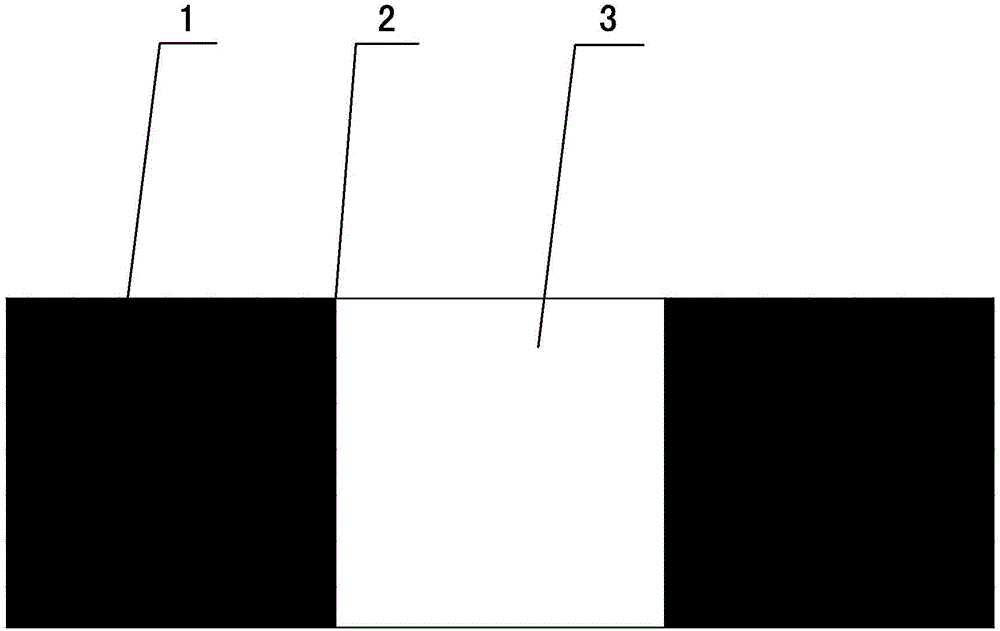

Striped full-biodegradable mulching film and preparation method thereof

A technology of degrading plastic film and whole biology, applied in the field of strip fully biodegradable plastic film and its preparation, which can solve the problems of white pollution, soil structure hardening, harming the ecological environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

