Method for preparing porous polymer microneedle based on phase separation technology and application of method

A porous polymer and phase separation technology, applied in the directions of microneedles, medical preparations with non-active ingredients, needles, etc., can solve the problems of harsh conditions, difficulties, complicated processes, etc., and achieve regular pore structure, uniform pore size, and flexibility good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

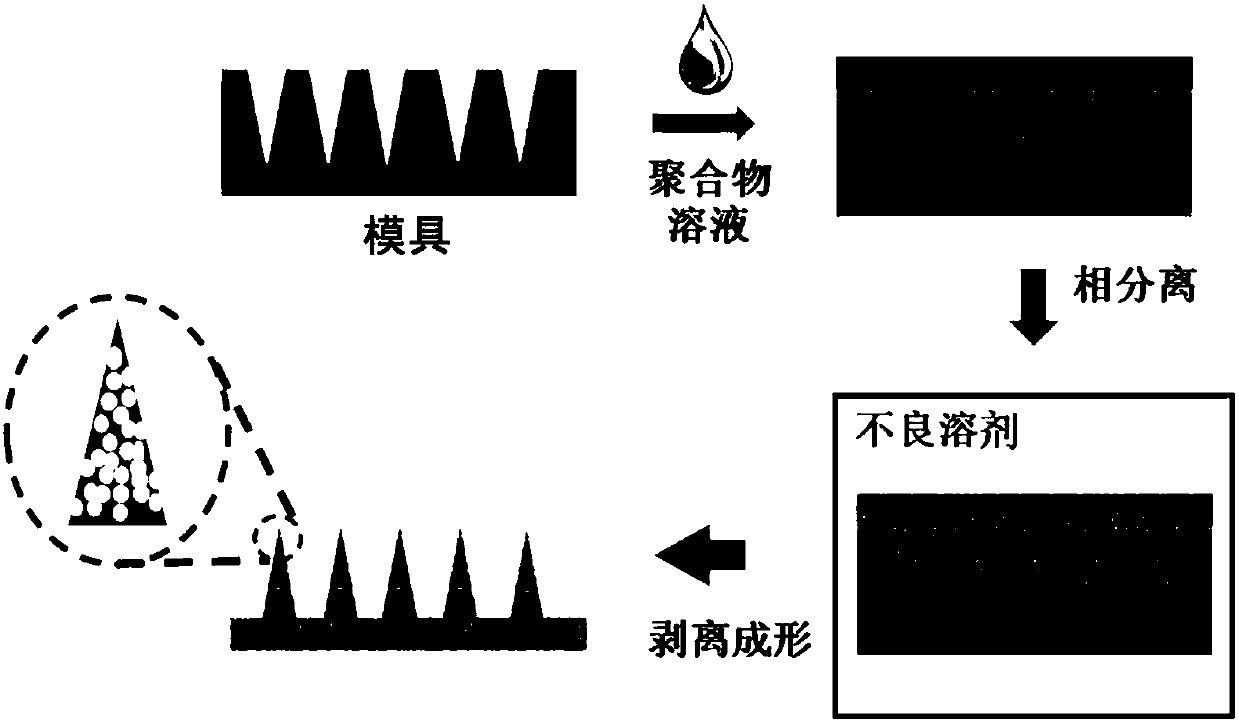

Method used

Image

Examples

Embodiment 1

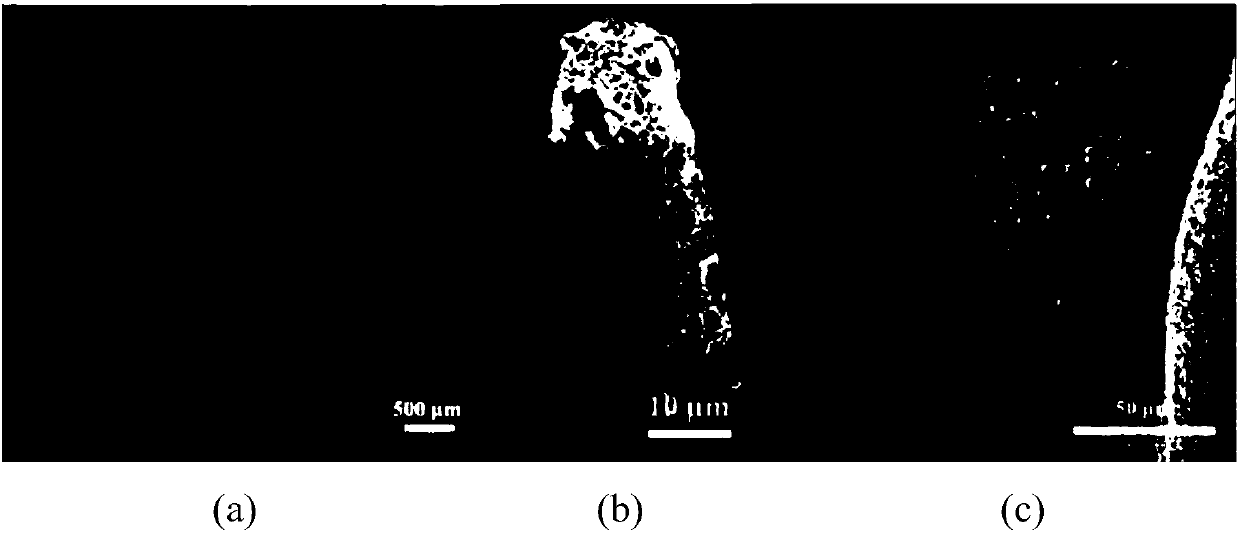

[0051] A porous polymer microneedle array prepared by phase separation technology is prepared according to the following method: first, a PDMS (polydimethylsiloxane) negative mold is obtained by using a microneedle positive mold through a reverse replication method, and the negative mold is placed on the After soaking in dimethyl sulfoxide for 2 hours, take it out, remove excess dimethyl sulfoxide on the surface of the female mold (the dimethyl sulfoxide in the concave part of the female mold can not be removed; for example, filter paper can be used to wipe the surface of the female mold , the dimethyl sulfoxide in the depression of the female mold can not be completely removed like this); Then, the molecular weight is 10k, and the dimethyl sulfoxide solution of cellulose acetate that the mass fraction is 30wt% is added dropwise on the female mold, Put it in a beaker with dimethyl sulfoxide, put it in ultrapure water at 25°C after ultrasonication for 1 hour to make the phase se...

Embodiment 2

