Patents

Literature

61results about "Flat flow vortex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

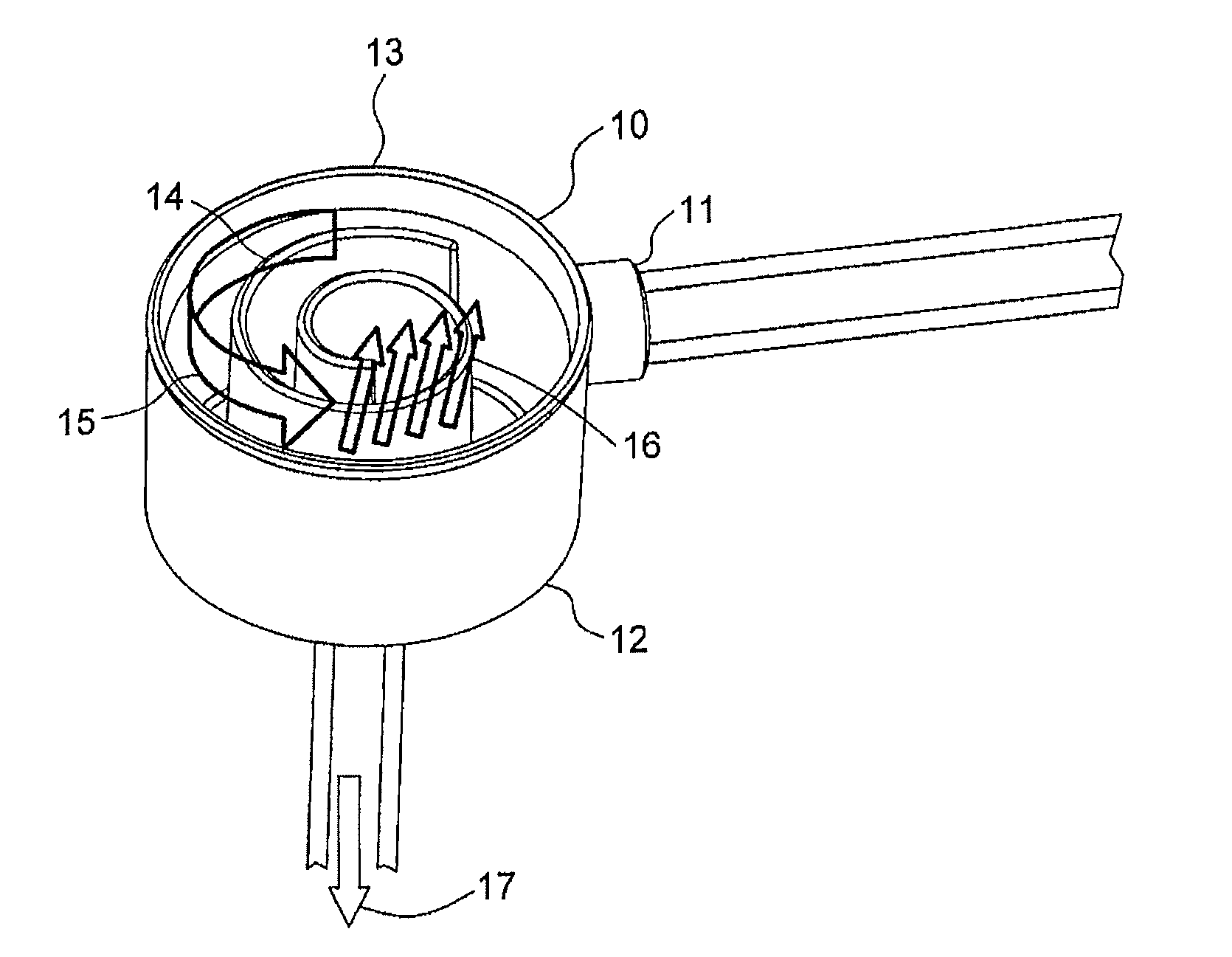

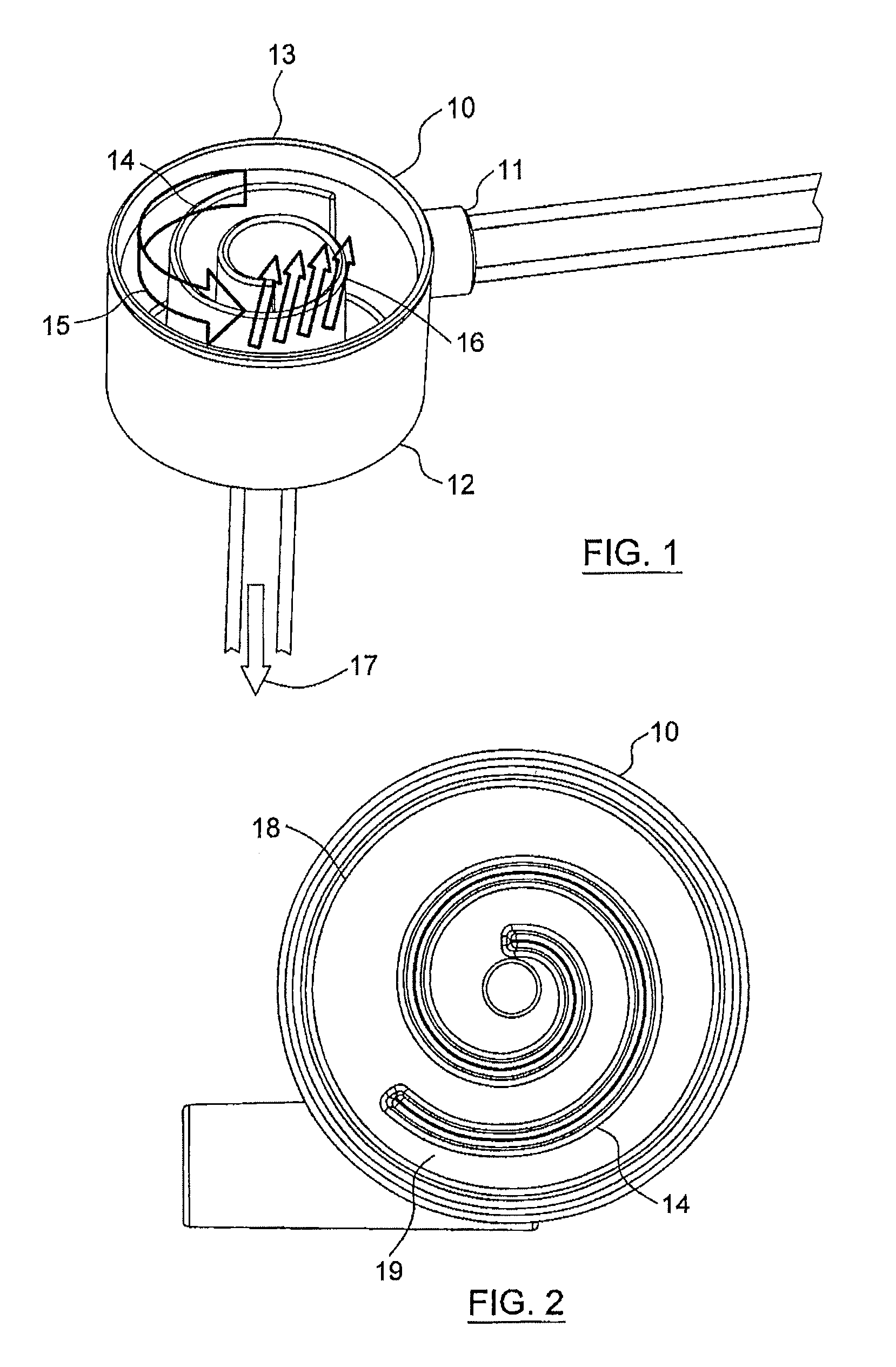

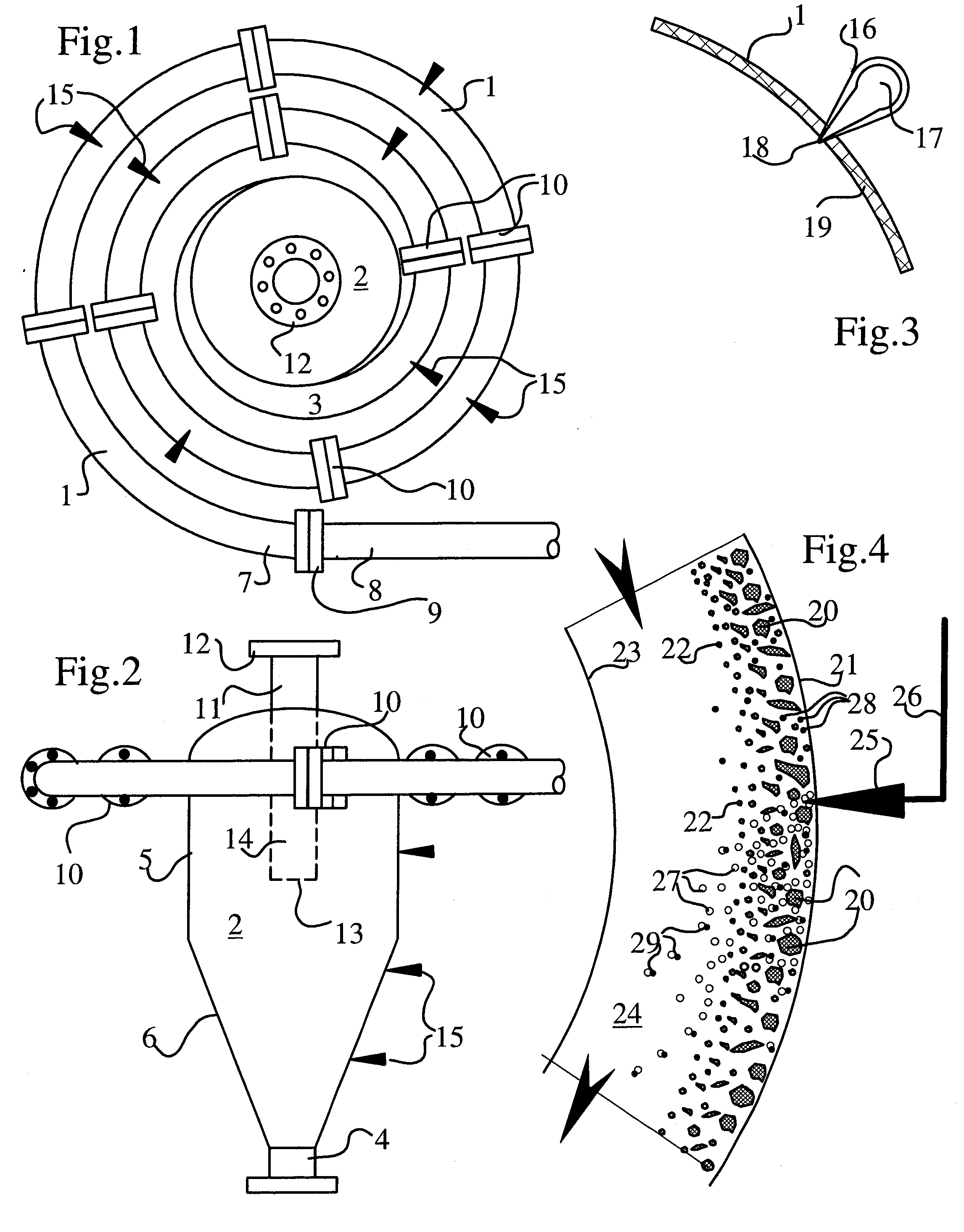

Particle separation and concentration system

This invention is based on size and mass separation of suspended particles, including biological matter, which are made to flow in a spiral channel. On the spiral sections, the inward directed transverse pressure field from fluid shear competes with the outward directed centrifugal force to allow for separation of particles. At high velocity, centrifugal force dominates and particles move outward. At low velocities, transverse pressure dominates and the particles move inward. The magnitudes of the two opposing forces depend on flow velocity, particle size, radius of curvature of the spiral section, channel dimensions, and viscosity of the fluid. At the end of the spiral channel, a parallel array of outlets collects separated particles. For any particle size, the required channel dimension is determined by estimating the transit time to reach the side-wall. This time is a function of flow velocity, channel width, viscosity, and radius of curvature. Larger particles may reach the channel wall earlier than the smaller particles which need more time to reach the side wall. Thus a spiral channel may be envisioned by placing multiple outlets along the channel. This technique is inherently scalable over a large size range from sub-millimeter down to 1 μm.

Owner:XEROX CORP

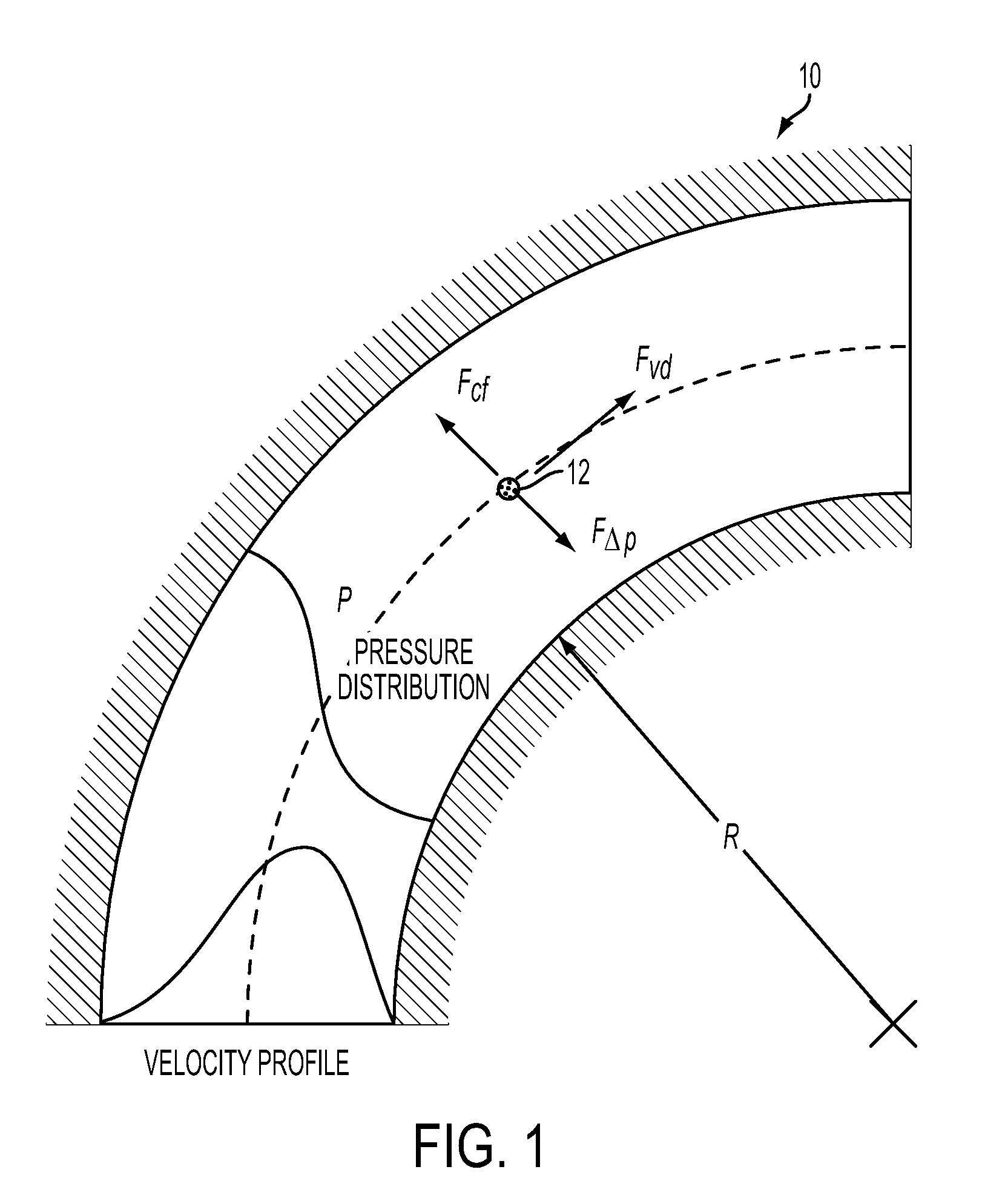

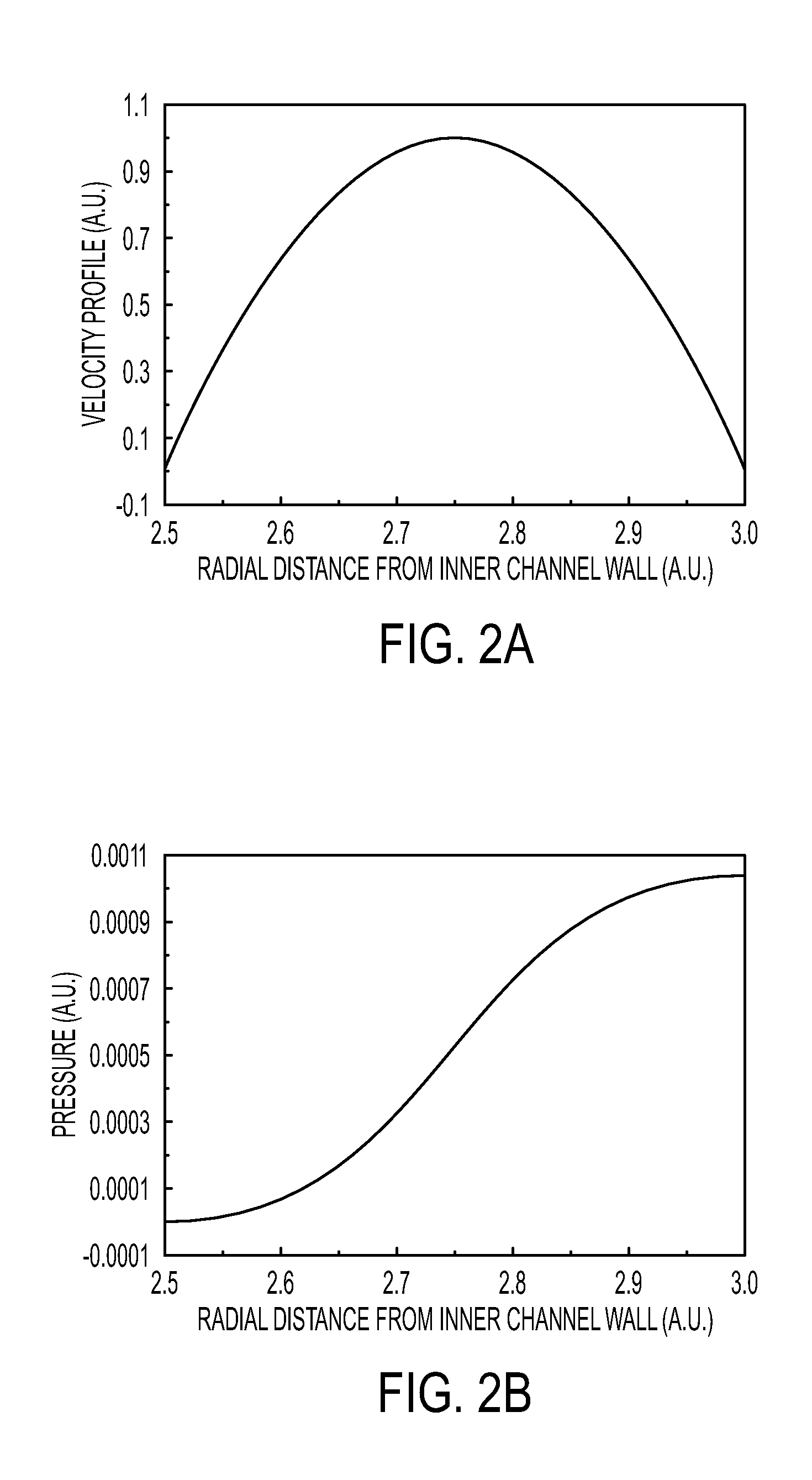

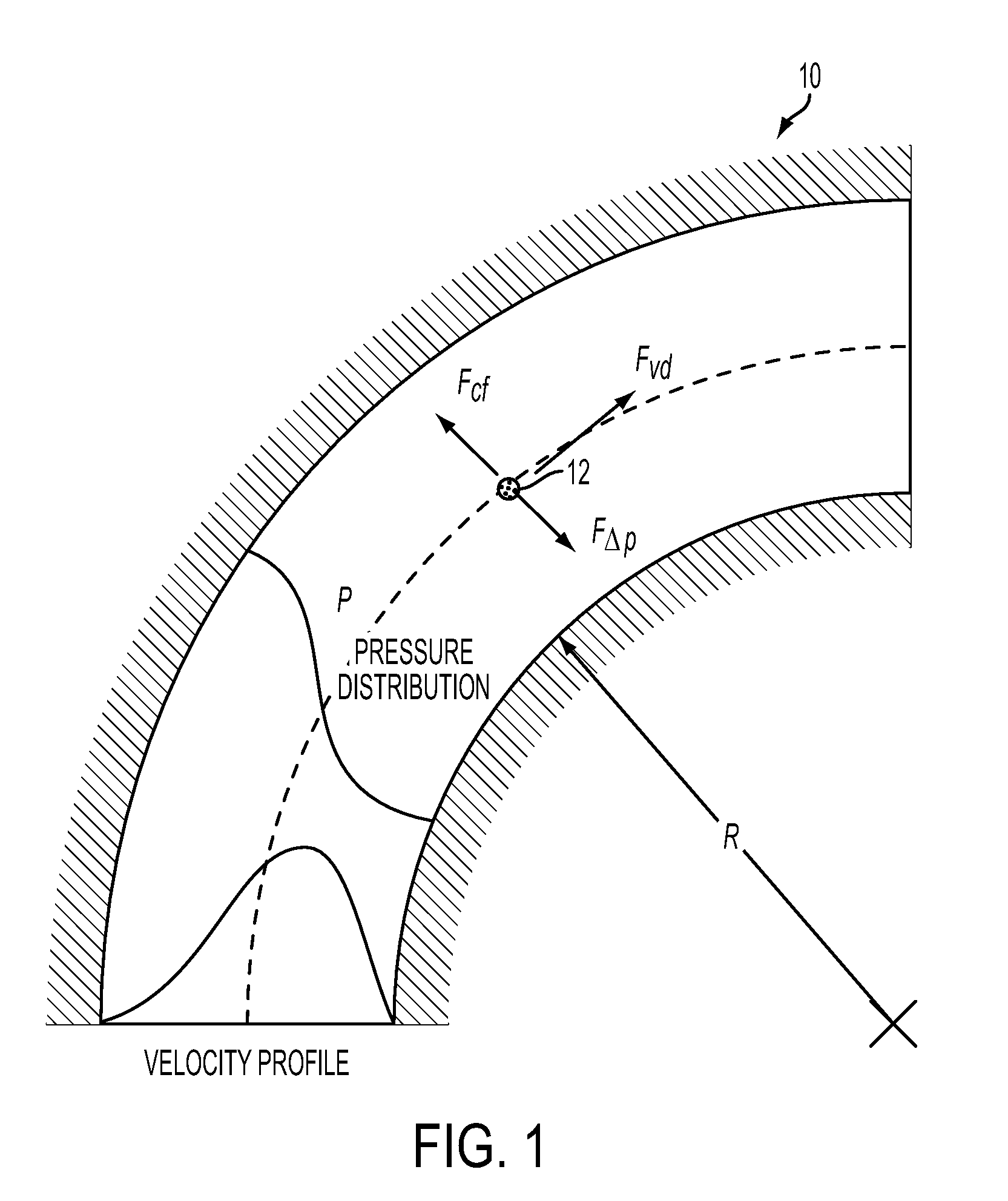

Fluidic Device and Method for Separation of Neutrally Buoyant Particles

ActiveUS20090114607A1Promote early formationWater/sewage treatment by centrifugal separationReversed direction vortexParticulatesParticle flow

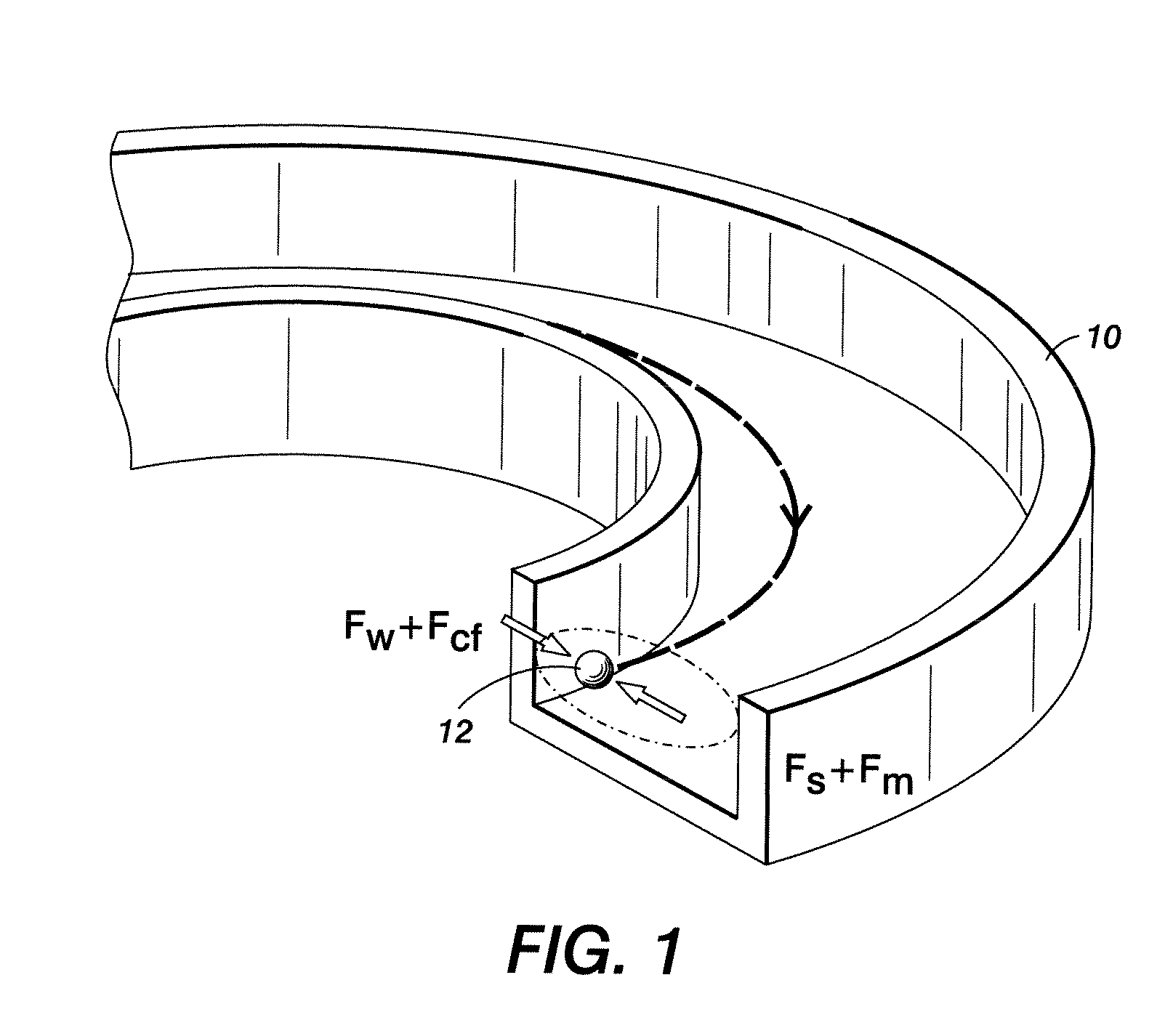

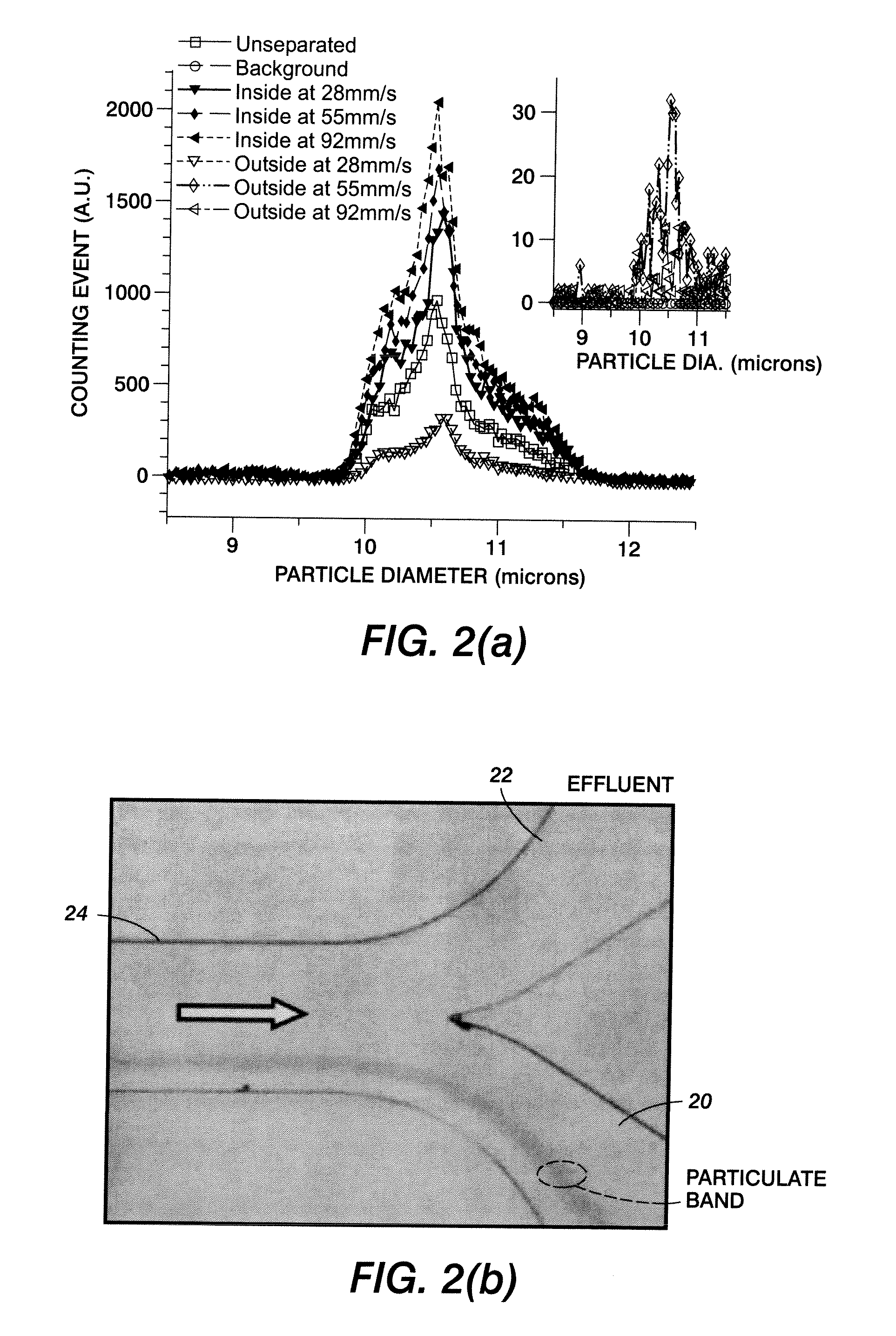

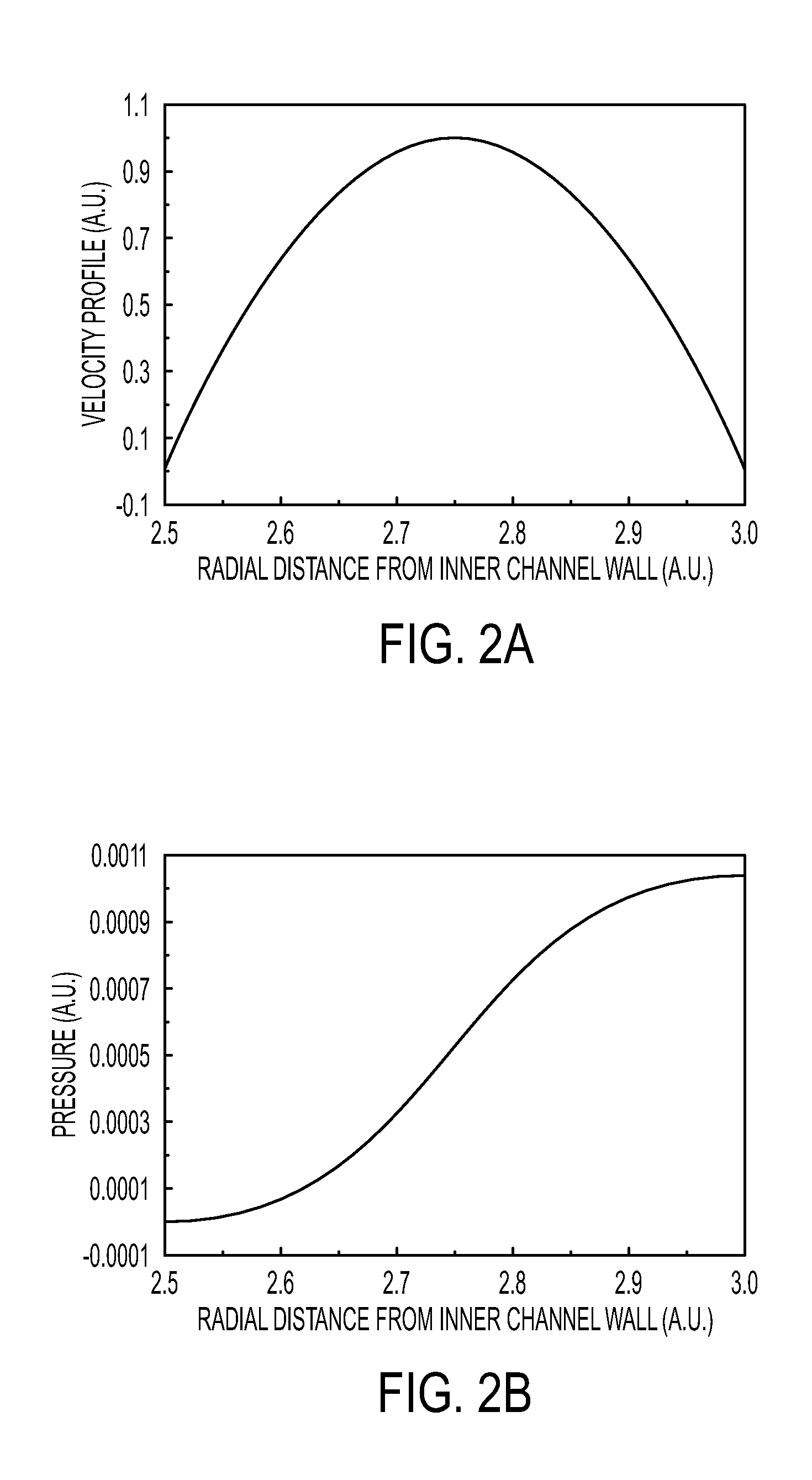

A technique using a curved channel of a spiral device to introduce a centrifugal force upon neutrally buoyant particles flowing in a fluid, e.g. water, to facilitate improved separation of such particles from the fluid is provided. As these neutrally buoyant particles flow through the channel, a tubular pinch effect causes the particles to flow in a tubular band. The introduced centrifugal force perturbs the tubular band (e.g. forces the tubular band to flow in a manner offset from a center of the channel), resulting in an asymmetric inertial migration of the band toward the inner wall of the channel. This allows for focusing and compaction of suspended particulates into a narrow band for extraction. The separation principle contemplated herein implements a balance of the centrifugal and fluidic forces to achieve asymmetric inertial equilibrium near the inner sidewall.

