Superconducting magnet excitation automatic current lead plugging and unplugging device

A technology of current leads and automatic plugging and unplugging, applied to superconducting magnets/coils, magnetic objects, circuits, etc., can solve problems such as low work efficiency, loss, short circuit, etc., and achieve high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

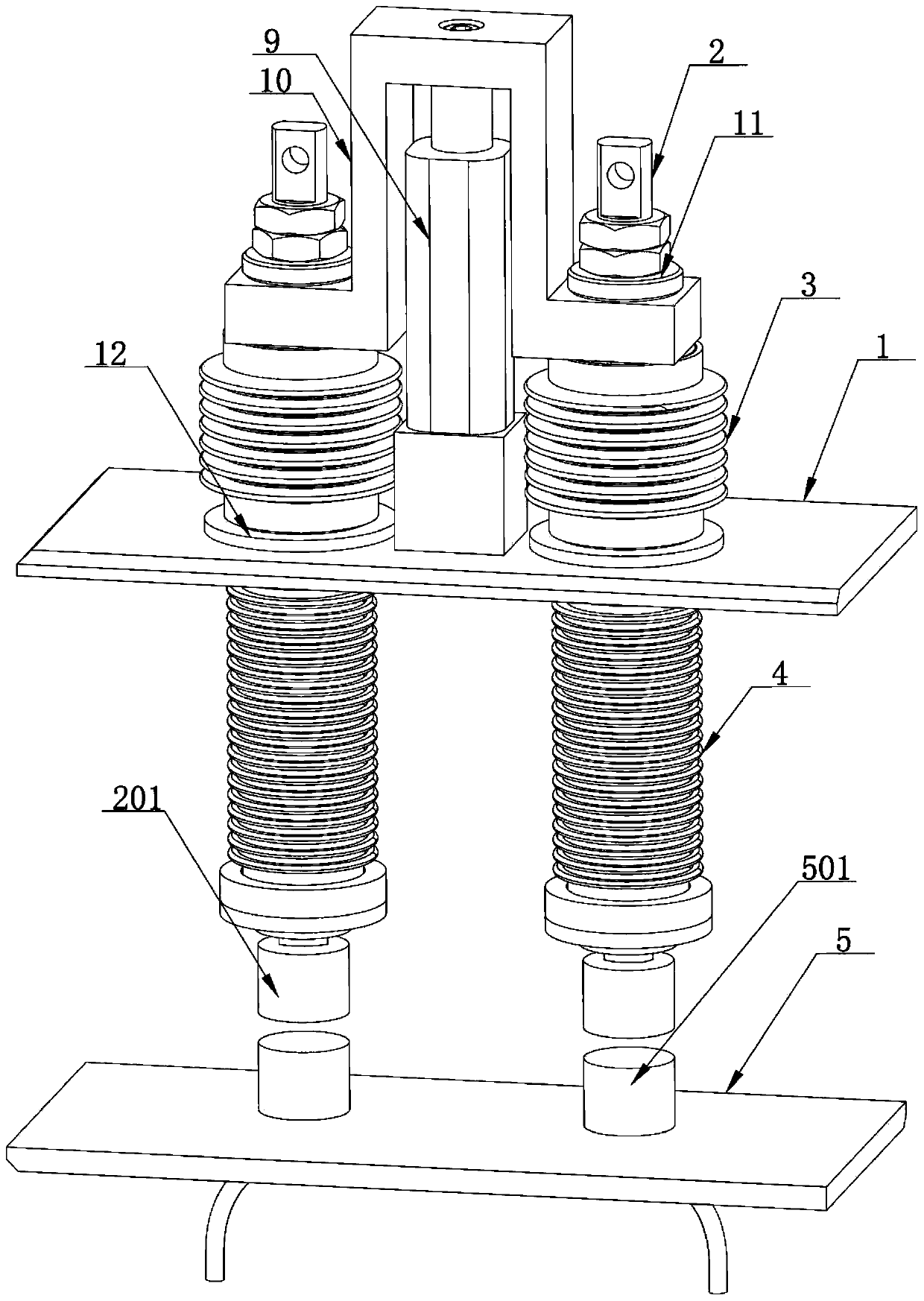

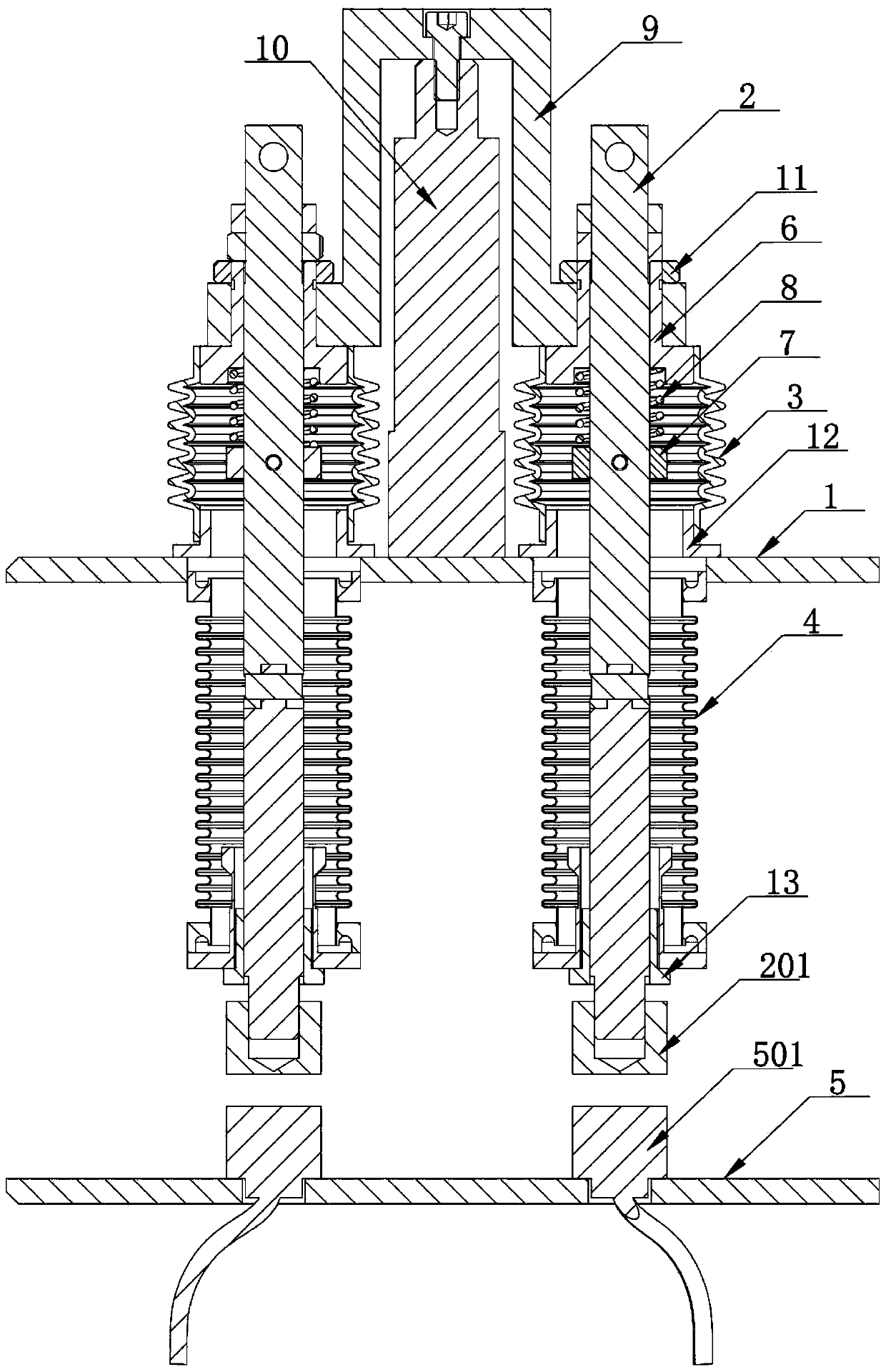

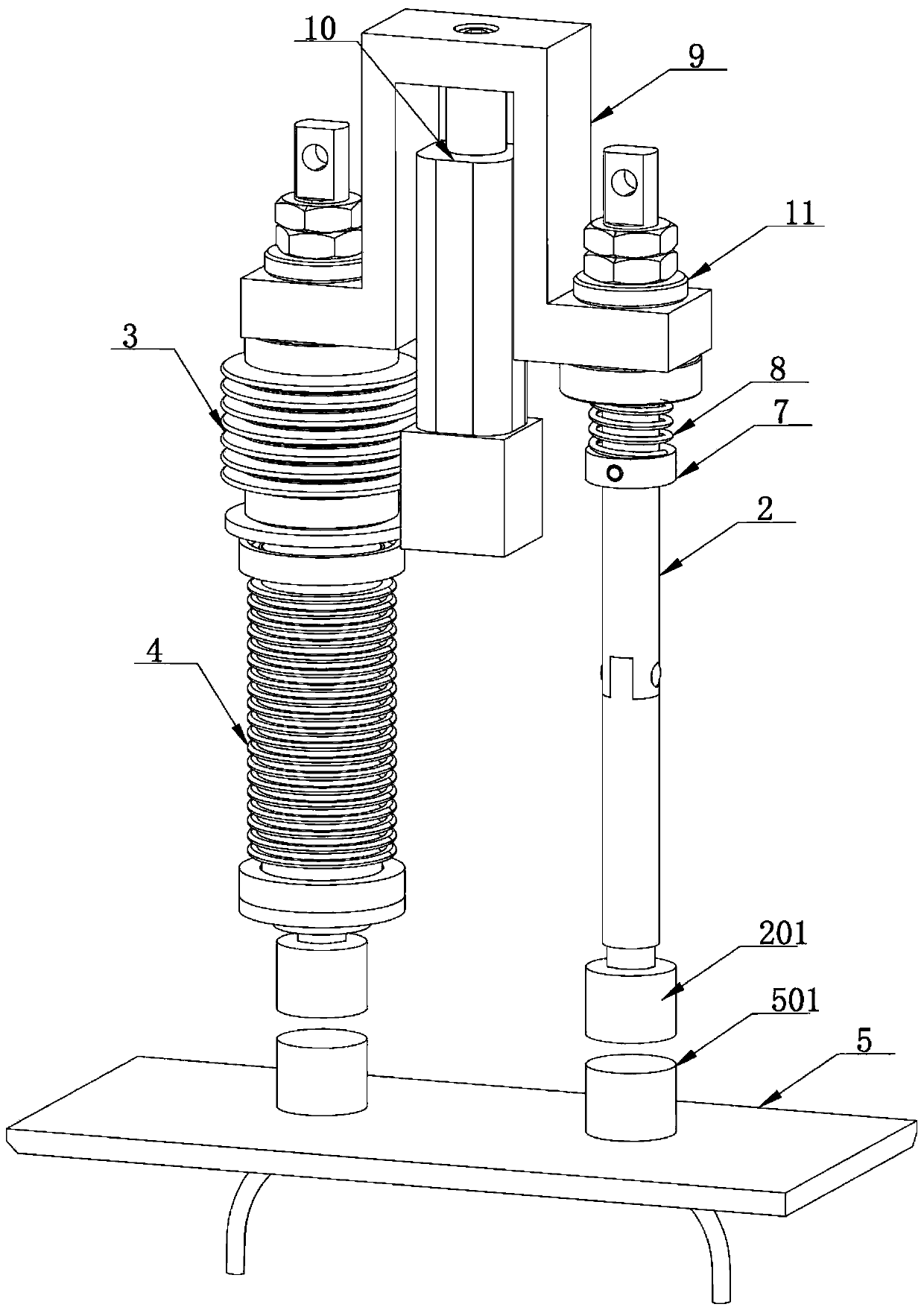

[0021] refer to Figure 1 to Figure 4 , the present invention provides a superconducting magnet excitation automatic plugging and unplugging current lead device, which is installed on an external room temperature container 1, including: a conductive rod 2, a first compression sealing tube 3, a second compression sealing tube 4, a driving device and a synchronization frame 9. A vacuum chamber is set between the room temperature container 1 and the external 4K container 5, and two superconducting coil terminal electrodes 501 are arranged on the 4K container 5, and the two superconducting coil terminal electrodes 501 are located in the vacuum chamber, and the superconducting coil terminal electrodes 501 It is connected with the superconducting coil in the 4K container 5 .

[0022] refer to Figure 2 to Figure 4 , The superconducting magnet excitation automatic plugging and unplugging current lead device is two sets of current lead devices with left and right symmetry, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com