A prefabricated structure hoisting control management system

A technology of control management and assembly, applied in general control system, control/adjustment system, program control, etc., can solve the problems of component loss, human error, assembly deviation loss, etc., and achieve the effect of improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

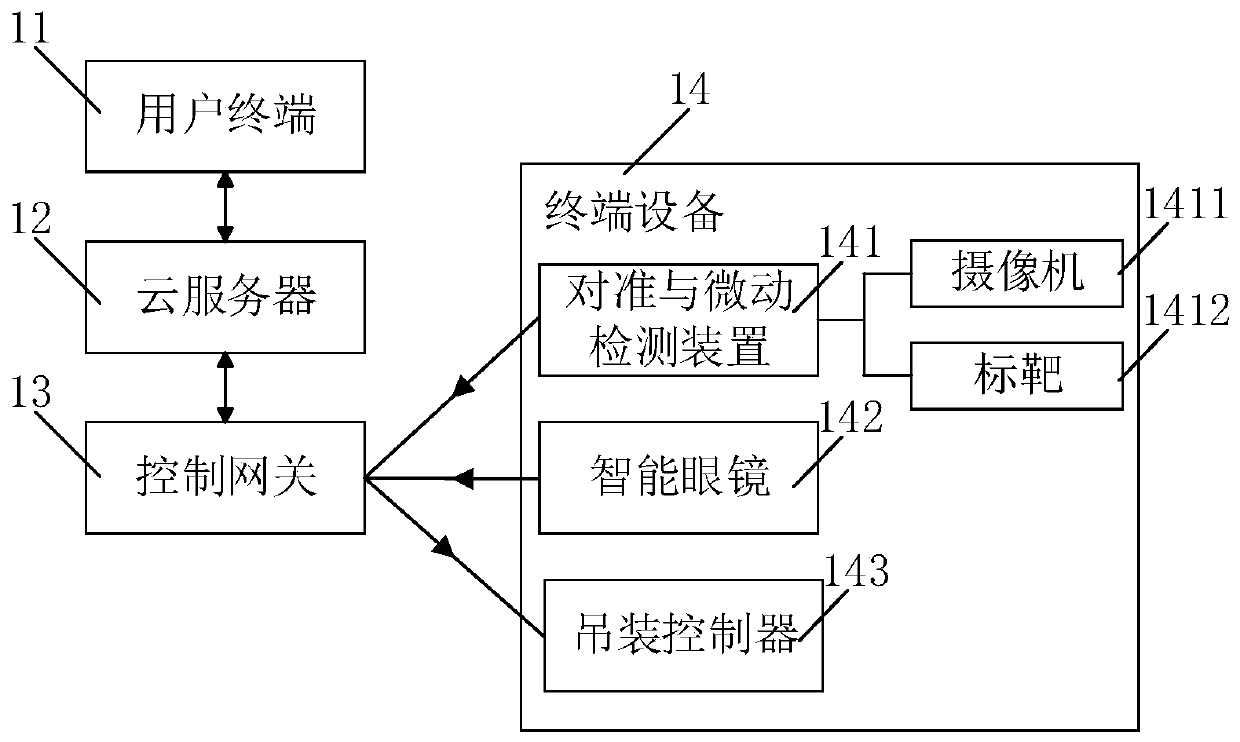

[0034] see figure 1 , figure 1 It is a structural schematic diagram of a prefabricated structure hoisting control management system provided by the first embodiment of the present invention.

[0035] A prefabricated structure hoisting control management system includes: a user terminal 11 , a cloud server 12 , a control gateway 13 and a terminal device 14 . The terminal device 14 includes at least one smart glasses 142 , at least one alignment and micro-motion detection device 141 and at least one suspension controller 143 .

[0036] In this embodiment, the control gateway 13 is connected to the terminal device 14 through a wireless local area network, and controls several smart glasses 142, the alignment and micro-motion detection device 141 and the hoisting controller in linkage. 143.

[0037] The user terminal 11 is configured to obtain construction information stored in the database of the cloud server 12 according to relevant instructions input by the user, and send re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com