Owner:XEROX CORP

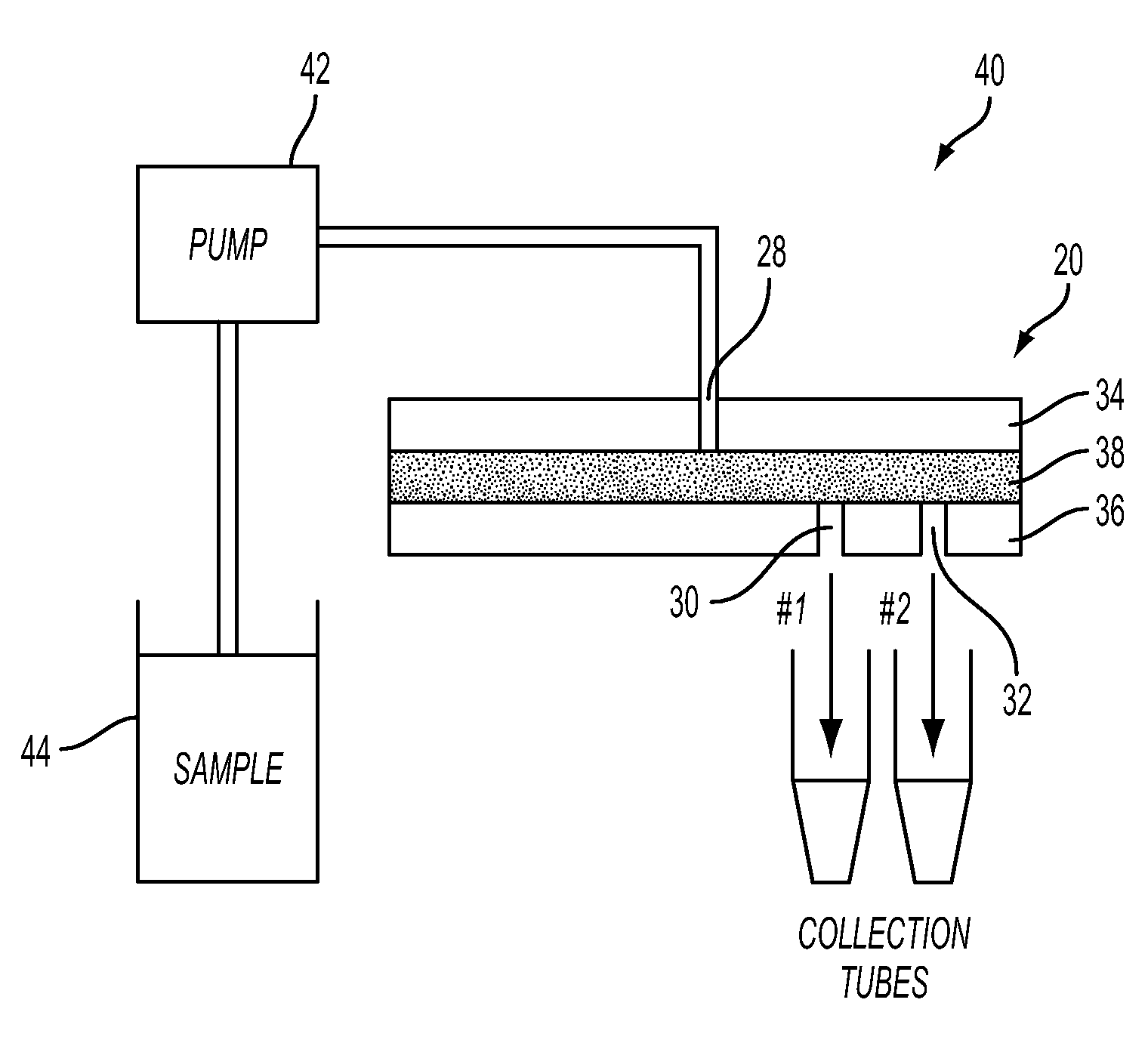

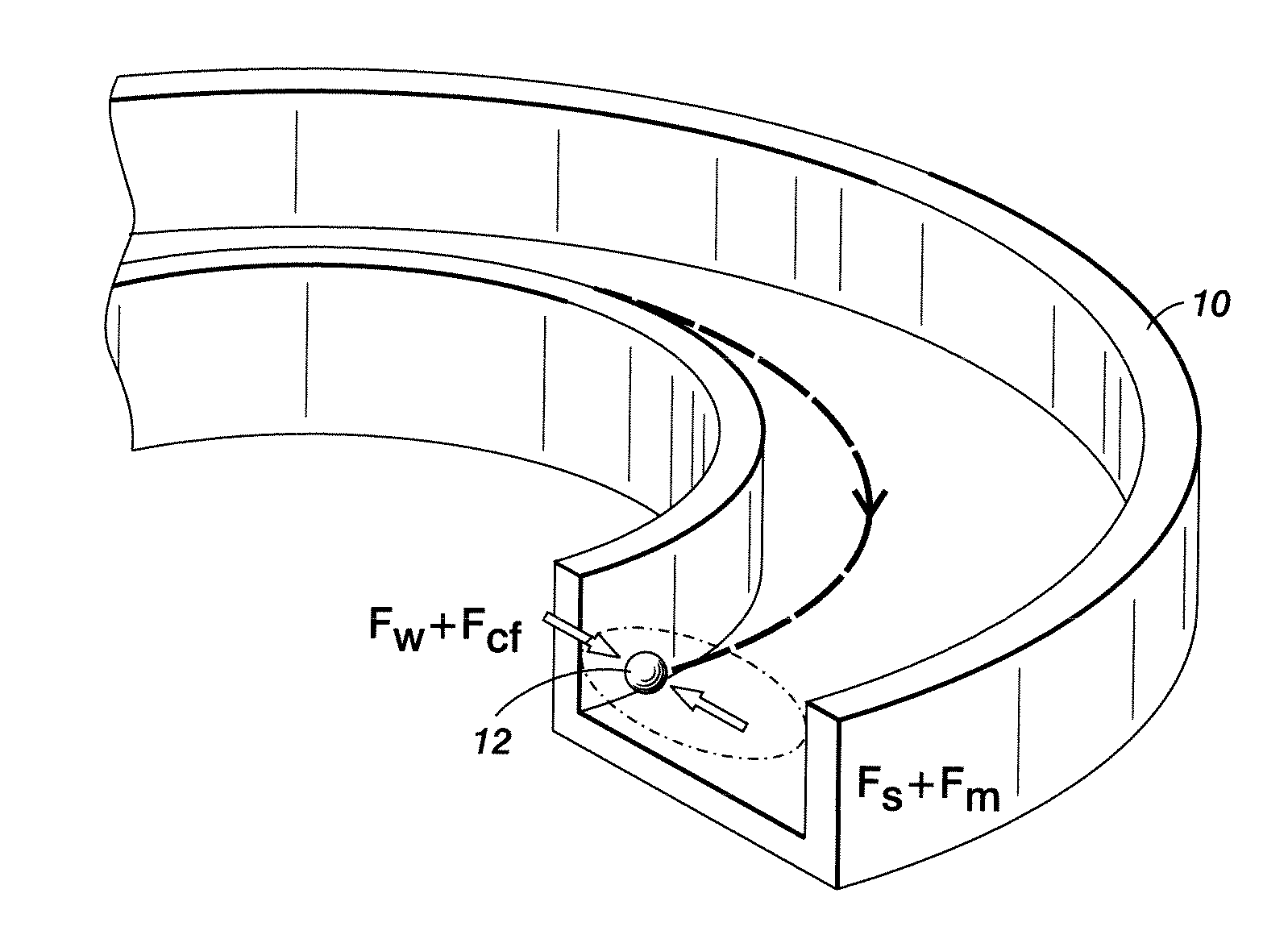

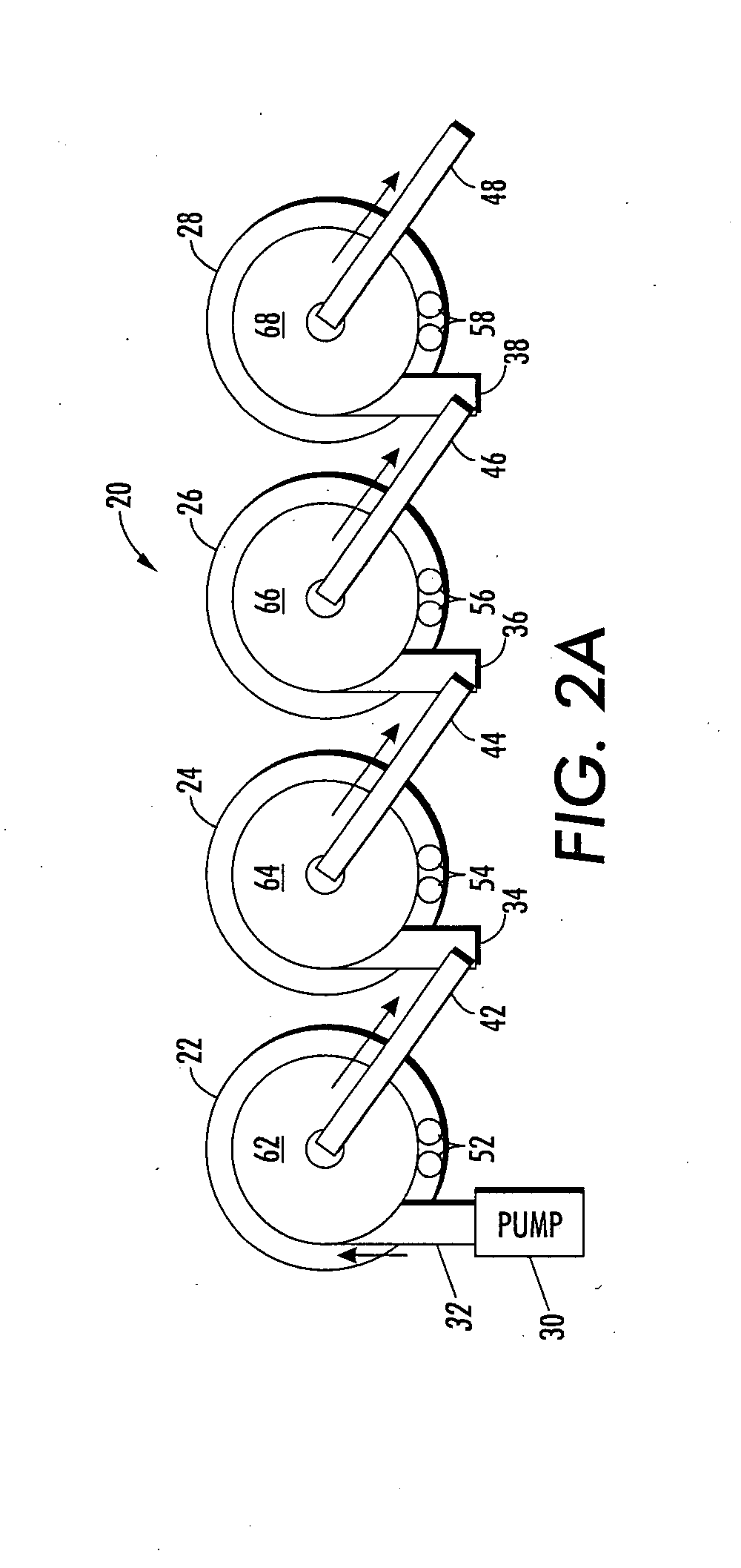

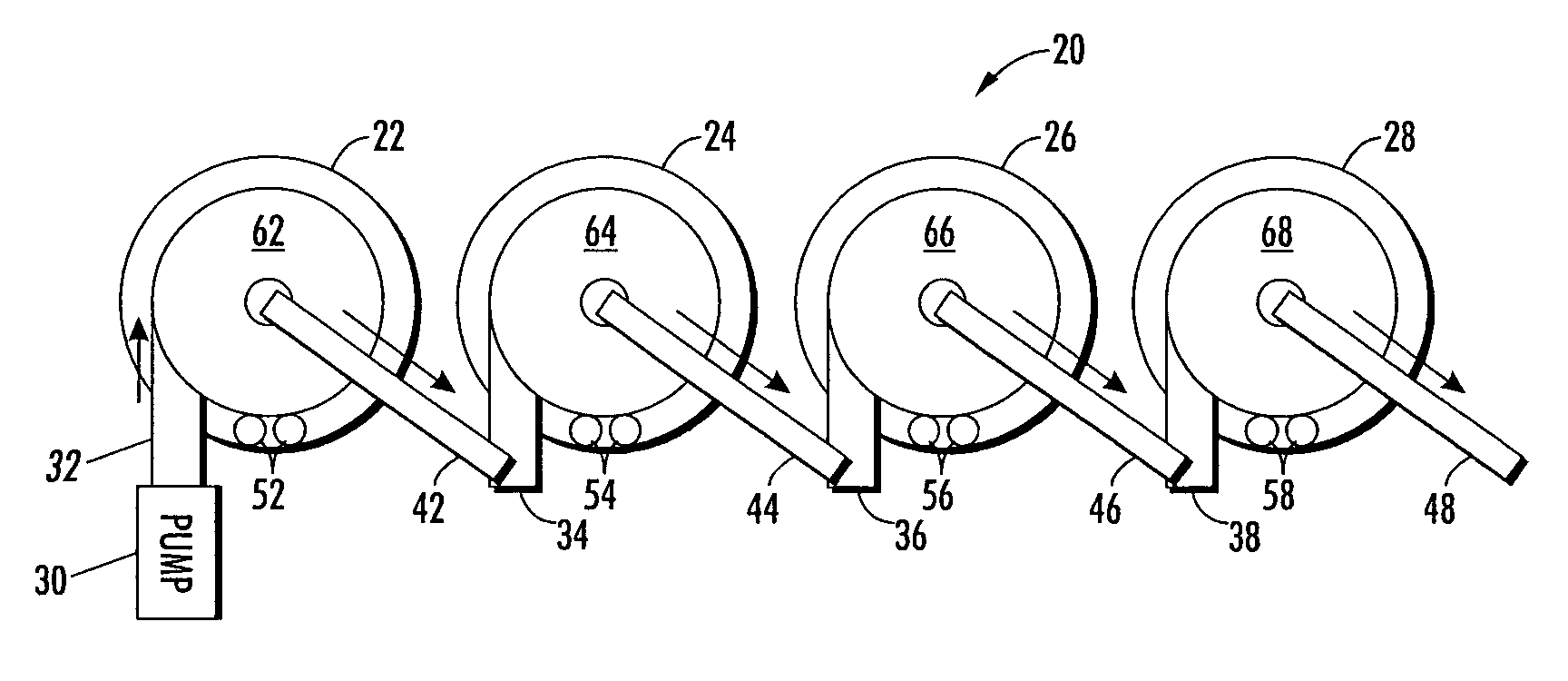

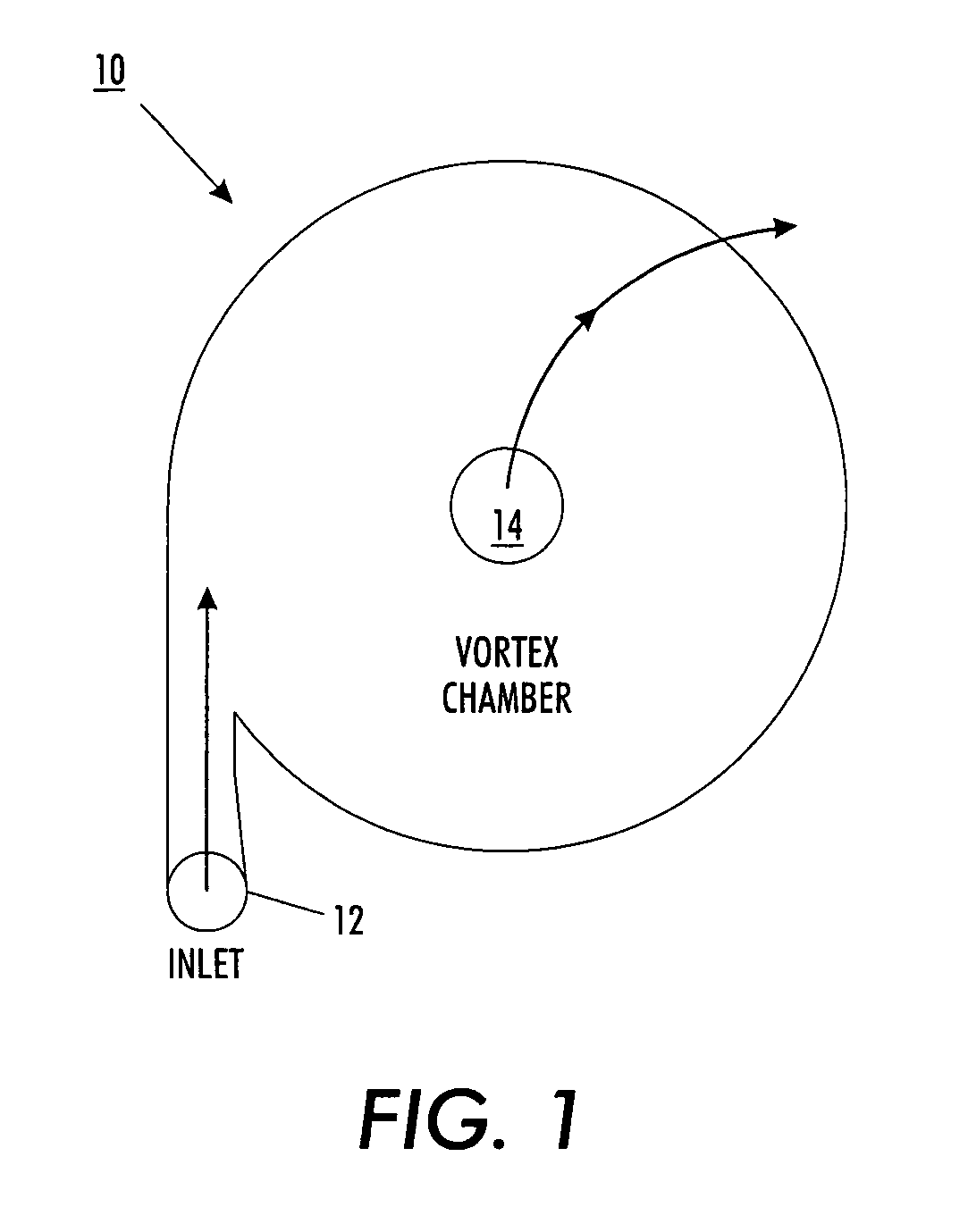

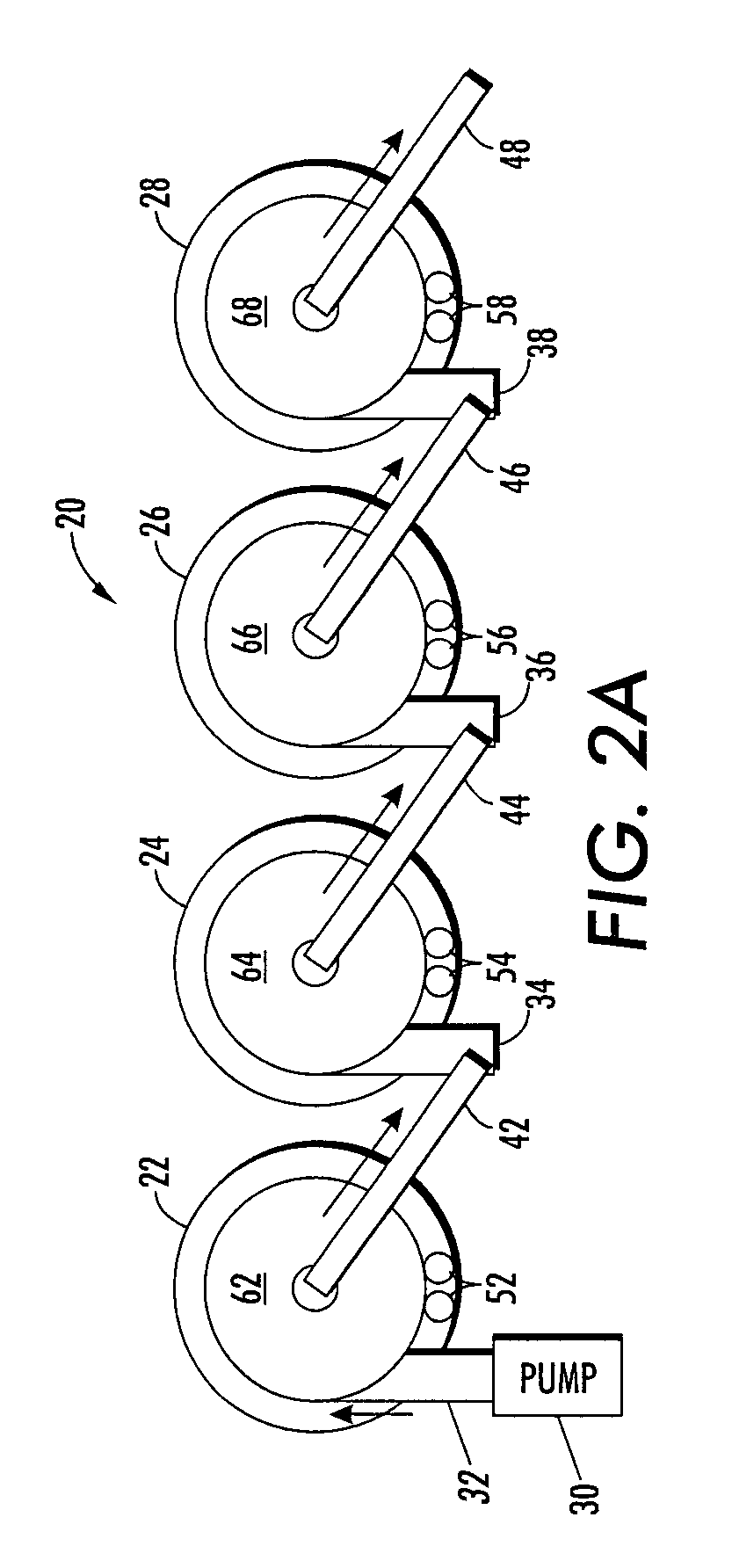

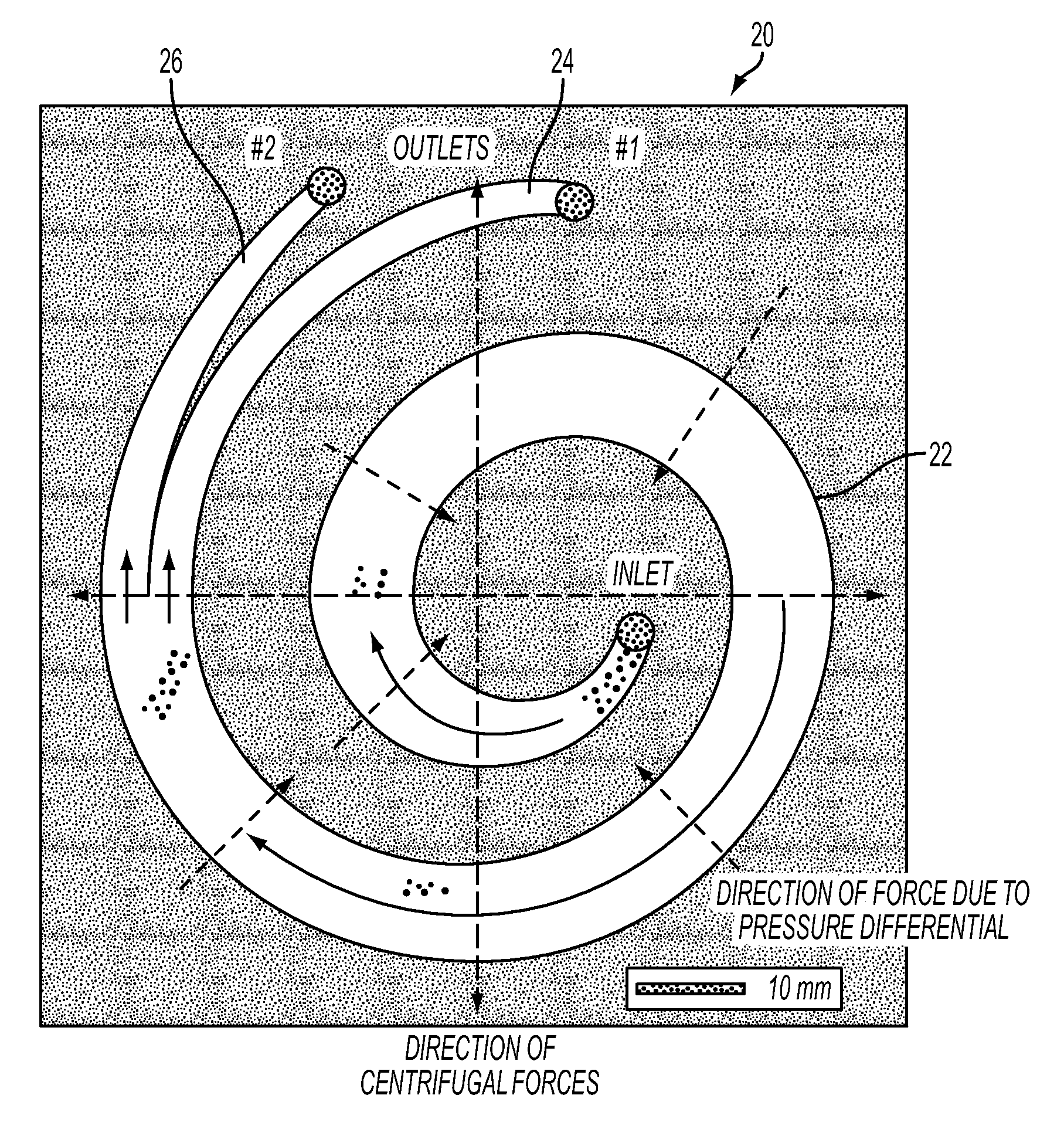

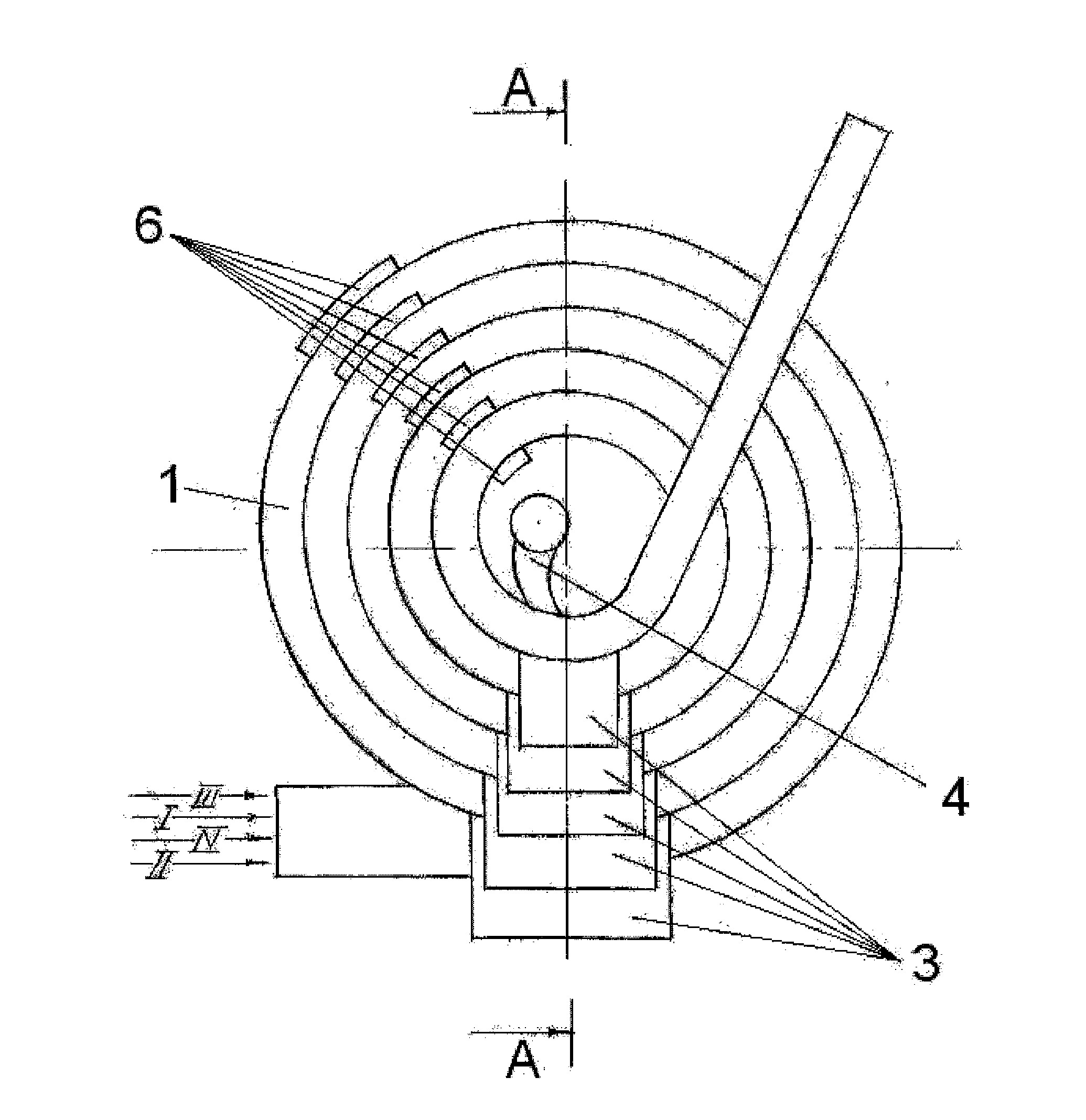

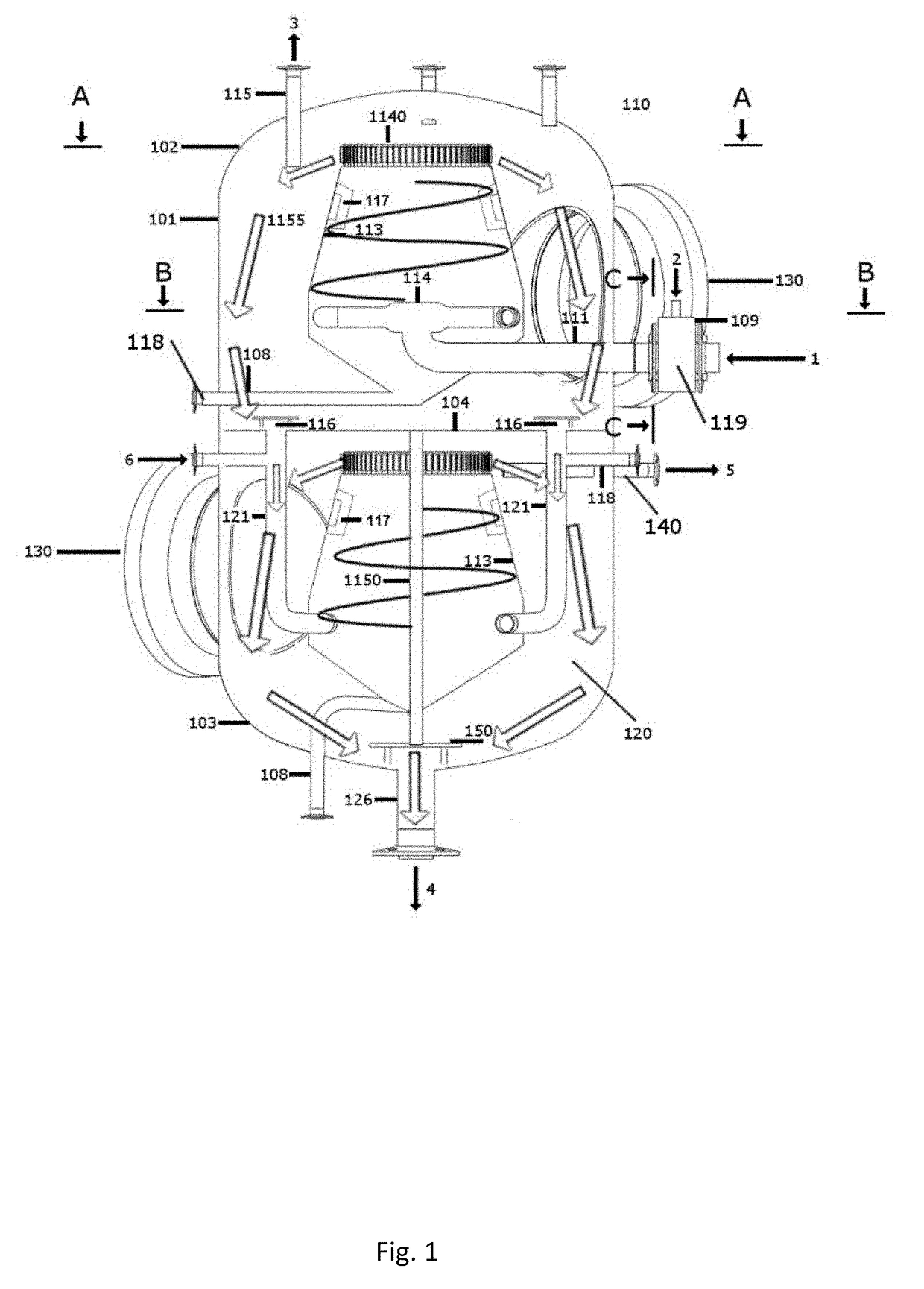

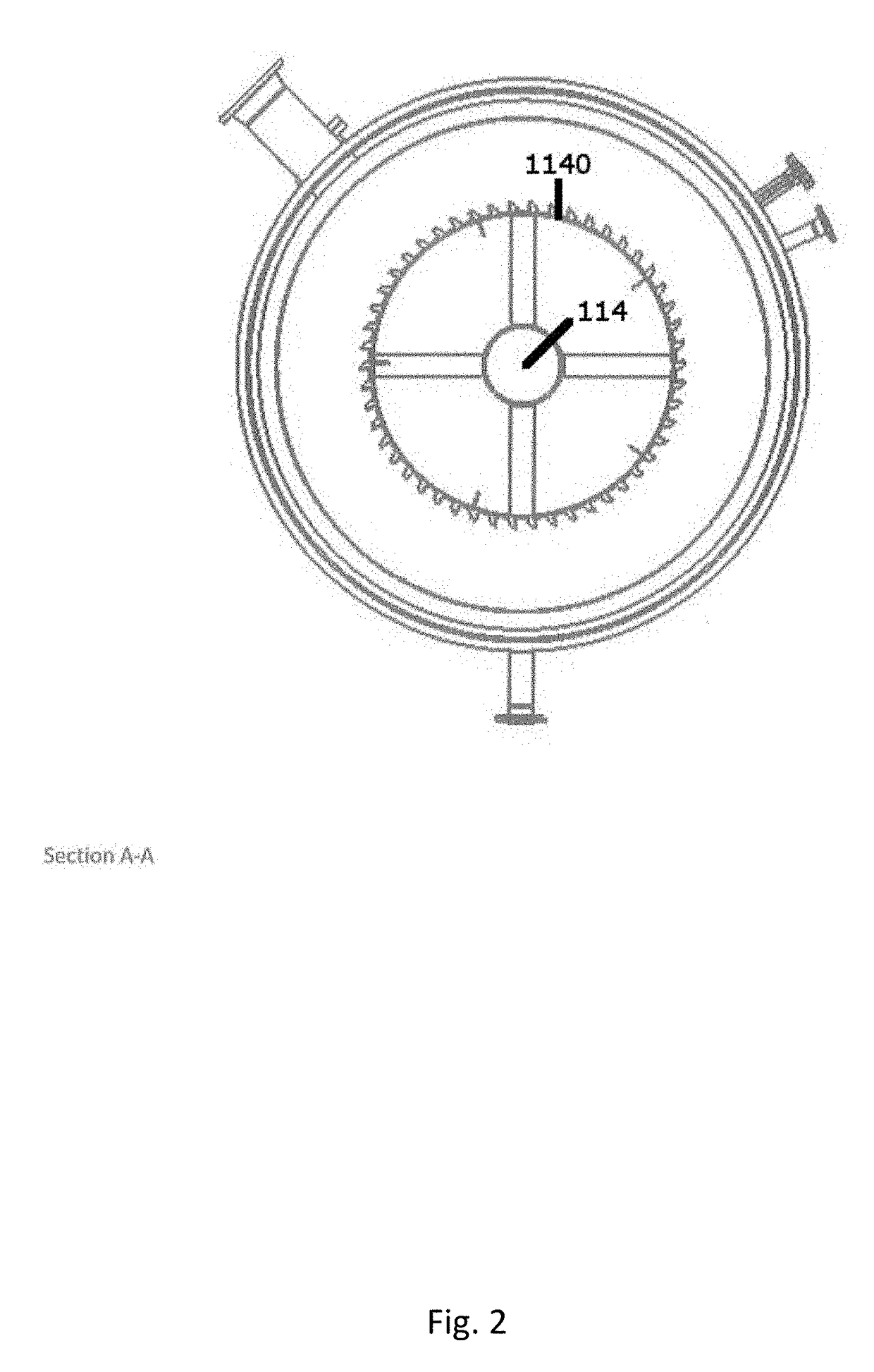

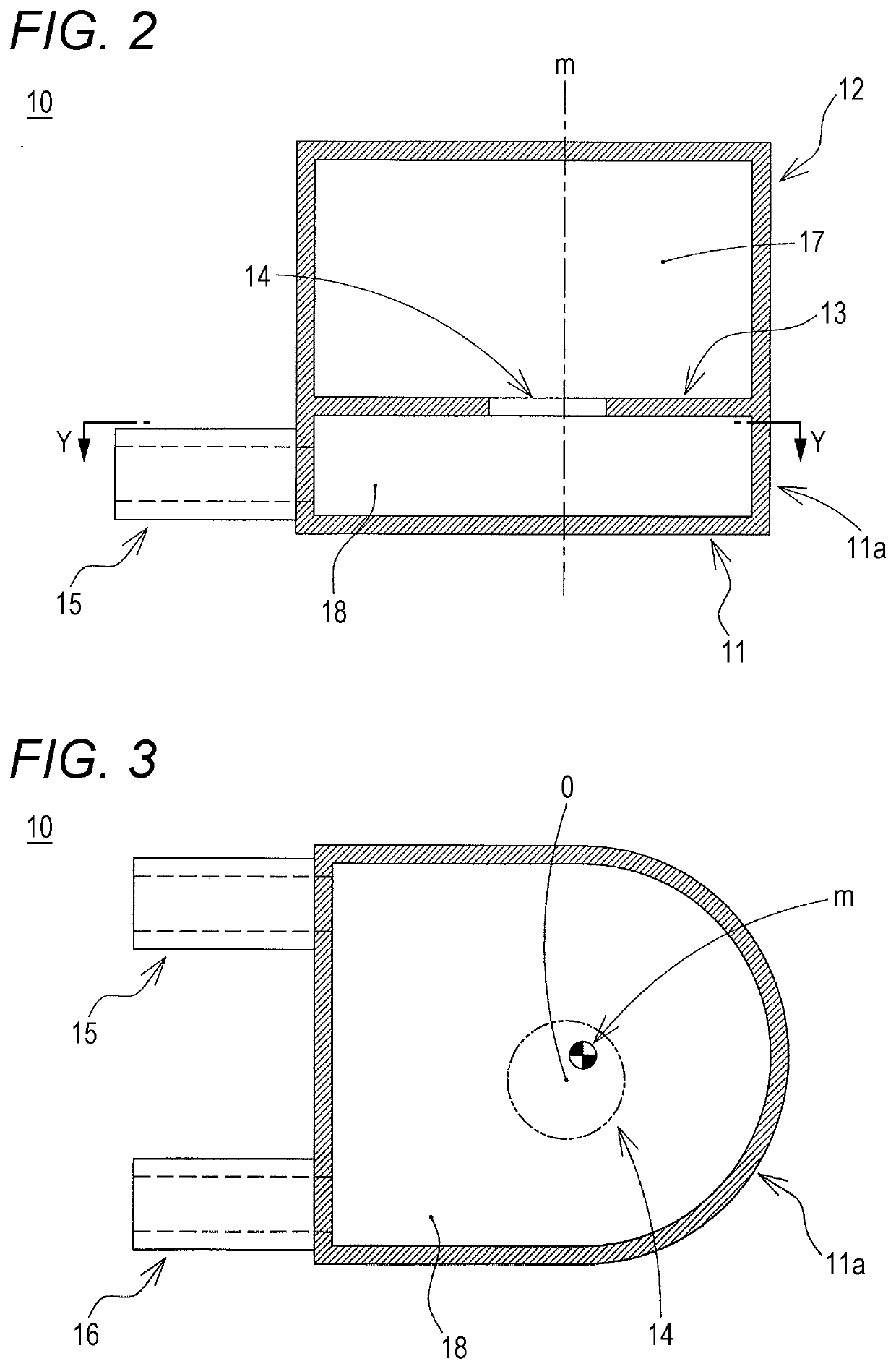

Vortex structure for high throughput continuous flow separation

InactiveUS20080230458A1Improve efficiencyHigh selectivityReversed direction vortexDispersed particle separationSuspended particlesEngineering

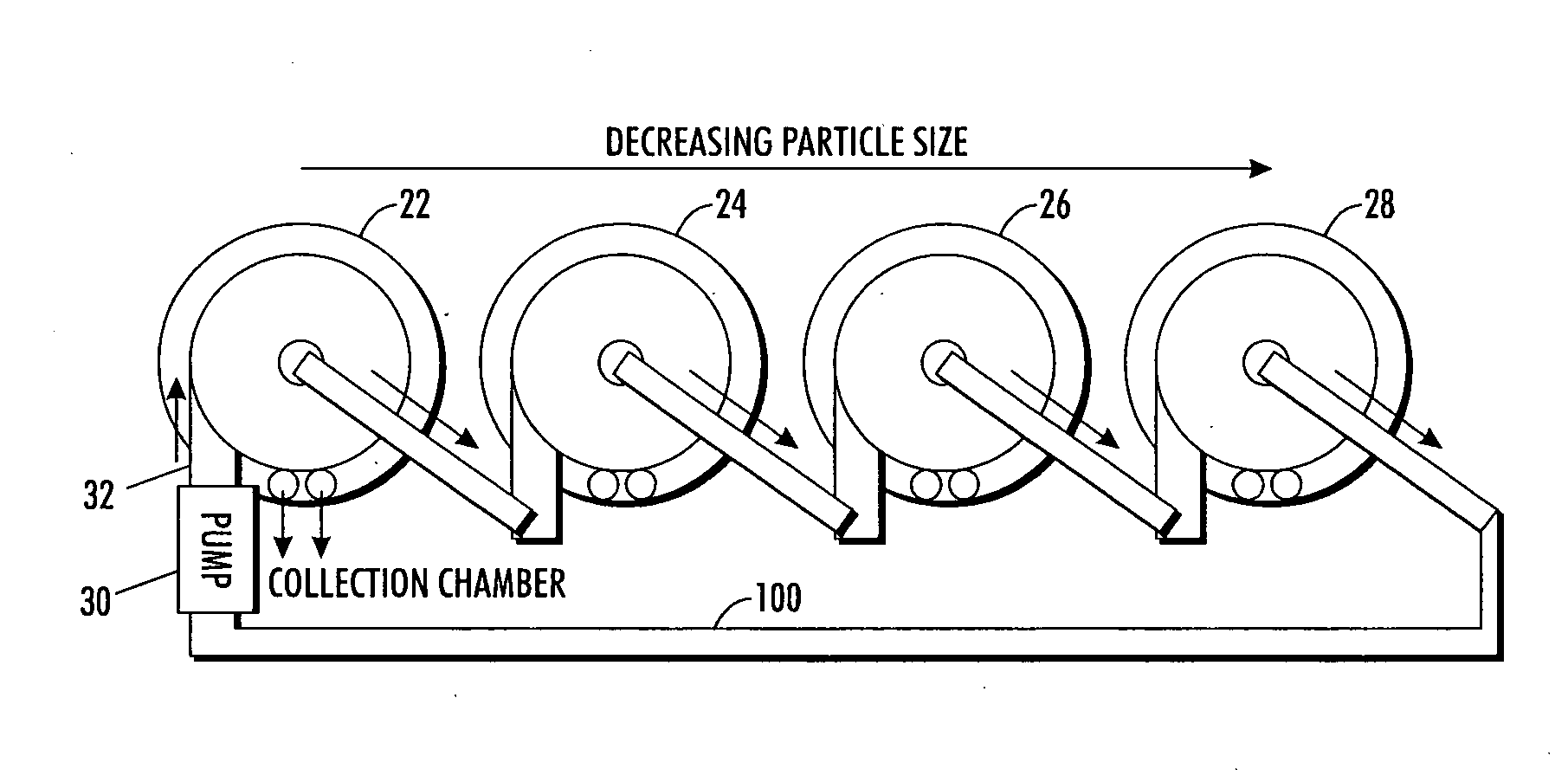

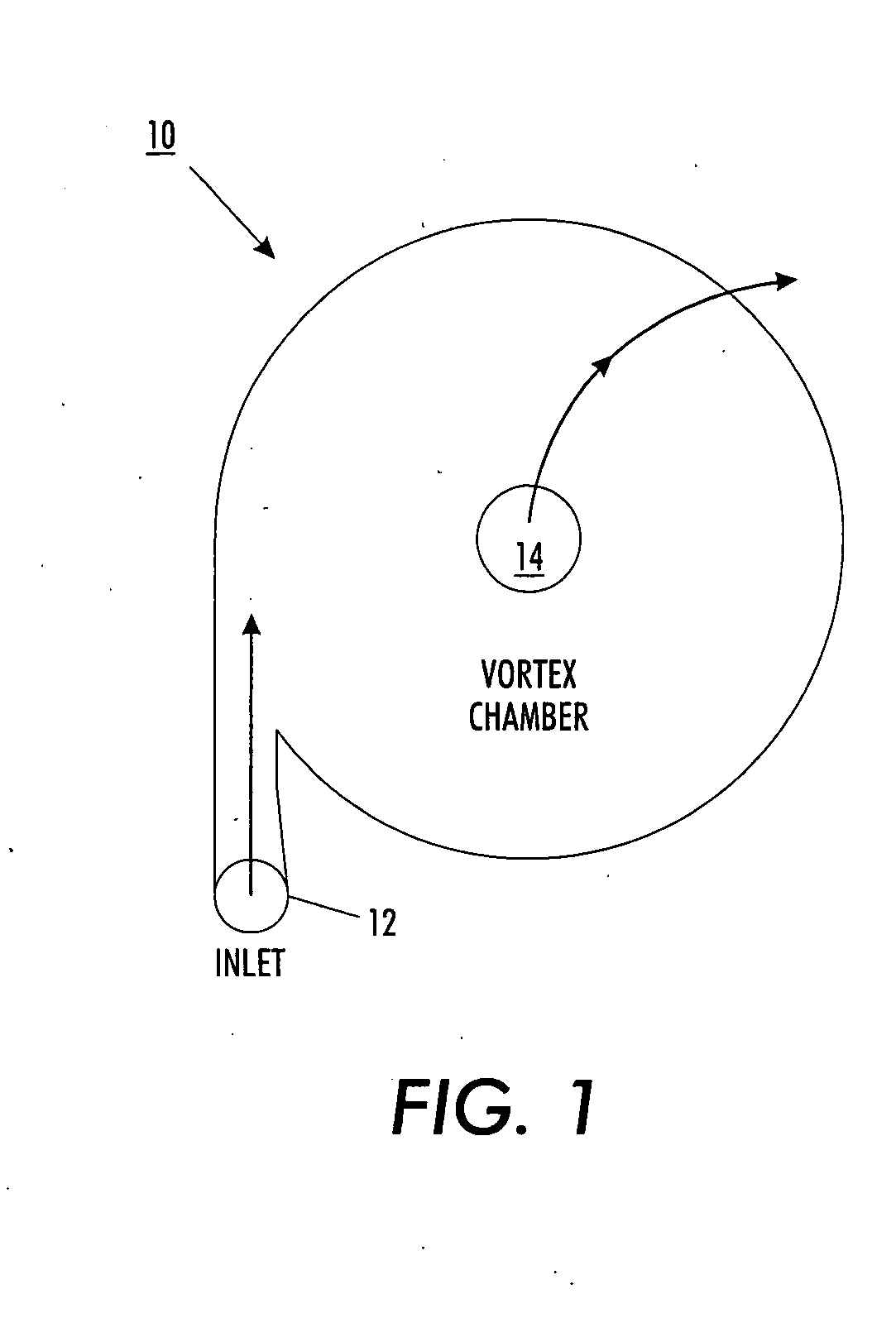

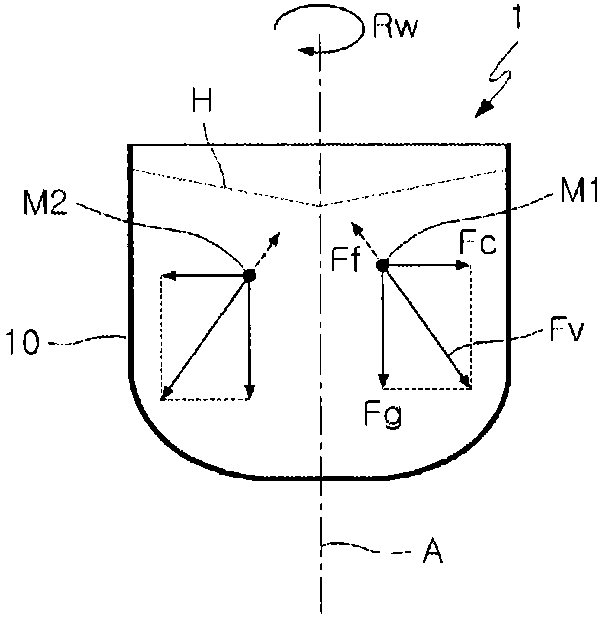

A system to facilitate separation and concentration of particles based on centrifugal force on suspended particles, including biological matter, which are made to flow in a vortex structure is provided. The centrifugal force urges larger particles to collect along outer portions of the vortex flow. Conversely, within a vortex structure, a radial hydrodynamic pressure drop is also amplified to urge smaller particles toward inner portions of the vortex flow. This force created by the pressure can reach magnitudes that encourage a sharp cut-off and improved resolution discrimination between particle sizes. Thus, separated streams of particles can be collected with both increased concentration and purification.

