Full-automatic pull head polishing machine

A fully automatic, polishing machine technology, applied in the field of polishing machines, can solve the problems of poor product quality consistency, low production efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

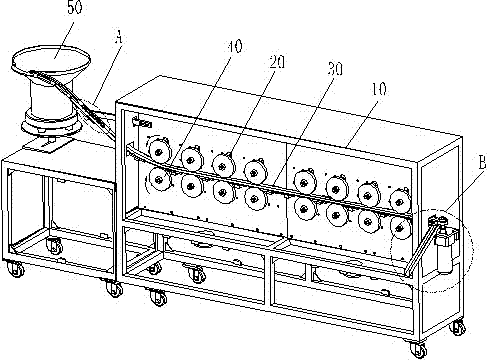

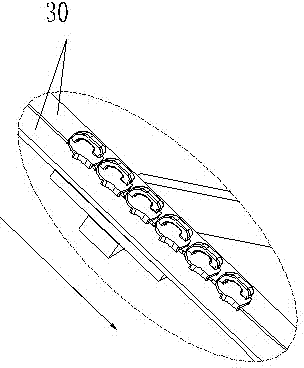

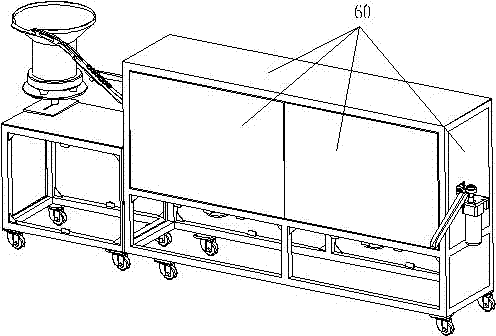

[0049] refer to figure 1 and figure 2 , the embodiment of the present invention provides a fully automatic slider polishing machine for polishing the slider, including a frame 10 and a driving device, the frame 10 is provided with polishing wheels and parallel guide rails 30; the guide rails 30 are arranged at intervals, Form an accommodating space for placing the slider to be polished; the slider to be polished includes a slider top surface and a slider bottom surface, two inner grooves are arranged between the slider top surface and the slider bottom surface, and the adjacent two guide rails 30 are respectively It is socketed with two inner grooves to realize the sliding connection between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com