In-situ centrifugal casting device and centrifugal casting method for thin-wall alloy castings with circular ring sections

An alloy casting and centrifugal casting technology, applied in the field of centrifugal casting equipment, can solve the problems of easy generation of cold insulation, air entrapment, low utilization rate of materials, hidden dangers to the safety of users, etc. The effect of eliminating the need for mechanical processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

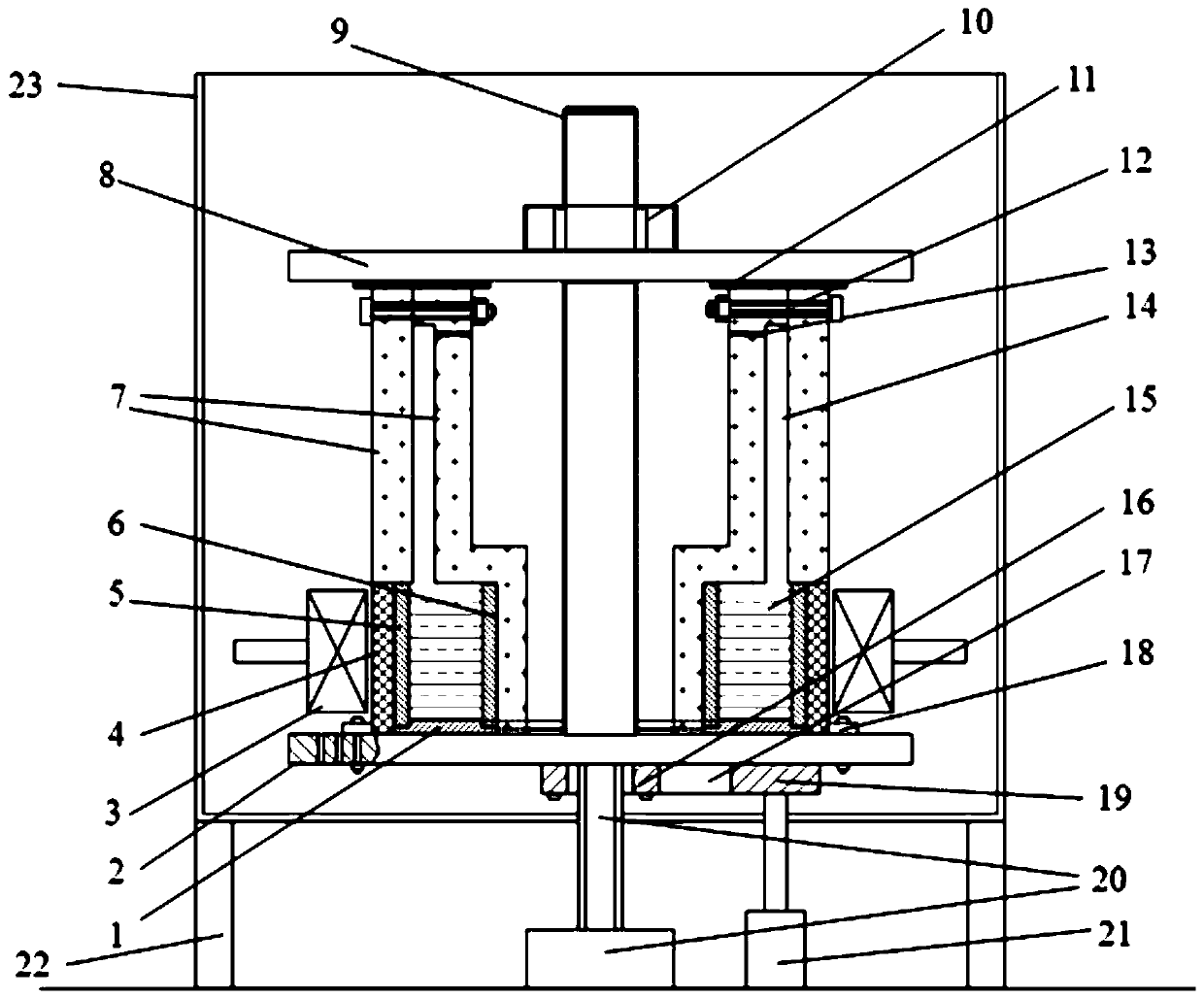

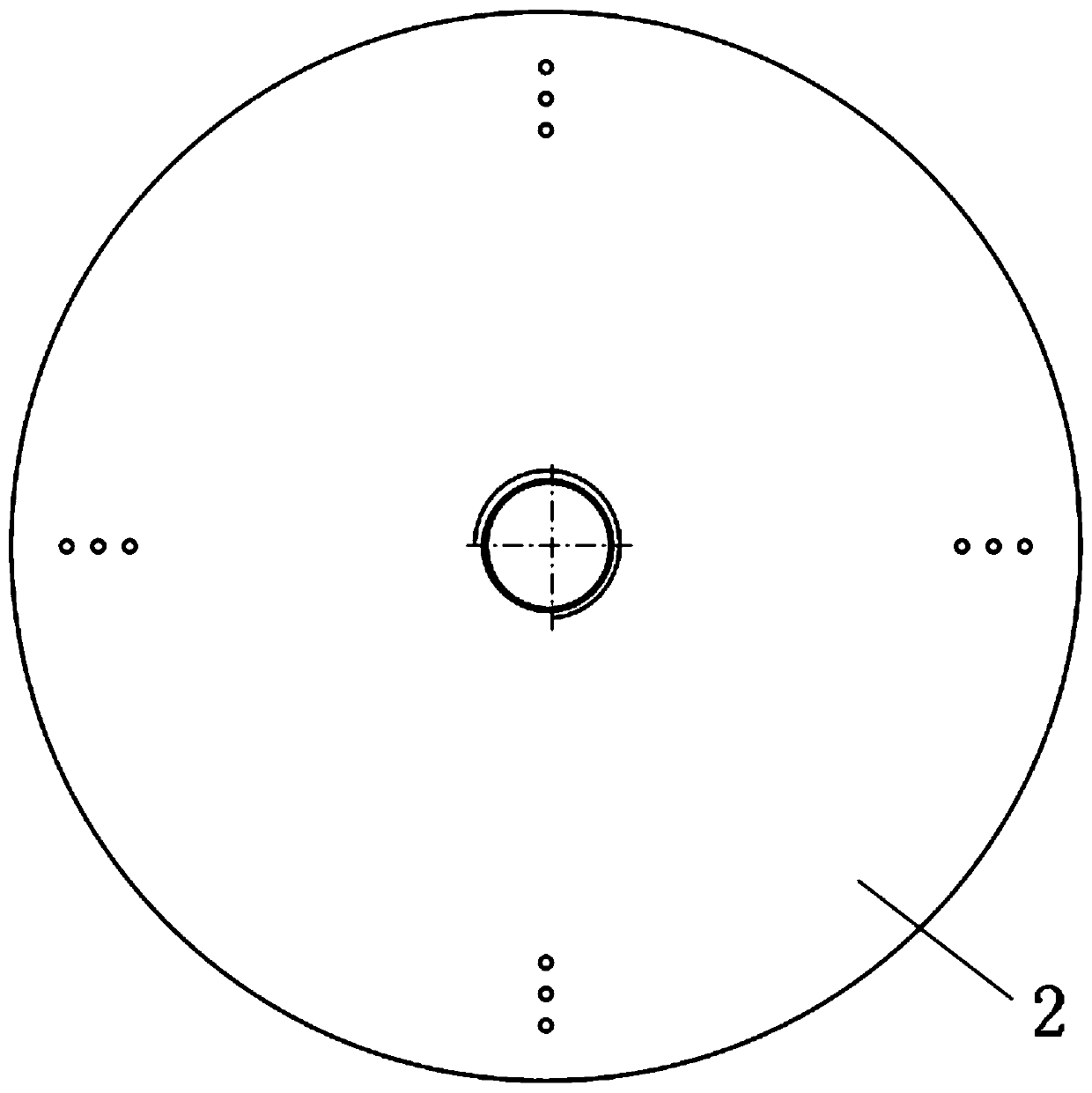

[0021] Specific Embodiment 1: The in-situ centrifugal casting equipment for thin-walled circular cross-section alloy castings in this embodiment includes an in-situ smelting system, a casting system, a limit fixing system, and a centrifugal rotation system; wherein, the in-situ smelting system includes graphite heaters, induction heating Coil 3 and heat preservation tube 4; casting mold system is casting mold 7; limit fixing system includes upper platen 8, limit guide post 9, axial limit nut 10 and chassis 2; centrifugal rotation system includes motor 21, driving wheel 19 , driven wheel 16, transmission belt 17; Described graphite heater is made up of graphite bottom ring 1, graphite outer cylinder 5 and graphite inner cylinder 6, and graphite inner cylinder 6 is positioned at graphite outer cylinder 5, and graphite outer cylinder 5 and graphite inner cylinder 6 is arranged on the graphite bottom ring 1 to form a circular cylindrical cavity, the alloy raw material 15 is put int...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the material of the insulation cylinder 4 is zirconia.