Owner:PALO ALTO RES CENT INC

Vacuum loader with louvered tangential cyclone separator

A tangential cyclone separator includes a support, a first sidewall, a second sidewall, and tube. The first sidewall extends away from the support and,includes a plurality of louvers each having a louver width and an inner edge. The plurality of inner edges define at least a portion of a first circle. The plurality of louvers are,spaced apart about the first circle. Each louver width defines a louver direction, and each louver direction and the first circle define a louver intersection. Each louver intersection and the first circle define a louver tangent line. Each louver tangent line is associated with a respective louver direction, where each louver tangent line and associated louver direction share a common louver intersection. Each louver direction and associated louver tangent form a louver angle, wherein each louver angle is approximately between 10° and 60°. The second sidewall extends upwardly from the support and includes an opening. The tube is connected to the opening and extends generally tangentially to the first circle.

Owner:DEMARCO VACUUM CORP

Vortex structure for high throughput continuous flow separation

InactiveUS8875903B2Improve efficiencyHigh selectivityReversed direction vortexDispersed particle separationSuspended particlesContinuous flow

A system to facilitate separation and concentration of particles based on centrifugal force on suspended particles, including biological matter, which are made to flow in a vortex structure is provided. The centrifugal force urges larger particles to collect along outer portions of the vortex flow. Conversely, within a vortex structure, a radial hydrodynamic pressure drop is also amplified to urge smaller particles toward inner portions of the vortex flow. This force created by the pressure can reach magnitudes that encourage a sharp cut-off and improved resolution discrimination between particle sizes. Thus, separated streams of particles can be collected with both increased concentration and purification.

Owner:PALO ALTO RES CENT INC

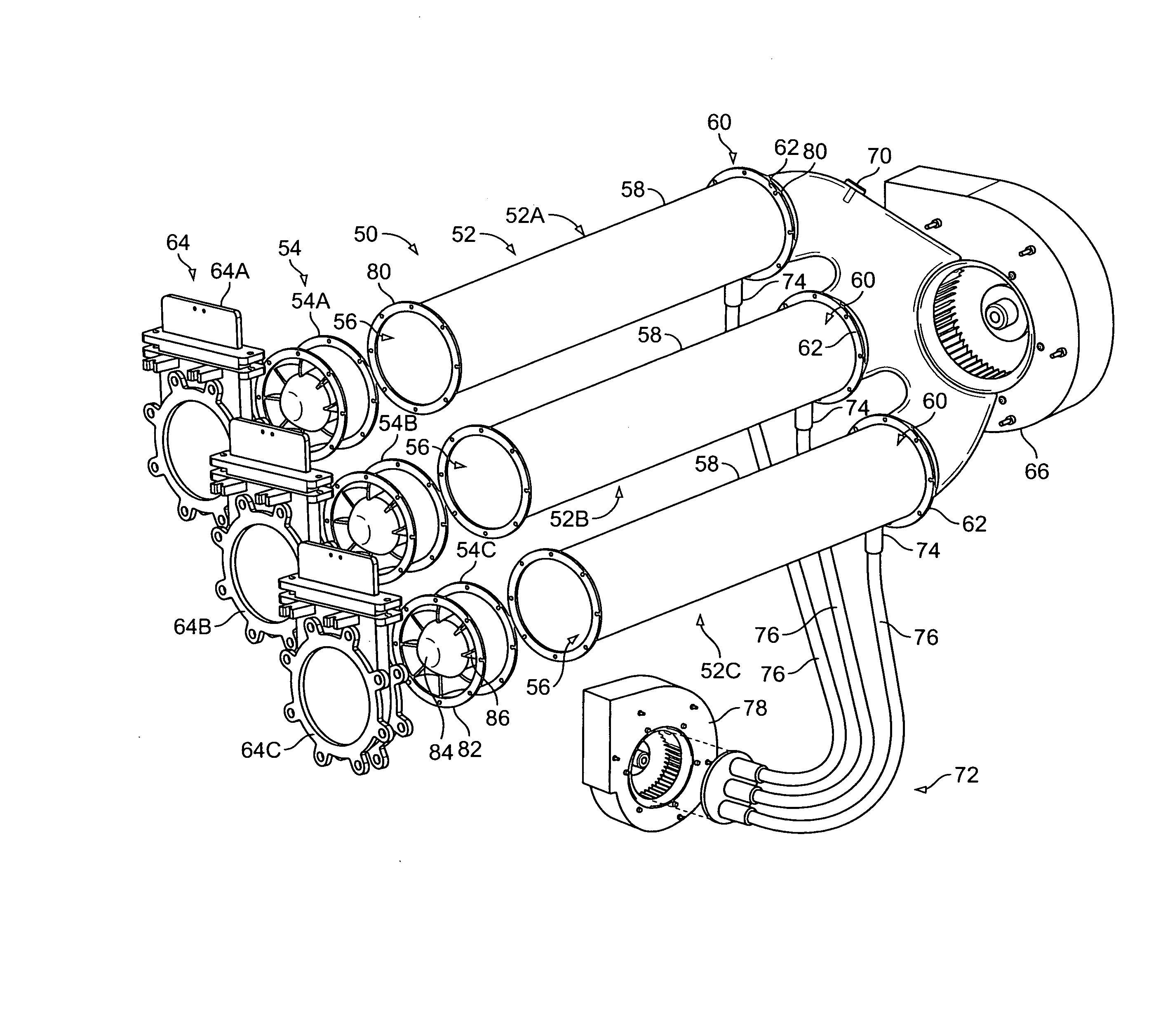

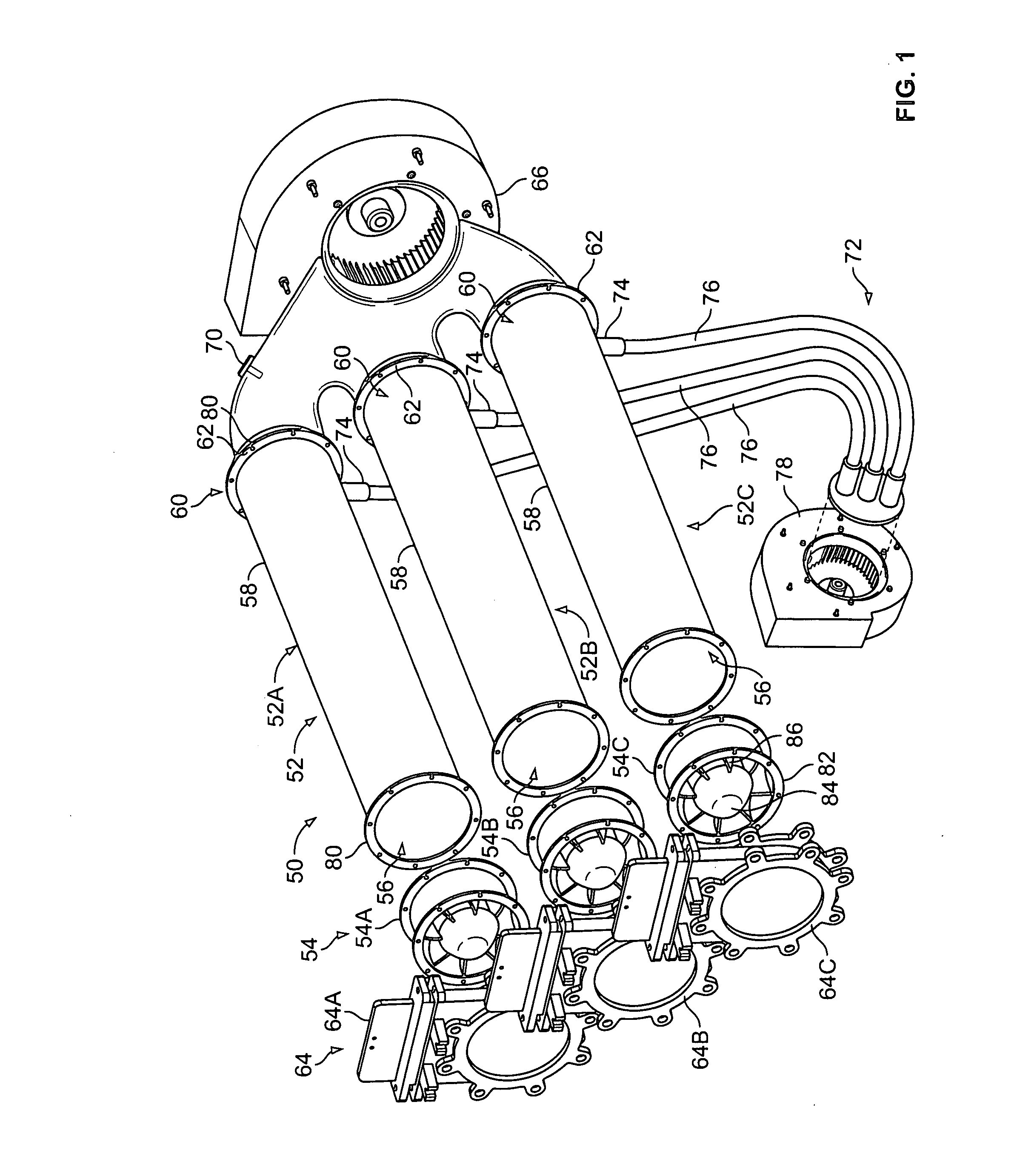

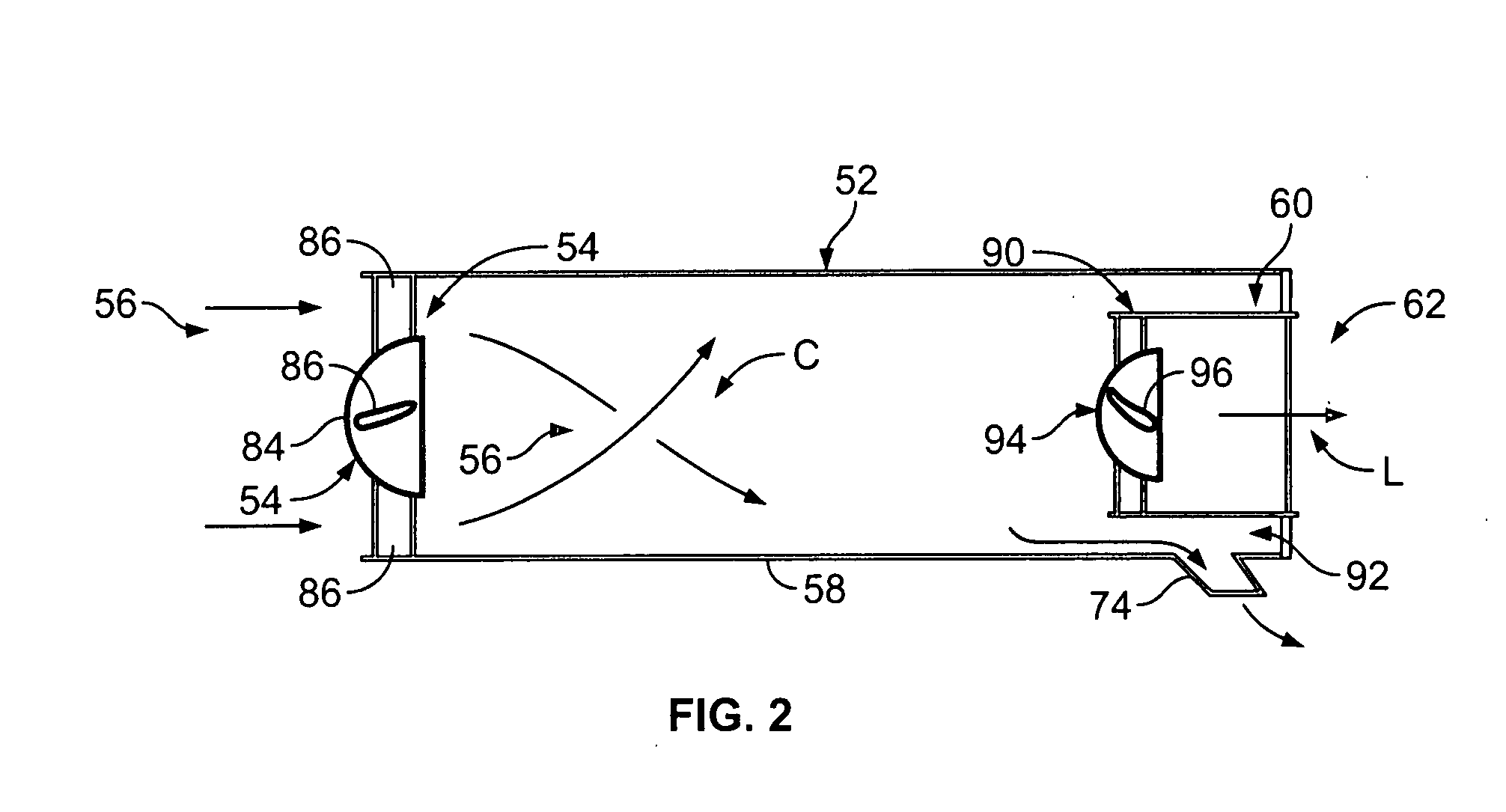

Dust separation system for use with mobile equipment

InactiveUS20070295209A1Good collection efficiencyIncrease air flowCleaning filter meansCombination devicesCycloneEngineering

Embodiments of the invention include a dust extraction system including an array of two or more centrifugal dust removal devices, e.g., axial cyclones. The array of axial cyclones is configured to operate in parallel. The array of axial cyclones includes one or more sensor and a controller in communication with the sensor and adapted to receive air flow information from the one or more sensor. Inflow valves are operatively connected to the controller such that air flow through the array of axial cyclones is monitored and maintained at an optimum operating condition for each of the individual cyclones in the array. This is done, in general, by opening inflow valves as the air flow increases above a predetermined air flow value and shutting inflow valves as air flow decreases below the predetermined air flow value threshold.

Owner:FEDERAL SIGNAL CORPORATION

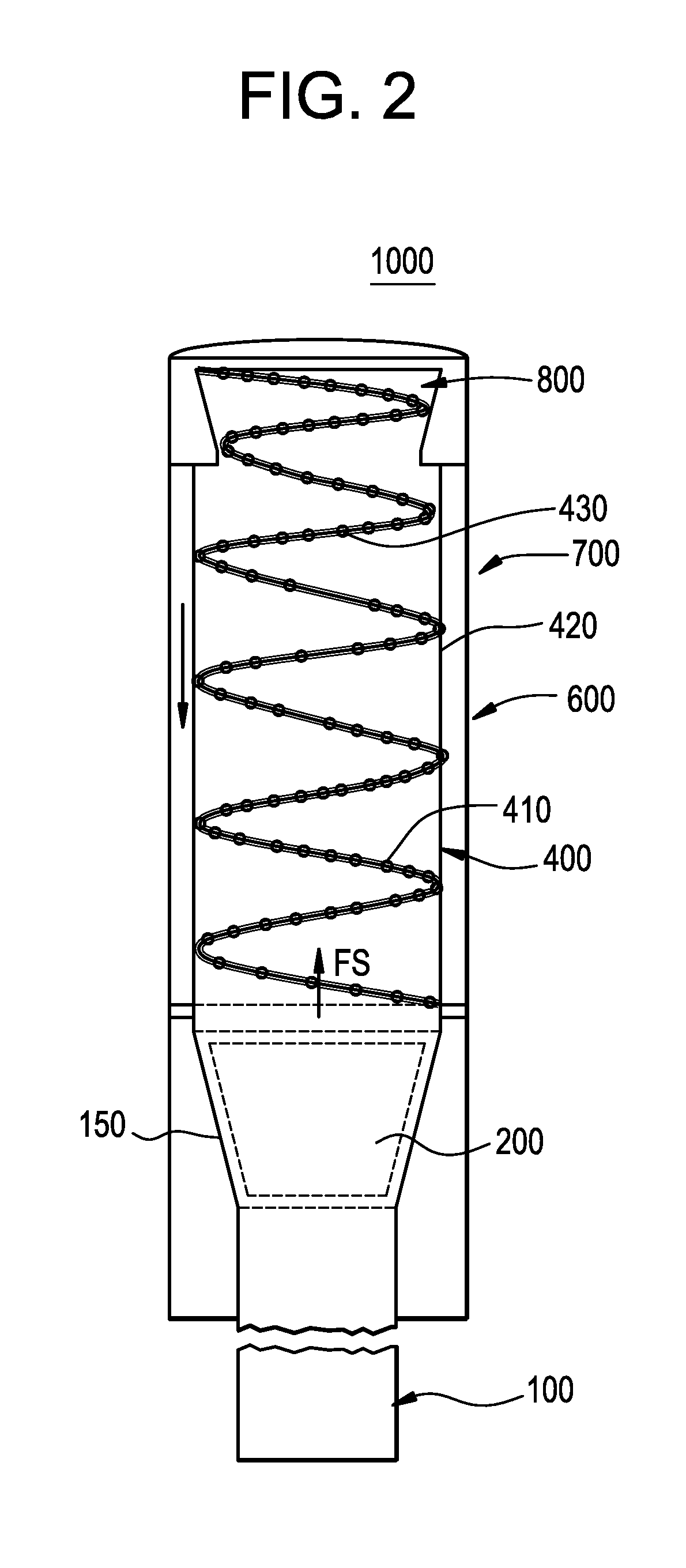

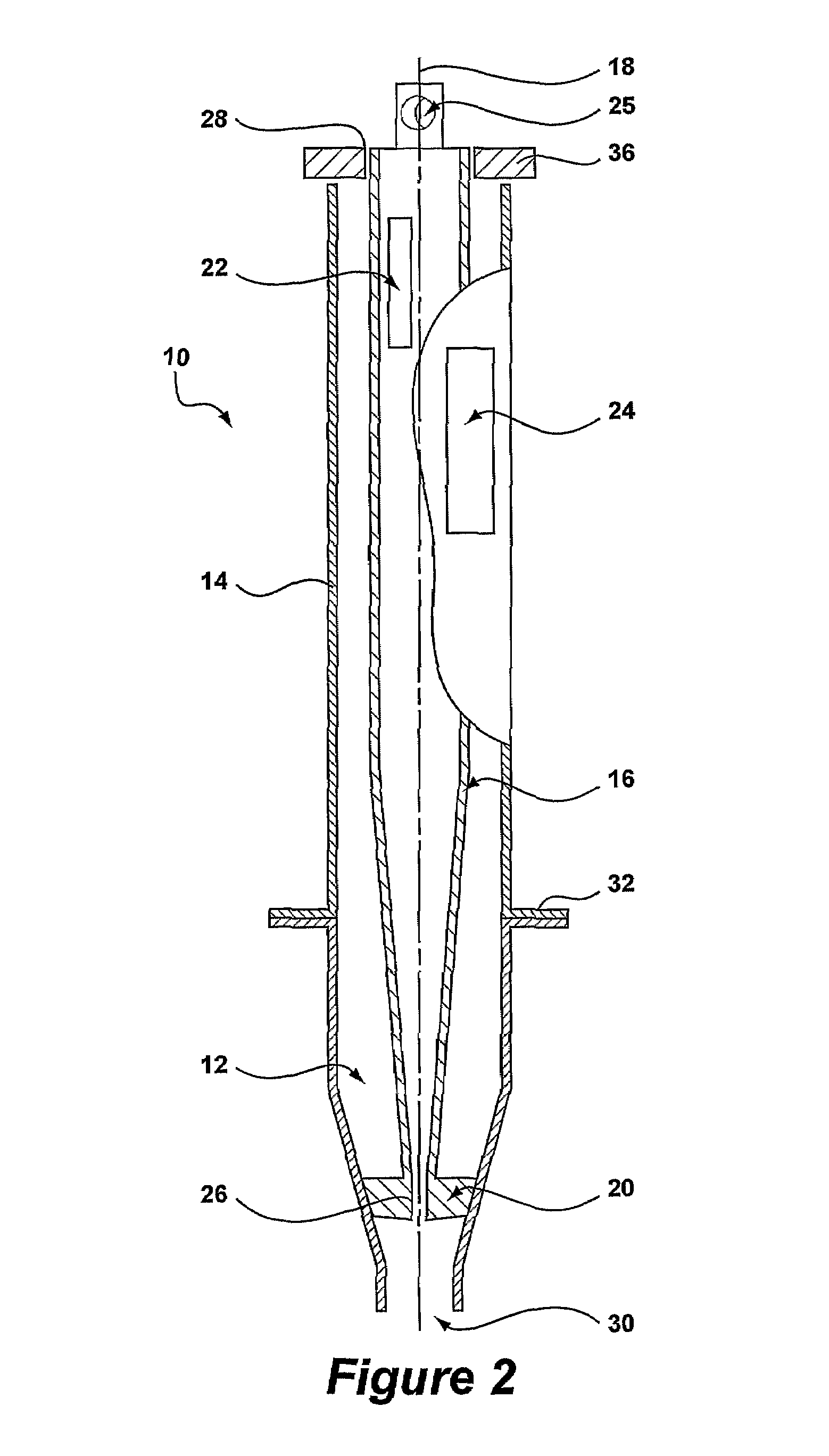

Degassing device

ActiveUS8444586B2Lower the volumeLarge heightLiquid degasificationOther blood circulation devicesEngineeringSpiral flow

