Preparation method of magnesium-based high-sulfur free-cutting steel

A free-cutting steel and high-sulfur technology, applied in the field of iron and steel metallurgy, can solve the problems of inability to meet the production needs of high-precision products and application restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] In this embodiment, a method for preparing a magnesium-based high-sulfur free-cutting steel, calculated by mass percentage, is a low-carbon magnesium-containing high-sulfur free-cutting steel based on 1215 free-cutting steel, and its composition is: C:0.05 ~0.09%, Si≤0.15%, Mn:1.0~1.3%, P≤0.08%, S:0.25~0.35%, Mg:0.0003~0.0015%, O≤0.0030%, the balance is iron and unavoidable trace elements ; Its production process is converter → LF → continuous casting → rolling, and the specific operation of each process is as follows:

[0071] (1) Converter smelting:

[0072] Add molten iron and scrap steel to the converter for oxygen blowing smelting, melt the scrap steel, and remove excessive carbon in the steel. When the carbon and temperature are qualified, the steel is tapped. The tapping process adopts aluminum-iron deoxidation alloying; aluminum-iron, sulfur-iron and other alloys And slag material is added when the tapping amount reaches 1 / 4, and all the addition is completed b...

Embodiment 2

[0086] This embodiment is basically the same as Embodiment 1, especially in that:

