Modified biopolymer and use thereof in 3D printing

A biopolymer and modification technology, applied in biochemical equipment and methods, microorganisms, 3D culture, etc., can solve the problem of reducing biological activity, low ink viscosity, and the inability to simultaneously solve the problem of good and accurate printing of biopolymer-based bioinks. Responsibility and other issues, to achieve the effect of high biological activity, stable performance, good viscosity and self-coagulation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

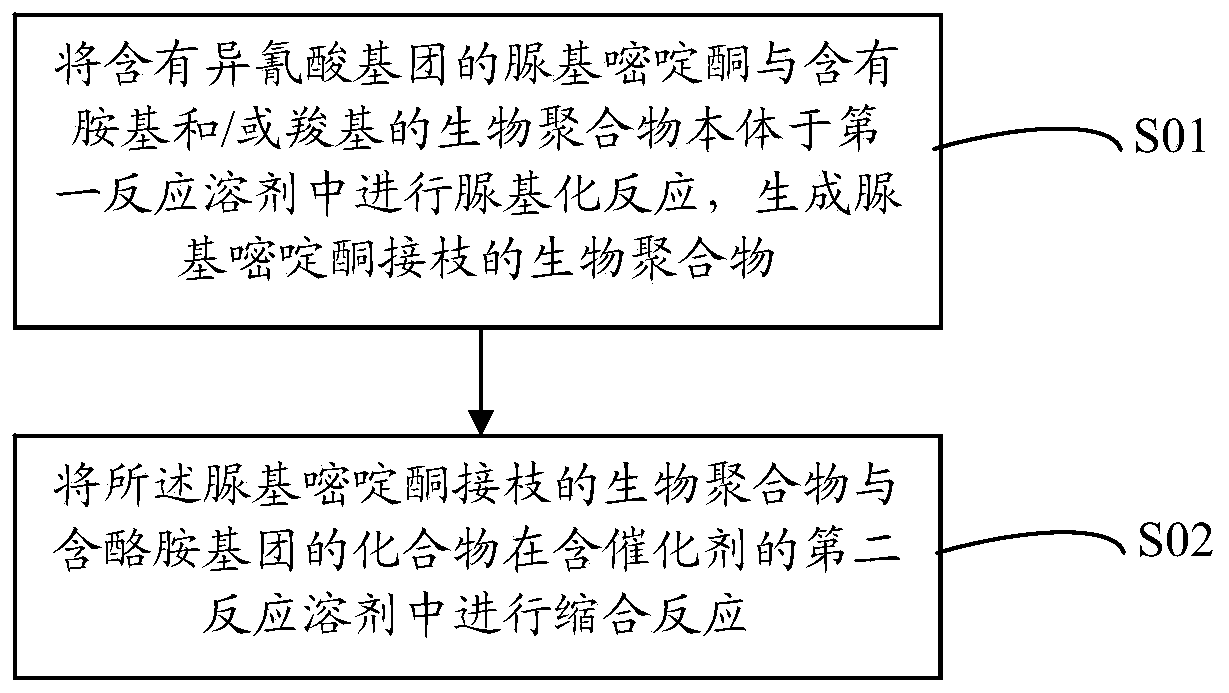

[0043] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned modified biopolymer. The technical process of the preparation method of the modified biopolymer is as figure 1 As shown, it includes the following steps:

[0044] S01: Carry out ureidation reaction between ureidopyrimidone containing isocyanate group and biopolymer body containing amine group and / or carboxyl group in the first reaction solvent to generate ureidopyrimidone grafted biopolymer ;

[0045] S02: Condensing the biopolymer grafted with ureidopyrimidone and a compound containing tyramide groups in a second reaction solvent containing a catalyst to obtain a biopolymer modified with ureidopyrimidone groups and tyramide groups Modified biopolymers.

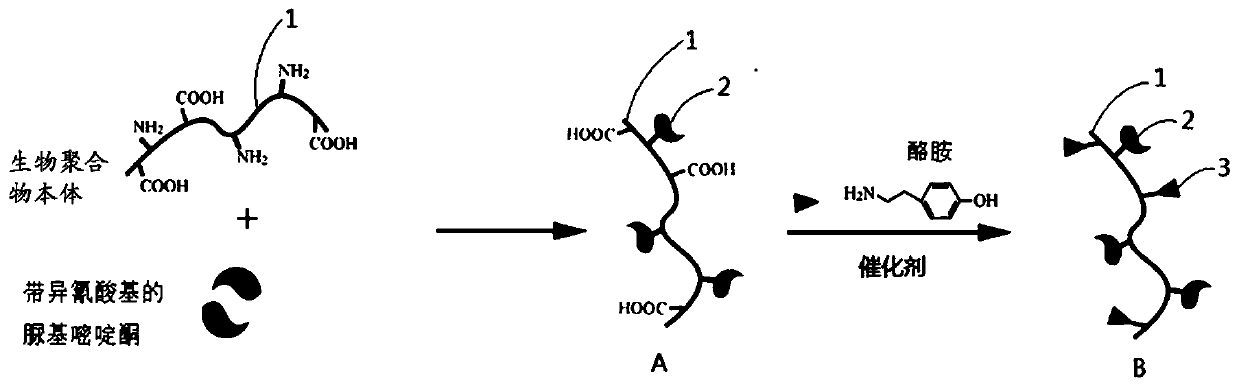

[0046] Wherein, the ureidopyrimidinone containing isocyanate group in the step S01 and the biopolymer body are carried out in the first reaction solvent for ureidation reaction formula as follows figu...

Embodiment 11

[0070] This embodiment provides a modified biopolymer and a preparation method thereof. The modified biopolymer comprises a gelatin backbone onto which ureidopyrimidone groups and tyramine groups are grafted.

[0071] The preparation method of the modified biopolymer comprises the following steps:

[0072] Step S11: Under nitrogen protection, 6 g of gelatin was dissolved in 100 mL of dimethyl sulfoxide at 55 °C by magnetic stirring, and then cooled to room temperature; 0.3 g of 2(6-isocyanatohexylaminocarbonylamino)- 6-Methyl-4[1H]pyridone was added to the gelatin solution and reacted at room temperature for 24 hours; the reacted solution was precipitated 3 times through 1 L of ethanol solution, and then vacuum-dried for 24 hours to obtain 5.1 g of light yellow fixed , which is to generate ureidopyrimidinone-grafted gelatin, and its yield is calculated to be 85%;

[0073] Step S12: Weigh 1.5 g of the light yellow solid obtained in Step S11 and dissolve it in 100 mL of deioni...

Embodiment 12

[0076] This embodiment provides a modified biopolymer and a preparation method thereof. The modified biopolymer comprises a gelatin backbone onto which ureidopyrimidone groups and tyramine groups are grafted.

[0077] The preparation method of the modified biopolymer comprises the following steps:

[0078] Step S11: Under nitrogen protection, 6 g of gelatin was dissolved in 100 mL of dimethyl sulfoxide at 55 °C by magnetic stirring, and then cooled to room temperature; 0.15 g of 2(6-isocyanatohexylaminocarbonylamino)- 6-Methyl-4[1H]pyridone was added to the gelatin solution and reacted at room temperature for 24 hours; the reacted solution was precipitated 3 times through 1 L of ethanol solution, and then vacuum-dried for 24 hours to obtain 5.1 g of light yellow fixed , which is to generate ureidopyrimidinone-grafted gelatin, and its yield is calculated to be 85%;

[0079] Step S12: Weigh 1.5 g of the light yellow solid obtained in Step S11 and dissolve it in 100 mL of deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com