Owner:GAMBRO LUNDIA AB

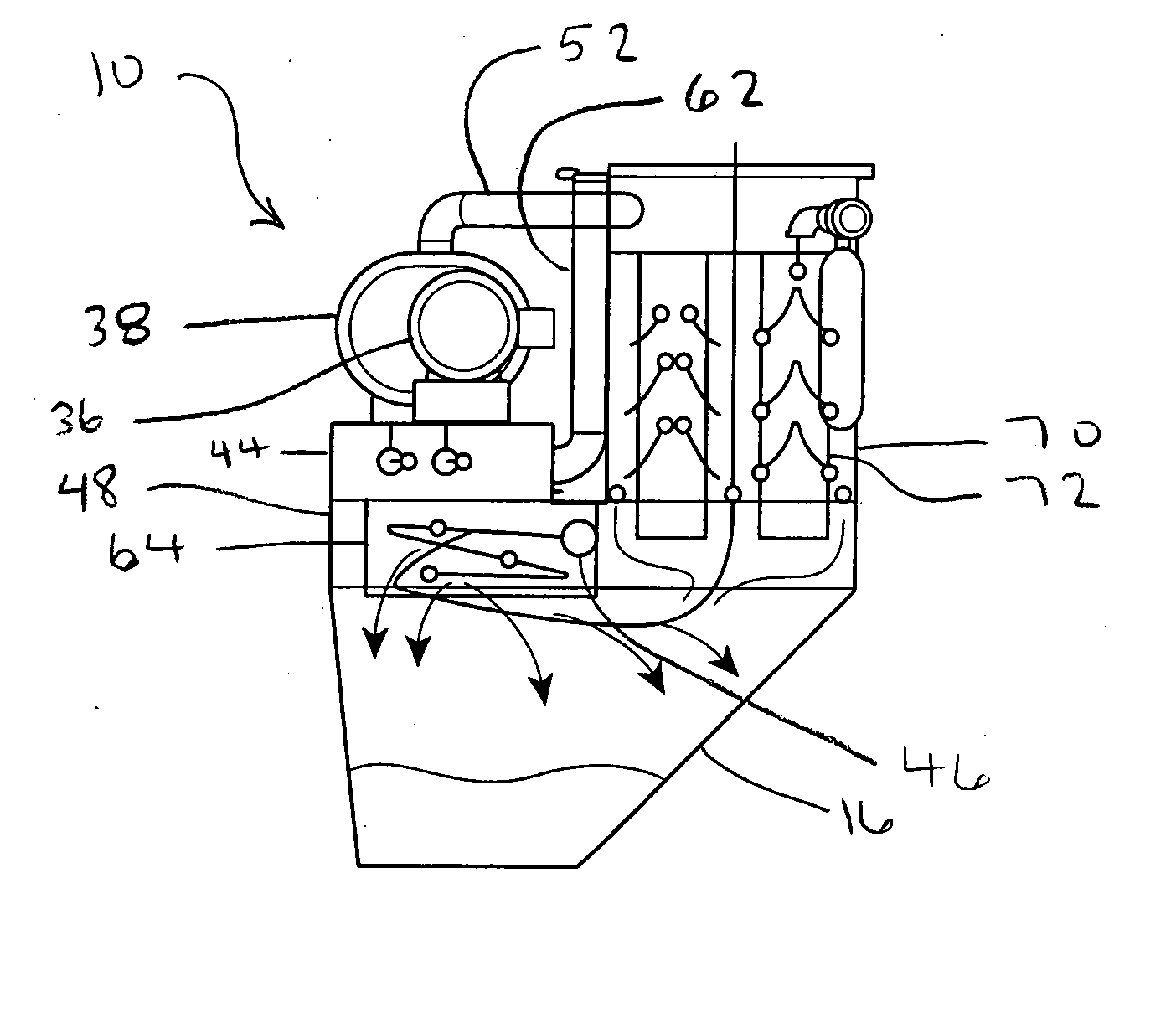

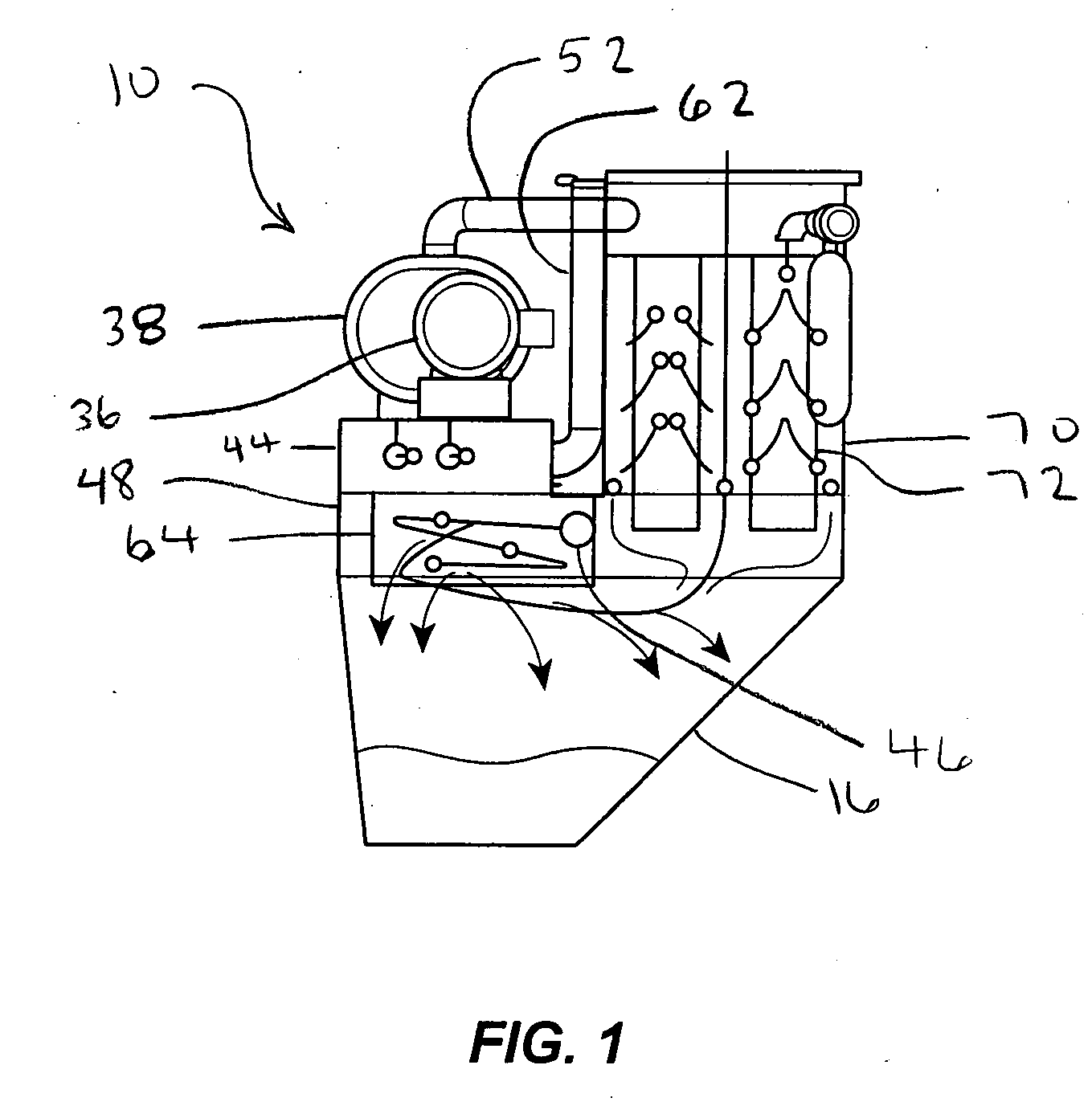

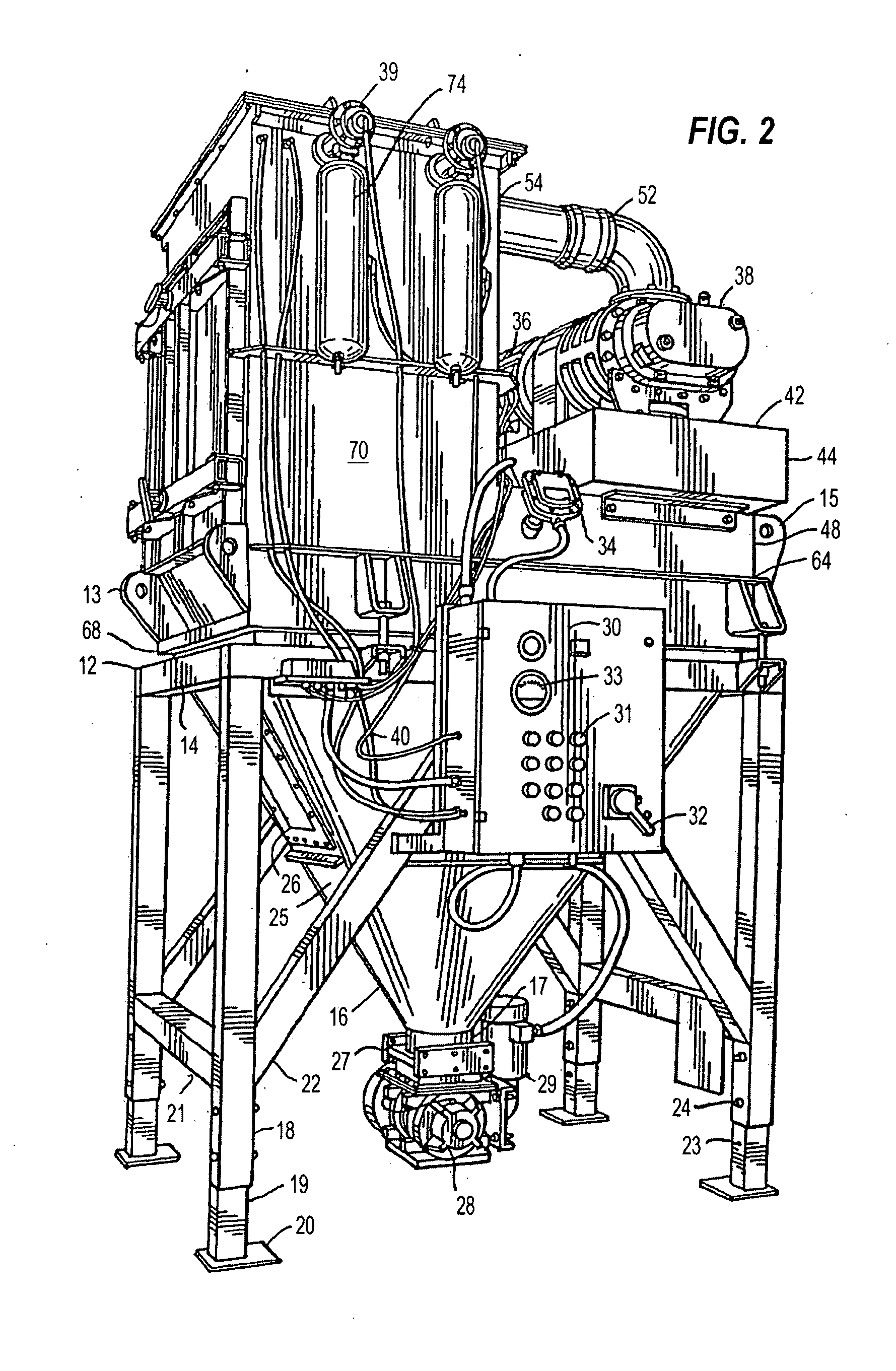

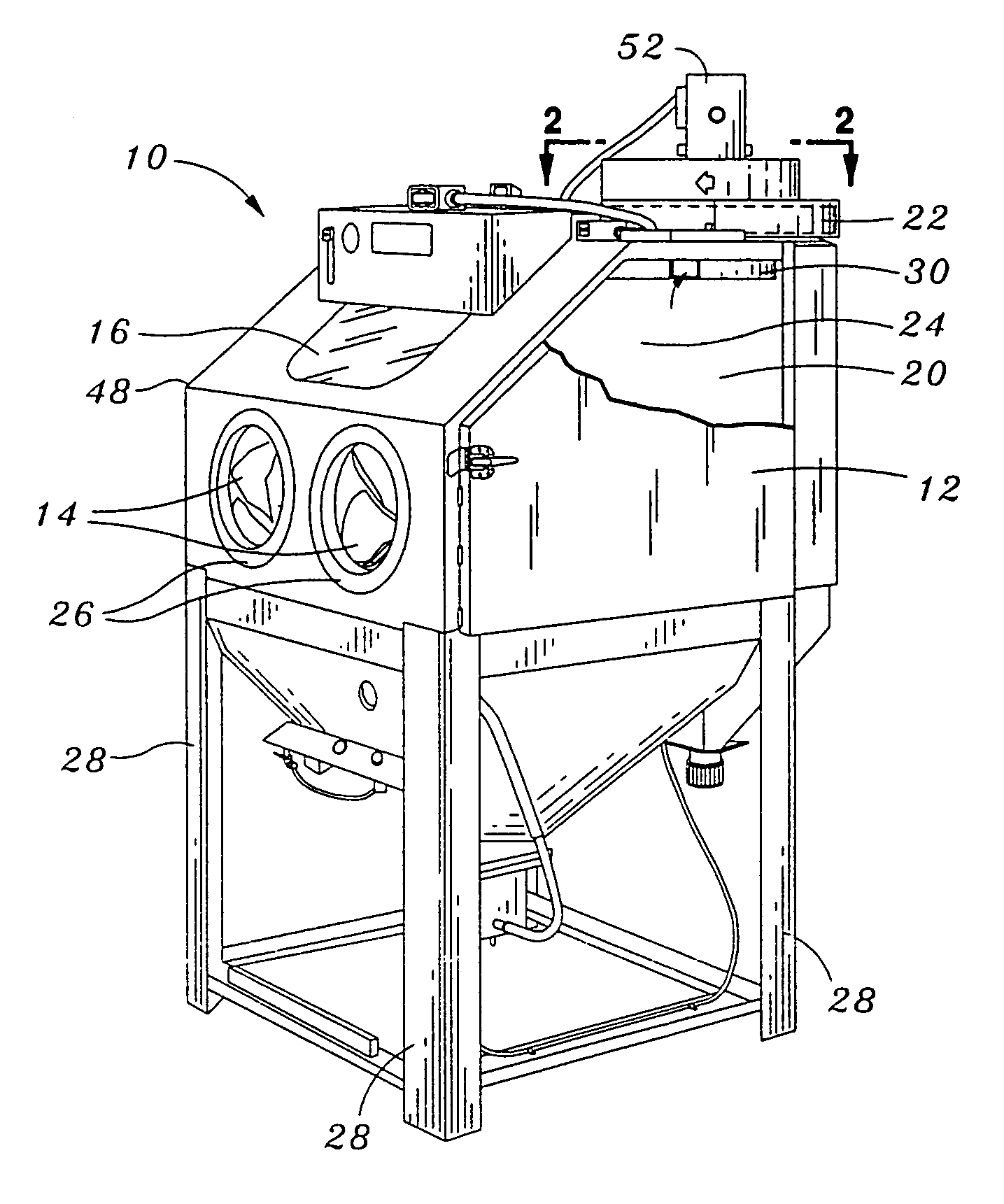

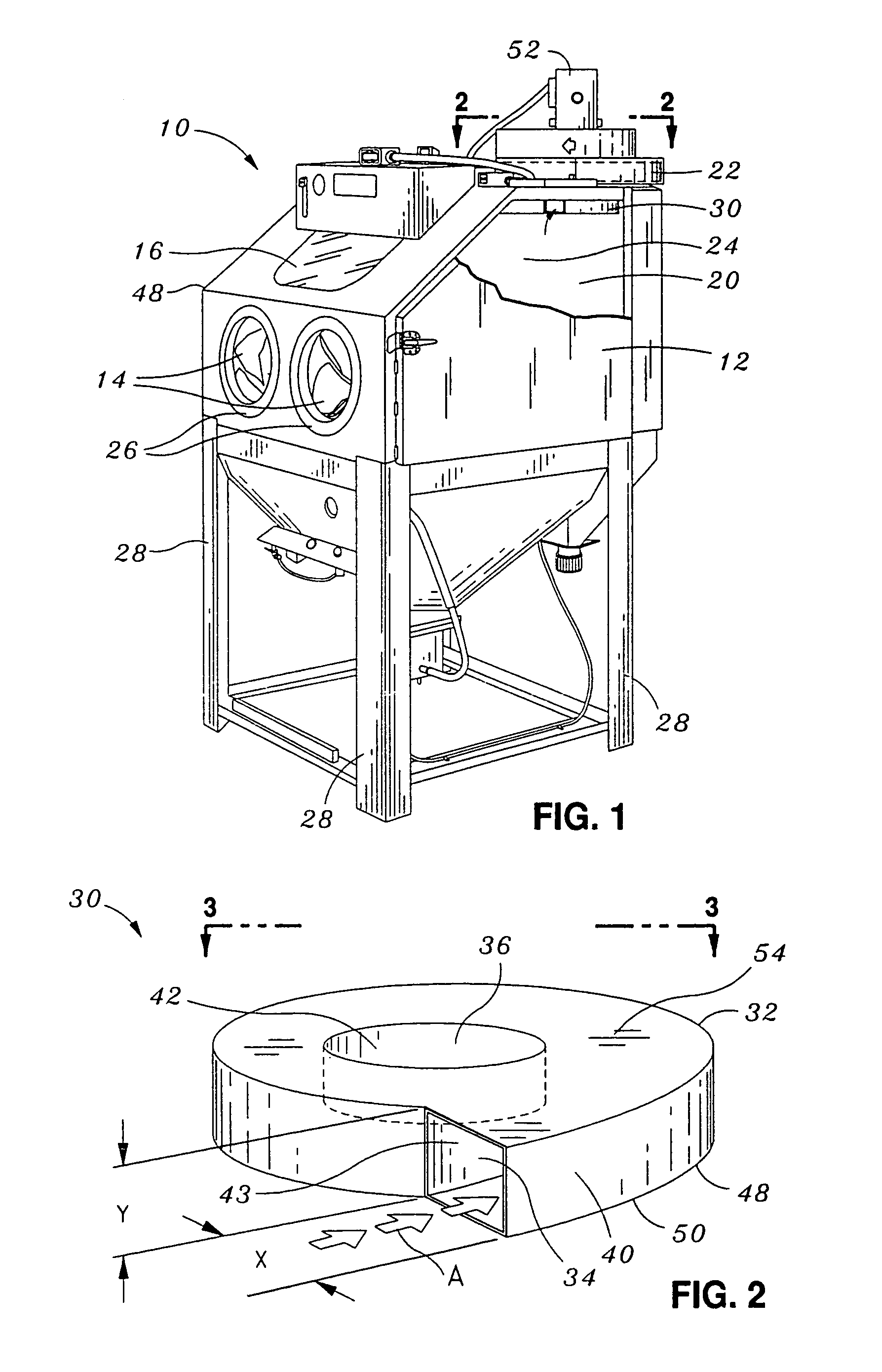

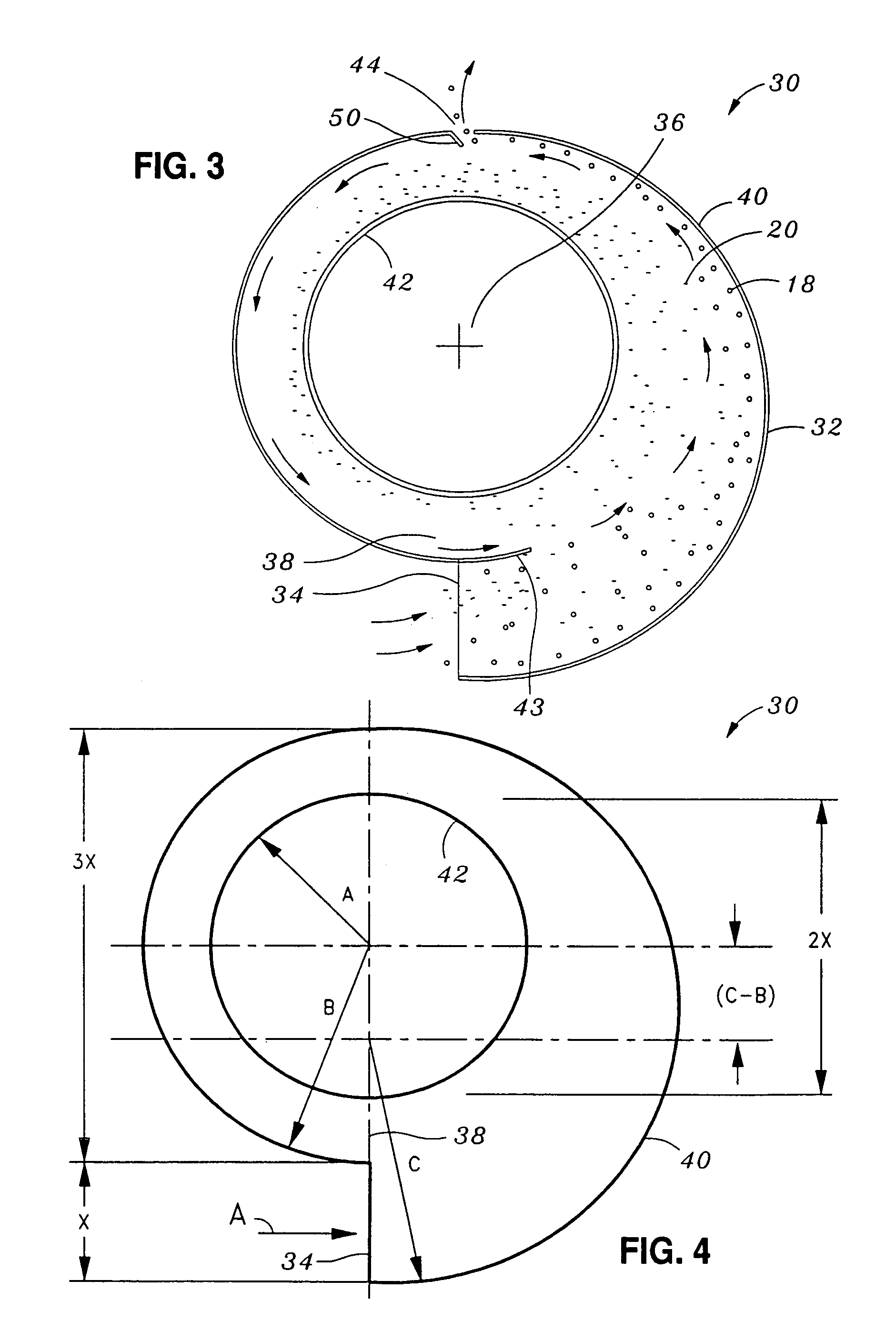

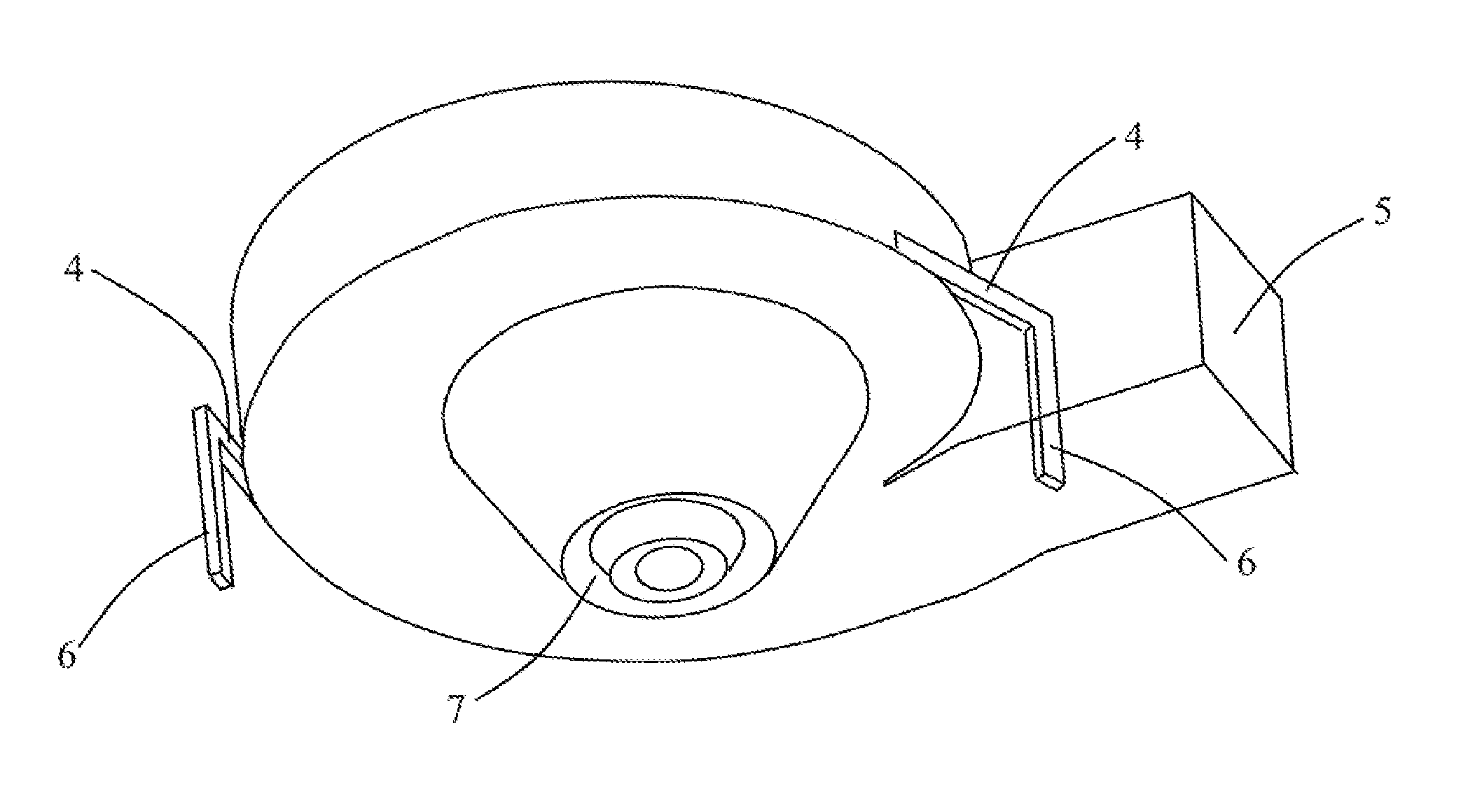

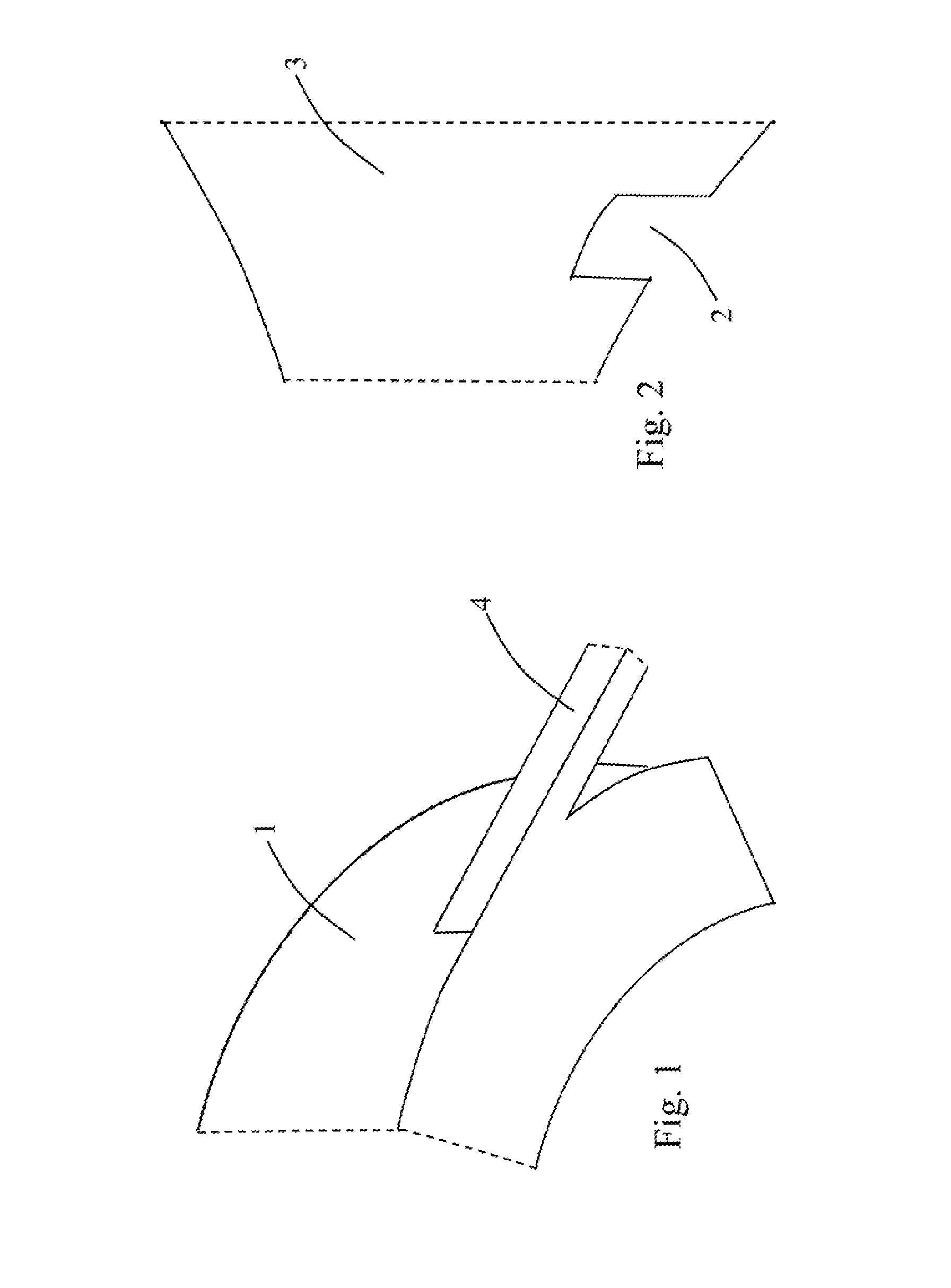

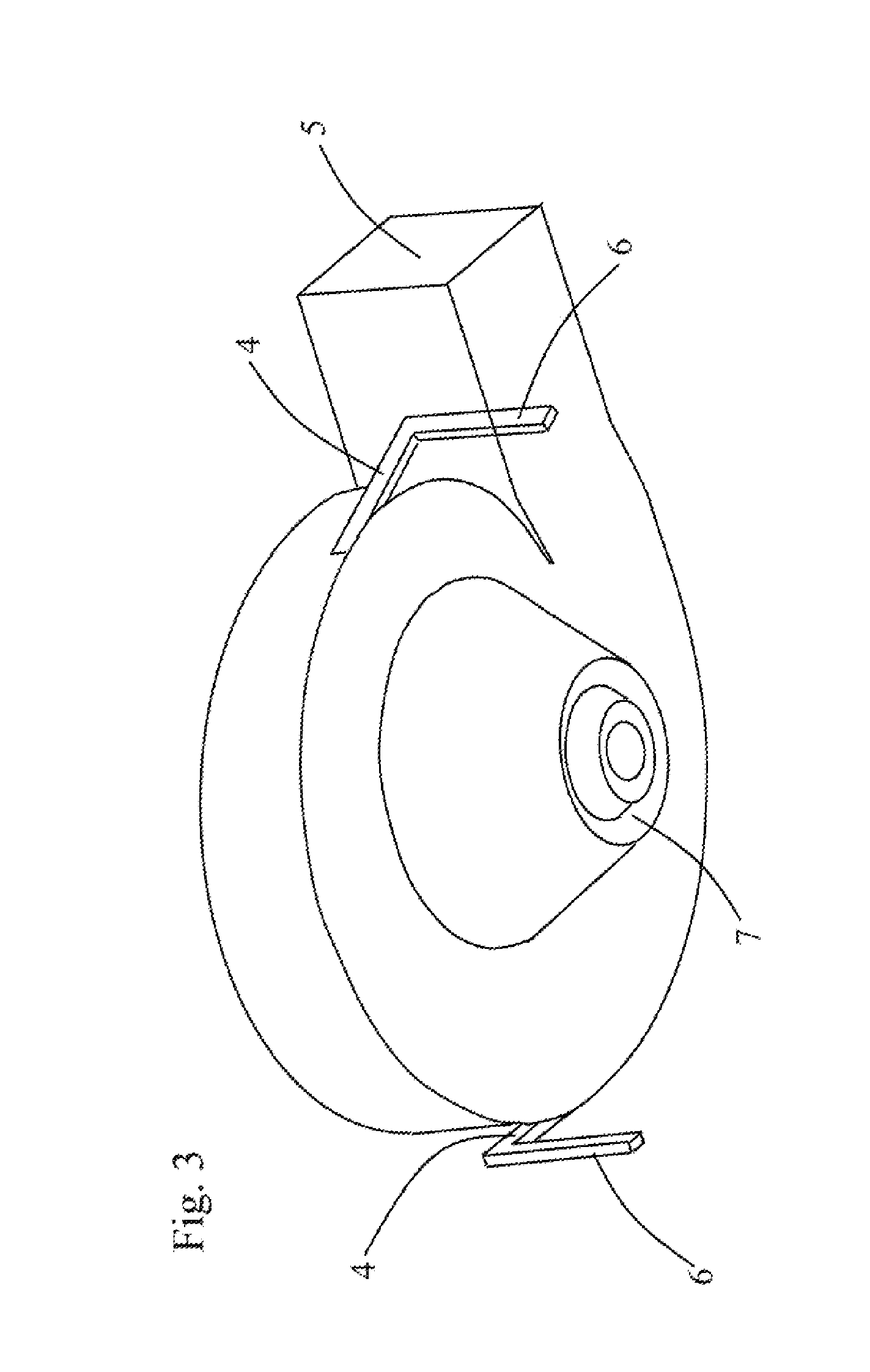

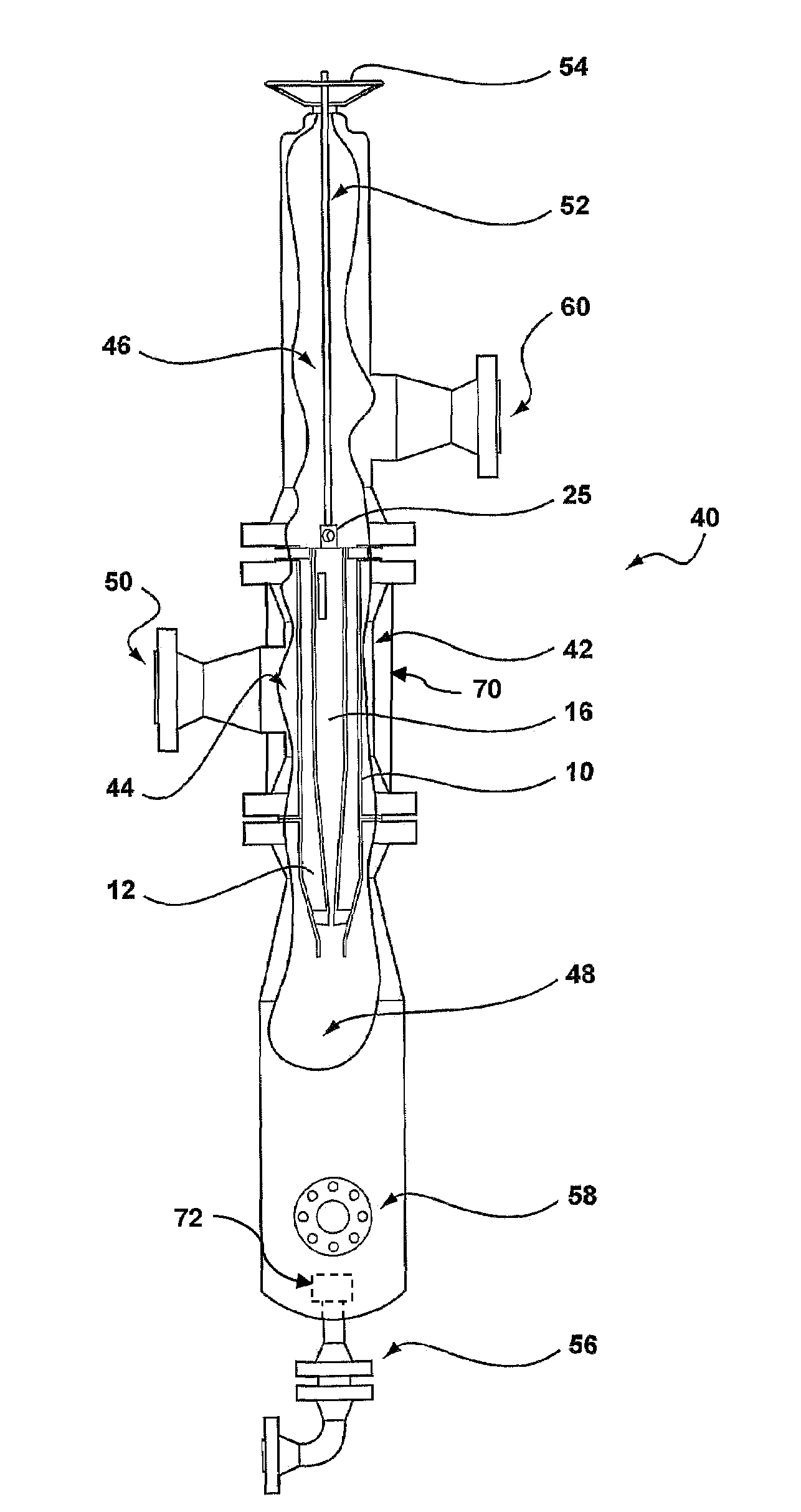

Abrasive and dust separator

ActiveUS20060040596A1Increase awarenessImprove fatigueAbrasive feedersFlat flow vortexEngineeringFine particulate

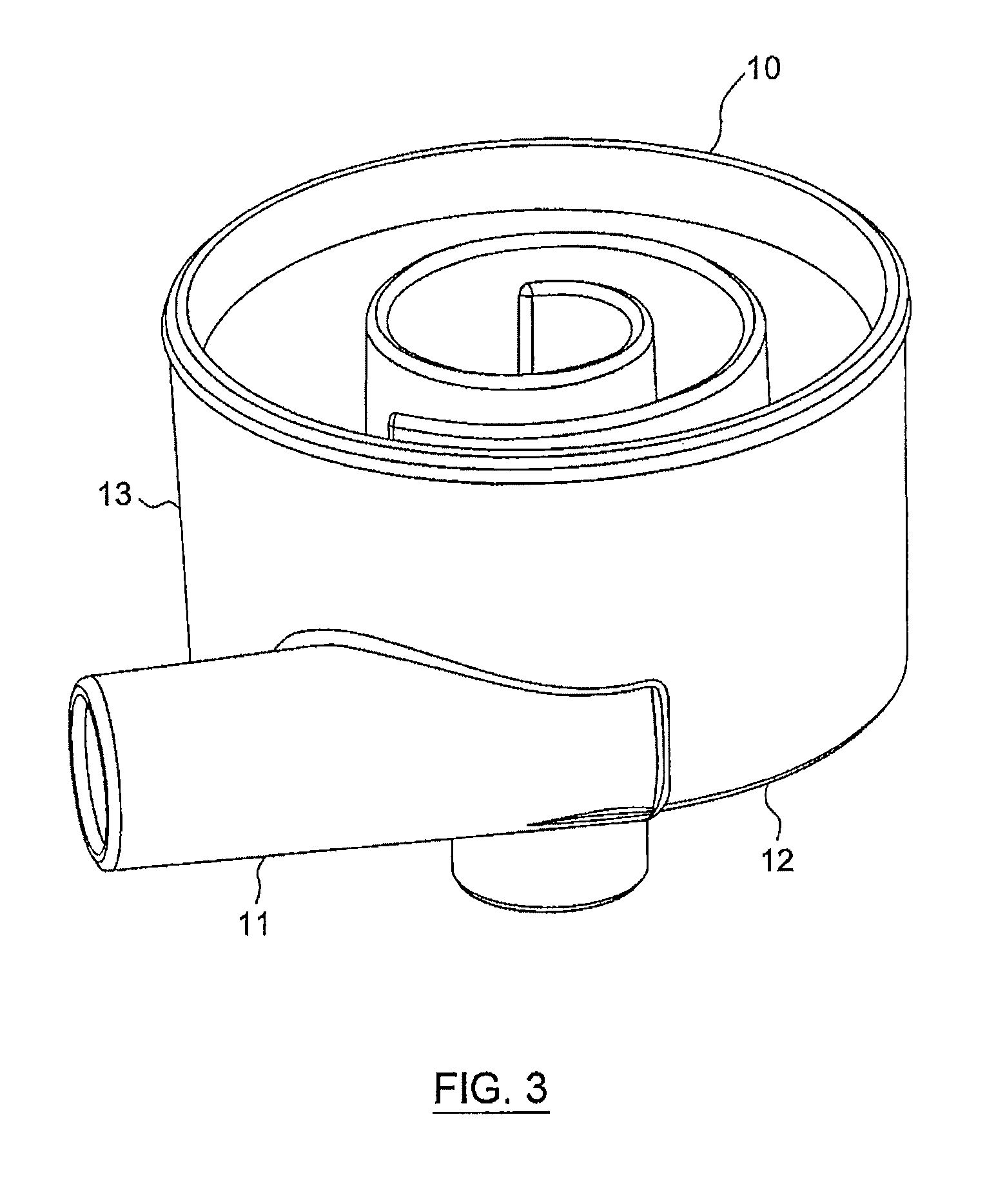

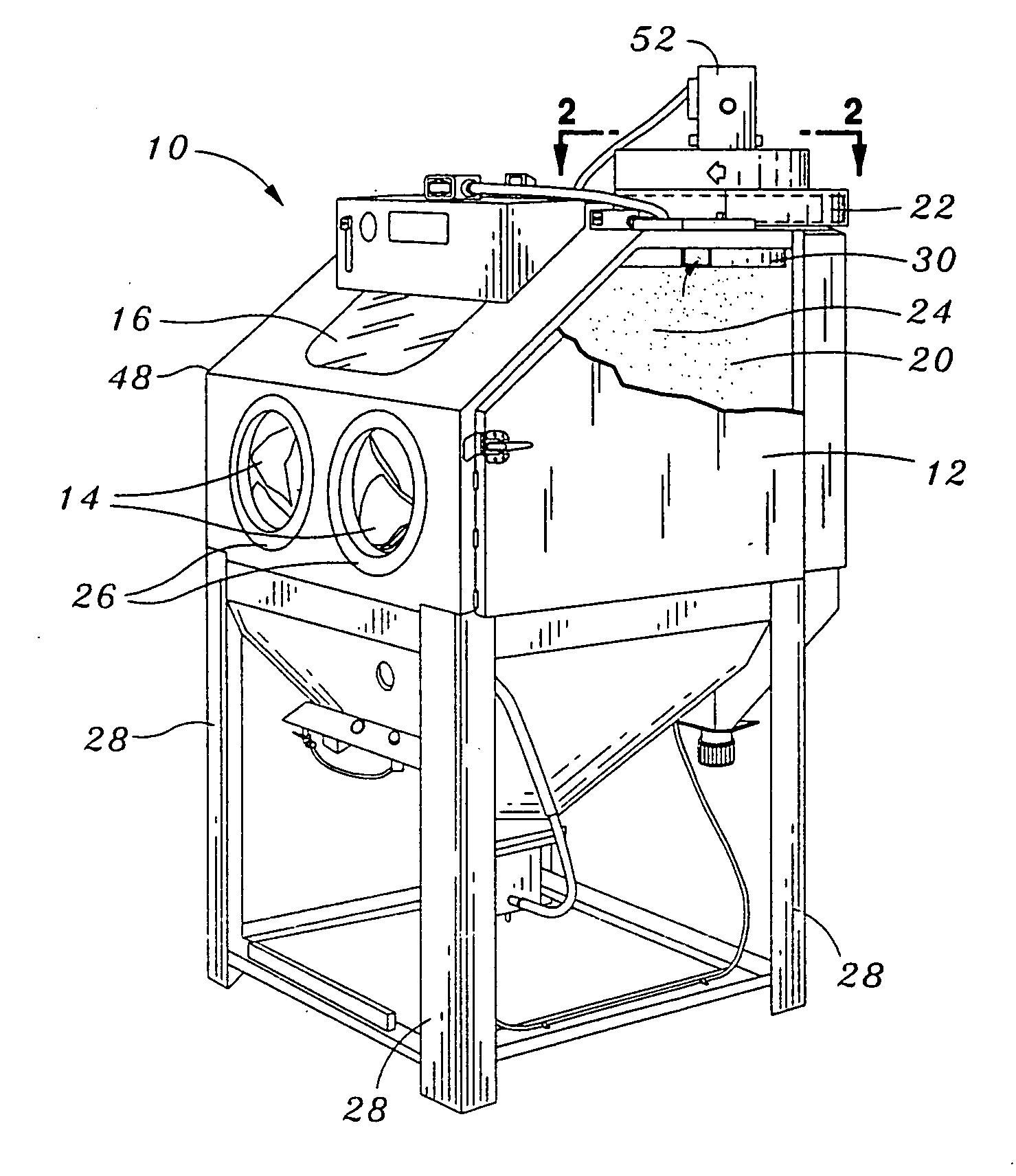

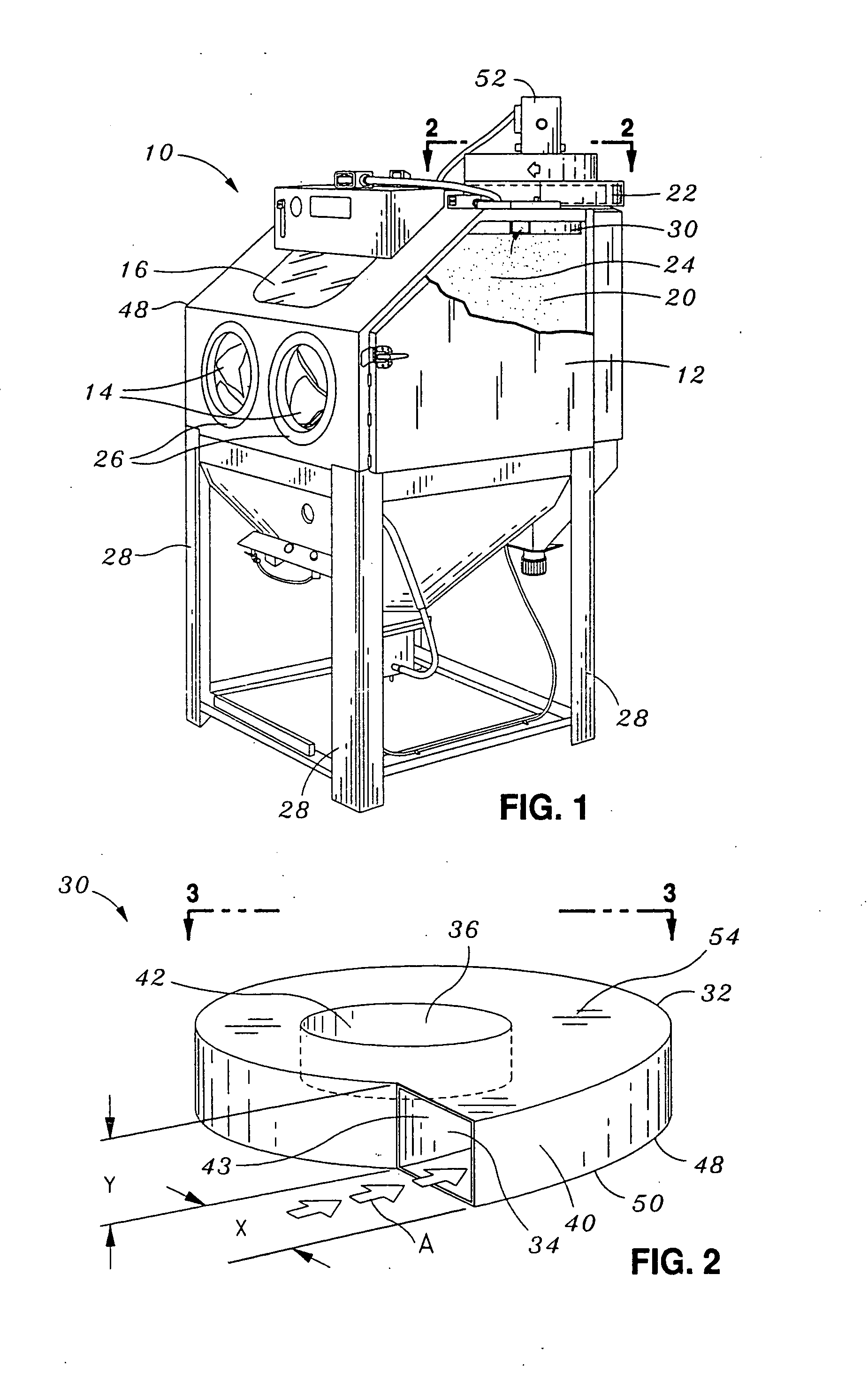

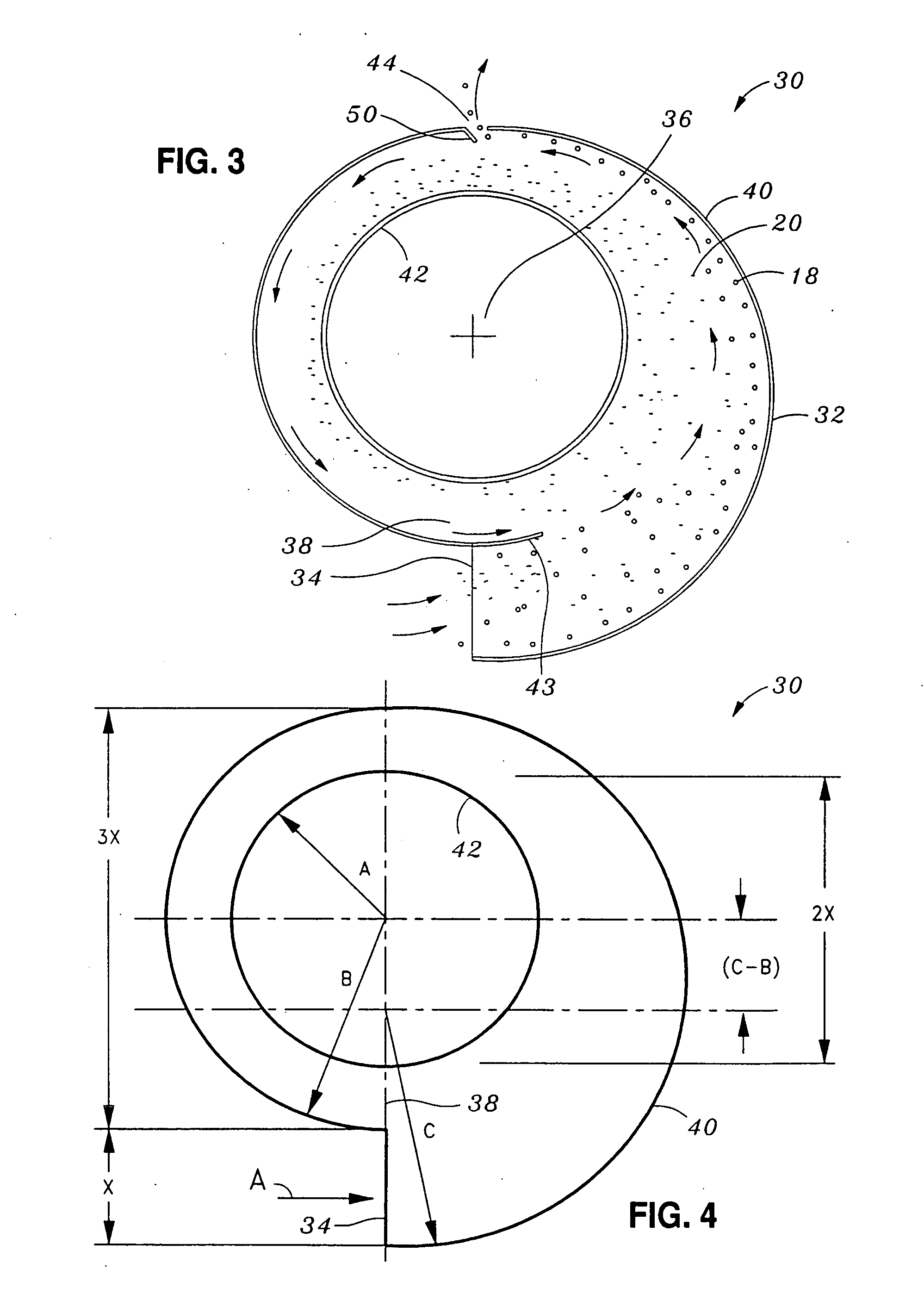

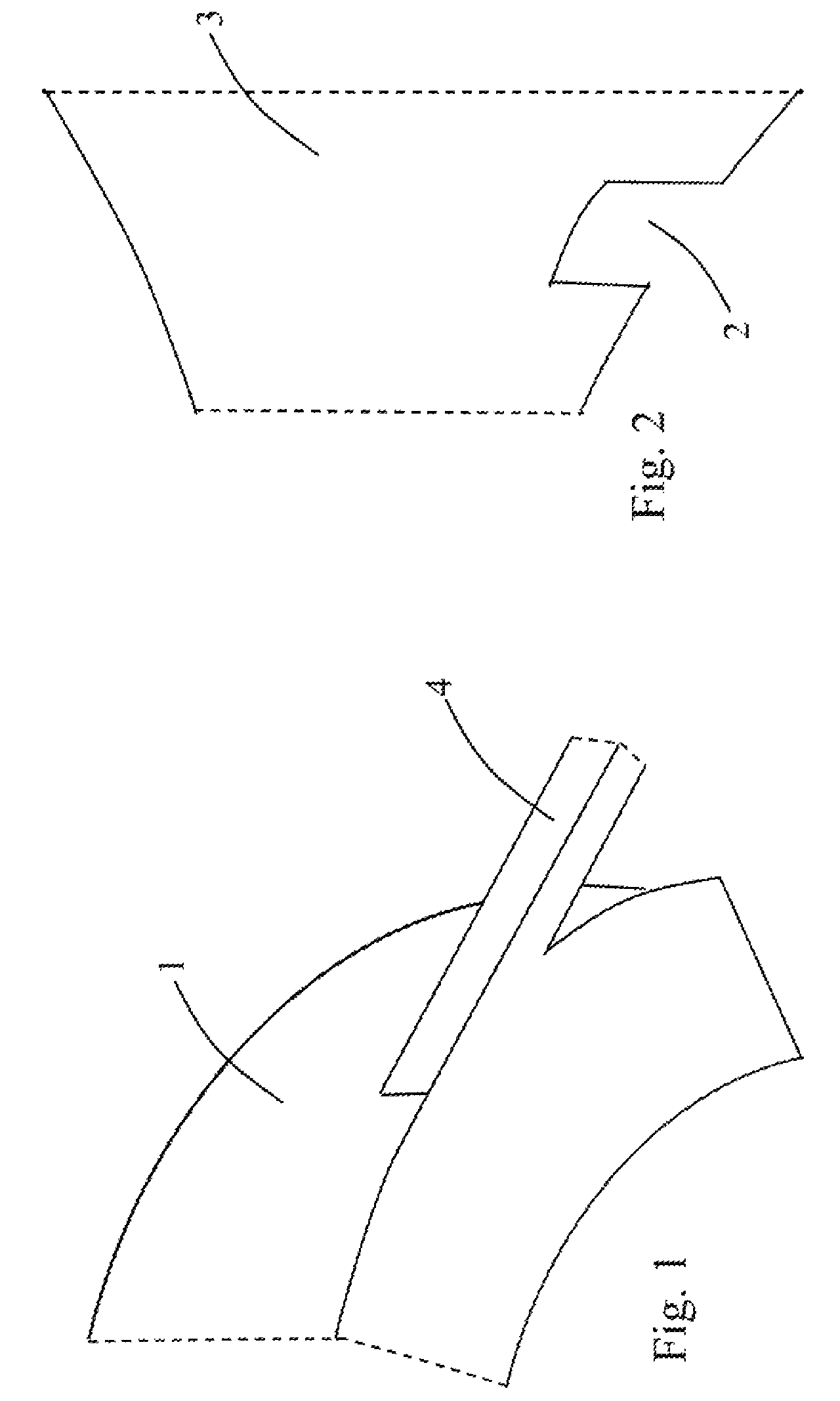

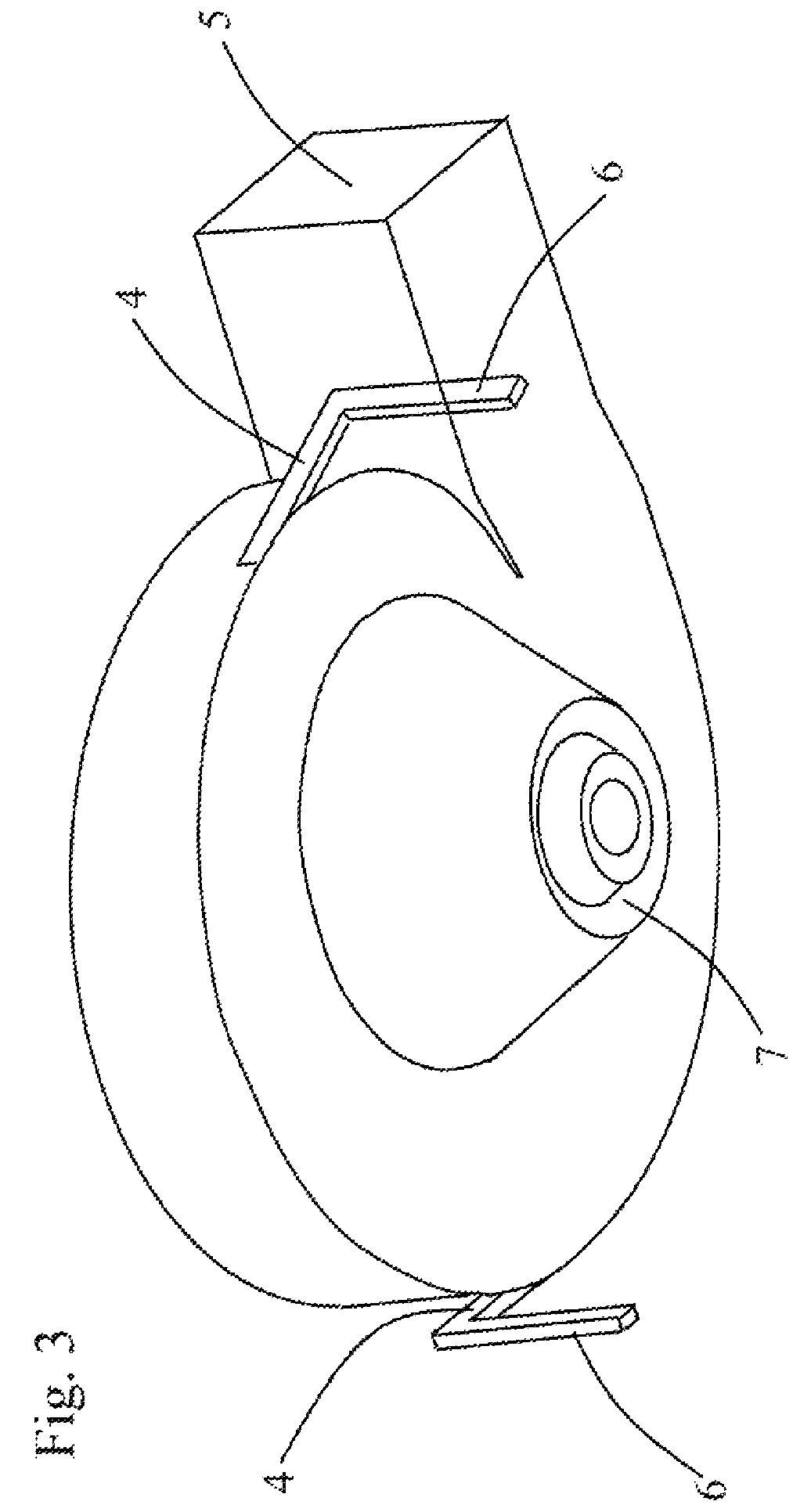

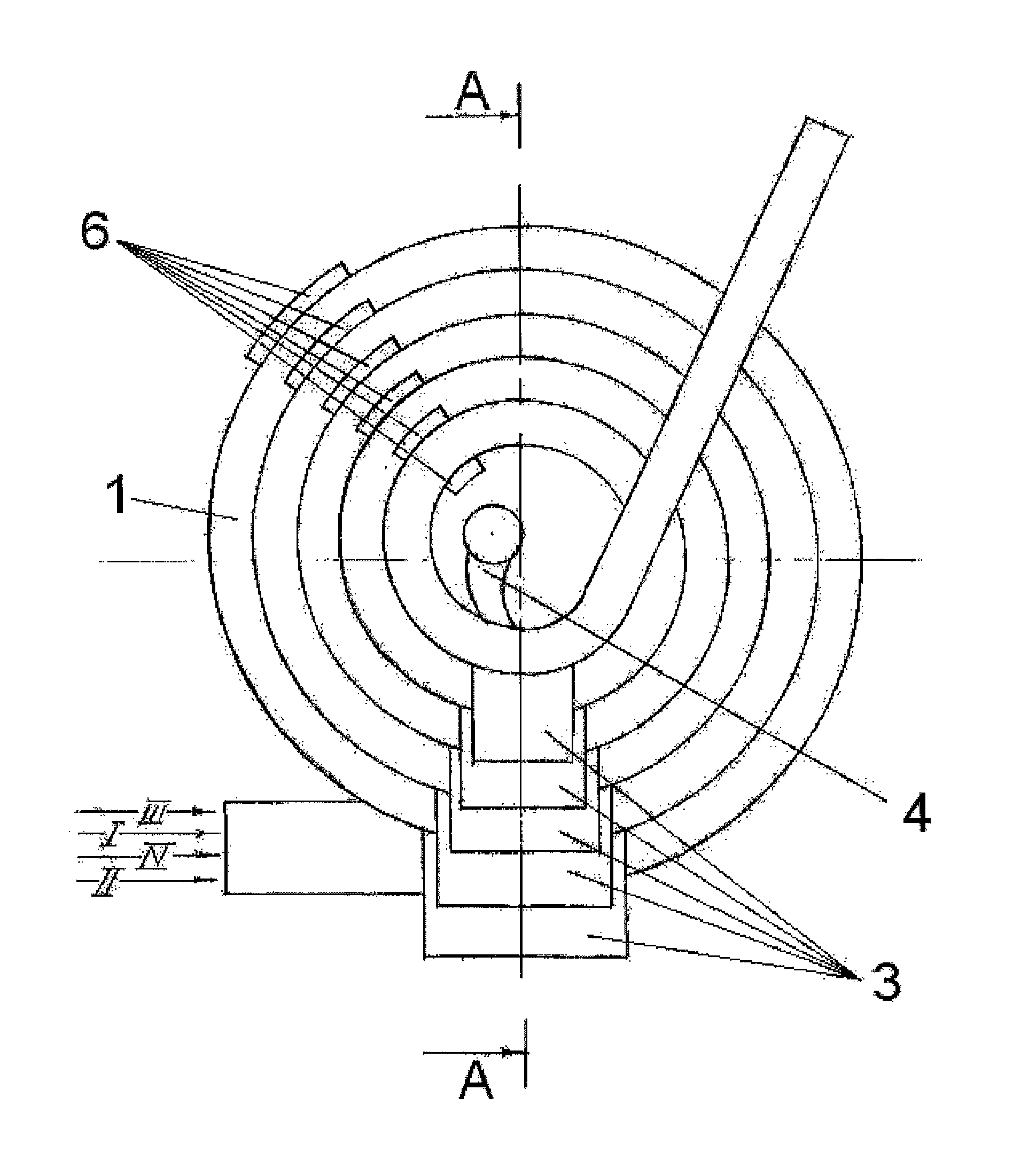

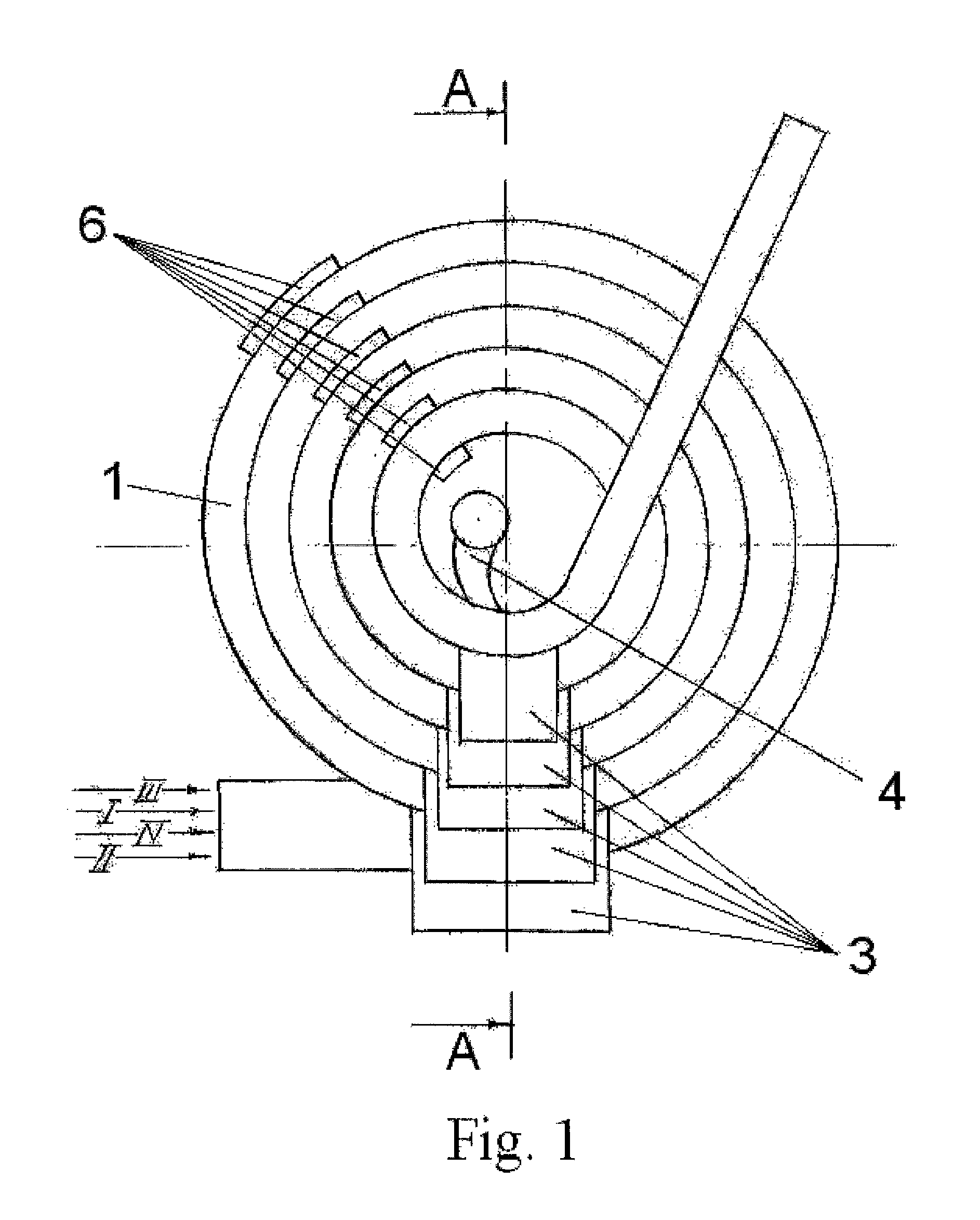

Provided is a centrifuge media separator for separating blast particulate from fine particulate carried by air flowing from a blast cabinet and through the media separator. The centrifuge media separator comprises an upper panel, a lower panel, and an outer wall. The upper panel has a central opening formed therein. The outer wall is configured in a generally curvilinear shape and which extends between the upper and lower panels. The outer wall has at least one particulate escape aperture formed therein. The upper panel, lower panel and outer wall collectively define a curvilinear air passageway having an inlet and an outlet. The inlet is configured to allow a flow of air to enter the air passageway and circulate therethrough toward the outlet. The escape aperture is configured to exhaust the blast particulate out of the passageway. The central opening is configured to exhaust the fine particulate out of the passageway.

