Composite luminescent material and preparation method thereof

A luminescent material, solid-phase mixing technology, applied in luminescent materials, chemical instruments and methods, lead compounds, etc., can solve the problems of high production cost of quantum dots, restricting industrialization and application, and high requirements for bulk purity. The effect of saving raw materials, reducing production costs and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] CsPbBr 3 / Al 2 O 3 Preparation of composite luminescent materials

[0069] a. (1) Put 158.5mg (0.745mmol) CsBr, 273.4mg (0.745mmol) PbBr 2 And 4.5648g (22.35mmol) of aluminum isopropoxide raw materials are charged into the planetary ball mill, and the raw materials are fully mixed by ball milling;

[0070] (2) Spread the homogeneous mixture obtained in step (1) flat in an alumina crucible, and place it in a tube furnace for high-temperature calcination at 800°C for 10 minutes under a nitrogen atmosphere;

[0071] (3) After the product of step (2) is cooled to room temperature, it is pulverized in a planetary ball mill so that the particle size of the obtained material is less than 80μm, and then annealed in a box furnace at 500°C for 10 minutes under an air atmosphere to obtain the final CsPbBr 3 / Al 2 O 3 Composite luminescent material.

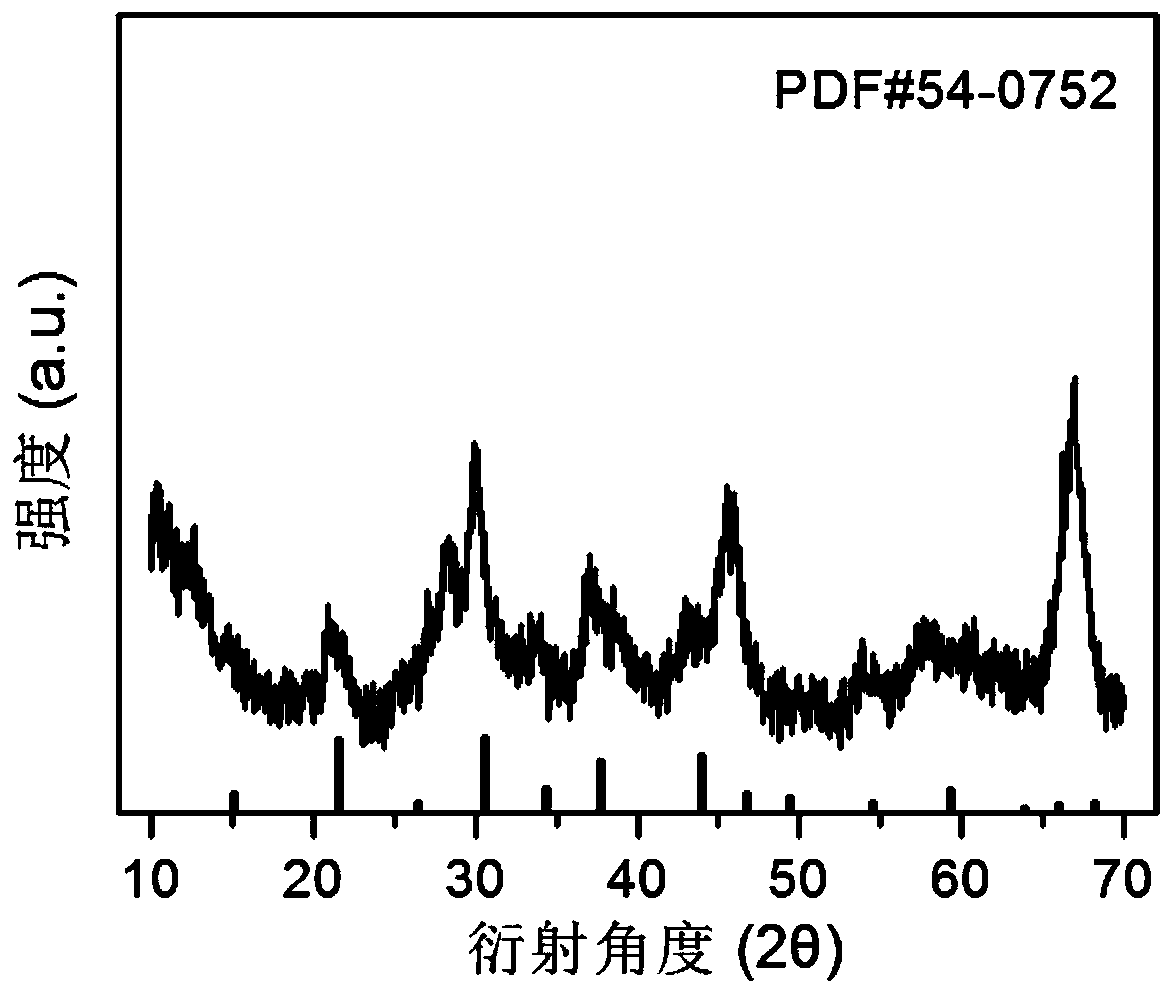

[0072] For the CsPbBr prepared in Example 1a 3 / Al 2 O 3 The composite luminescent material is tested for TEM, XRD, optical performance and ...

Embodiment 2

[0097] CsPbBr 3 / SiO 2 Preparation of composite luminescent materials

[0098] a. (1) Combine 106.4mg (0.5mmol) CsBr, 183.5mg (0.5mmol) PbBr 2 And 901.2 (15mmol) silica raw materials are put into a planetary ball mill, and the raw materials are fully mixed by ball milling;

[0099] (2) Spread the homogeneous mixture obtained in step (1) flat in an alumina crucible, and place it in a tube furnace for high-temperature calcination at 800°C for 10 minutes under a nitrogen atmosphere;

[0100] (3) After the product of step (2) is cooled to room temperature, it is pulverized in a planetary ball mill so that the particle size of the obtained material is less than 80 μm, which is the final CsPbBr 3 / SiO 2 Composite luminescent material.

[0101] b. (1) Combine 53.2mg (0.25mmol) CsBr, 91.7mg (0.25mmol) PbBr 2 Mix with 1.13mL (7.5mmol) of tetramethyl silicate raw material, add 10mL pure water and react for 4h under magnetic stirring to completely hydrolyze tetramethyl silicate;

[0102] (2) Dry t...

Embodiment 3

[0105] CsPbBr 3 / ZrO 2 Preparation of composite luminescent materials

[0106] (1) Combine 53.2mg (0.25mmol) CsBr, 91.7mg (0.25mmol) PbBr 2 And 924.1mg (7.5mmol) zirconium dioxide raw materials are put into the planetary ball mill, fully ball milled to make the raw materials evenly mixed;

[0107] (2) Spread the homogeneous mixture obtained in step (1) flat in an alumina crucible, and place it in a tube furnace for high-temperature calcination at 800°C for 10 minutes under a nitrogen atmosphere;

[0108] (3) After the product of step (2) is cooled to room temperature, it is pulverized in a planetary ball mill so that the particle size of the obtained material is less than 80 μm, which is the final CsPbBr 3 / ZrO 2 Composite luminescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com