Automatic pipe orifice butt-joint pipe contracting device

A driving device and moving device technology, applied in the field of mechanical equipment, can solve the problems of slow shrinkage of pipe fittings, broken pipe openings, and deformation of the nozzles, so as to reduce employee fatigue, avoid extrusion rupture, and achieve high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It will be described in detail below in conjunction with specific embodiments according to the accompanying drawings.

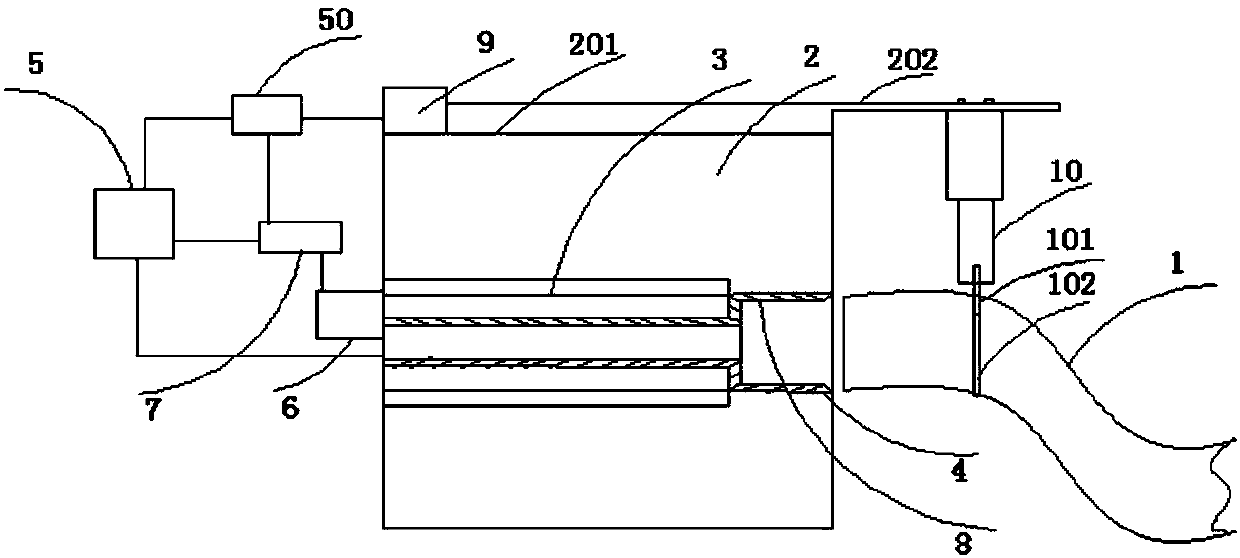

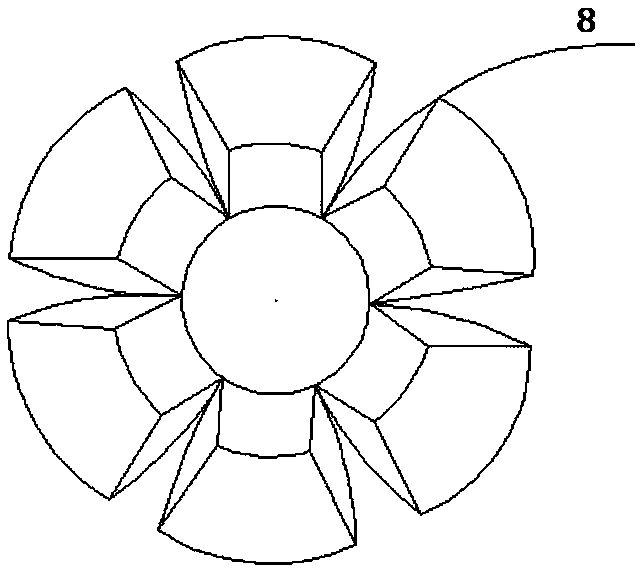

[0029] Such as figure 1 The shown automatic nozzle butt shrinking device includes a driving device 50, a pipe fitting 1 and a fixing seat 2. A heating element 8 is arranged inside the fixing seat 2, and the outside of the heating element 8 is wrapped with a heat-insulating and pressure-resistant component 4. The driving device The 50 is connected with an automatic pick-up device, an automatic extruding device 9 and an automatic heating device,

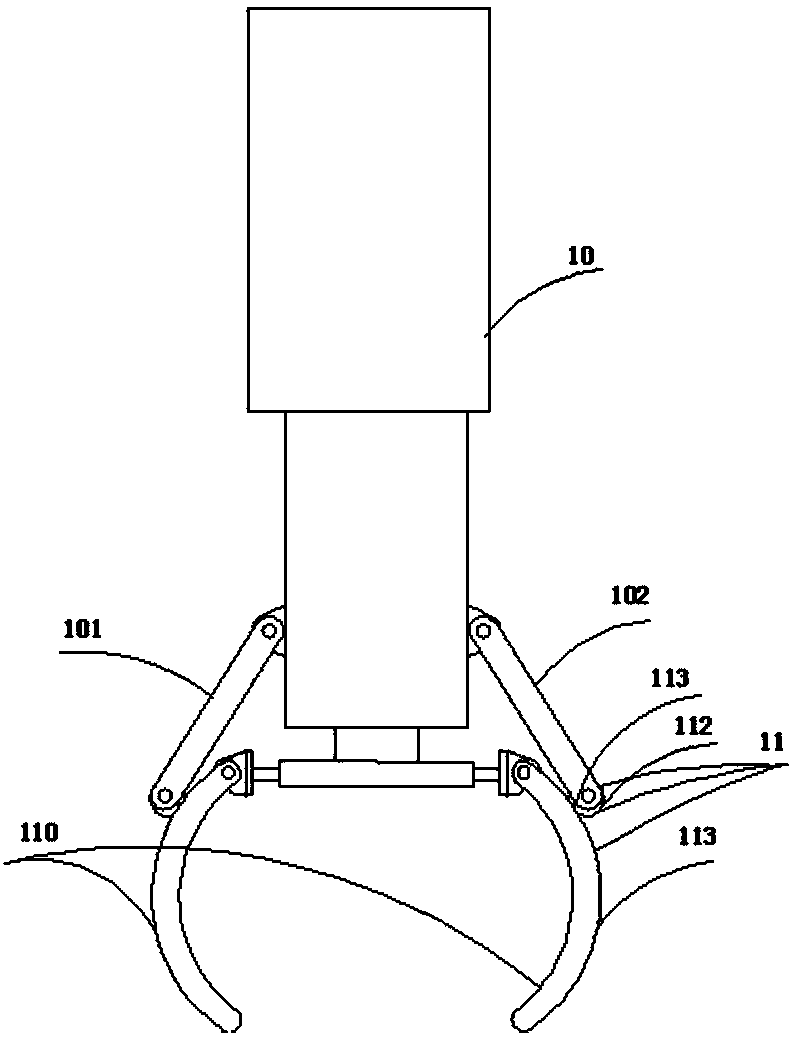

[0030] The automatic pick-up device includes a manipulator 11 for grabbing pipe fittings 1, a lifting device, a moving device, and a servo mechanism 9 set on the upper end of the fixed seat to control the operation of the lifting device and the moving device. The manipulator 11 is located at the bottom of the lifting device. It is connected with the fixed seat 2 by sliding;

[0031] The automatic extruding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com