Owner:MEDIA BLAST & ABRASIVES

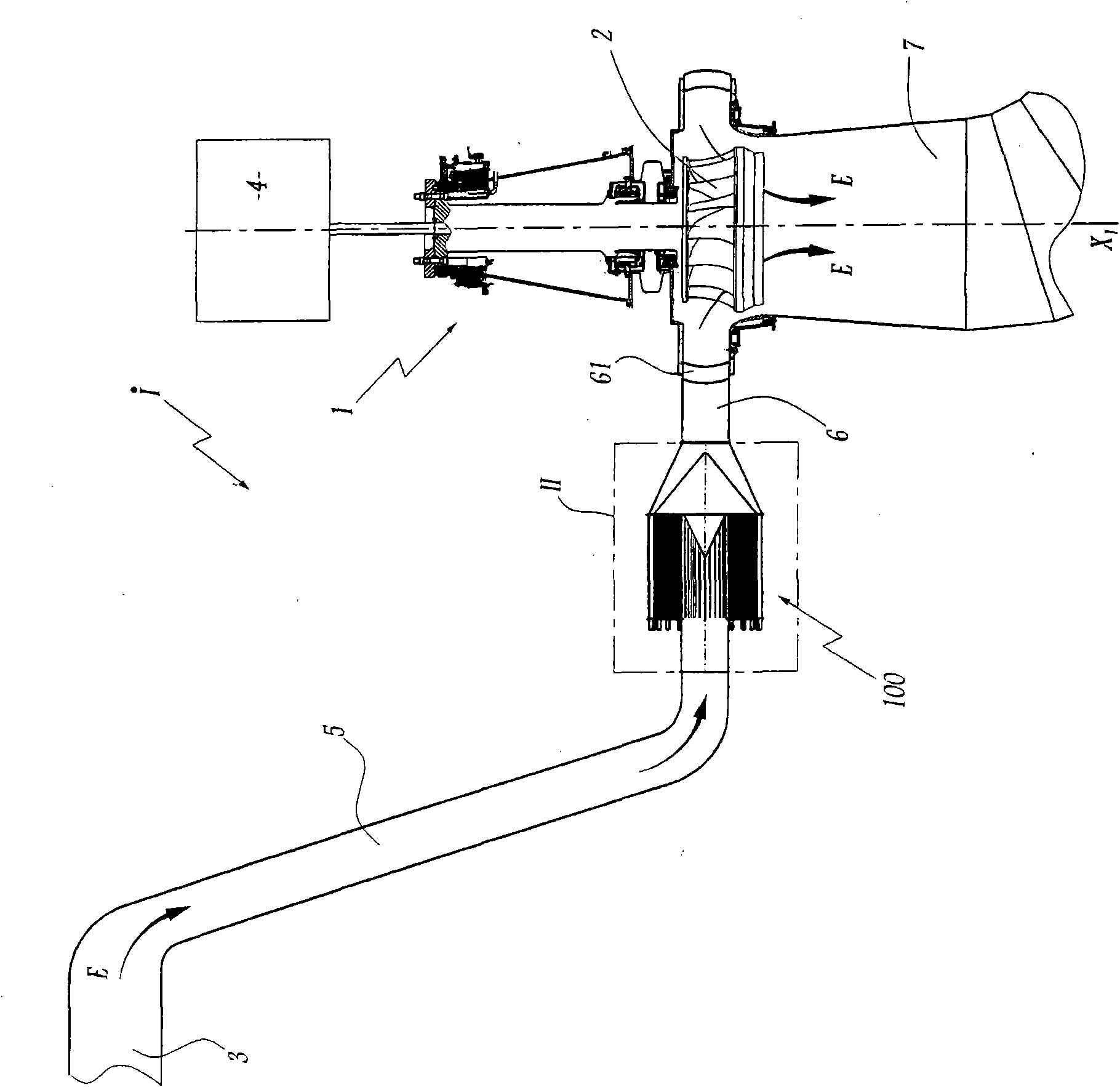

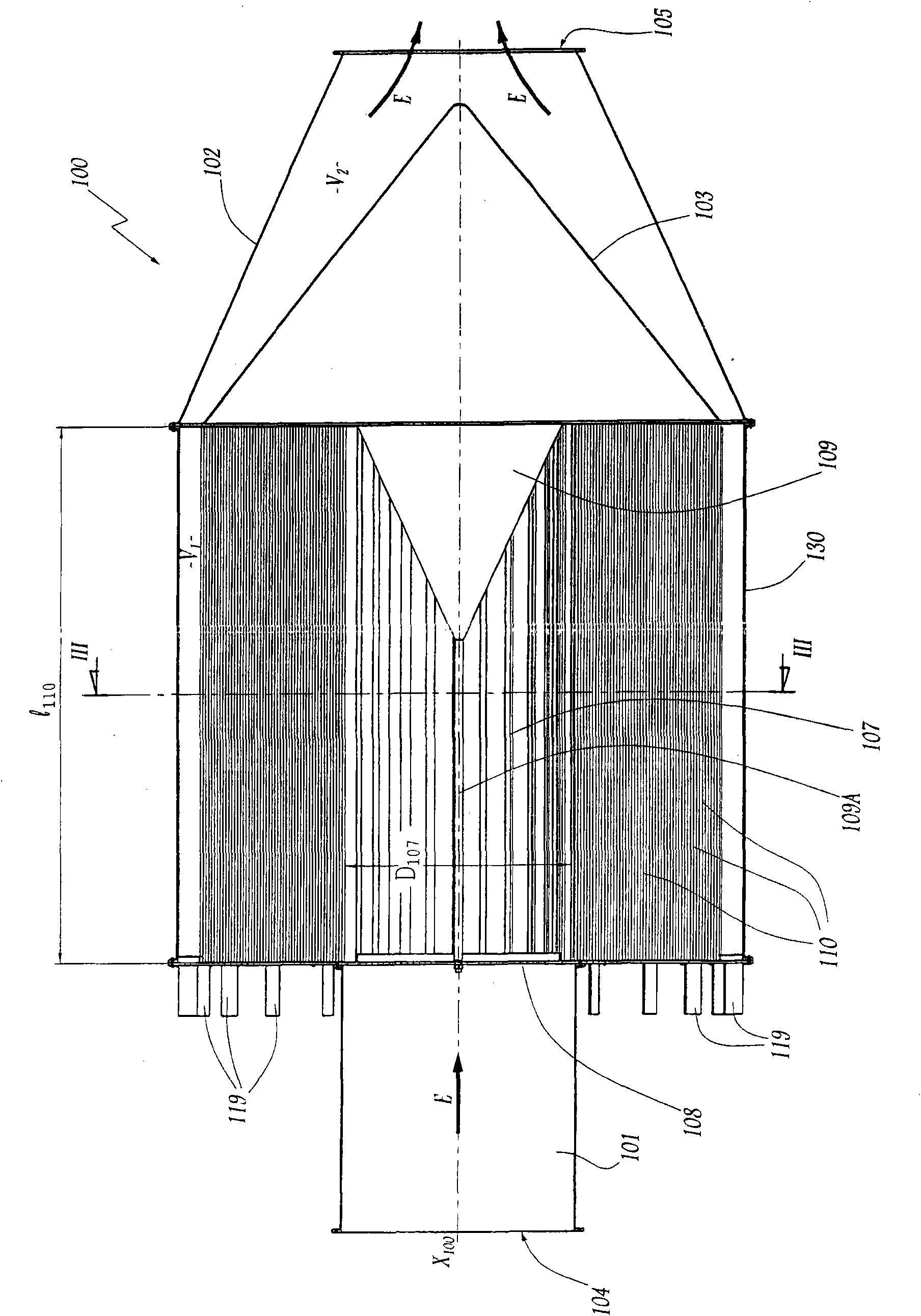

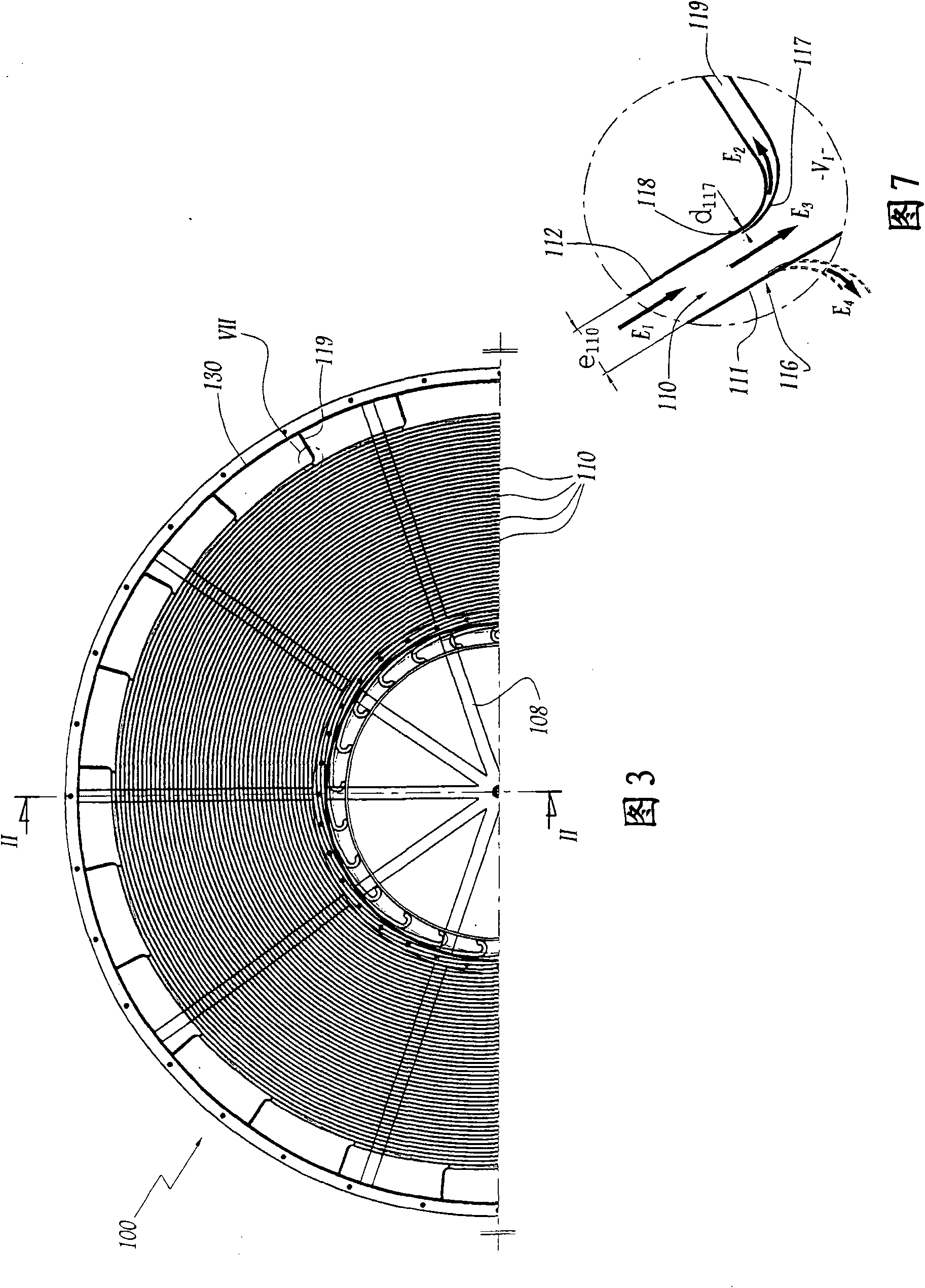

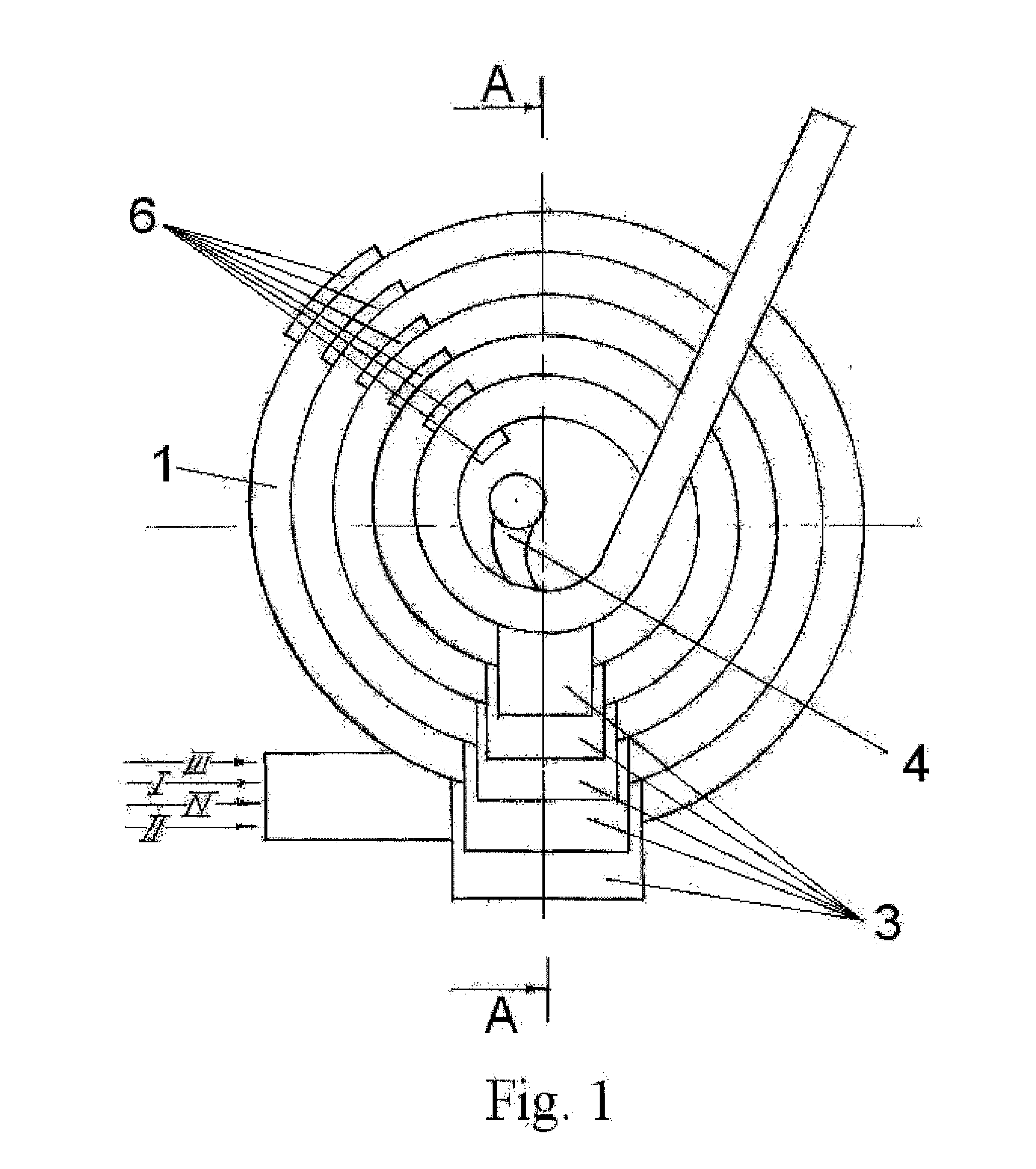

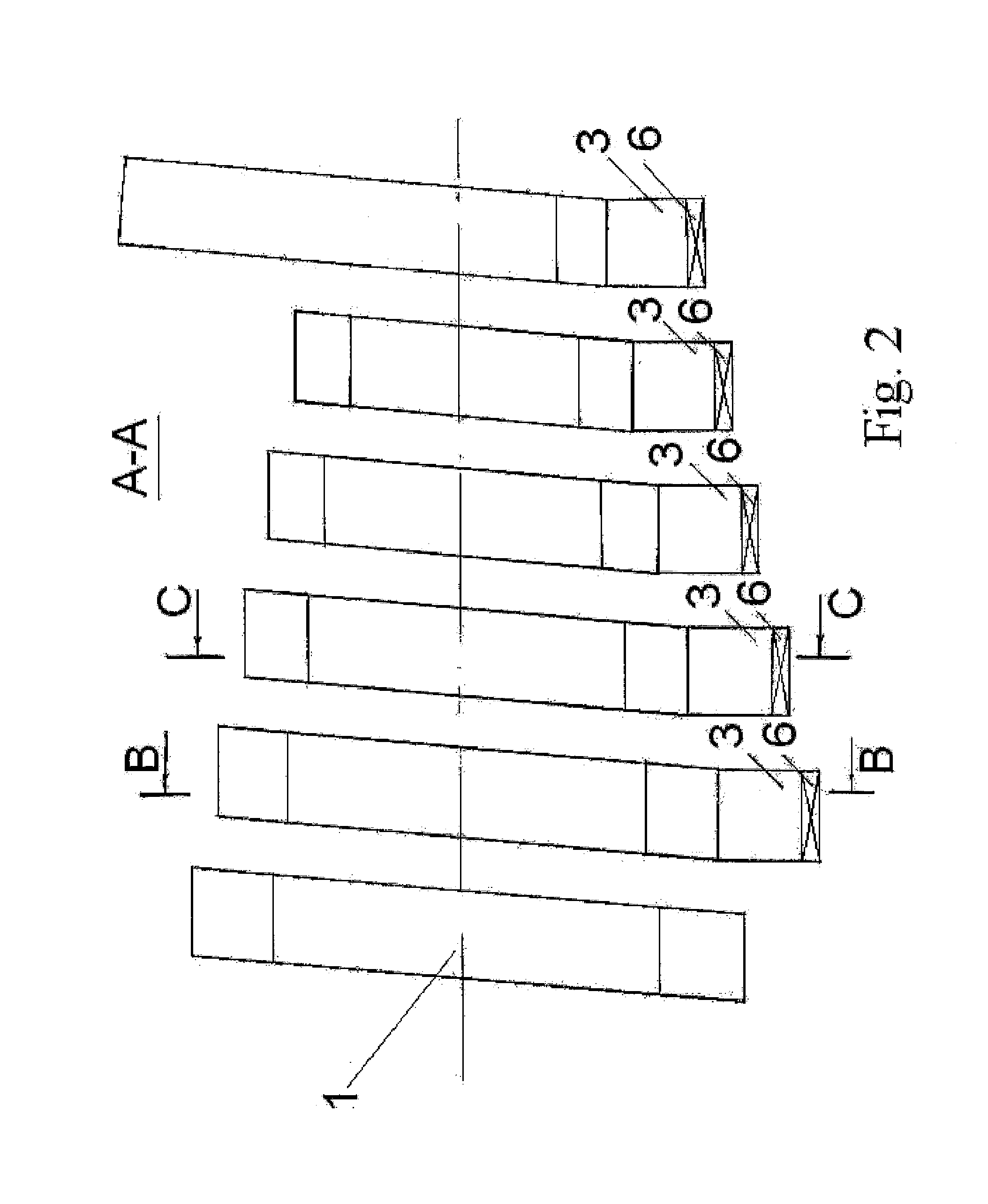

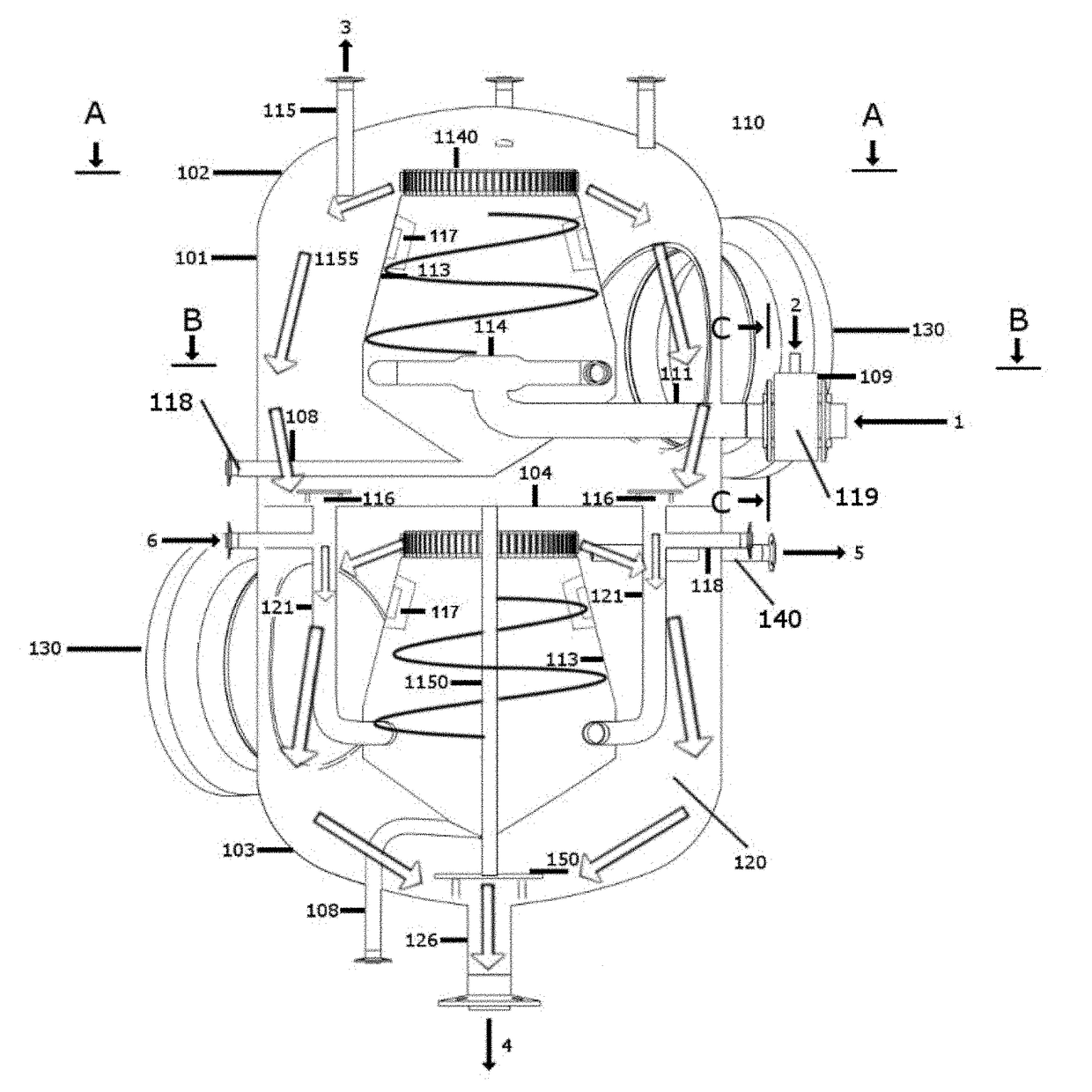

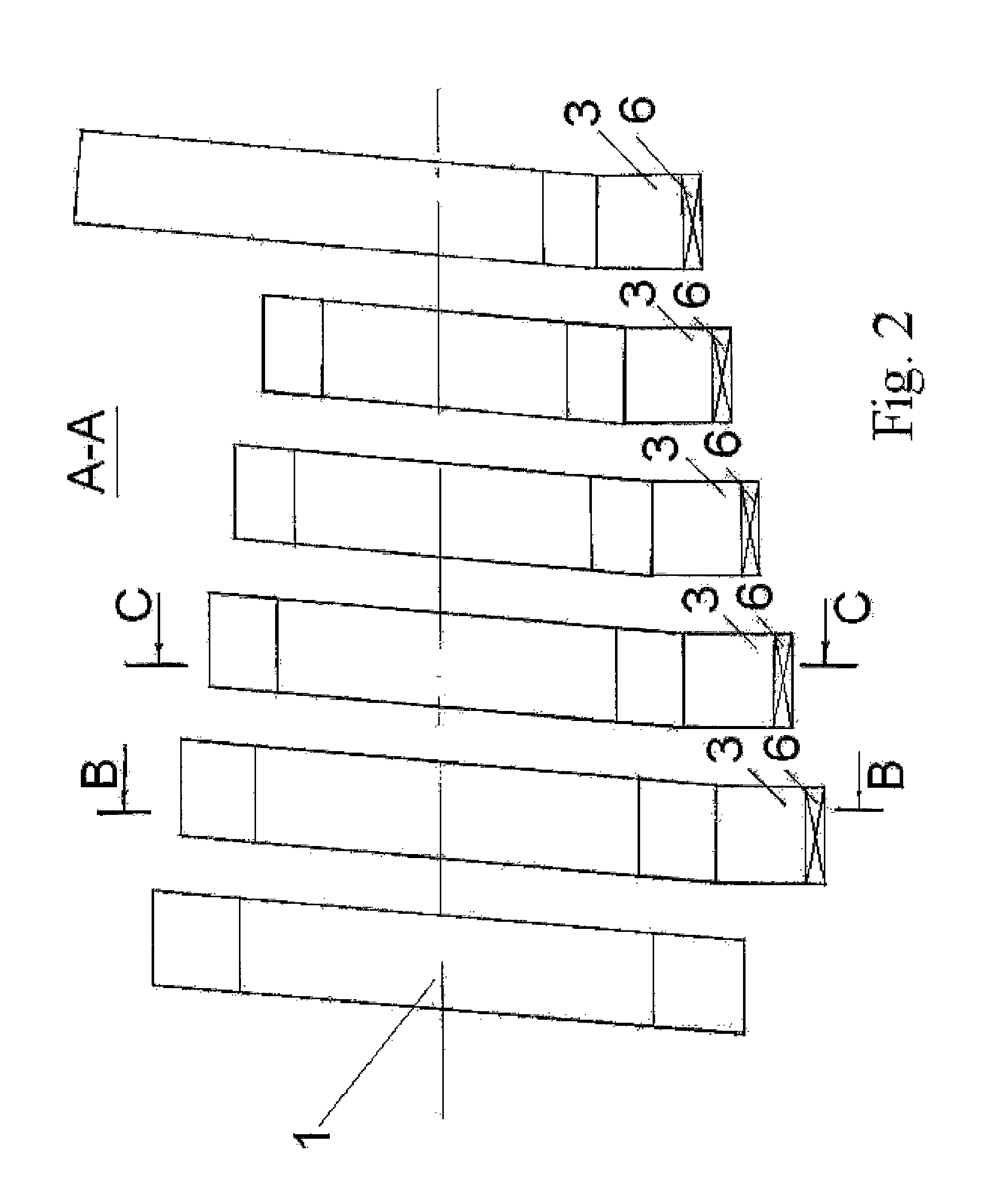

Apparatus for the separation of solid particles from water and haudraulic installation containing such separation apparatus

InactiveCN101628187AReduce workloadLow costBarrages/weirsCentrifugal force sediment separationSection planeWater flow

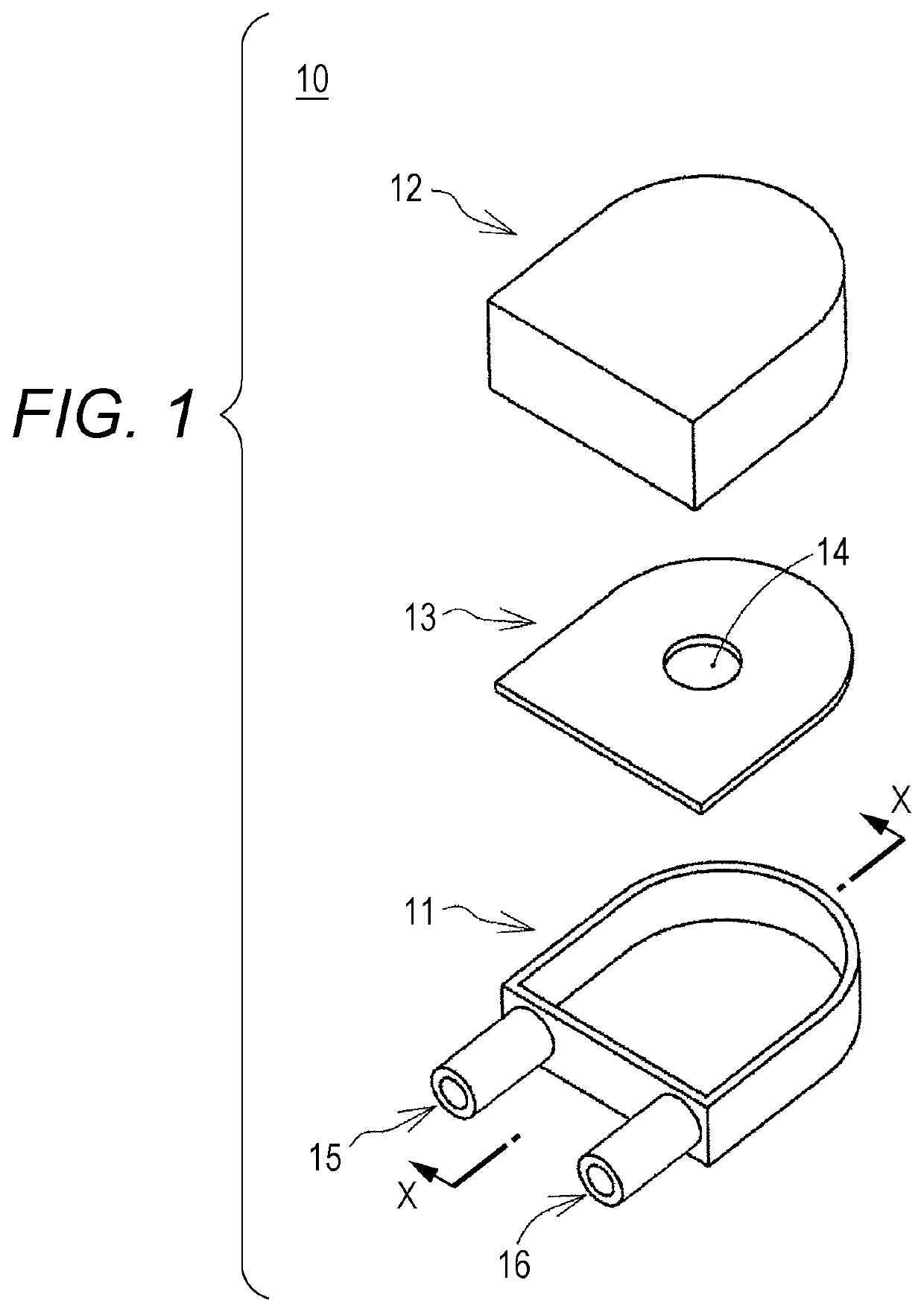

The device (100) serves to separate solid particles from the water of a flow (E) feeding a hydraulic machine of the turbine, pump, or turbine-pump type. The device has flow inlet and outlet zones (104, 105) for the flow that are spaced apart along an advance axis (X100) of flow advance-through the device (100). The device (100) comprises a plurality of ducts (110) placed in parallel, each having a mouth and a downstream end between the inlet zone (104) and the outlet zone (105). In section perpendicular to the advance axis (X100), each duct presents a section in the form of a spiral with a radius of curvature that increases from the mouth towards the downstream end or from the downstream end towards the mouth, with each duct (110) presenting a thickness measured in a generally radial direction relative to the advance axis that is less than 10% of the width (l110) of said duct, measured parallel to said axis (X100).

