Automatic fuel nozzle

An automatic refueling and refueling valve technology, applied in special distribution devices, packaging, workpiece clamping devices, etc., can solve problems such as environmental protection technology does not meet the requirements, and achieve the effect of effortless and simple replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

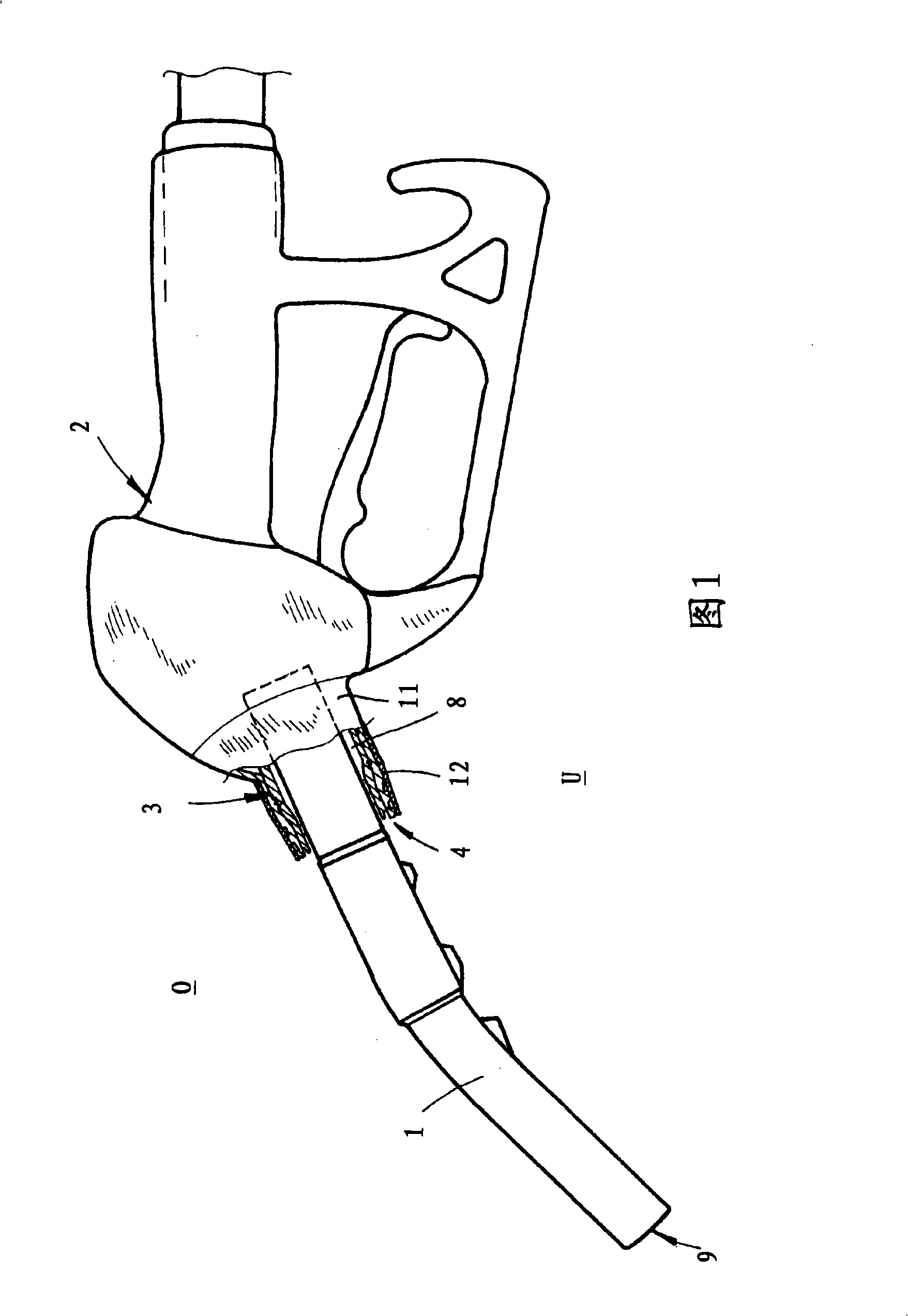

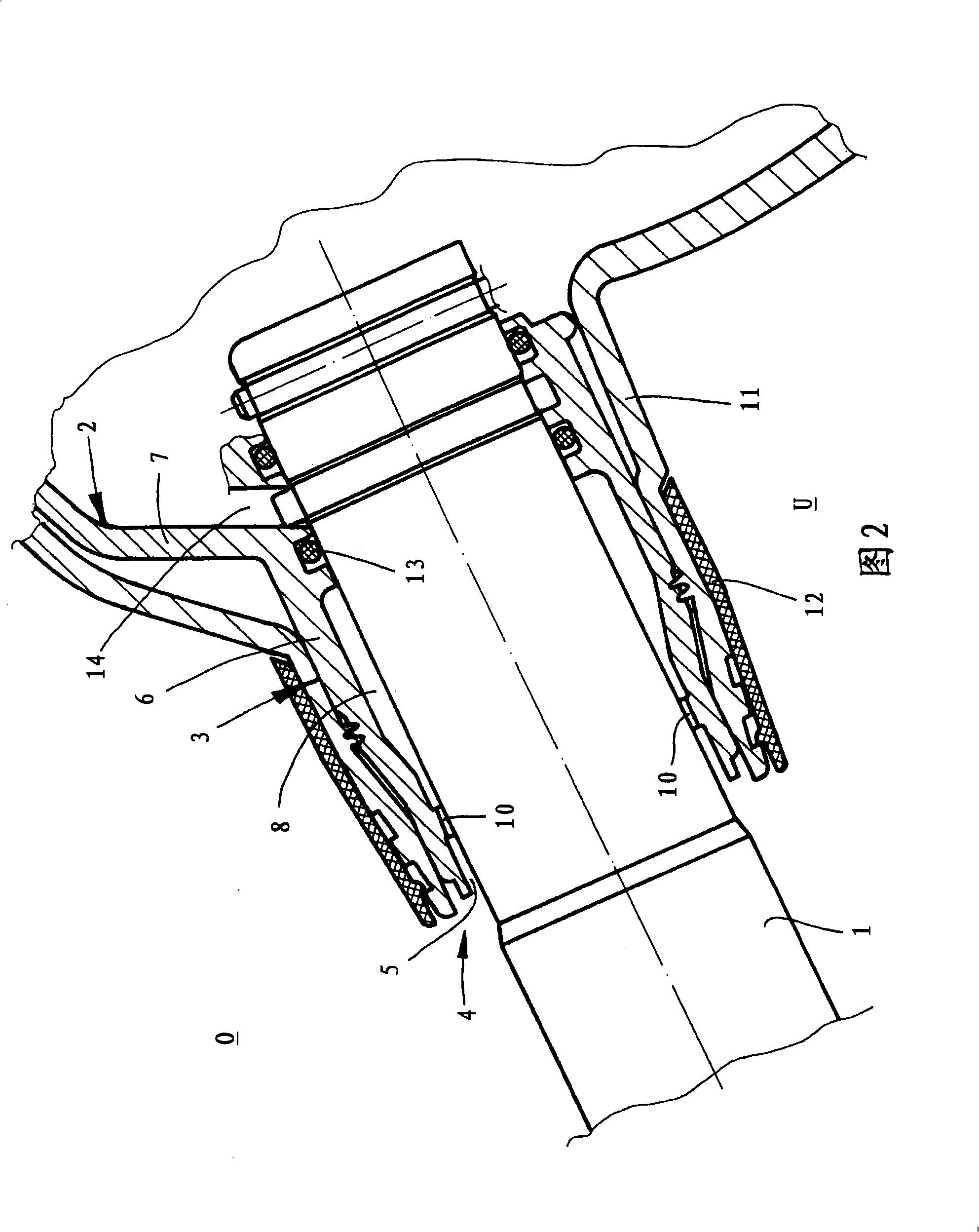

[0019]The accompanying drawing shows an automatic refueling valve for the fuel delivery hose of a petrol station fueling column supplying diesel fuel. The filling valve comprises a filling pipe 1 , a housing 2 with a housing connection 3 and a return drip collector 4 with a return channel 5 . Filler pipe 1 engages in housing socket 3 of housing 2 . The housing connection wall 6 is preferably, and in the exemplary embodiment, integrally connected to the housing wall 7 of the remaining housing 2 .

[0020] The return channel 5 of the return droplet collector 4 is connected to a receiving chamber of the return droplet collector 4 accommodated in the housing connection 3 . According to a particularly preferred embodiment, and in this exemplary embodiment according to the drawings, the oil return drop collector 4 with its return channel 5 and its receiving chamber 8 is completely integrated into the housing socket 3 . The return channel 5 is designed to be open toward the fuel-fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com