[0087] In this example,

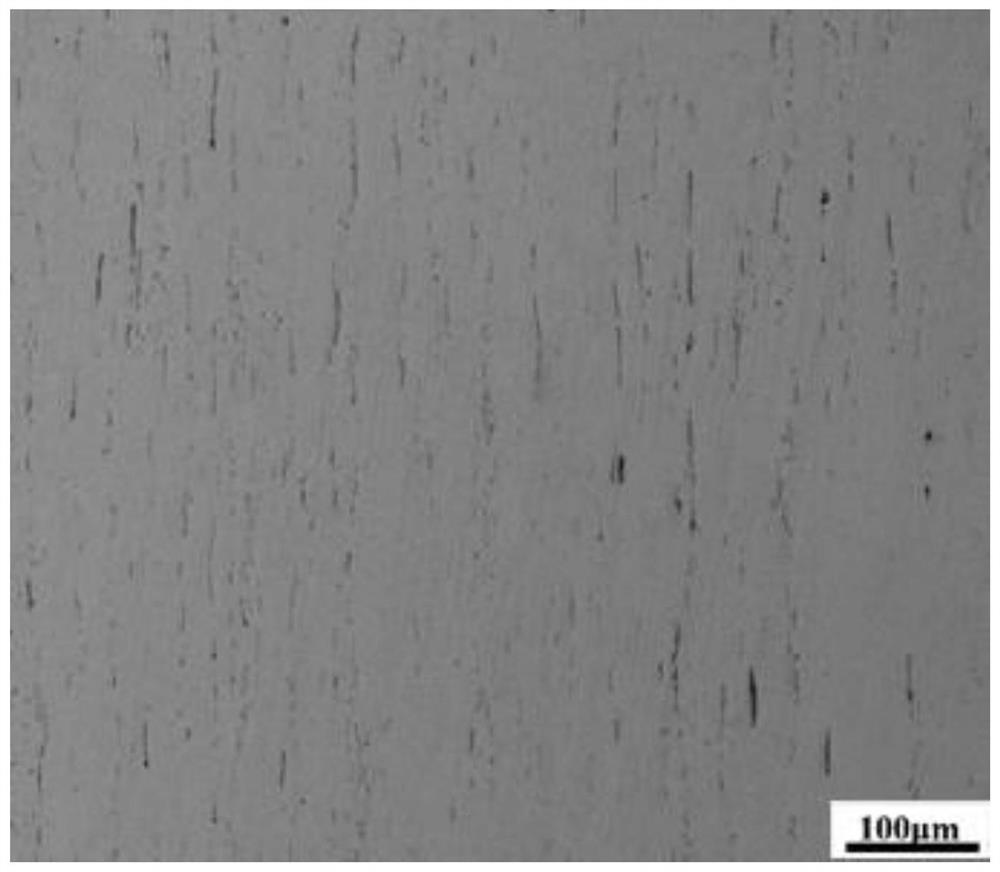

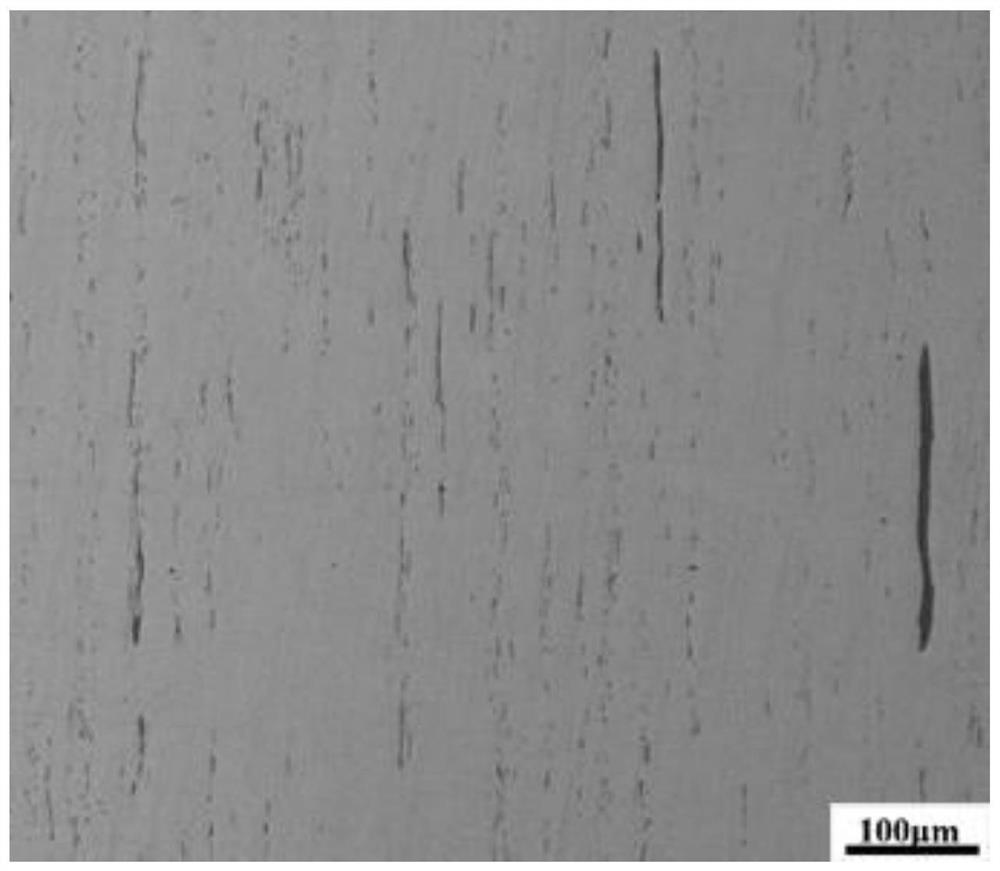

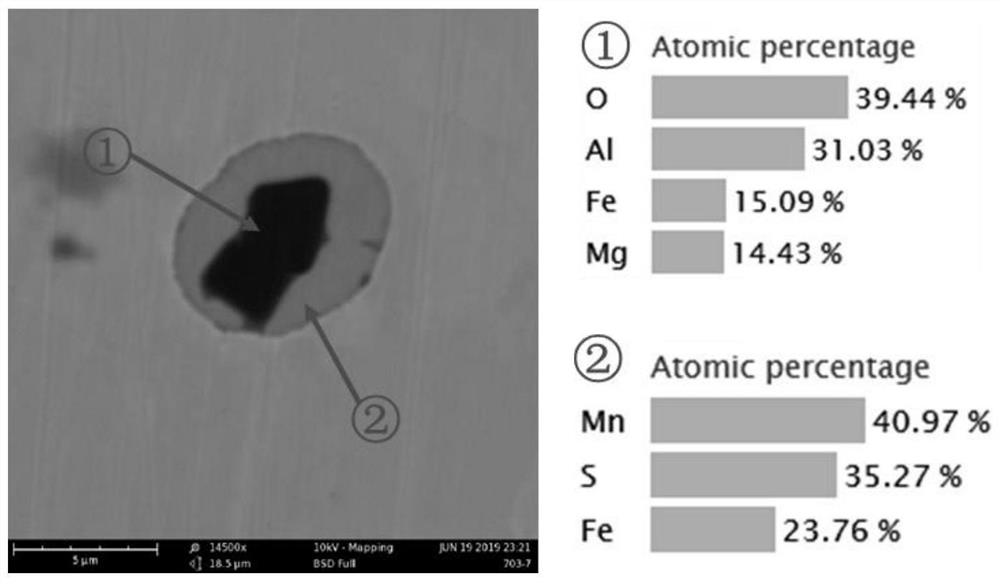

[0088] In this example, see figure 1 , a method for preparing a magnesium-based high-sulfur free-cutting steel. Calculated by mass percentage, the medium-carbon magnesium-containing high-sulfur free-cutting steel based on 1144 has the following components: C: 0.40-0.48%, Si: 0.25- 0.45%, Mn:1.4~1.7%, P≤0.08%, S:0.25~0.35%, Mg:0.0003~0.0015%, O≤0.0020%, the rest is iron and unavoidable trace elements; its production process is electric furnace →LF→VD→Continuous casting→Rolling, the specific operation of each process is as follows:

[0089] (1) Electric furnace smelting:

[0090] Add steel scrap and molten iron to the electric furnace, energize and blow oxygen, and tap the steel after the composition and temperature of the electric furnace reach the standard. Argon; slag blocking operation during the tapping process. After tapping the steel, blow the argon at the arg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com