Owner:ALSTOM RENEWABLE TECH

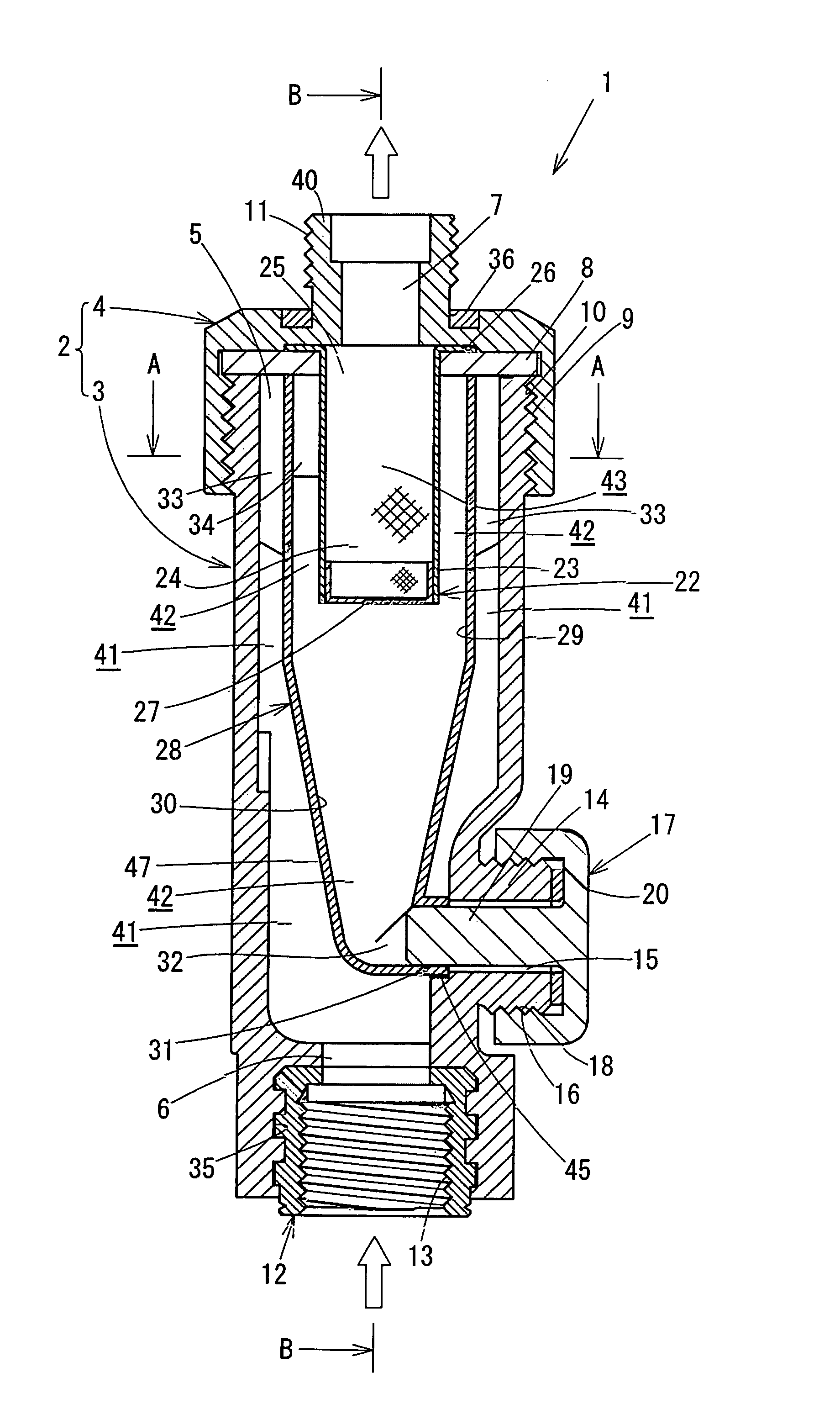

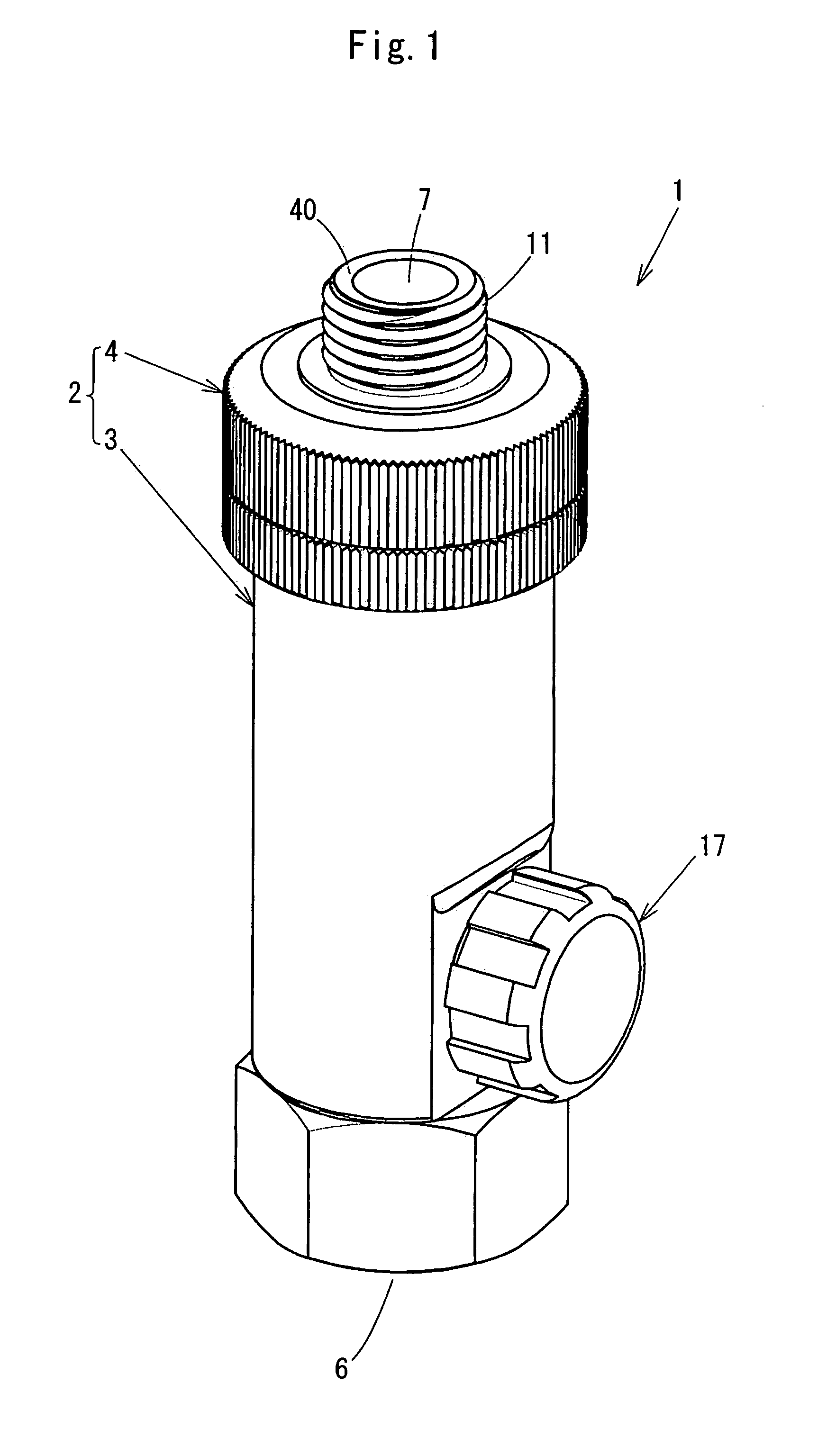

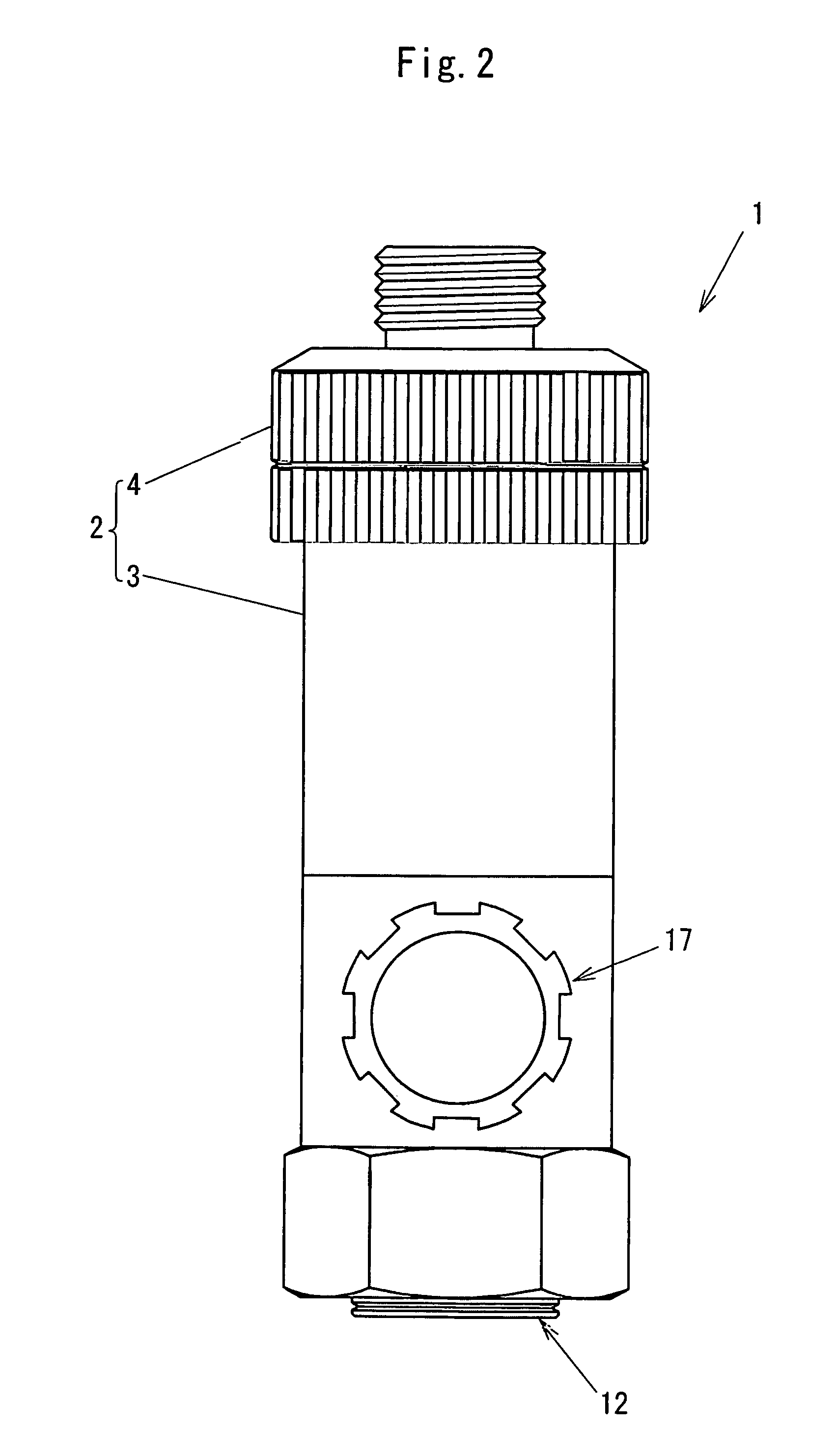

In-line strainer

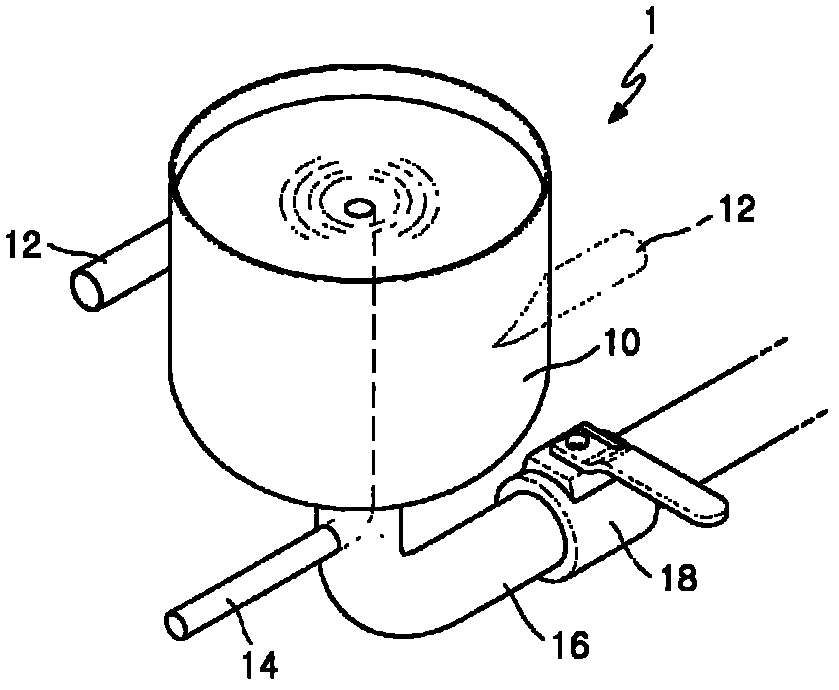

ActiveUS8828228B2Less frequent cleaningEasy to remove impuritiesCentrifugal force sediment separationFlat flow vortexEngineeringMechanical engineering

An in-line strainer 1 includes: a cylindrical-shaped housing 2 having an inflow port 6 for liquid and an outflow port 7 which are coaxial with each other; and a strainer element 22 disposed in the housing 2. A cyclone cylindrical body 28 having a diametrically-reduced cylinder portion 30 whose inner diameter is reduced toward one end, and having a cyclone inflow port formed on the other end, is arranged inside the housing 2 such that the diametrically-reduced cylinder portion 30 is close to the inflow port 6, and that the cyclone inflow port is close to the outflow port 7. A cylindrical-shaped strainer element 22 having a closed first end and an open second end is in the cyclone cylindrical body 28, and an open second end 25 of the strainer element 22 is connected to the outflow port 7 of the housing 2.

Owner:YAMAHO IND

Particle separation and concentration system

This invention is based on size and mass separation of suspended particles, including biological matter, which are made to flow in a spiral channel. On the spiral sections, the inward directed transverse pressure field from fluid shear competes with the outward directed centrifugal force to allow for separation of particles. At high velocity, centrifugal force dominates and particles move outward. At low velocities, transverse pressure dominates and the particles move inward. The magnitudes of the two opposing forces depend on flow velocity, particle size, radius of curvature of the spiral section, channel dimensions, and viscosity of the fluid. At the end of the spiral channel, a parallel array of outlets collects separated particles. For any particle size, the required channel dimension is determined by estimating the transit time to reach the side-wall. This time is a function of flow velocity, channel width, viscosity, and radius of curvature. Larger particles may reach the channel wall earlier than the smaller particles which need more time to reach the side wall. Thus a spiral channel may be envisioned by placing multiple outlets along the channel. This technique is inherently scalable over a large size range from sub-millimeter down to 1 μm.

Owner:XEROX CORP

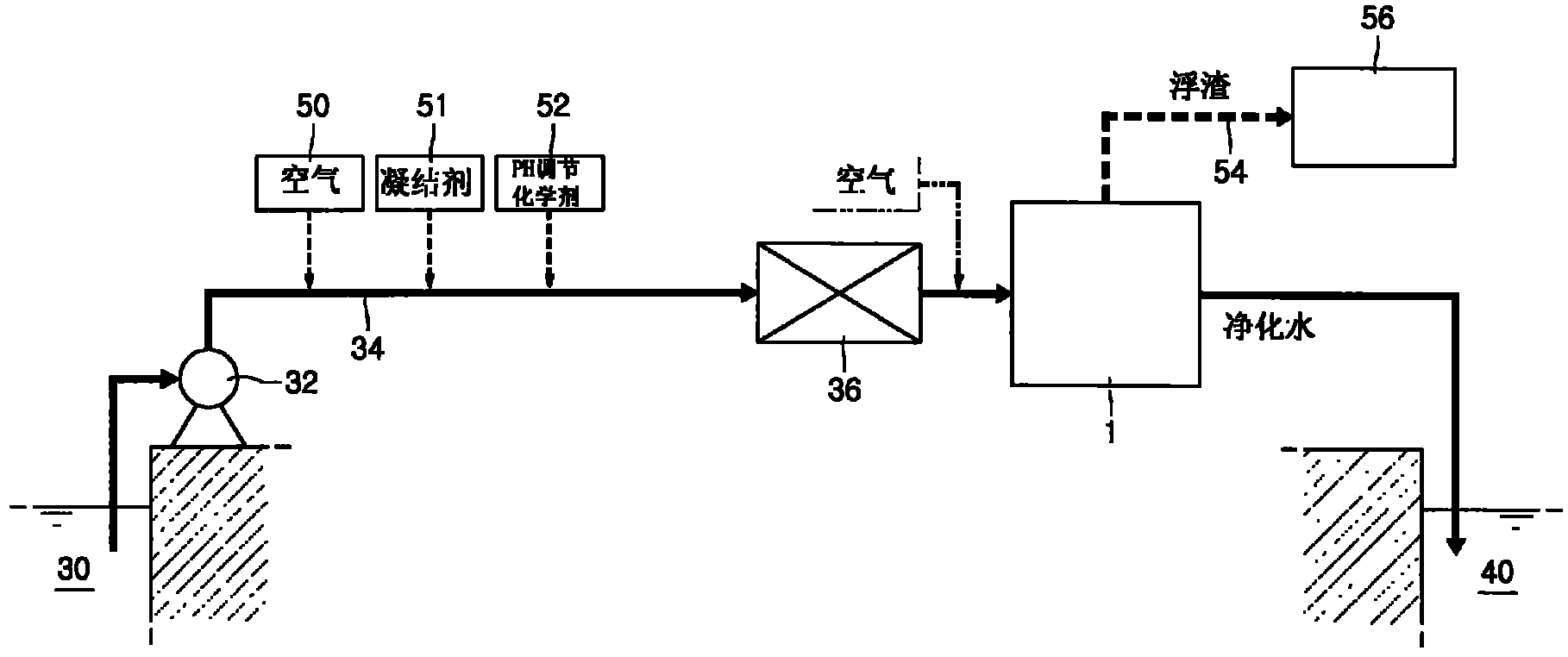

Hydrocyclone flotation system and water pollution prevention system equipped with the same

InactiveCN102056673ASmall sizeQuick and effective removalWater/sewage treatment by centrifugal separationFlat flow vortexWater dischargeWater volume

The present invention discloses a hydrocyclone flotation system comprising: a hydrocyclone body; air injection means for injecting air into water being supplied to the hydrocyclone body; drain water volume regulation means for regulating the volume of drain water discharged out of the hydrocyclone body to maintain a constant water level in the hydrocyclone body; suspended solids filtration means for taking suspended solids out of the hydrocyclone body, the suspended solids staying dispersed in water being supplied to the hydrocyclone body and then floating and gathering towards the vortex center of the water by the swirling flow of the water and air foam while the water passes through the hydrocyclone body. With such a hydrocyclone flotation system, a water pollution prevention system of the present invention can effectively treat suspended solids produced from a purification process of waste water, sewage, used water, etc., at a relatively low cost.

Owner:KOREA AQUOSYS

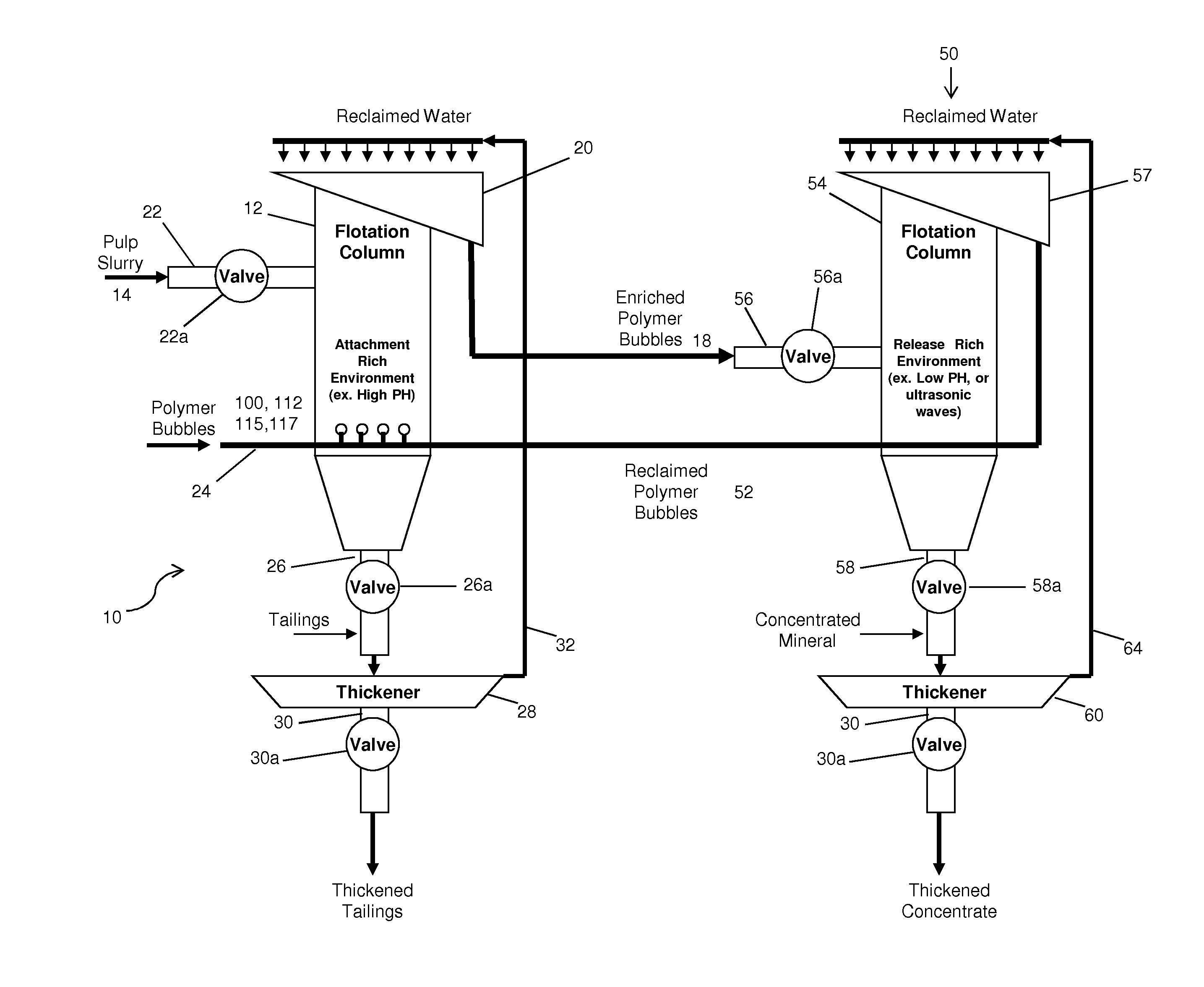

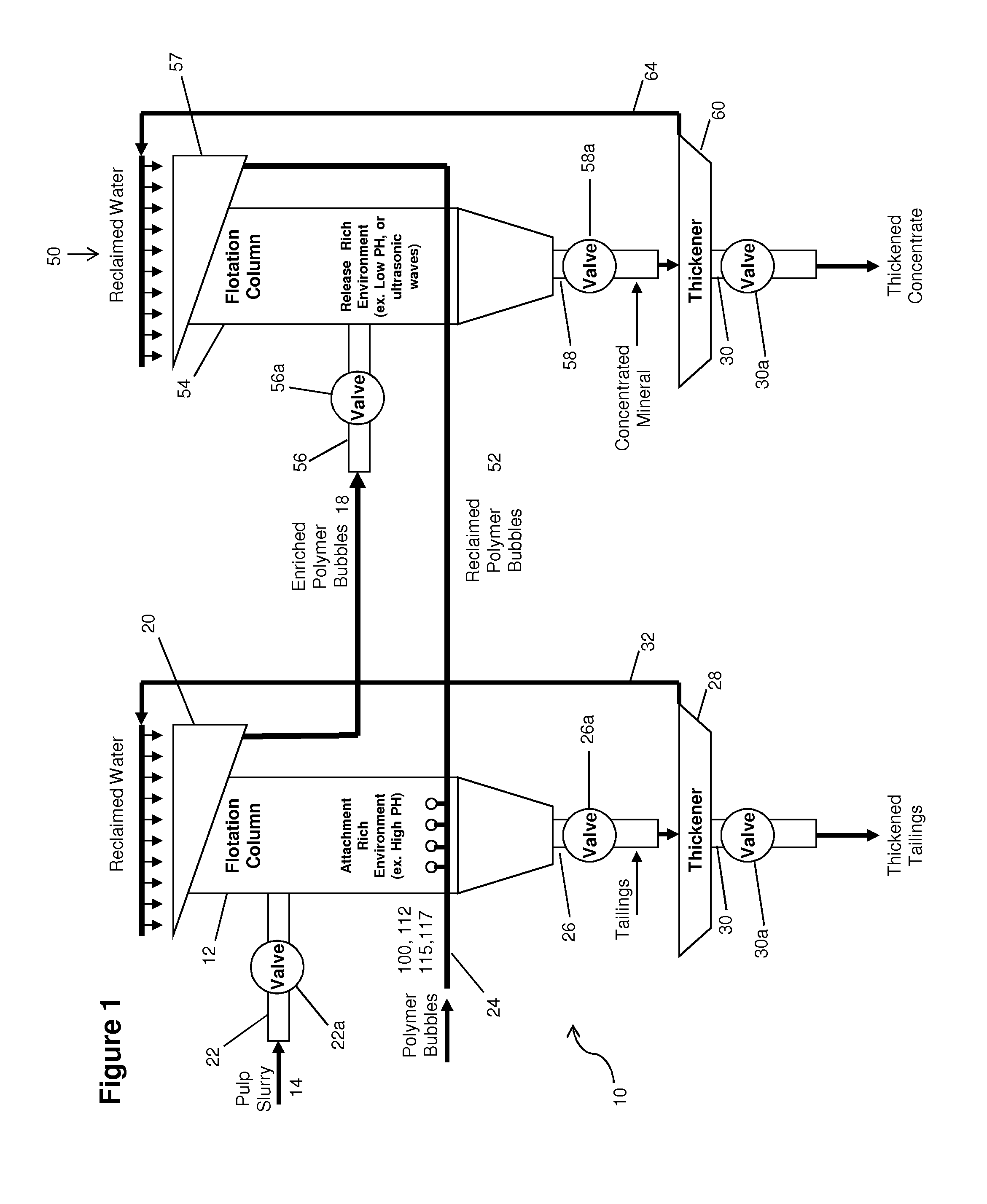

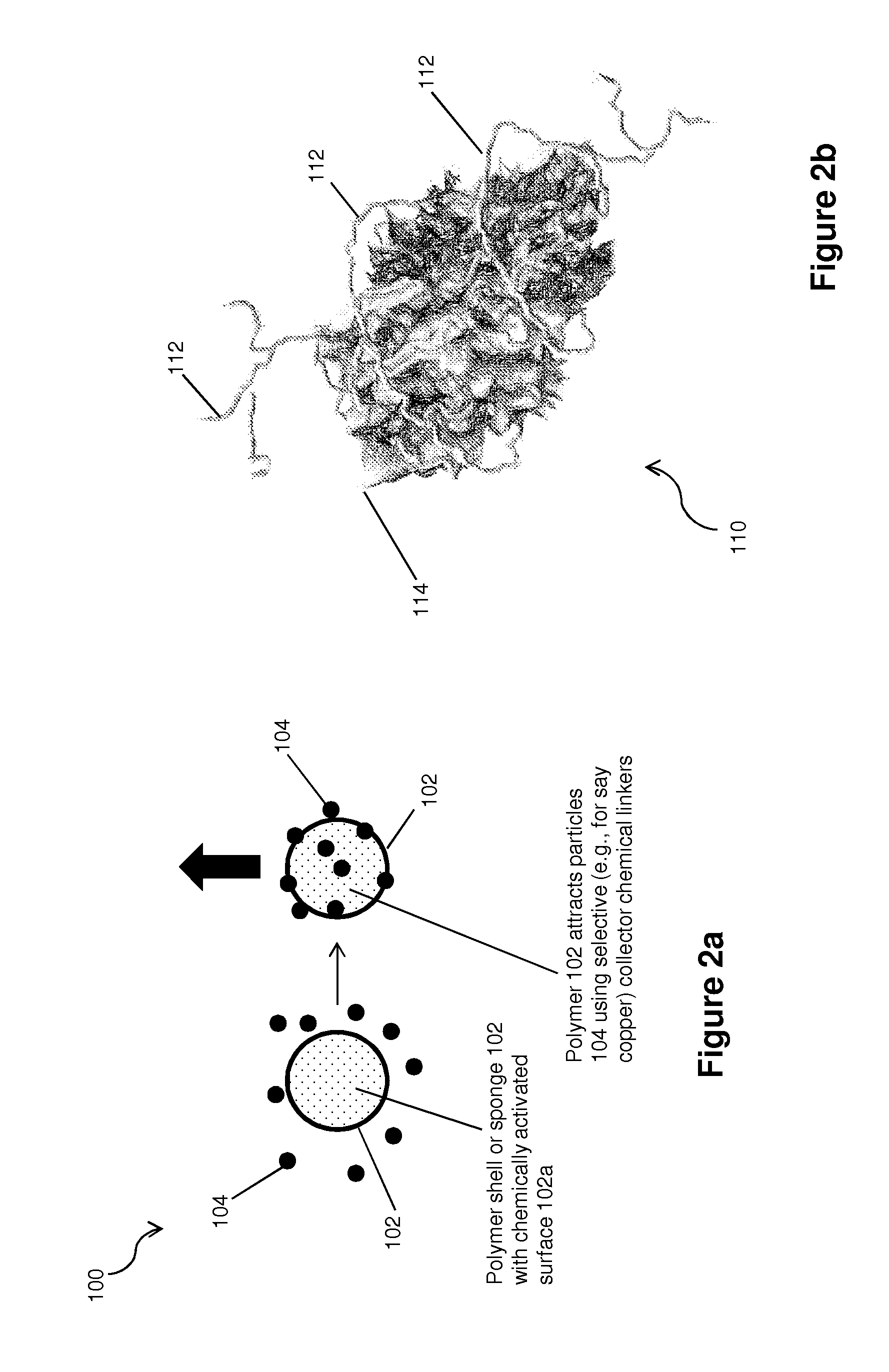

Flotation Separation Using Lightweight Synthetic Beads or Bubbles

ActiveUS20140166585A1Controllable sizeReduce manufacturing costElectrostatic separatorsUsing liquid separation agentPolymer substrateMaterials science

Owner:CIDRA CORP SERVICES

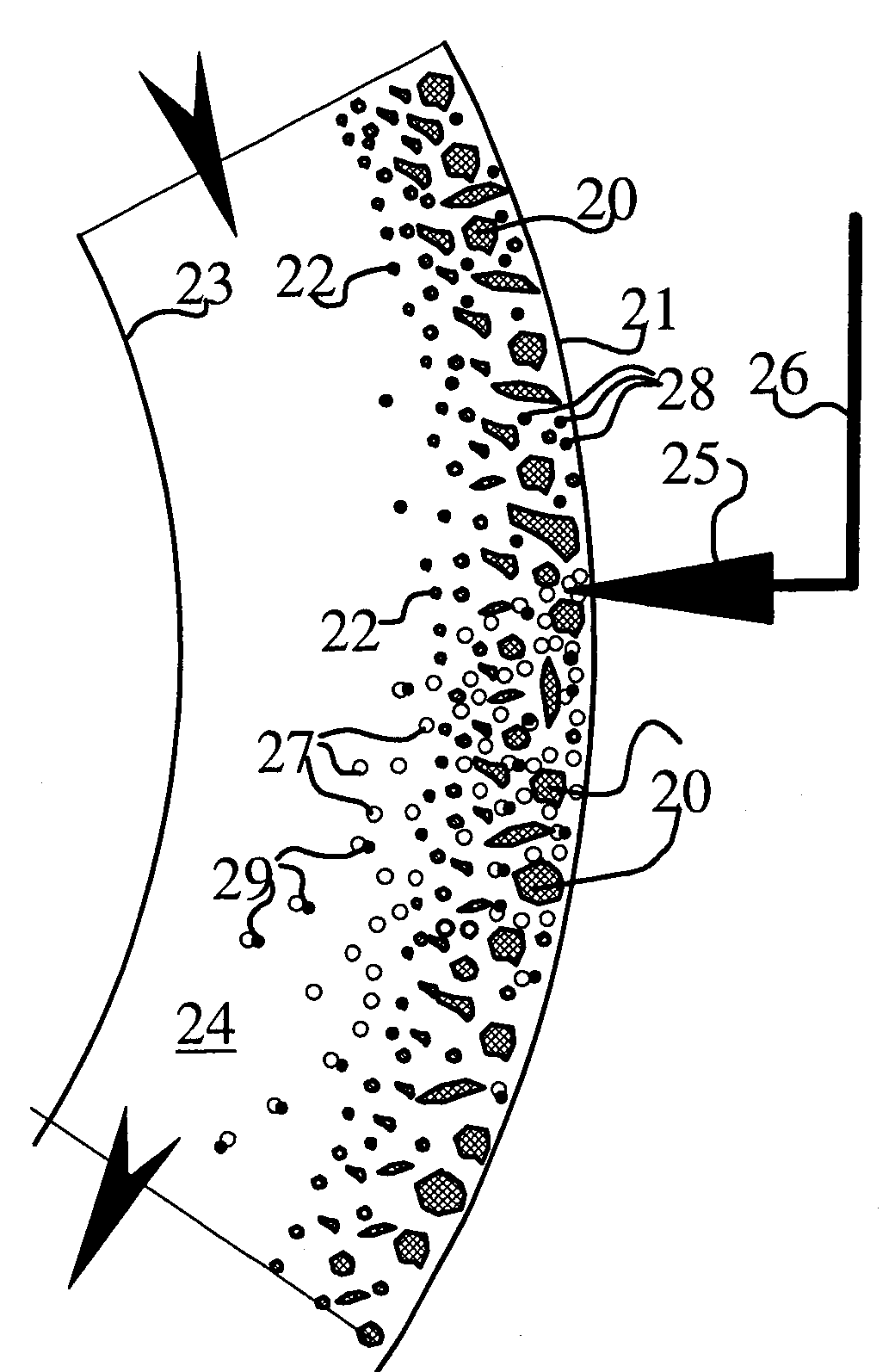

Method and device for purifying fluid media by removal of contaminating multicomponent ingredients

The group of inventions relates to the technology for purifying liquids and gases by removal of contaminating multicomponent ingredients. The device comprises a housing comprising at least one hollow spiral element with a conical shape, with separation openings being formed in at least some of the turns of the spiral element, each of the openings communicating with a corresponding separation chamber. Arranged opposite the separation opening is a nozzle, which is intended for compensating for the mass and centrifugal moment of the fluid medium. A guide element around which a flow passes is mounted on the wall of the nozzle. The cross-sectional area and the radius of each successive turn is selected from the condition for maintaining an estimated value for the centrifugal moment of the substance to be purified. The method consists in that a flow of medium to be purified is spun by the above-described device. Contaminating components in each turn are positioned by coaxial layers. Layer-by-layer removal of the contaminating components via the separation openings is performed. A reduction in the centrifugal moment of the flow to be purified is compensated for by a clean layer of fluid medium being injected. Technical result: as complete purification of fluid media as possible.

Owner:ABAYEV ALEXANDR DZAKHOTOVICH +2

Removal of bitumen from slurry using a scavenging gas

InactiveUS20090294384A1Waste water treatment from quariesWater/sewage treatment by centrifugal separationEngineeringSlurry

A separating apparatus can be used for separating components of a fluid. The apparatus can include a substantially open cylindrical vessel and a helical confined conduit connected upstream of the cylindrical vessel. The open vessel can include an open vessel inlet configured to introduce a fluid tangentially into the open vessel. The helical confined conduit can be connected to the open vessel at the open vessel inlet. A series of gas nozzles can be used to introduce gas bubbles into the helical confined path and / or the open vessel which draw bitumen from an outer flow region to an inner flow region of the slurry. An overflow outlet and underflow outlet can be operatively attached to the open vessel for removal of the separated fluid components. Although a number of fluids can be effectively treated, de-sanding of bitumen slurries from oil sands can be readily achieved.

Owner:KRUYER JAN

Process and apparatus for the production of alumina

InactiveUS20050238571A1Easy to separateInstallation economyFlat flow vortexCalcinationCalcinationOne stage

A process for the production of alumina from aluminum trihydrate in which the trihydrate is dried and pre-heated, after which the remaining free and chemically-bonded water is removed when the trihydrate is converted by calcination to form hot calcined alumina which is cooled to about 50-100° C. in one or more stages. In at least one stage the hot calcined alumina is cooled in a countercurrent cyclone

Owner:ALCOA WORLD ALUMINIA LLC +1

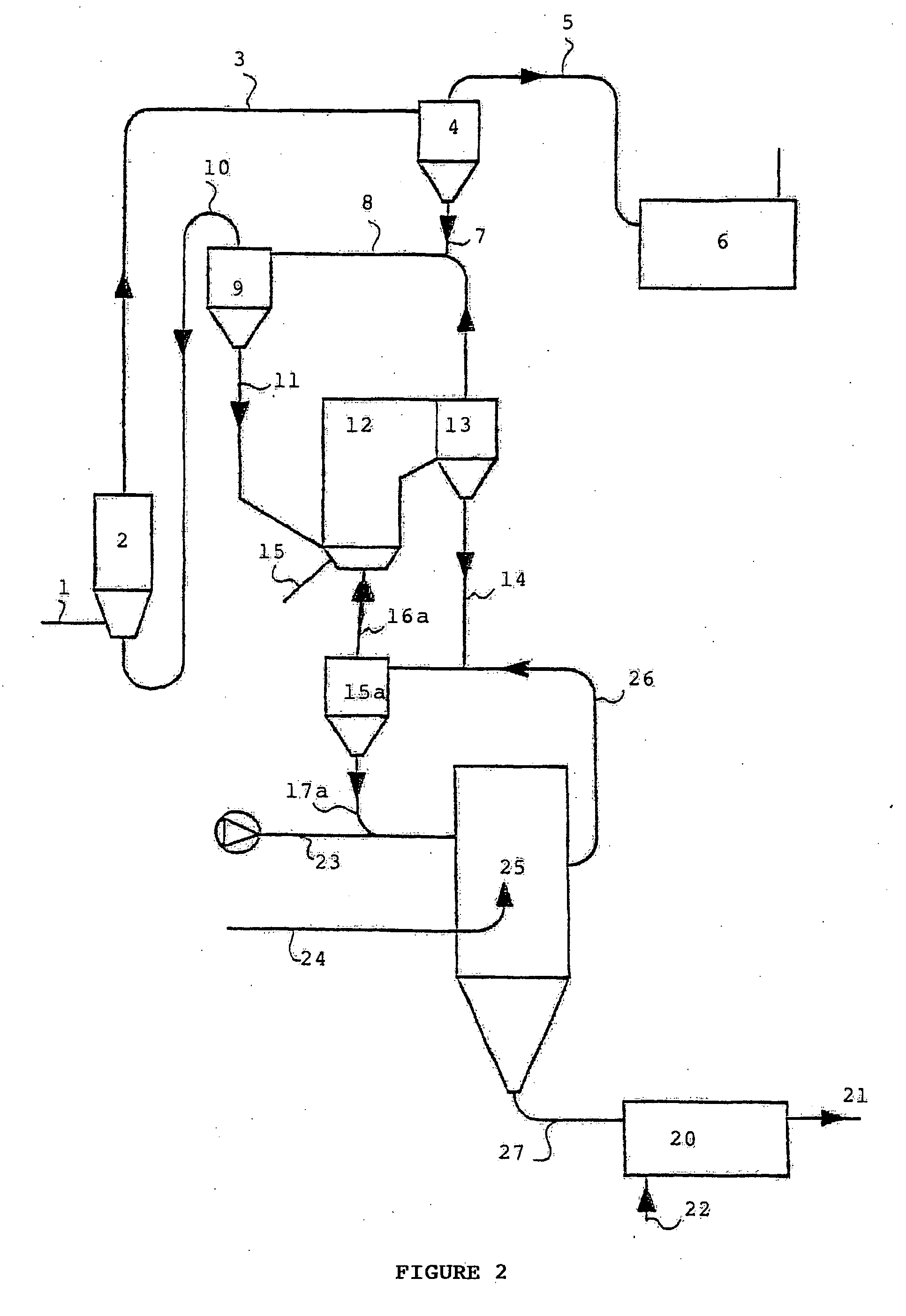

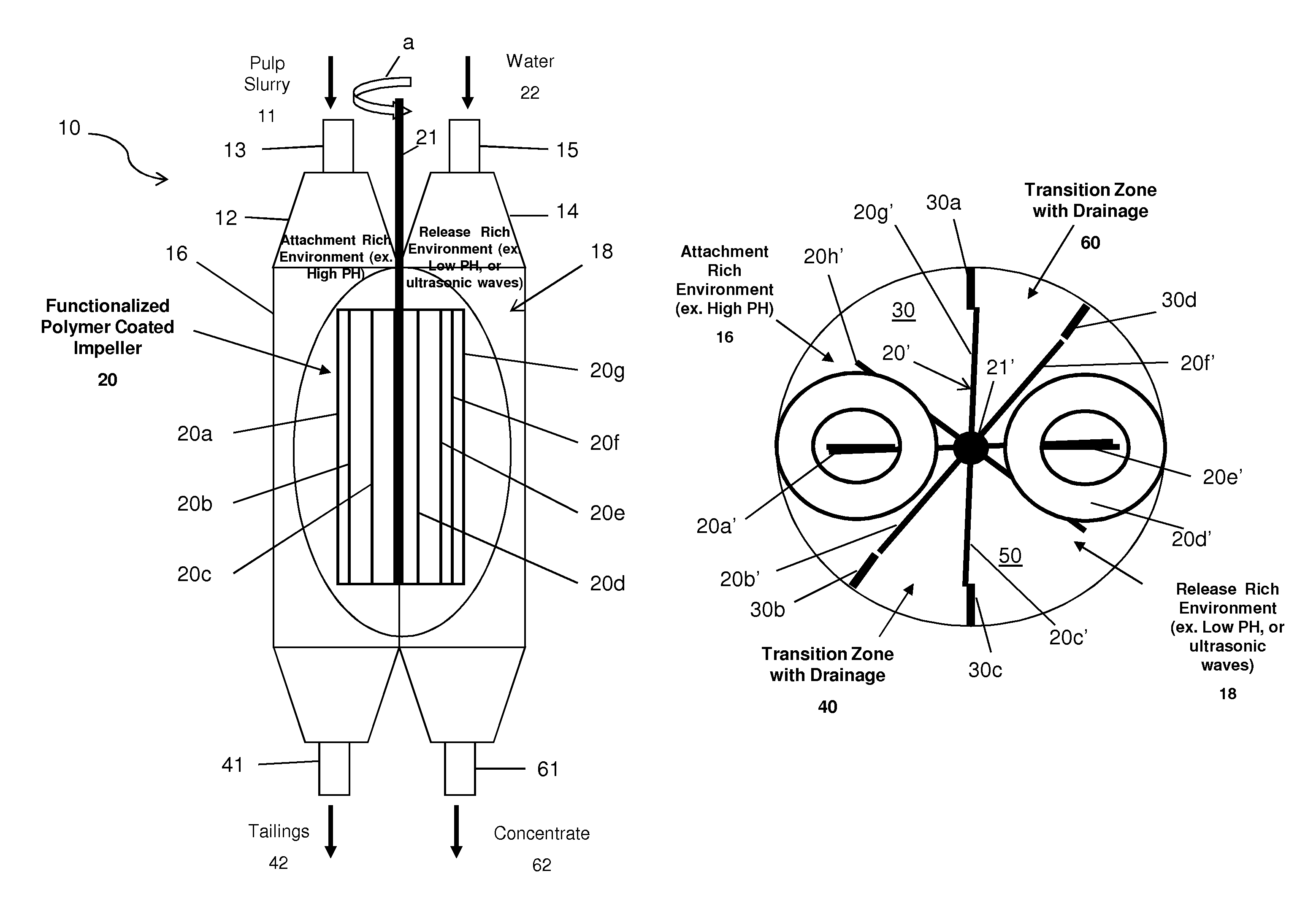

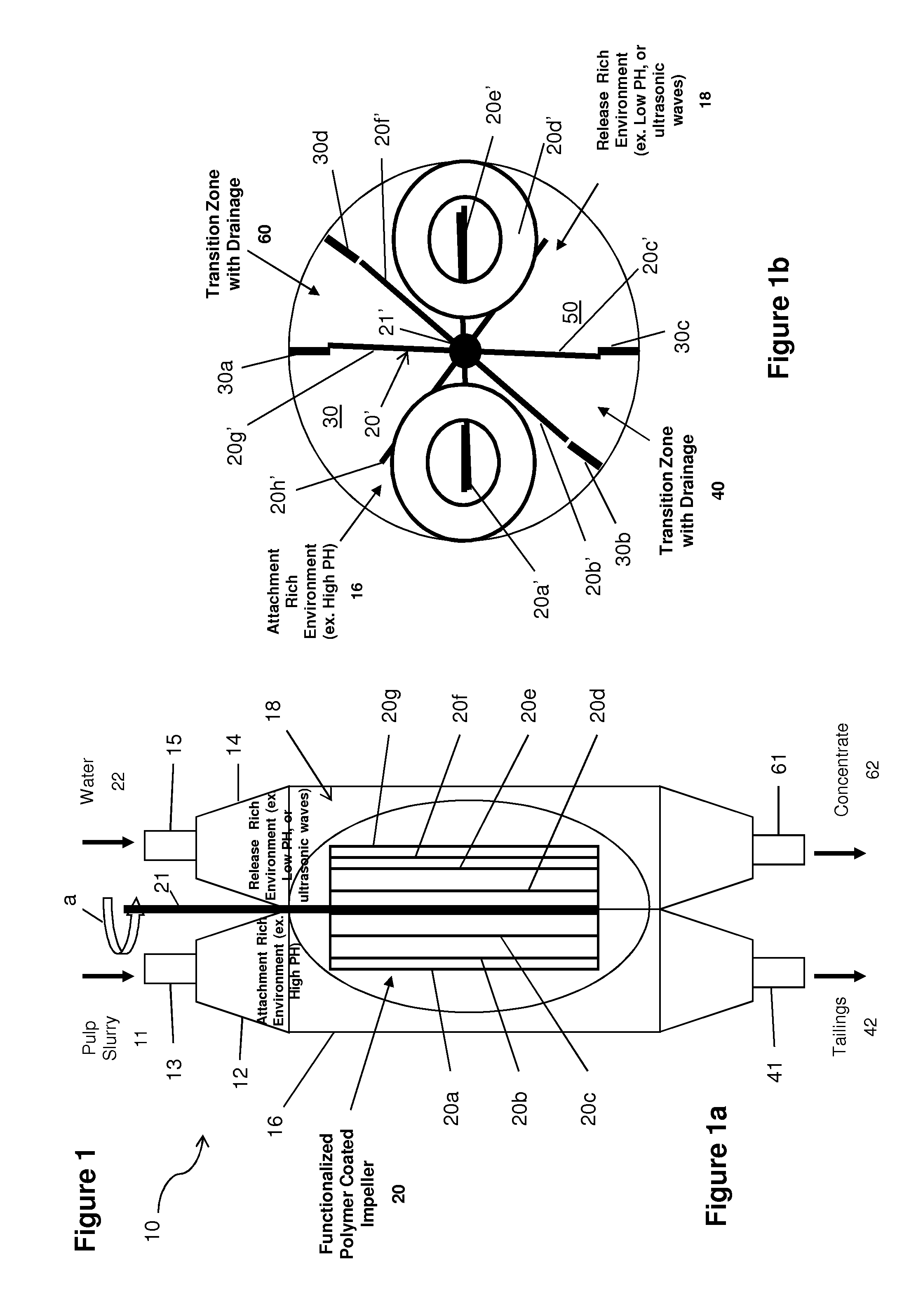

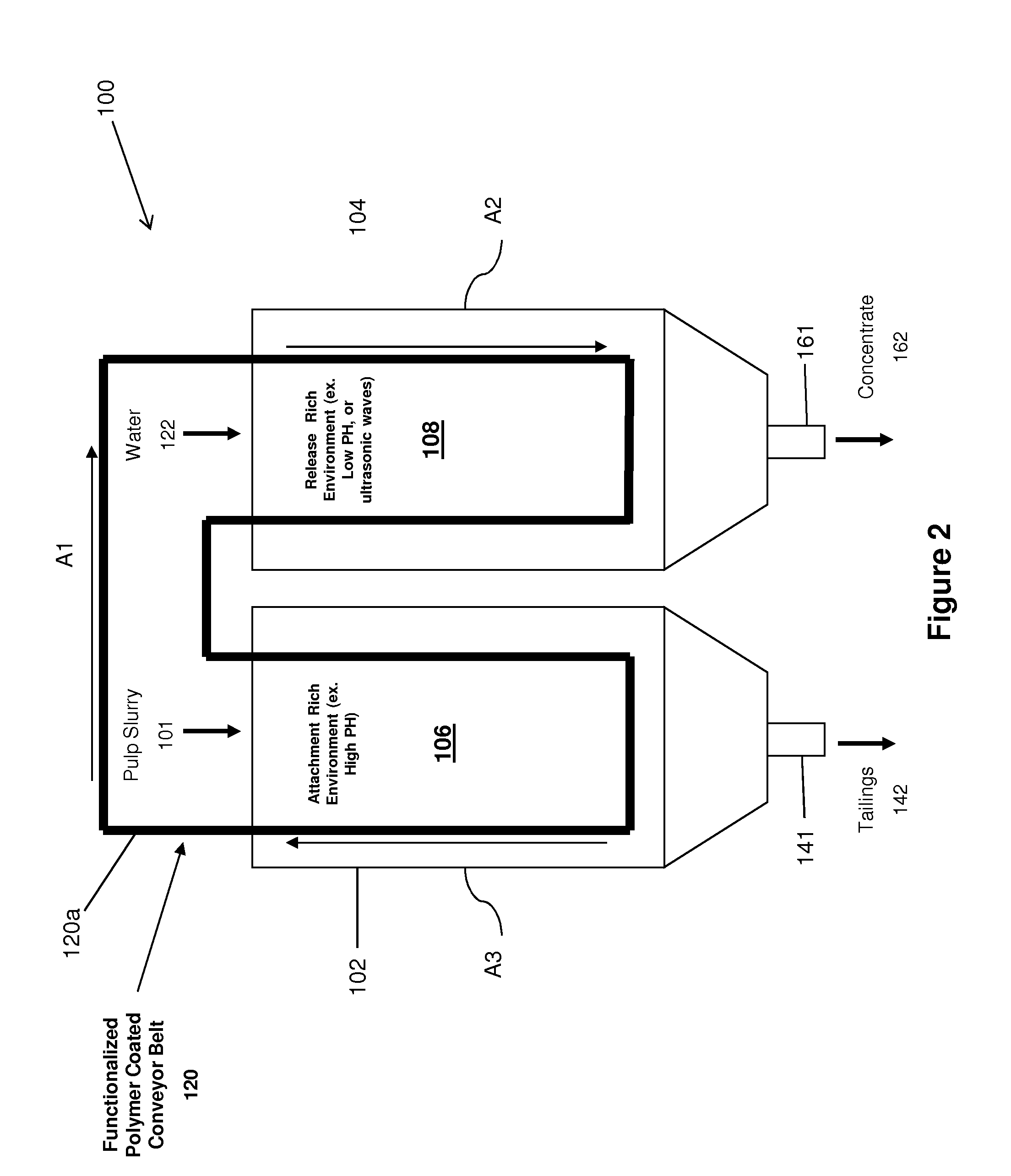

Mineral separation using functionalized membranes

A machine or apparatus featuring a first processor and a second processor. The first processor is configured to receive a mixture of fluid, valuable material and unwanted material and a functionalized polymer coated member configured to attach to the valuable material in an attachment rich environment, and provide an enriched functionalized polymer coated member having the valuable material attached thereto. The second processor is configured to receive a fluid and the enriched functionalized polymer coated member in a release rich environment to release the valuable material, and provide the valuable material released from the enriched functionalized polymer coated member.