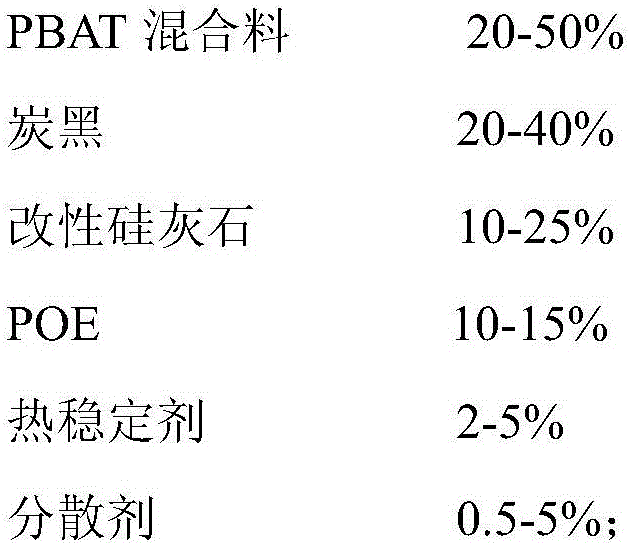

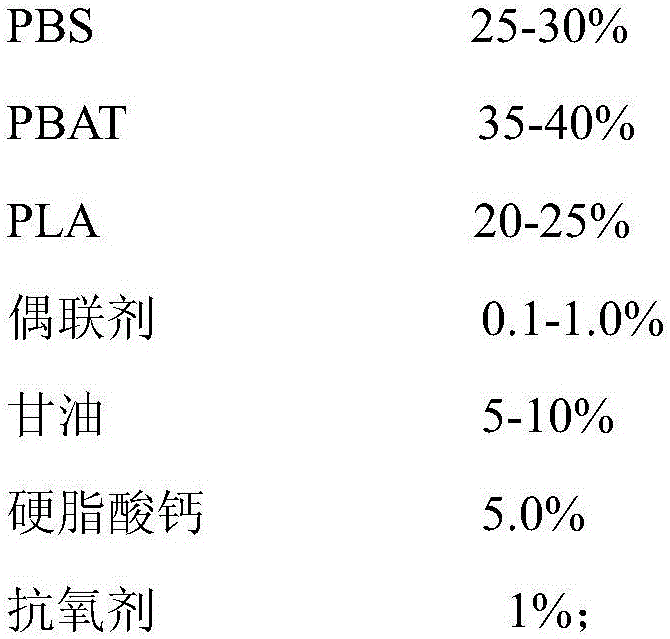

Embodiment 1

[0048] The degradation base material is produced by: 25% PBS + 20% PLA + 40% PBAT + 5% calcium stearate + 1% antioxidant 1010 + 1% coupling agent + 8% glycerin. The degradation black masterbatch is composed of: It is produced by 45% PBAT compound + 25% carbon black + 10% modified wollastonite + 15% POE + 3% heat stabilizer + 2% dispersant. Take 94.9% degraded base material + 5% degraded black masterbatch + 0.1% opening agent for the black belt layer, and 4% light stabilizer 622 + 95.9% degraded base material + 0.1% lubricant for the white belt layer. The temperature of the two-layer co-extrusion equipment is adjusted as follows: black belt barrel: 140°C, 150°C, 160°C; white belt barrel: 145°C, 155°C, 165°C; connecting body 155°C; machine head: 170°C; Under the nose: 180°C. After the temperature rises, the film is lifted to produce two black and one white fully biodegradable mulches. The mechanical properties of the fully biodegradable mulch film were tested according to the ...

Embodiment 2

[0053] The degradation base material is produced by: 30% PBS + 20% PLA + 35% PBAT + 5% calcium stearate + 1% antioxidant 168 + 0.7% coupling agent + 8.3% glycerin. The degradation black masterbatch is composed of: It is produced by 40% PBAT compound + 30% carbon black + 10% modified wollastonite + 15% POE + 3% heat stabilizer + 2% dispersant. Take 96.9% degraded base material + 3% degraded black masterbatch + 0.1% opening agent for the black belt layer, and 2% light stabilizer 622 + 97.9% degraded base material + 0.1% lubricant for the white belt layer. After stirring evenly, put The temperature of the two-layer co-extrusion equipment is adjusted as follows: black belt layer: 135°C, 145°C, 155°C; white belt layer: 140°C, 150°C, 160°C; connecting body 155°C; head: 175°C; Bottom: 180°C. After the temperature rises, the film is lifted to produce two white and one black fully biodegradable mulches.

Embodiment 3

[0055]The degradation base material is produced by: 25% PBS + 20% PLA + 40% PBAT + 5% calcium stearate + 1% antioxidant 1010 + 1% coupling agent + 8% glycerin. The degradation black masterbatch is composed of: It is produced by 50% PBAT compound + 20% carbon black + 15% modified wollastonite + 10% POE + 3% heat stabilizer + 2% dispersant. Take 94.9% degraded base material + 5% degraded black masterbatch + 0.1% opening agent for the black belt layer, and 3% light stabilizer 944 + 96.9% degraded base material + 0.1% lubricant for the white belt layer. After stirring evenly, put The temperature of the two-layer co-extrusion equipment is adjusted as follows: black belt layer: 135°C, 145°C, 155°C; white belt layer: 145°C, 155°C, 165°C; connecting body 155°C; head: 175°C; Bottom: 180°C. After the temperature rises, the film is lifted to produce two black and one white fully biodegradable mulches.

[0056] The use process of biodegradable agricultural mulch film generally goes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com