Powder multistage suspension preheating kiln outside calcium oxide calcining method

A technology of suspension preheating and decomposition outside the kiln, applied in chemical instruments and methods, calcination, preheating costs, etc., can solve the problems of increasing environmental protection desulfurization, poor combustion effect, long calcination and decomposition time, etc. The effect of decomposing quickly and fully and reducing unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

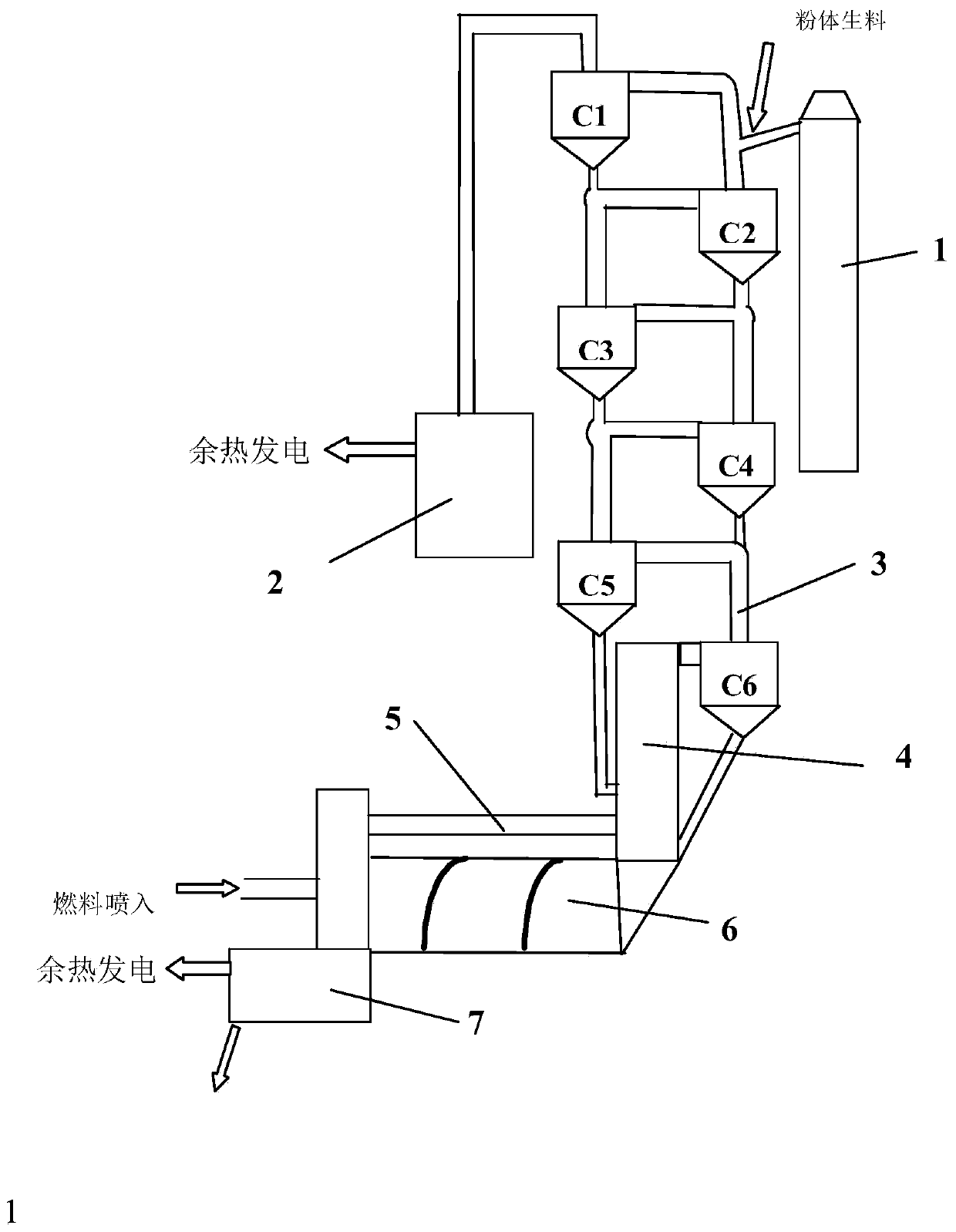

[0035] Such as figure 1 As shown, the processing system used in the method for decomposing and calcining calcium oxide outside the powder multi-stage suspension preheating kiln described in this embodiment includes six-stage hot flue gas cyclone C1-C6, decomposition furnace 4, rotary kiln 6 and cooler 7. The rotary kiln 6 is provided with a fuel injection port, and a tertiary hot air pipe 5 is provided between the fuel injection port of the rotary kiln 6 and the calciner 4. The smoke chamber of the rotary kiln 6 is connected with the calciner 4 and the hot air duct 3. The outlet of the outlet is connected with cooler 7.

[0036]The six-stage hot flue gas cyclones C1-C6 are sequentially connected in series on the hot air duct 3 that conveys the hot flue gas upwards. An exhaust fan 2 is installed at the end of the hot air duct 3, and the hot flue gas cyclone at the top is the first-stage hot air duct. The flue gas cyclone C1, the blanking outlet of the first stage hot flue gas...