Owner:CIDRA CORP SERVICES

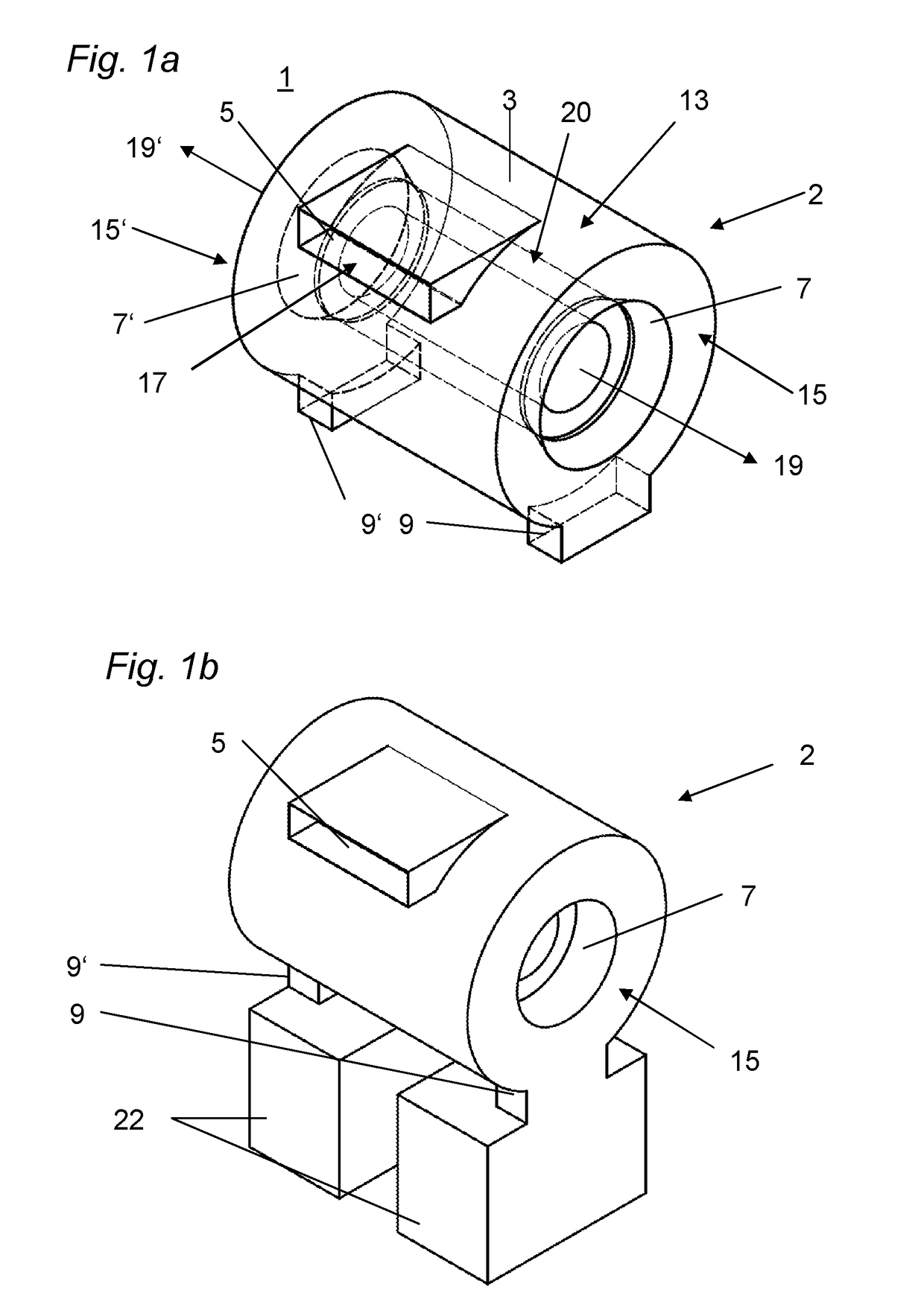

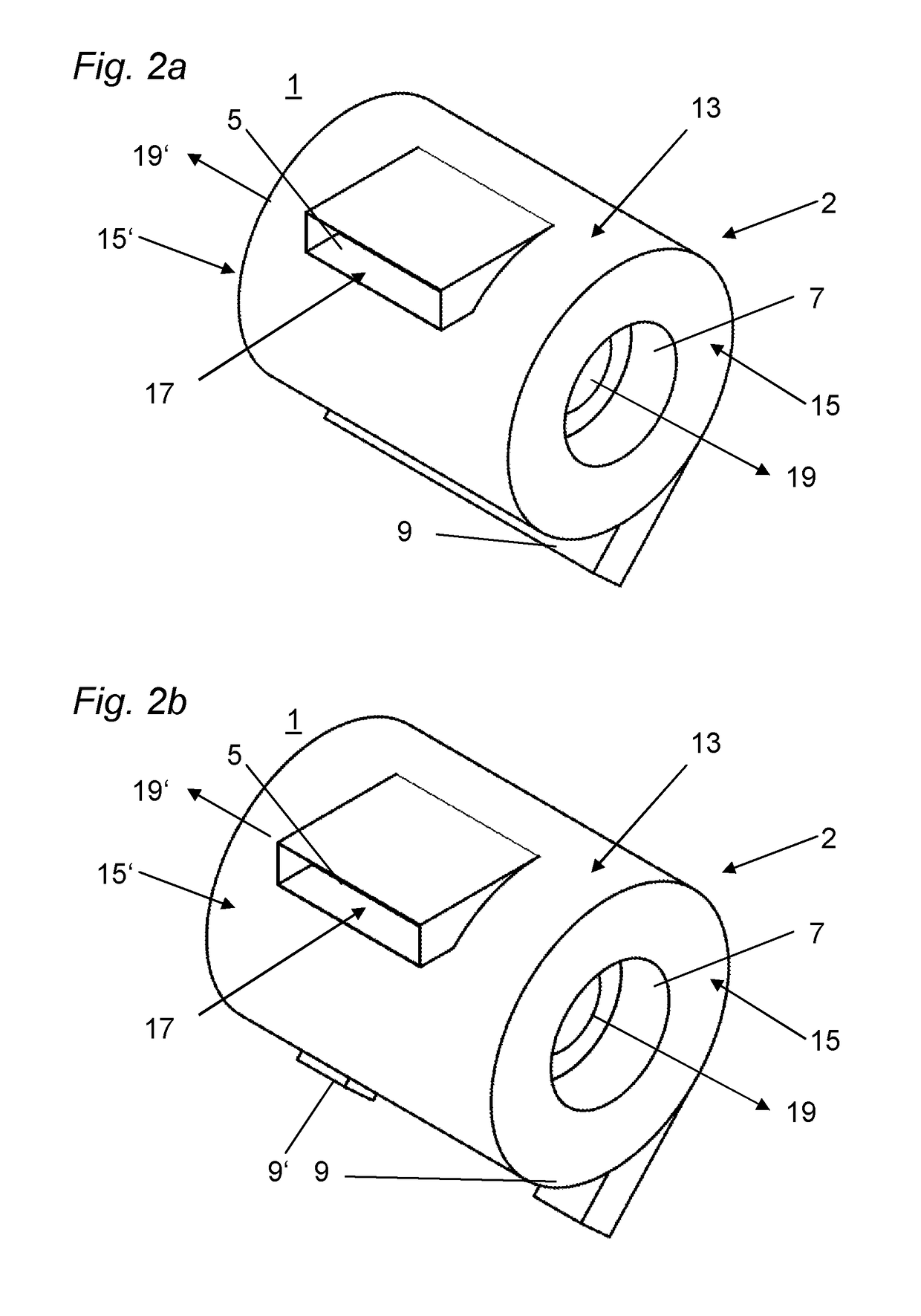

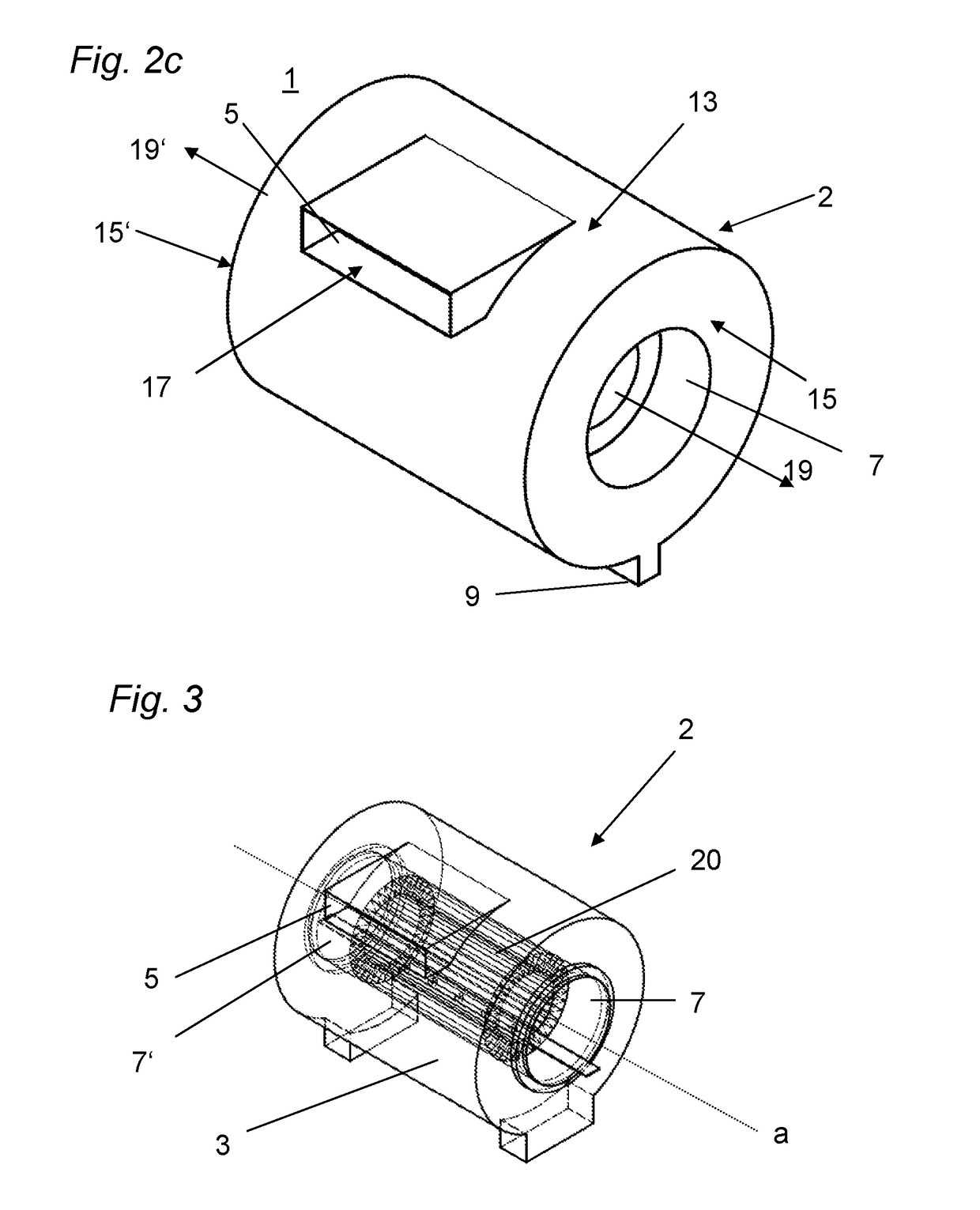

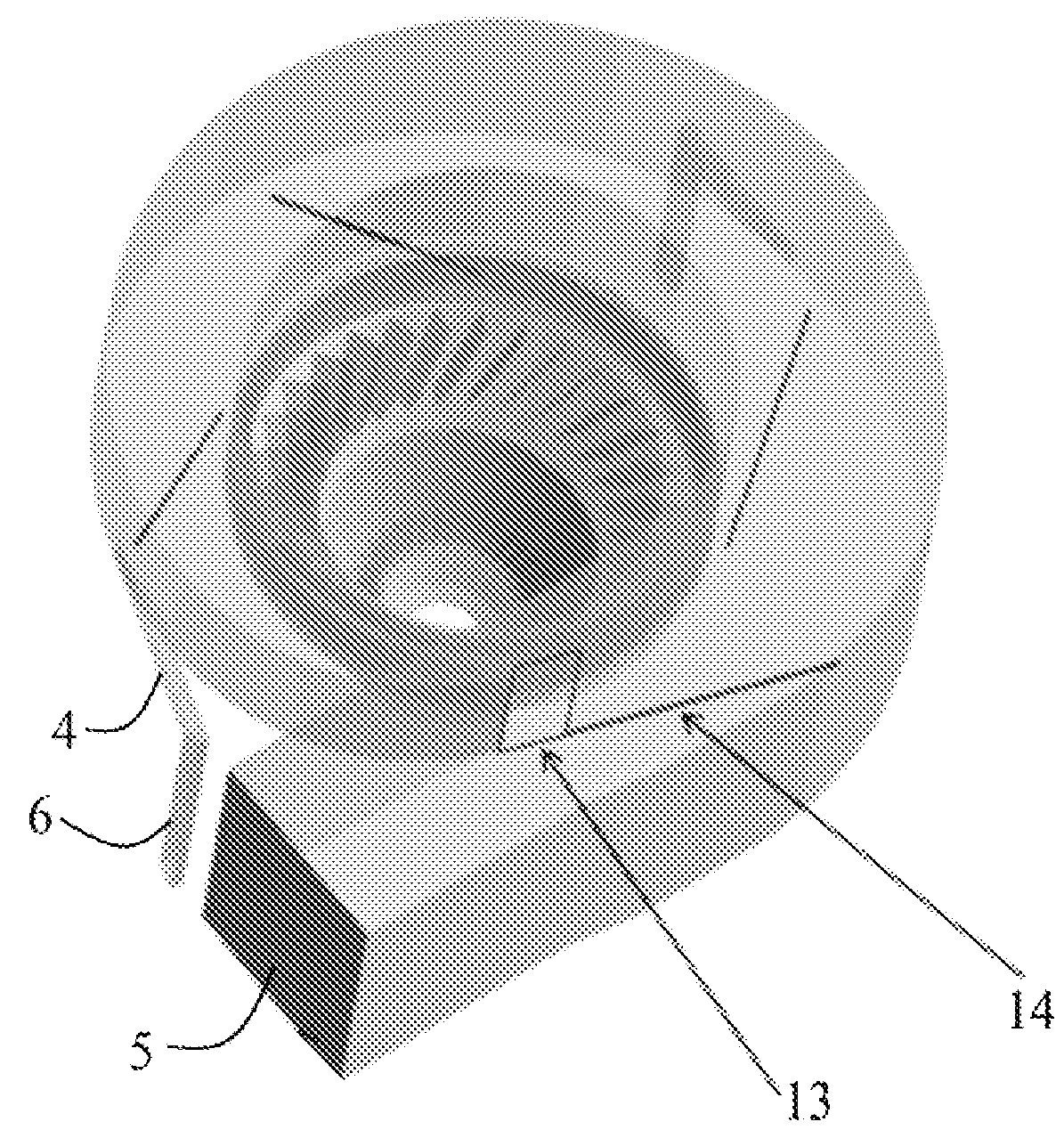

Separation device for separating particles from a fluid flow

ActiveUS20190009281A1Compact designCombination devicesReversed direction vortexEngineeringCentrifugal separator

A separation device (1) for separating particles from a fluid flow, comprising a centrifugal separator (2), wherein the centrifugal separator (2) comprises a separation chamber (3), a fluid inlet (5), at least two dip tubes (7, 7′) and at least one particle discharge opening (9, 9′) and the separation chamber (3) is substantially formed as a rotational body. The rotational body has a casing (13) and two end faces (15, 15′), the fluid inlet (5) opening into the separation chamber (3) tangentially to the surface of the casing (13) and one dip tube (7) being situated in one of the end faces (15) and the other dip tube (7′) being situated in the other end face (15′).

Owner:MCI MANAGEMENT CENT INNSBRUCK INT HOCHSCHULE

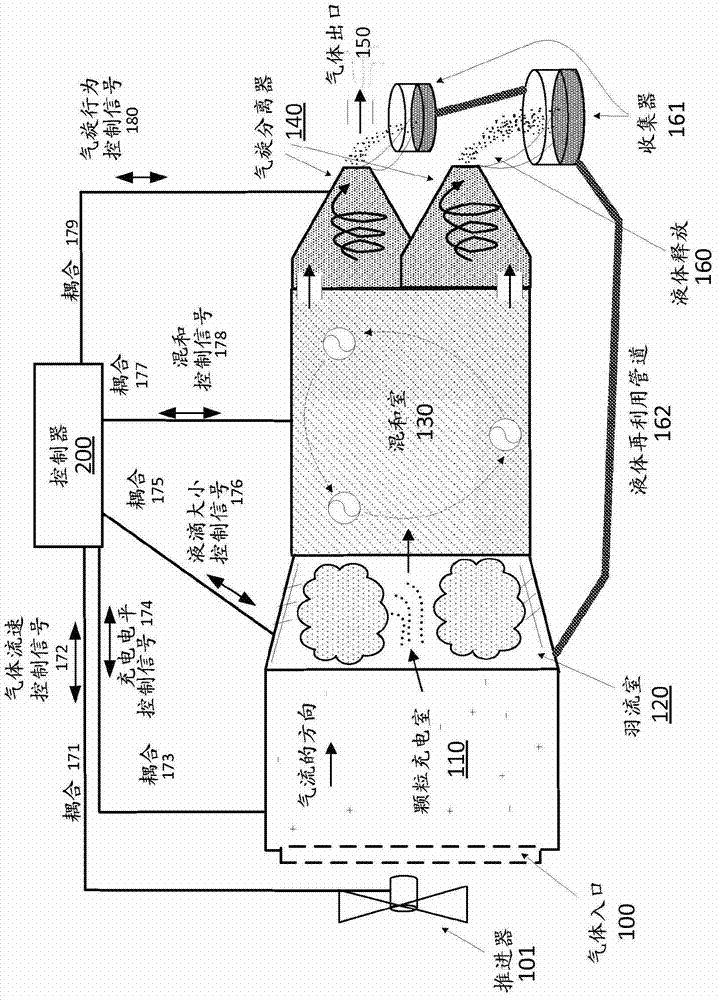

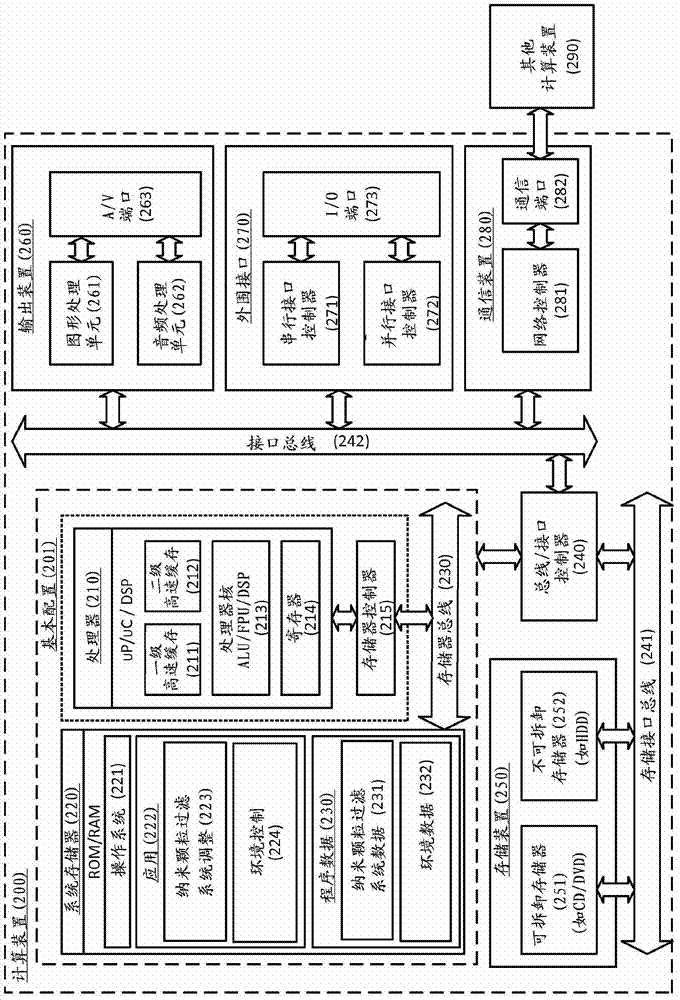

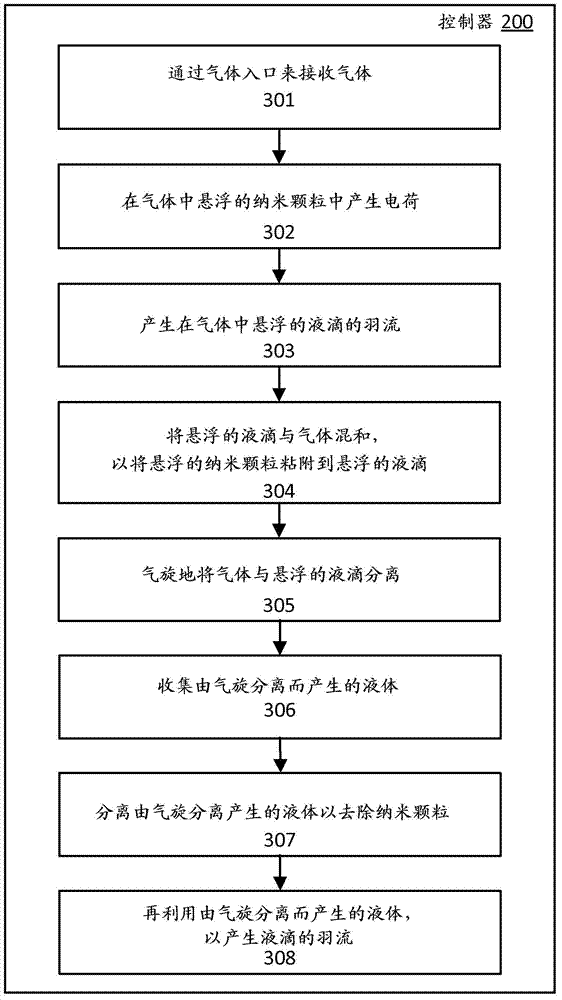

Nanoparticle separation

The present disclosure generally relates to cyclonic separation or filtering of nanoparticles suspended in a gas. A plume of liquid droplets may be generated using an ultrasound or other generator. The gas may be mixed with the plume of liquid droplets, which may have received an electrostatic charge prior to mixing, to promote preferential adhesion of the nanoparticles to the liquid droplets. The gas with suspended nanoparticles and suspended liquid particles may flow through a cyclonic separator that spins rapidly, causing the cleaned gas to flow out of the filter while the liquid with adhered nanoparticles may be discharged, collected, and / or re-used in the plume generator. By causing nanoparticles to adhere to larger liquid particles, the filter may allow the filtering and collection of much smaller particles than current systems may filter under atmospheric pressure.

Owner:EMPIRE TECH DEV LLC

Abrasive and dust separator

ActiveUS7008304B1Increase awarenessImprove fatigueAbrasive feedersFlat flow vortexEngineeringFine particulate

Provided is a centrifuge media separator for separating blast particulate from fine particulate carried by air flowing from a blast cabinet and through the media separator. The centrifuge media separator comprises an upper panel, a lower panel, and an outer wall. The upper panel has a central opening formed therein. The outer wall is configured in a generally curvilinear shape and which extends between the upper and lower panels. The outer wall has at least one particulate escape aperture formed therein. The upper panel, lower panel and outer wall collectively define a curvilinear air passageway having an inlet and an outlet. The inlet is configured to allow a flow of air to enter the air passageway and circulate therethrough toward the outlet. The escape aperture is configured to exhaust the blast particulate out of the passageway. The central opening is configured to exhaust the fine particulate out of the passageway.

Owner:MEDIA BLAST & ABRASIVES

Hydrocarbon-water separator

ActiveUS20170275185A1Improve efficiencyImprove gas releaseWaste water treatment from quariesLiquid degasification with auxillary substancesProduct gasEngineering

An apparatus for separating hydrocarbons from water, comprising a tank segment with a fluid inlet subsequent a housing with a liquid gas mixer. The fluid inlet through a cylindrical tank wall,and further through the wall of a conical wall segment, a pipe spread, combining radial and axial flow over ring mounted guide vanes at the upper part of the conical wall segment. A hydro carbon outlet is located at a top end and a water outlet at a bottom end of tank-segment. A pipe for scale and debris removal is connected to the lower part of the bowl. The inner conical wall segment extends to the top end of the tank segment and at this location comprises a ring of vertically mounted guide vanes.

Owner:STAUPER OFFSHORE AS

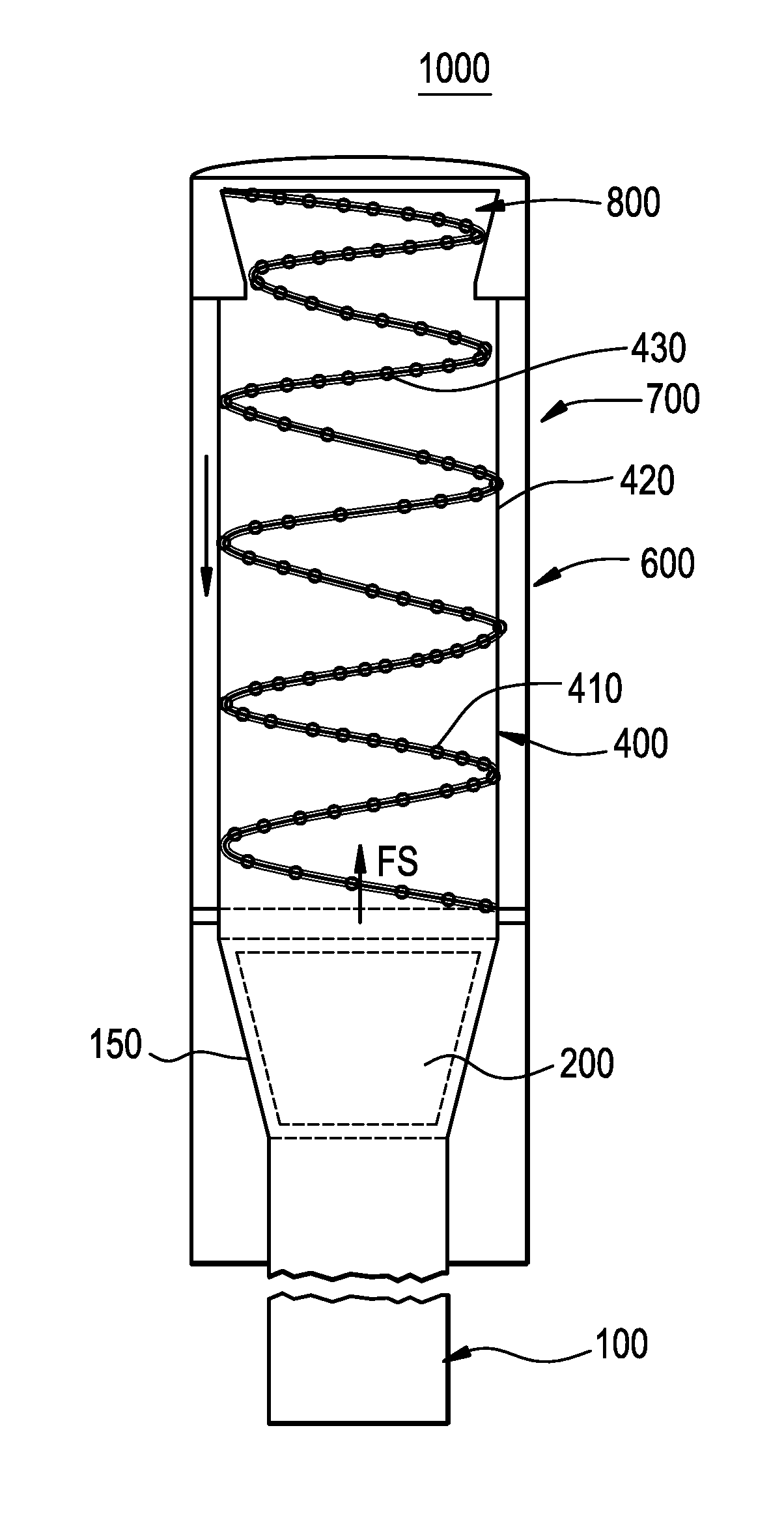

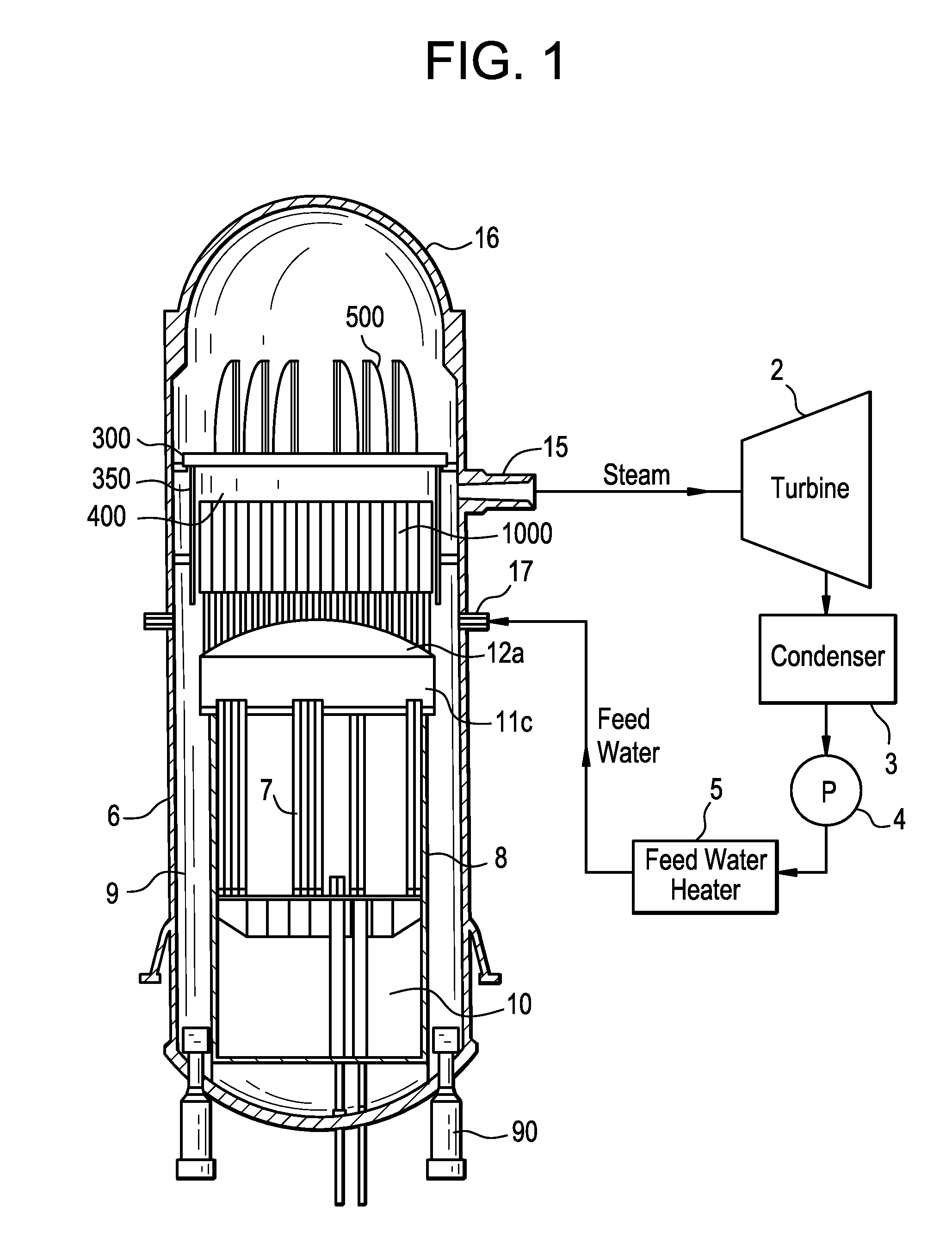

Swirler, steam separator including the swirler, and nuclear boiling water reactor including the same

ActiveUS20160189810A1Nuclear energy generationDispersed particle separationEngineeringBoiling water reactor

In one embodiment, the steam separator includes a standpipe configured to receive a gas-liquid two-phase flow stream, and a first swirler configured to receive the gas-liquid two-phase flow stream from the standpipe. The first swirler is configured to separate the gas-liquid two-phase flow stream. The first swirler includes a direct flow portion and an indirect flow portion. The direct flow portion has a direct flow channel for permitting direct flow of the gas-liquid two-phase flow stream through the first swirler, and the indirect flow portion has at least one indirect flow channel defined by at least one vane in the first swirler for providing an indirect flow of the gas-liquid two-phase flow stream through the first swirler.

Owner:GE HITACHI NUCLEAR ENERGY AMERICAS

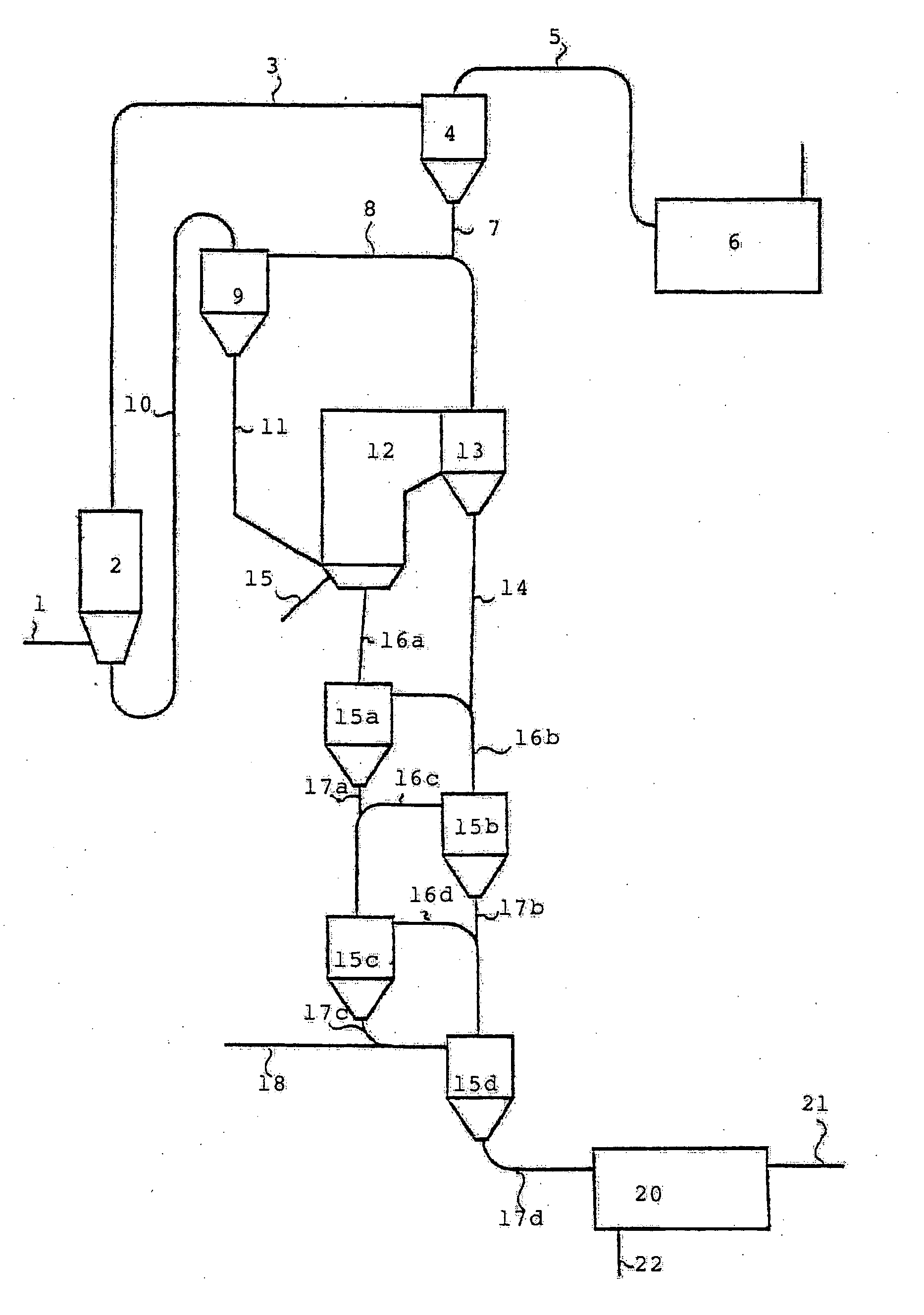

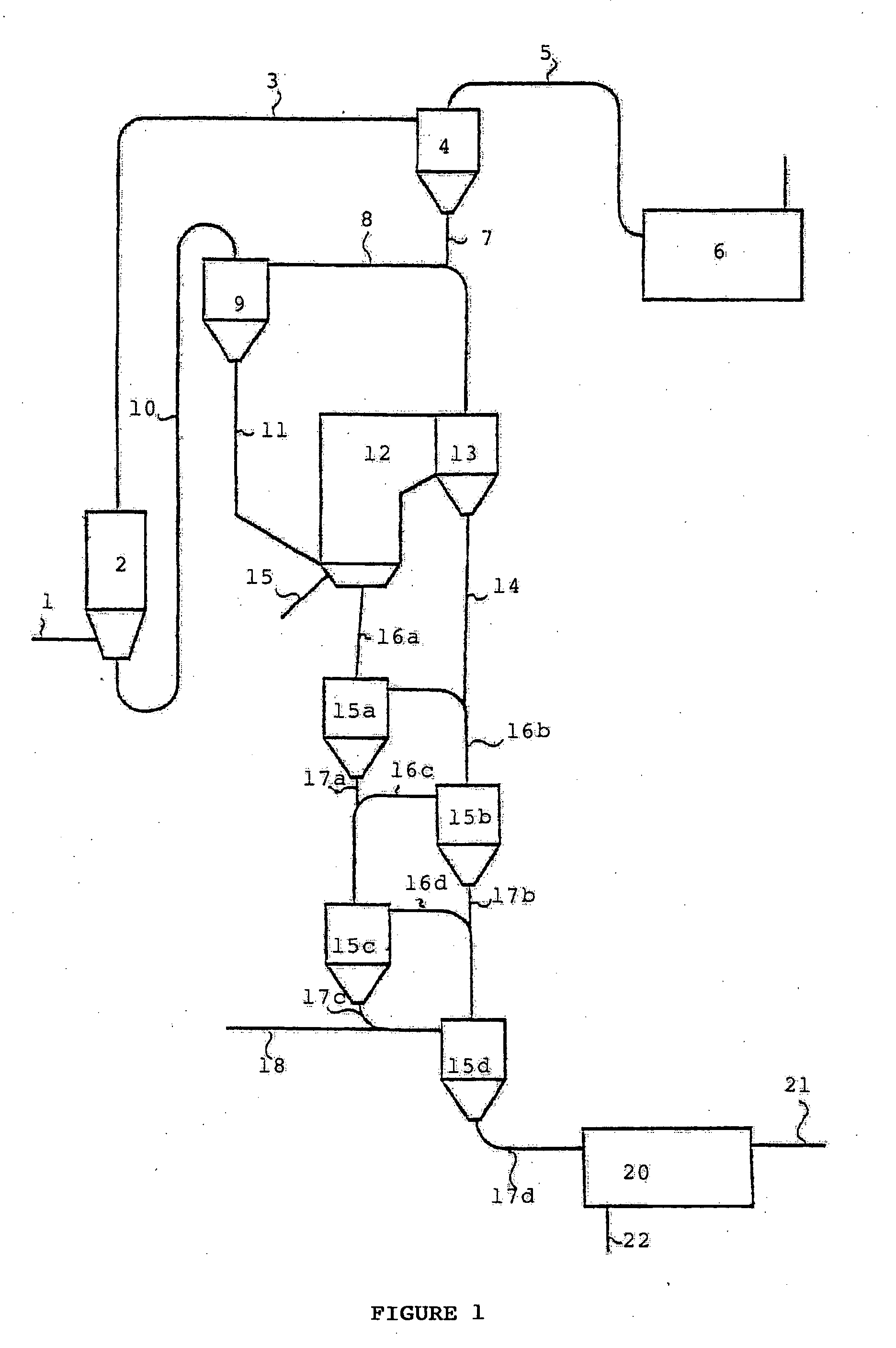

Spray dryer absorption process for flue gas with entrained coarse particles

ActiveUS20110139004A1Reduce the amount requiredGas treatmentUsing liquid separation agentFlue gasProcess engineering

Disclosed herein is a method for reducing the amount of coarser particles from a stream of flue gas prior to treatment by a spray dryer absorption process (SDA). The method comprises the steps of directing a stream of flue gas containing entrained particles of varying sizes through a curve, thereby subjecting the particles to a centrifugal effect, collecting the particles predominately of the coarser size at a particles collecting means provided in the outer circumference of the curve, dispersing the flue gas reduced in particles of coarse particle sizes into the chamber of a spray dryer absorption apparatus, wherein the particles content of the original flue gas stream is above 20 g / Nm3. Also an apparatus for performing the method and a gas disperser is disclosed. The method substantially reduces the cost of the entire plant for treating flue gas having a high content of entrained coarse particles by eliminating the need for a particle pre-collector upstream the SDA.