specific Embodiment approach 3

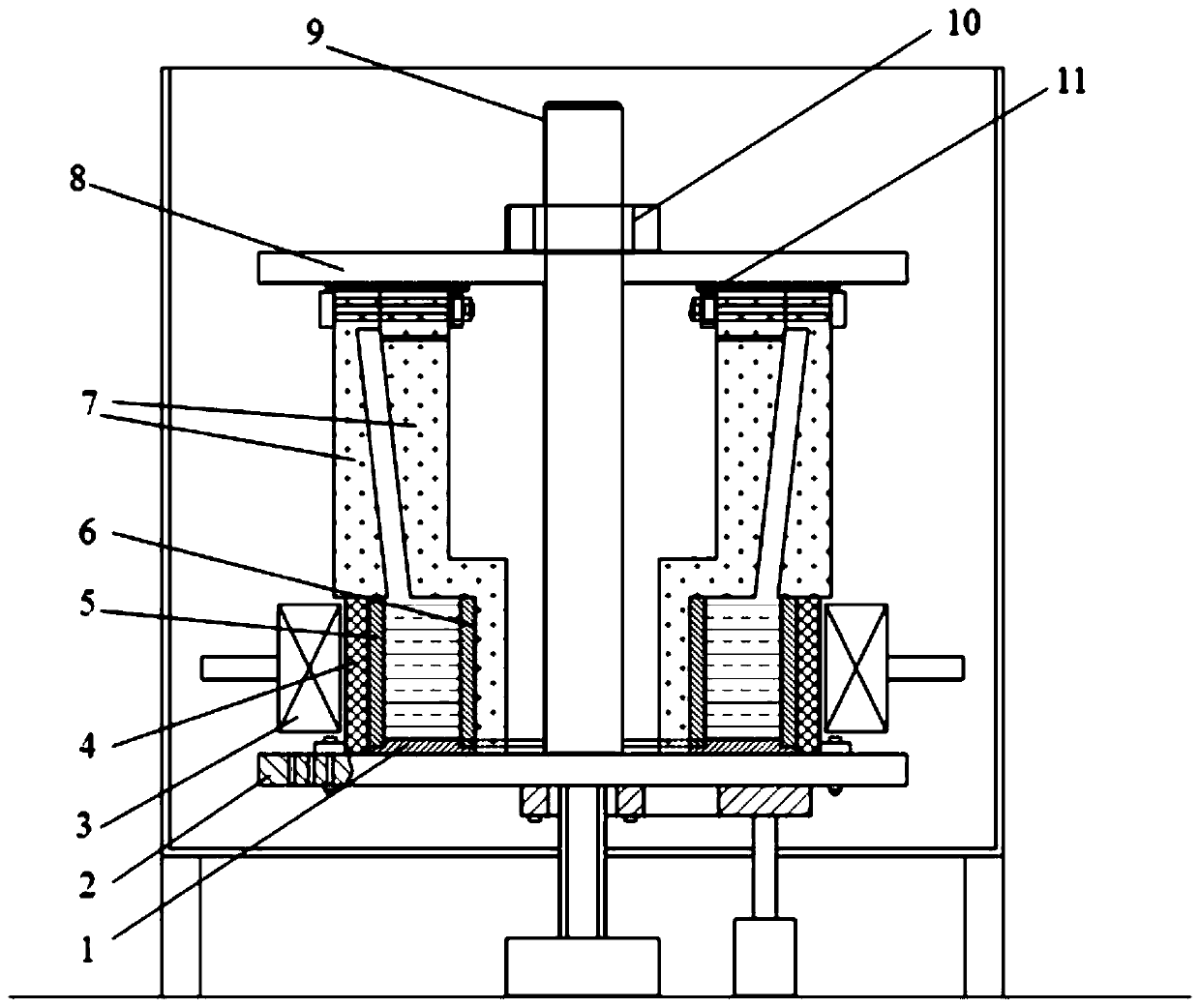

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the cavity 14 of the mold 7 is a cylindrical cavity or a cone-shaped cavity, and the mold 7 is a two-half mold through the fixing bolts (12) CONNECTION.

[0029] In this embodiment, when the cavity of the mold is cone-shaped, the schematic diagram of the structure is as follows: figure 2 shown. The shape of the mold is matched with the shape of the casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com