Embodiment 2

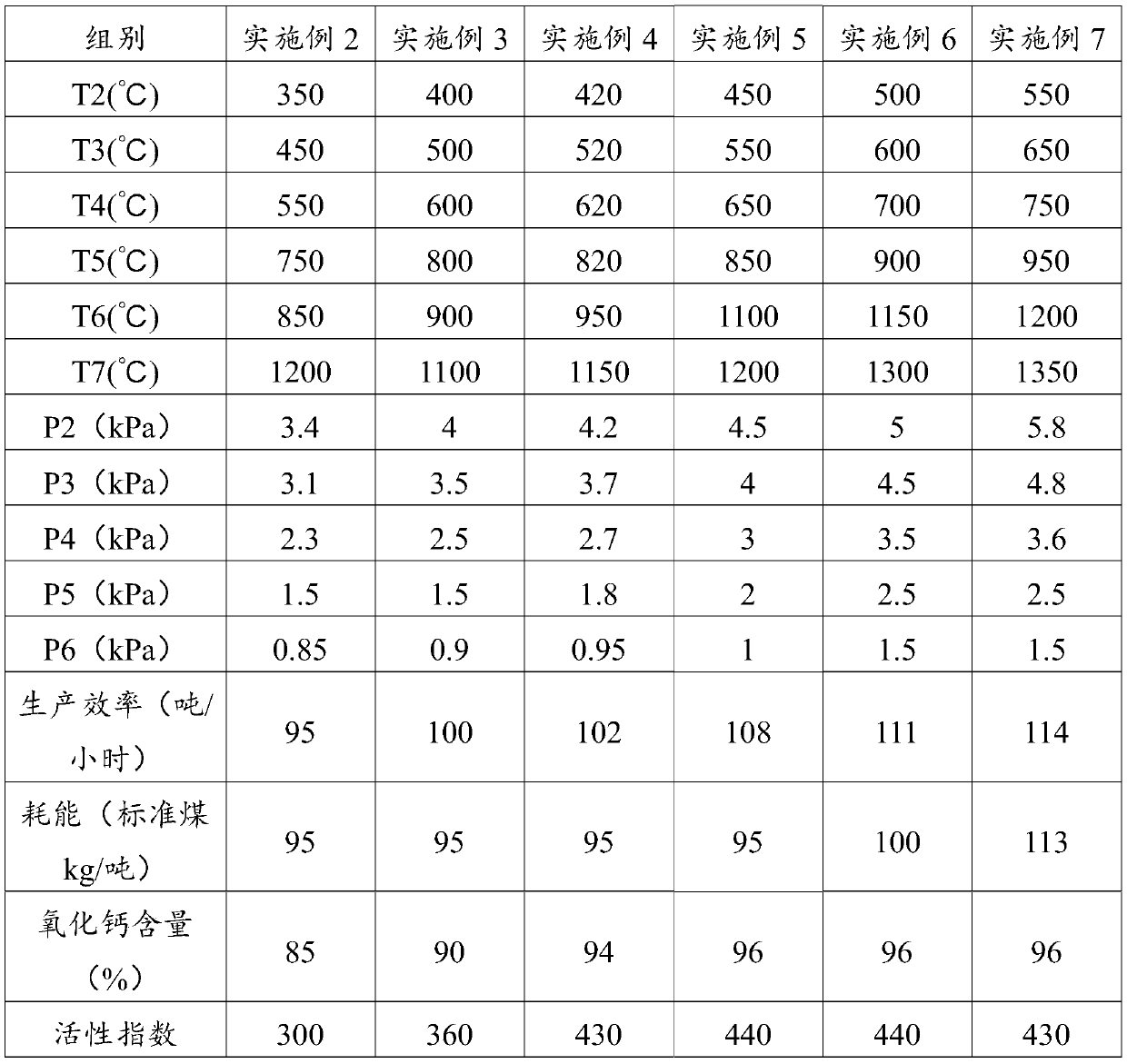

[0049] In this embodiment, the processing system described in Example 1 is used to prepare calcium oxide, and the production capacity is 2250 tons / day. The size of the hot flue gas cyclones at all levels is: the diameter of cyclone C1 is 5.67m, and the height is 5.35m; the diameter of cyclone C2 Cyclone C3 is 6.58m in diameter and 5.83m in height; cyclone C3 has a diameter of 6.96m and a height of 6.93m; cyclone C4 has a diameter of 7.15m and a height of 5.58m; cyclone C5 has a diameter of 7.86m and a height of 5.91m; C6 has a diameter of 7.93m and a height of 5.98m. The calciner has a diameter of 6.8m and a height of 13.5m; the size of the rotary kiln is Φ4.2×60m, and the kiln speed is 3.5 rpm.

[0050] The specific method is: crush the limestone and grind it into powder raw meal with a particle size of less than 70 mesh, and put 180 tons of raw meal per hour into the first-stage hot flue gas cyclone C1 and the second-stage hot flue gas through the elevator. After suspension ...

Embodiment 3

[0052] The present embodiment adopts the processing system identical with embodiment 2 to prepare calcium oxide, and concrete method is:

[0053]The limestone is crushed and ground into powder raw meal with a particle size of less than 70 mesh, and the raw meal is put into the first-stage hot smoke cyclone C1 and the second-stage hot smoke cyclone C2 through the hoist at a rate of 195 tons per hour. After suspending and preheating in the connecting pipe between them, it enters the first-stage hot gas cyclone C1. After suspending and preheating, the material enters the hot air passage between the second-stage hot-flue gas cyclone C2 and the third-stage hot-flue gas cyclone C3. Suspension preheating, the material is brought into the second-stage hot smoke cyclone C2 by the hot air flow to collect and preheat. At this time, the temperature of the second-stage hot smoke cyclone C2 is controlled at 400°C (T2), and under the control of the exhaust fan, the negative pressure is 4Pa k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com