Owner:GEA PROCESS ENG

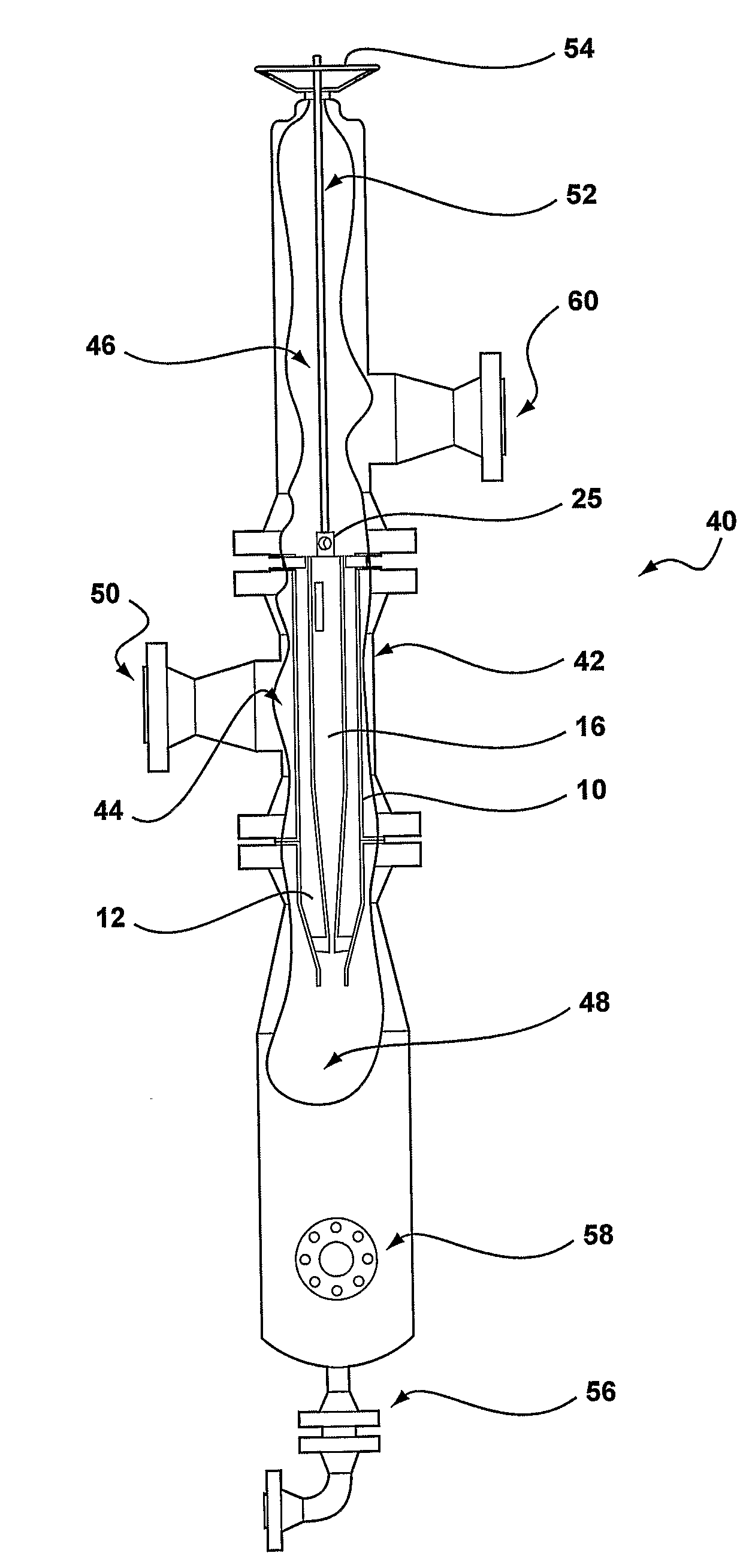

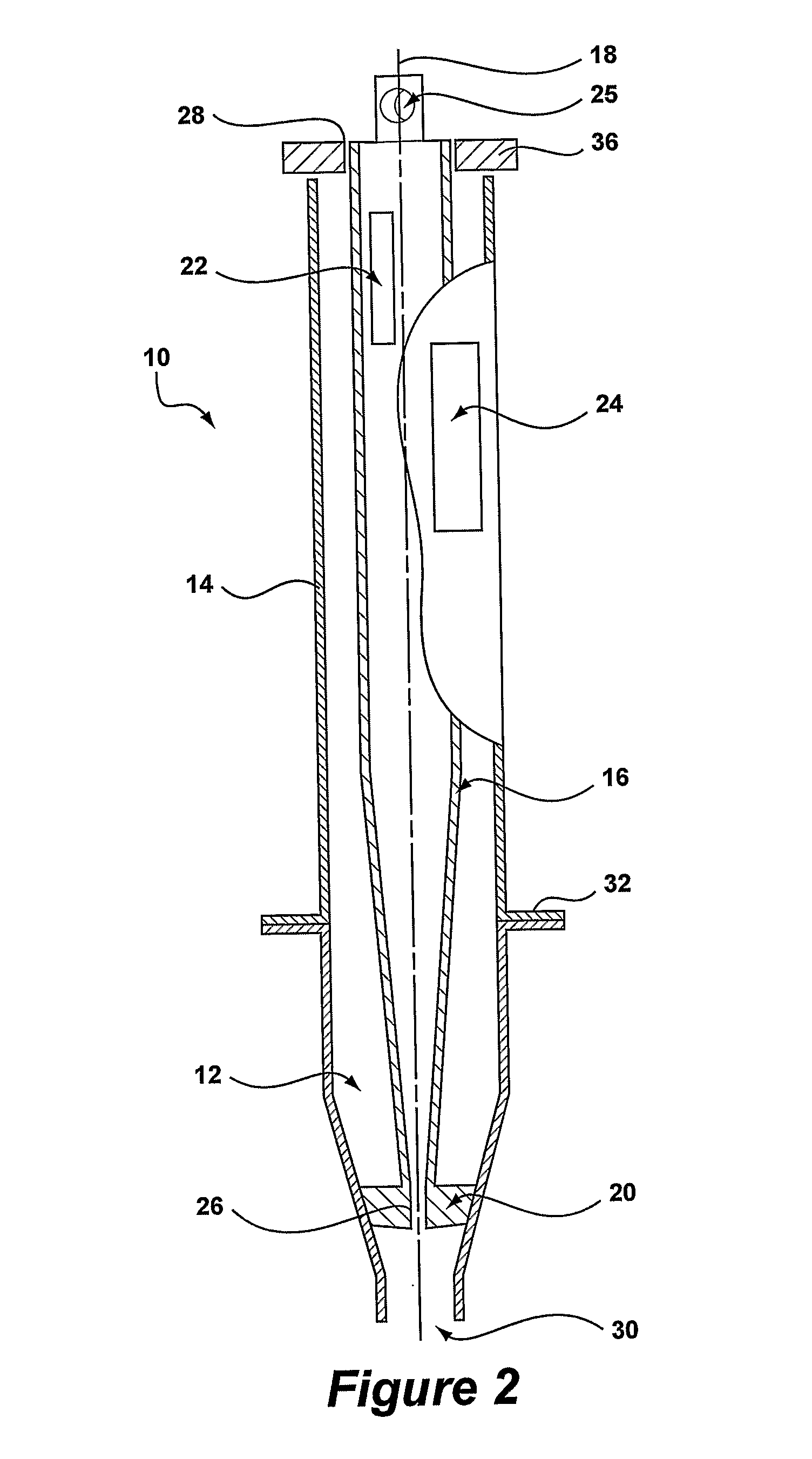

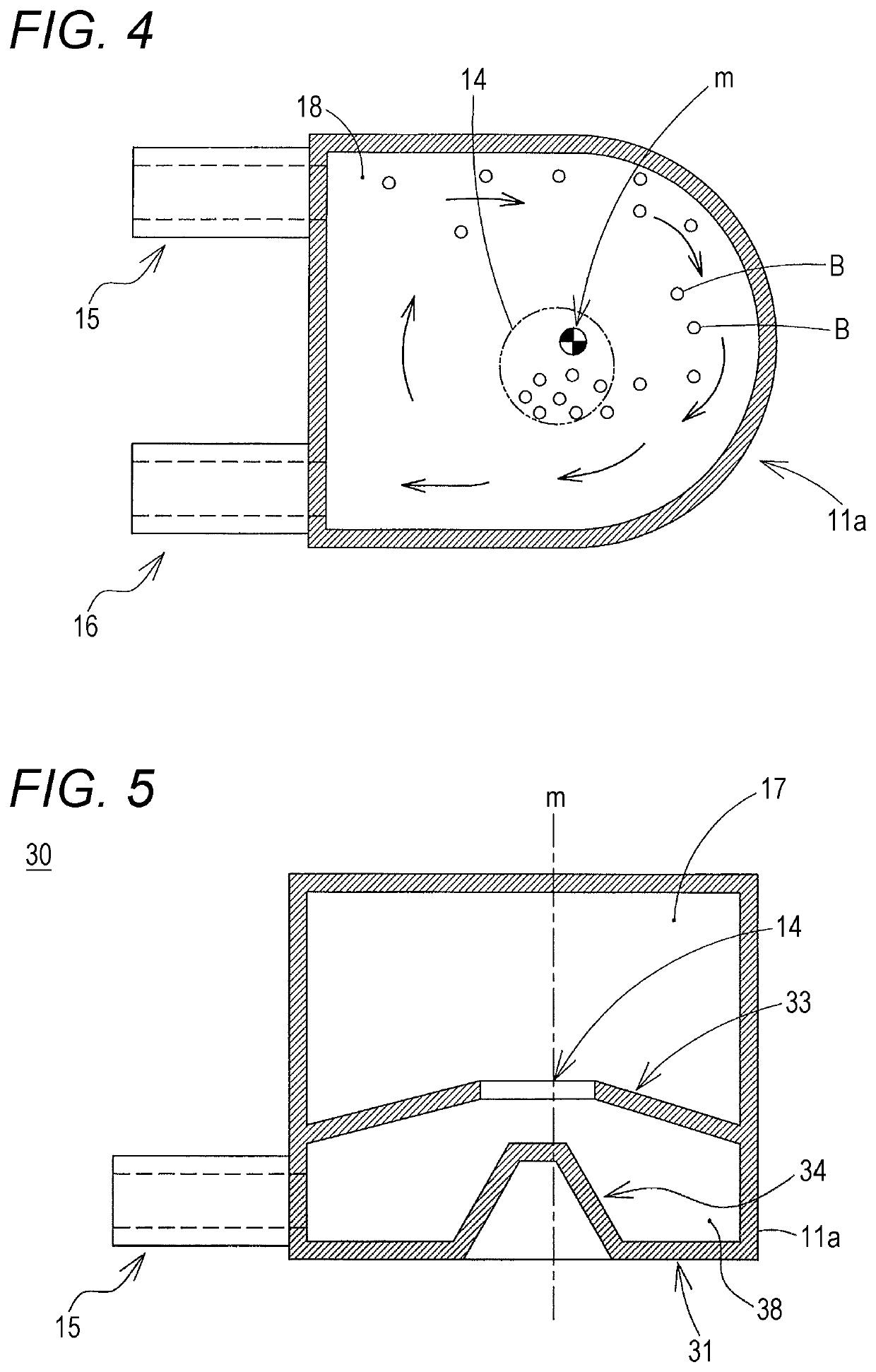

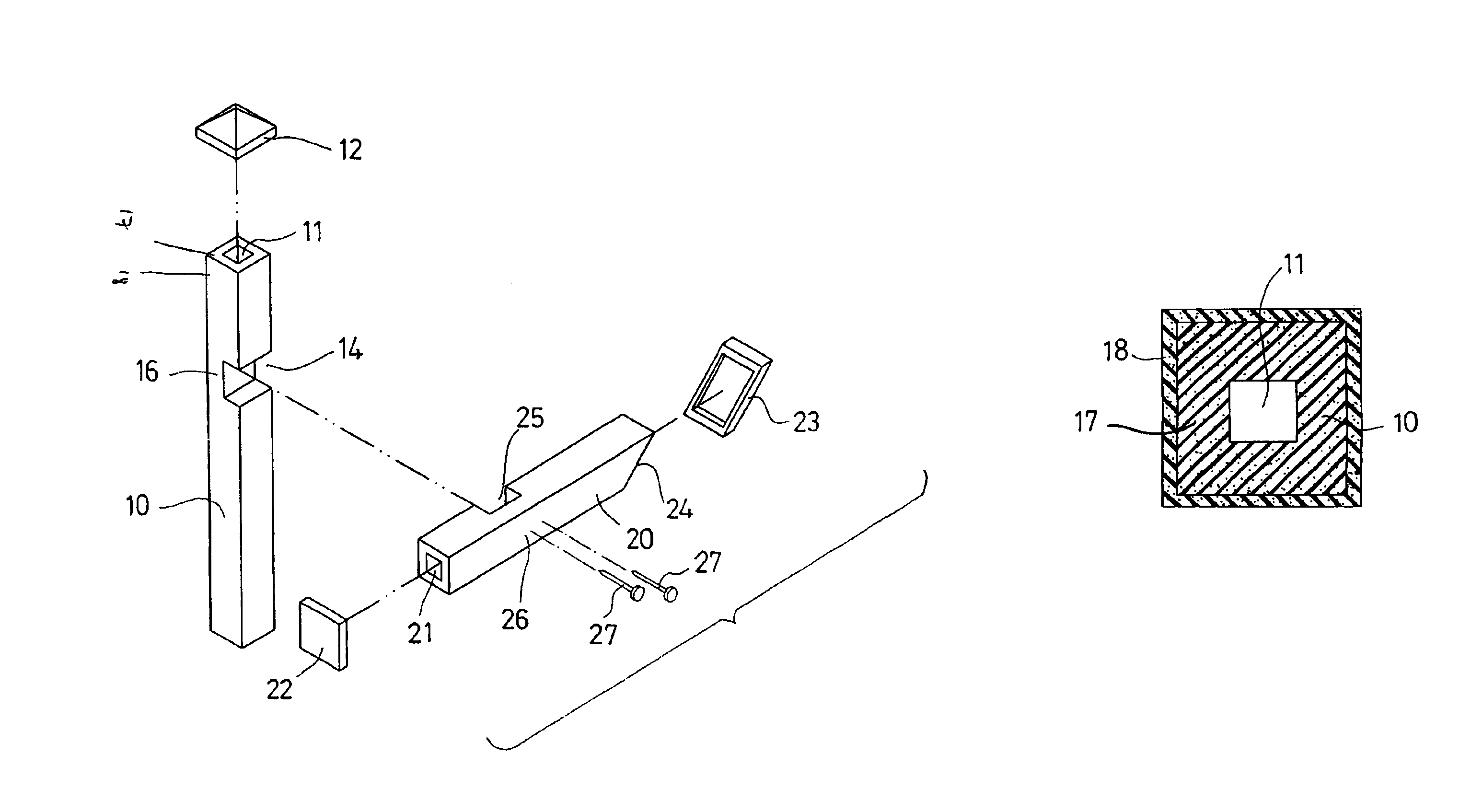

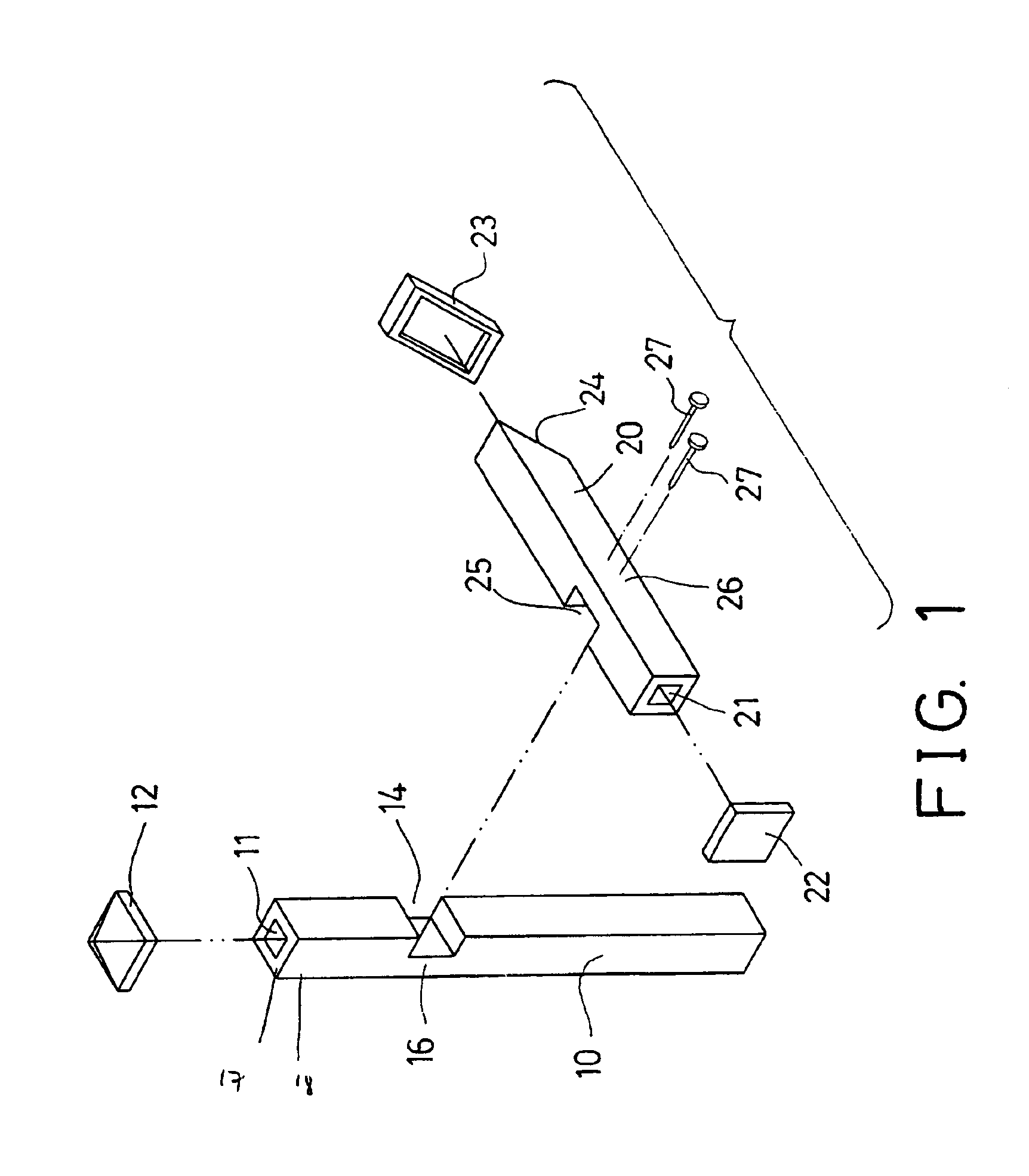

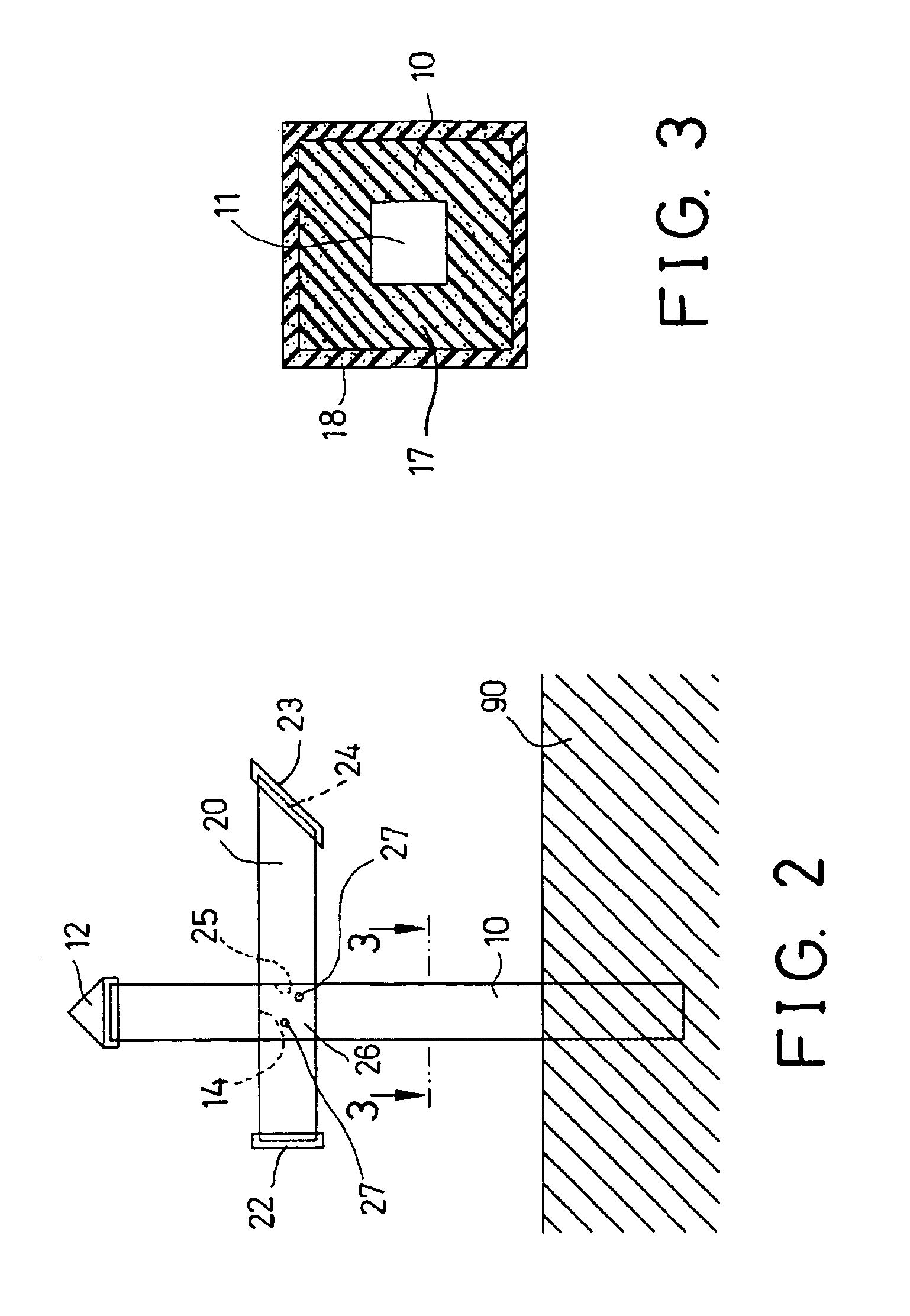

Cyclone Assembly and Method For Increasing or Decreasing Flow Capacity of a Cyclone Separator in Use

ActiveUS20080251468A1Reduce the cross-sectional areaHigh trafficReversed direction vortexSeawater treatmentCycloneStreamflow

A cyclone separator (40) includes a housing (42), in which a cyclone assembly (10) is contained. The housing (42) has an inflow chamber (44), an overflow chamber (46) and a discharge chamber (48). The cyclone assembly (10) has an inner cyclone liner (16) positioned concentrically within a cyclone chamber (12). A displacement means (52) is provided for displacing the inner cyclone liner (16) axially from an operative position in the cyclone chamber (12) to an inoperative position in the overflow chamber (46) of the housing (42). The cyclone chamber (12) has a larger internal diameter than the inner cyclone liner (16), therefore, when the inner cyclone liner is moved to the inoperative position, the flowrate through the cyclone assembly is increased.

Owner:CAMERSON INT CORP

Reservoir tank

InactiveUS20210001354A1Improve the effect of gas-liquid separationLiquid degasificationSafety devices for heat exchange apparatusThermodynamicsWater storage tank

A reservoir tank includes: a tank chamber for storing a cooling fluid; a gas-liquid separation chamber provided adjacently below the tank chamber in a vertical direction; a partition wall for partitioning the tank chamber and the gas-liquid separation chamber; an inflow pipe for sending the cooling fluid into the reservoir tank; and a discharge pipe for discharging the cooling fluid from the reservoir tank. The inflow pipe and the discharge pipe are connected to the gas-liquid separation chamber, the gas-liquid separation chamber has a cylindrical outer peripheral wall, the cooling fluid sent in from the inflow pipe to the gas-liquid separation chamber flows along the cylindrical outer peripheral wall in a curved manner so as to rotate around a vertical axis, and is guided to the discharge pipe, the partition wall is provided with a communication hole communicating the tank chamber with the gas-liquid separation chamber, and the communication hole is provided at a position closer to a central axis of the cylindrical outer peripheral wall than to the cylindrical outer peripheral wall when viewed in the vertical direction.

Owner:TAIGAASU HORIMAA

Cyclone assembly and method for increasing or decreasing flow capacity of a cyclone separator in use

ActiveUS7655061B2Reduce the cross-sectional areaHigh trafficWater/sewage treatment by centrifugal separationWater cleaningCycloneWaste management

Owner:CAMERSON INT CORP

Plastic post assembly for mailbox

InactiveUS6883285B2Easily supporting mailboxEasy to carryTravelling sacksCandle holdersCatheterUv absorber

A plastic post device for mailboxes includes a tubular member having a depression formed by a stem, a conduit having a recess formed by another stem. The recess of the conduit is aligned with the depression of the tubular member, and the stems of the tubular member and the conduit are engaged with each other, to laterally secure the conduit to the tubular member. The tubular member and the conduit each include an inner portion having a less specific weight than that of an outer peripheral covering which includes a ultraviolet absorber material and an anti-oxidation agent for protecting the post device from being rusted or damaged.

Owner:CHEN CHANG THAN

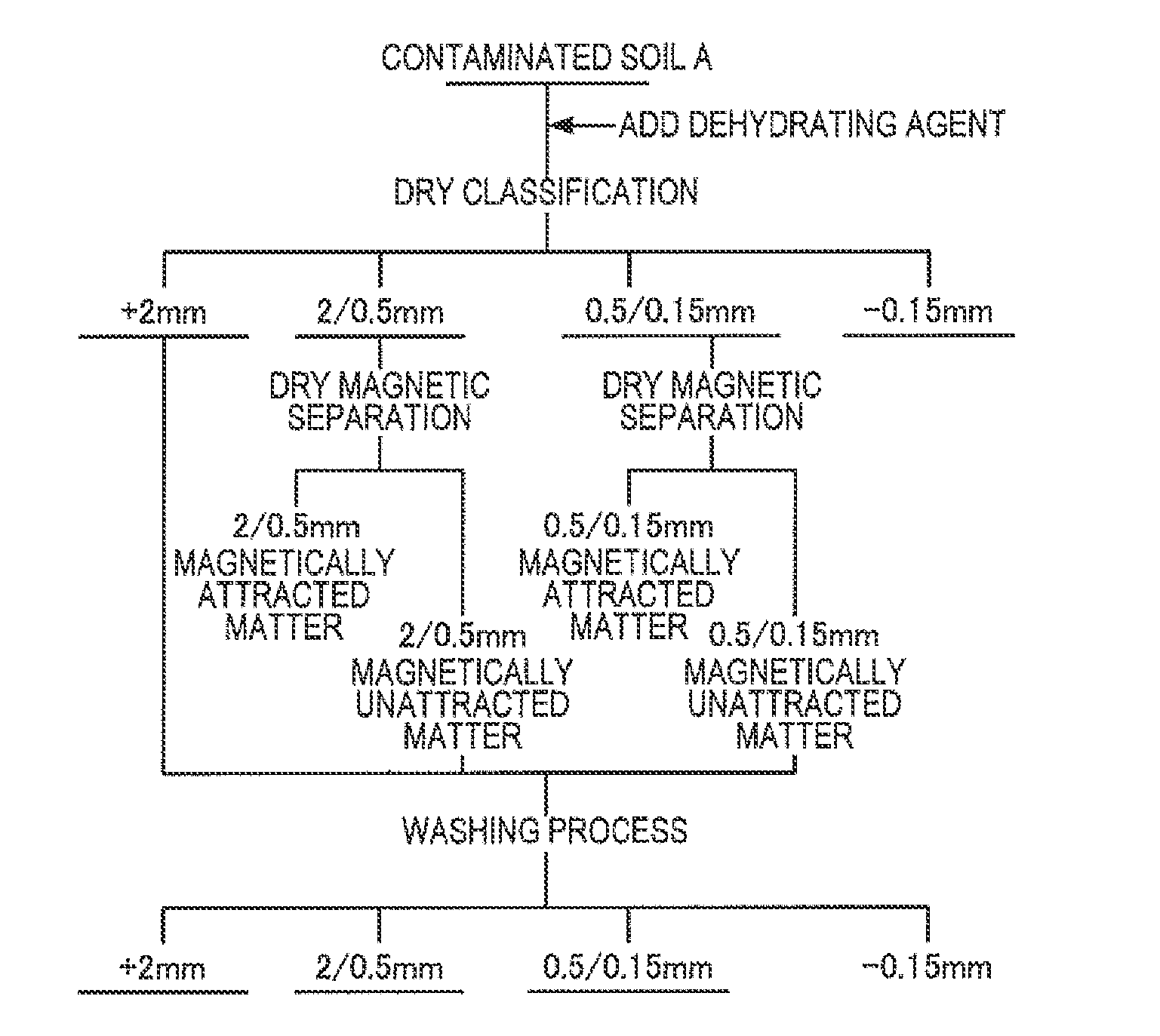

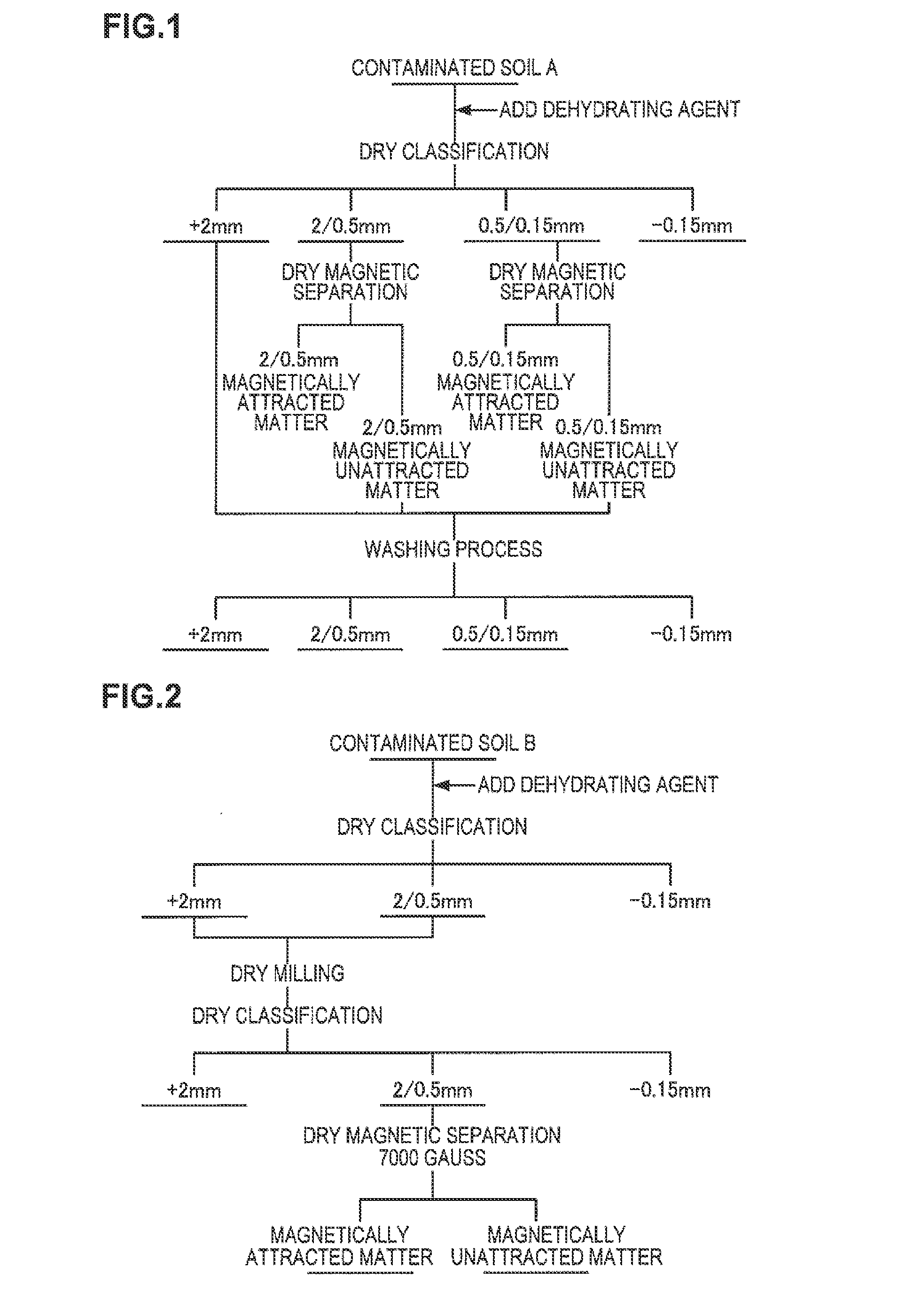

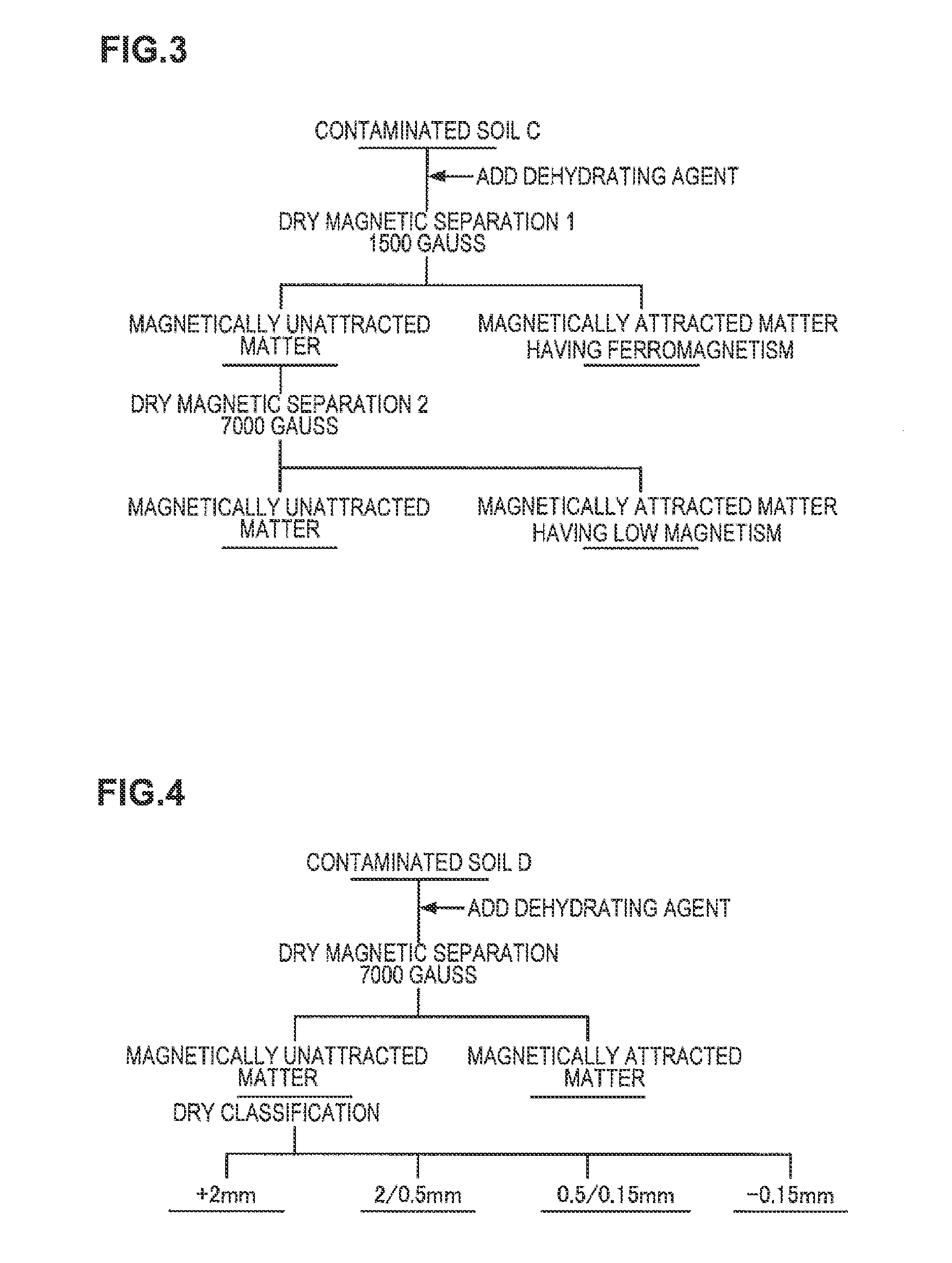

Soil cleaning method

InactiveUS20130115004A1Reduce pollutant contentReduce loadSievingScreeningSoil scienceMagnetic separator

The present invention provides a soil cleaning method. The soil cleaning method is characterized in that after a pre-treatment step of mixing a dehydrating agent in soil to reduce a water content of the soil to 10 mass % or less is performed, a magnetic separation step of feeding the soil whose water content is reduced to 10 mass % or less in the pre-treatment step, to a dry magnetic separator to separate and remove a contaminant in coarse soil as magnetically attracted matter is performed. By bringing the soil into a dry state to separate the soil into magnetically attracted matter and magnetically unattracted matter and collecting the heavily contaminated magnetically attracted matter, it is possible to facilitate separating fine soil from contaminated soil, which makes it possible to easily reduce the content of the contaminant in the coarse soil.

Owner:DOWA ECO SYST

Spray dryer absorption process for flue gas with entrained coarse particles

Disclosed herein is a method for reducing the amount of coarser particles from a stream of flue gas prior to treatment by a spray dryer absorption process (SDA). The method comprises the steps of directing a stream of flue gas containing entrained particles of varying sizes through a curve, thereby subjecting the particles to a centrifugal effect, collecting the particles predominately of the coarser size at a particles collecting means provided in the outer circumference of the curve, dispersing the flue gas reduced in particles of coarse particle sizes into the chamber of a spray dryer absorption apparatus, wherein the particles content of the original flue gas stream is above 20 g / Nm3. Also an apparatus for performing the method and a gas disperser is disclosed. The method substantially reduces the cost of the entire plant for treating flue gas having a high content of entrained coarse particles by eliminating the need for a particle pre-collector upstream the SDA.

Owner:GEA PROCESS ENG

Method and device for purifying fluid media by removal of contaminating multicomponent ingredients

The group of inventions relates to the technology for purifying liquids and gases by removal of contaminating multicomponent ingredients. The device comprises a housing comprising at least one hollow spiral element with a conical shape, with separation openings being formed in at least some of the turns of the spiral element, each of the openings communicating with a corresponding separation chamber. Arranged opposite the separation opening is a nozzle, which is intended for compensating for the mass and centrifugal moment of the fluid medium. A guide element around which a flow passes is mounted on the wall of the nozzle. The cross-sectional area and the radius of each successive turn is selected from the condition for maintaining an estimated value for the centrifugal moment of the substance to be purified. The method consists in that a flow of medium to be purified is spun by the above-described device. Contaminating components in each turn are positioned by coaxial layers. Layer-by-layer removal of the contaminating components via the separation openings is performed. A reduction in the centrifugal moment of the flow to be purified is compensated for by a clean layer of fluid medium being injected. Technical result: as complete purification of fluid media as possible.

Owner:ABAYEV ALEXANDR DZAKHOTOVICH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com