[0055] A porous polymer microneedle array prepared by phase separation technology is prepared according to the following method: first, use a microneedle positive mold to obtain a PDMS negative mold by reverse replication, and soak the negative mold in dimethyl sulfoxide for 2 hours Finally, take it out, and remove excess dimethyl sulfoxide on the surface of the female mold; then, drop the dimethyl sulfoxide solution of racemic polylactic acid with a molecular weight of 1000k and a mass fraction of 25wt% onto the female mold, and place In a beaker with dimethyl sulfoxide, place in ultrapure water at 25°C after ultrasonication for 1 hour to cause phase separation of the polymer, and freeze-dry after peeling to obtain porous racemic polylactic acid microneedles.

Embodiment 3

[0057] A porous polymer microneedle array prepared by phase separation technology is prepared according to the following method: first, use a microneedle positive mold to obtain a PDMS negative mold by reverse replication, and soak the negative mold in dimethyl sulfoxide for 2 hours Finally, take it out, remove excess dimethyl sulfoxide on the surface of the female mold; then, drop the dimethyl sulfoxide solution of polyarylsulfone with a molecular weight of 800k and a mass fraction of 35wt% onto the female mold, and place it in the presence of dimethyl sulfoxide. In a sulfoxide-based beaker, the polymer was placed in ultrapure water at 25°C after ultrasonication for 1 hour to cause phase separation of the polymer, and then freeze-dried to obtain porous polyarylsulfone microneedles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com