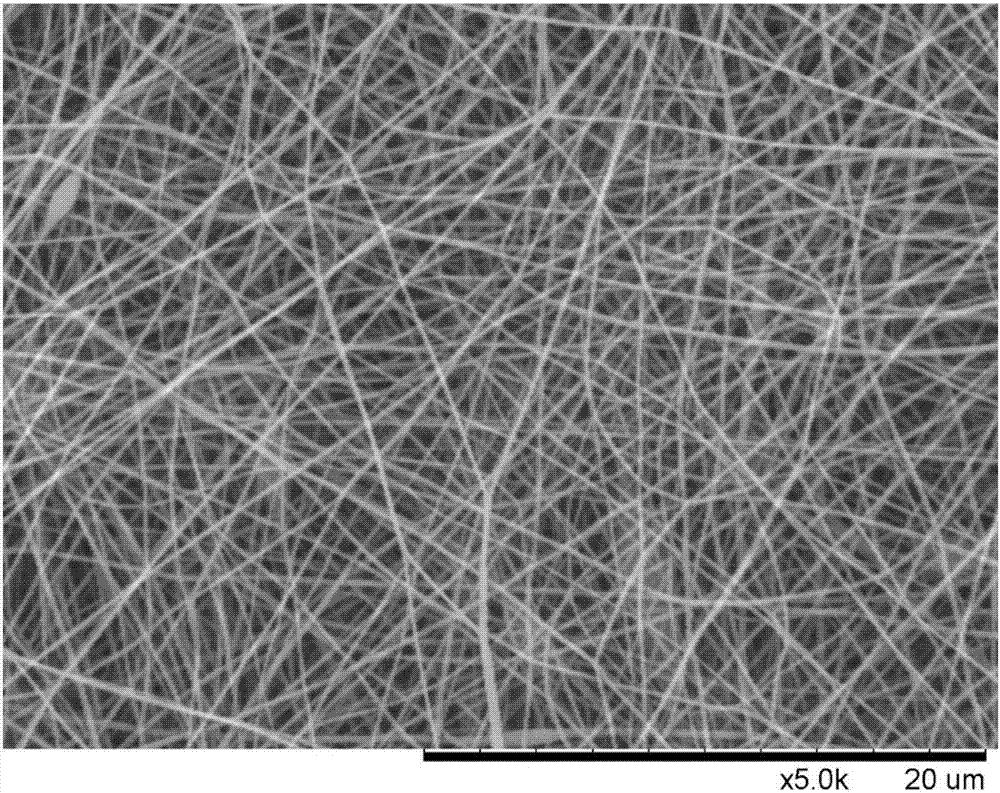

[0029] Step 3: Prepare the polyacrylonitrile nanofiber membrane by electrospinning method, then let it stand for 10 minutes, and then put it into a constant temperature drying oven at 37° C. to dry to obtain the polyacrylonitrile nanofiber membrane. figure 1 It is the SEM picture of the unmodified polyacrylonitrile nanofiber membrane.

Embodiment 2

[0031] The preparation of graphene oxide spreading solution comprises the steps:

[0032] First, 3.0 ml of a 1.0 mg / ml graphene oxide aqueous solution was prepared, then 15.0 ml of methanol was added to the above solution, and stirred for 20 min to obtain a graphene oxide spreading solution with a final concentration of 0.167 mg / ml.

Embodiment 3

[0034] The preparation of monomolecular layer graphene oxide comprises the steps:

[0035] Take 10.0ml of the above-mentioned graphene oxide spreading solution, and carefully spread it drop by drop on the water surface in the LB tank. The area of the tank is 10*20cm, and let it stand for 20 minutes. After the methanol on the water surface is completely volatilized, move the sliding barrier at a speed of 1.0cm / min, when the distance to the sliding barrier is 1cm, stop moving, stand still, and wait for the self-assembly of monomolecular layer graphene oxide film to form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com